Preparation method and equipment of SiC fiber prepreg tape with attached interface layer

A technology of interface layer and prepreg tape, which is applied in fiber processing, equipment configuration for processing textile materials, liquid/gas/steam fiber/sliver/roving processing, etc. It can solve the problems of low elongation at break and small elasticity, etc. Achieve excellent adhesion performance, consistent performance, and reduce surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

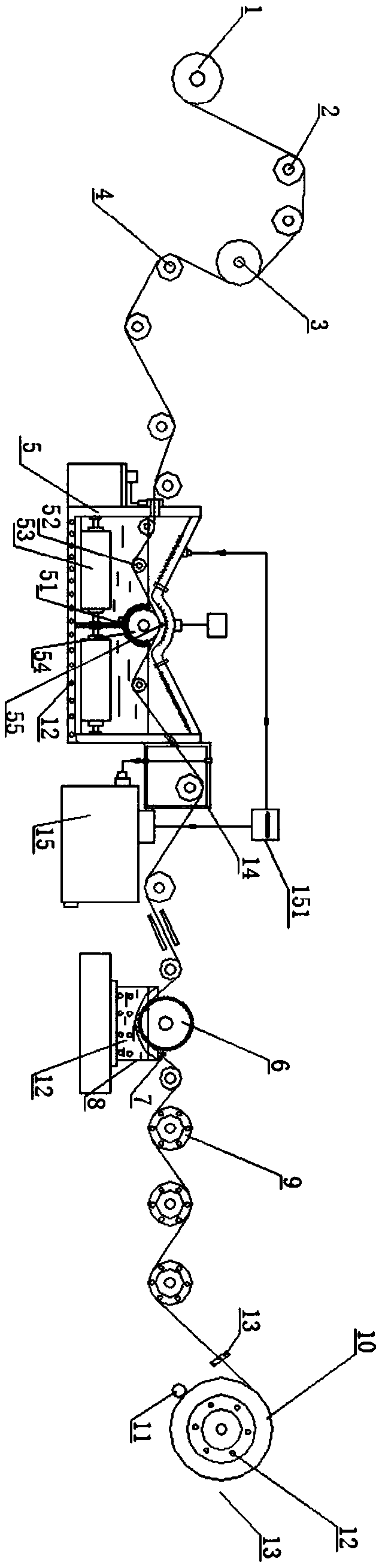

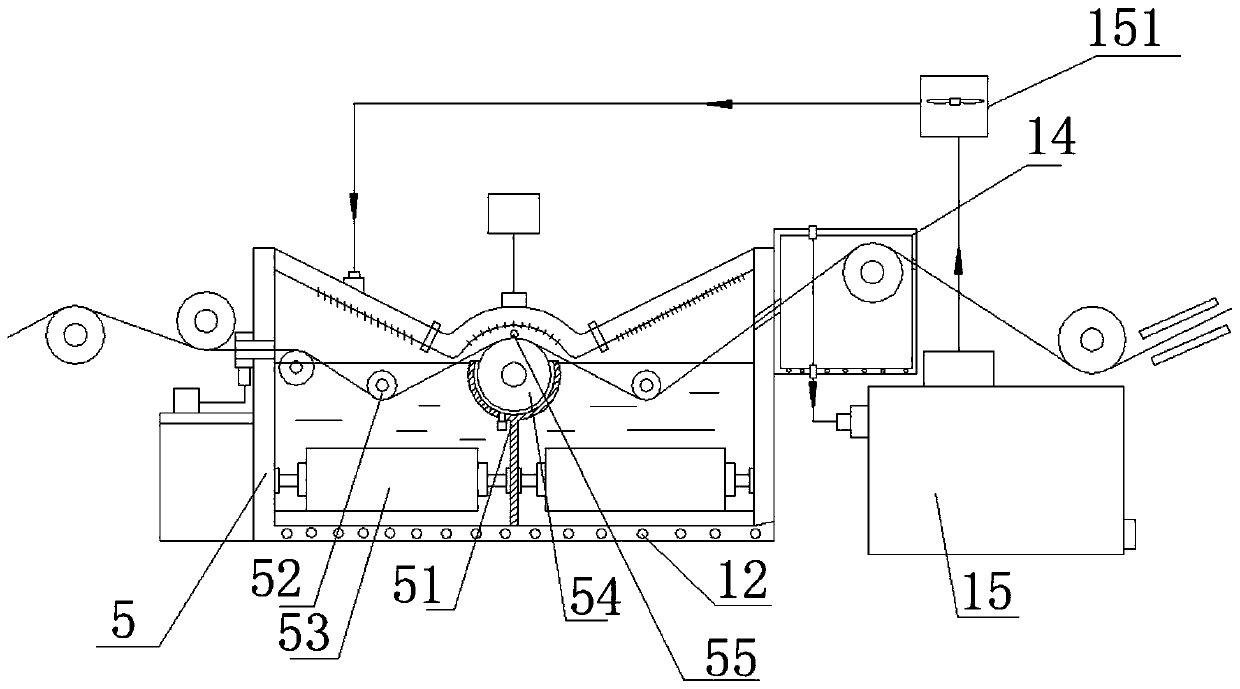

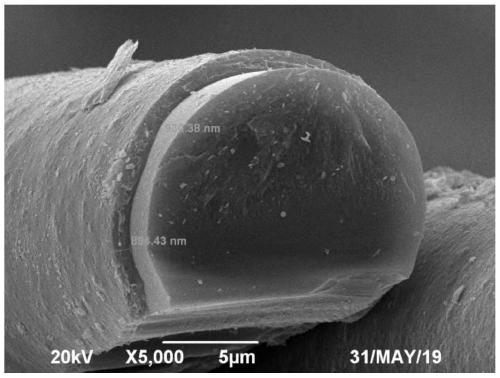

[0050] This embodiment provides a method for preparing a SiC fiber prepreg tape with an interface layer attached, comprising the following steps:

[0051] S1: After the continuous silicon carbide fiber bundle is unrolled, it is introduced to the tension wheel 4 through the godet roller 1 and the guide wheel 2, and the tension of the tension wheel 4 is 1N, which is used to stabilize the tension of the continuous silicon carbide fiber bundle;

[0052] S2: The tension wheel sends the continuous silicon carbide fiber bundle straight into the desizing device, and the processing solvent is acetone, so that the sizing agent on the surface of the continuous silicon carbide fiber is fully dissolved, and the continuous silicon carbide fiber bundle is unfolded;

[0053] S3: The continuous silicon carbide fiber bundle after desizing treatment is introduced into the gluing device through the guide wheel, and through the traction of the active rubber wheel in the gluing device and the lubric...

Embodiment 2

[0075] Compared with Example 1, the preparation method and equipment of the SiC fiber prepreg tape with interface layer attached in this embodiment differ in that:

