Preparation method of non-lining down-proof fabric

A velvet-proof fabric and fabric technology, applied in the direction of dyeing method, dry cleaning fiber products, fiber types, etc., can solve the problems of complicated operation and environmental hazards, and achieve the effect of smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

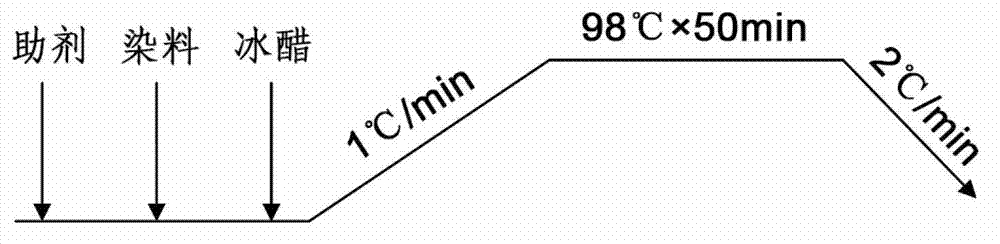

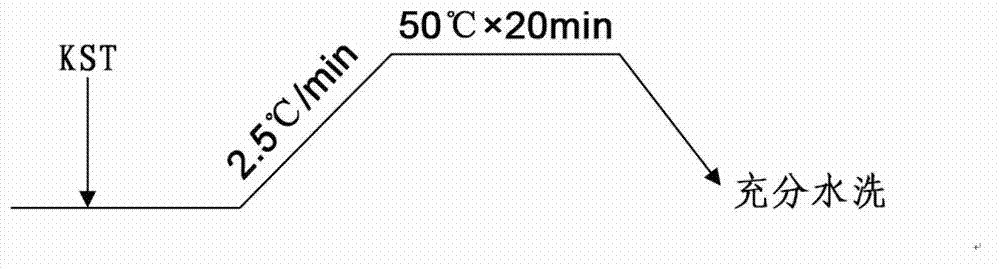

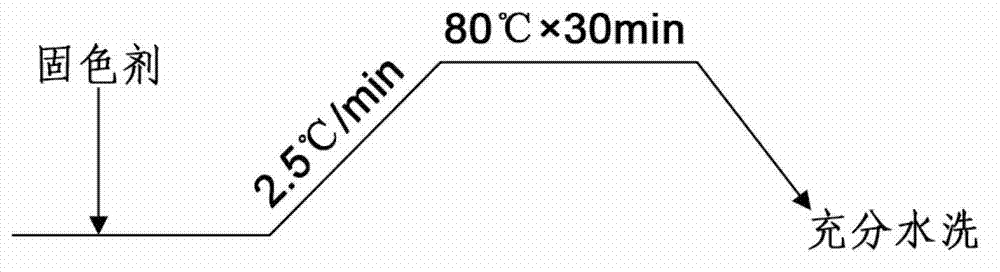

[0027] Specifically, the preparation method of the fleece-free fabric comprises the following steps:

[0028] The nylon fabric is subjected to cold-stacking treatment, open-width desizing treatment, presetting treatment, compounding treatment, dyeing treatment, color fixing treatment, resin finishing, shaping treatment and calendering treatment, and it is characterized in that, in the resin finishing step, finishing The liquid includes the following concentration components:

[0029] Resin finishing agent RCI 8-10g / l

[0030] Softener ULTRATEX UM NEW 13-15g / l

[0031] Non-ionic antistatic agent TF-480A 8-10g / l

[0032] Dry the resin-finished nylon fabric at 80°C, and then bake the dried nylon fabric at 130°C.

[0033] In the resin finishing step, the nylon fabric is subjected to the previous cold-stacking treatment, open-width desizing treatment, pre-setting treatment, compounding treatment, dyeing treatment, and color-fixing treatment. The resin finishing steps are specif...

Embodiment 1

[0084] The preparation method of the gall-free anti-velvet fabric according to the embodiment of the present invention includes the following steps:

[0085] The nylon fabric is subjected to cold heap treatment, and the treatment liquid in the cold heap treatment step includes components with the following concentrations:

[0086]

[0087]

[0088] The temperature of the cold stack treatment is 20°C, and the time is 30 hours;

[0089] The cold-stacked nylon fabric is subjected to open-width desizing treatment, and the treatment liquid in the open-width desizing treatment step includes components with the following concentrations:

[0090] 32% liquid caustic soda 140g / l

[0091] Desizing agent TF-127D 2g / l

[0092] Hydrogen peroxide 8g / l

[0093] Before the open-width desizing treatment, a wetting step is included, and after the open-width desizing treatment, a water washing step is included;

[0094] The nylon fabric after the open-width desizing treatment is subject...

Embodiment 2

[0113] The preparation method of the gall-free anti-velvet fabric according to the embodiment of the present invention includes the following steps:

[0114] The nylon fabric is subjected to cold heap treatment, and the treatment liquid in the cold heap treatment step includes components with the following concentrations:

[0115]

[0116] The temperature of the cold stack treatment is 20°C, and the time is 33 hours;

[0117] The cold-stacked nylon fabric is subjected to open-width desizing treatment, and the treatment liquid in the open-width desizing treatment step includes components with the following concentrations:

[0118] 32% liquid caustic soda 145g / l

[0119] Desizing agent TF-127D 2.5g / l

[0120] Hydrogen peroxide 9g / l

[0121] Before the open-width desizing treatment, a wetting step is included, and after the open-width desizing treatment, a water washing step is included;

[0122] The nylon fabric after the open-width desizing treatment is subjected to pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com