[0076] The tension adjusted by the tension wheel 4 is 5N.

[0077] The heat treatment temperature is 60° C., and the solvent is absolute ethanol.

[0078] The glue in the gluing device is phenolic resin, the heating temperature is controlled at 80°C, and the thickness of the resin is controlled at 0.3mm.

[0079] The number of said rollers 9 is 30, and the heating temperature of said rollers is controlled at 160°C.

[0080] The diameter of described wind-up roll 10 is 320mm, and rotational speed is 4r / min, and the pitch of described rolling roll 10 is 2mm, and the thickness that obtains prepreg tape is 0.2mm, and width is 1000mm.

[0081] The thickness gauge 13 is a laser thickness gauge.

Embodiment 3

[0083] Compared with Example 1, the preparation method and equipment of the SiC fiber prepreg tape with interface layer attached in this embodiment differ in that:

[0084] The tension adjusted by the tension wheel 4 is 10N.

[0085] The heat treatment temperature of the desizing device is 80° C., and the solvent is absolute ethanol.

[0086] The glue in the gluing device is phenolic resin, the heating temperature is controlled at 100°C, and the thickness of the resin is controlled at 0.1mm.

[0087] The number of the roller rollers 9 is 20, and the heating temperature of the roller rollers is controlled at 100°C.

[0088] The diameter of the winding roll 10 is 300mm, the rotational speed is 5r / min, and the pitch of the rolling roll 11 is 1.6mm, the thickness of the obtained prepreg tape is 0.1mm, and the width is 500mm.

[0089] The thickness gauge 13 is an ultrasonic thickness gauge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com