Textile fabric aftertreatment production technology

A textile fabric and production process technology, applied in the field of textile fabric post-processing production process, can solve the problems of affecting subsequent operations, uneven fabric, and lack of fabric kneading and cleaning, and achieve the advantages of promoting decomposition, high processing efficiency, and promoting absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

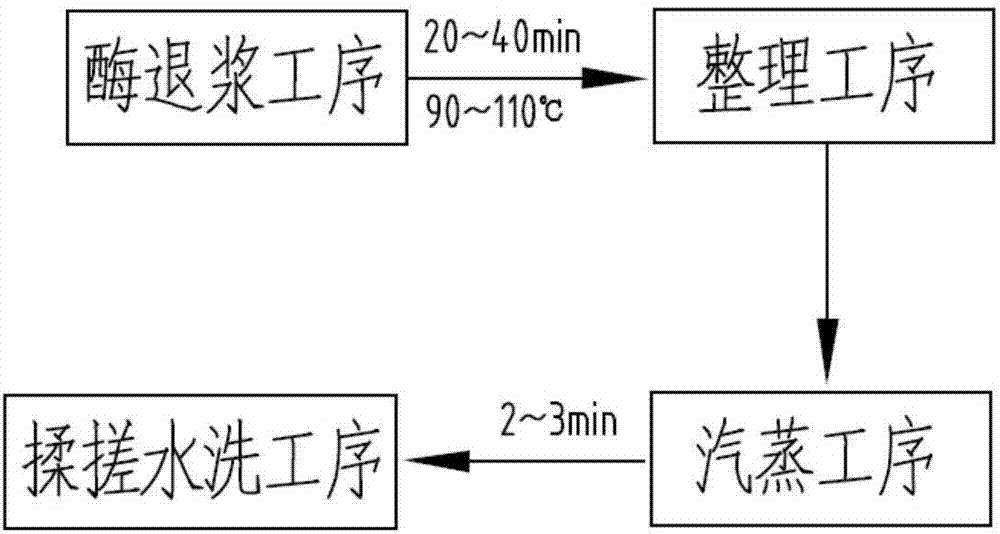

[0062] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 Shown, a kind of post-treatment production process of textile fabrics comprises the following processing steps:

[0063] a. Enzyme desizing process, soaking the fabric to be desized in amylase;

[0064] b. Finishing process, the textile fabric that has been soaked in amylase in step a and completed desizing is transported backwards. During the transmission process, two smoot...

Embodiment 2

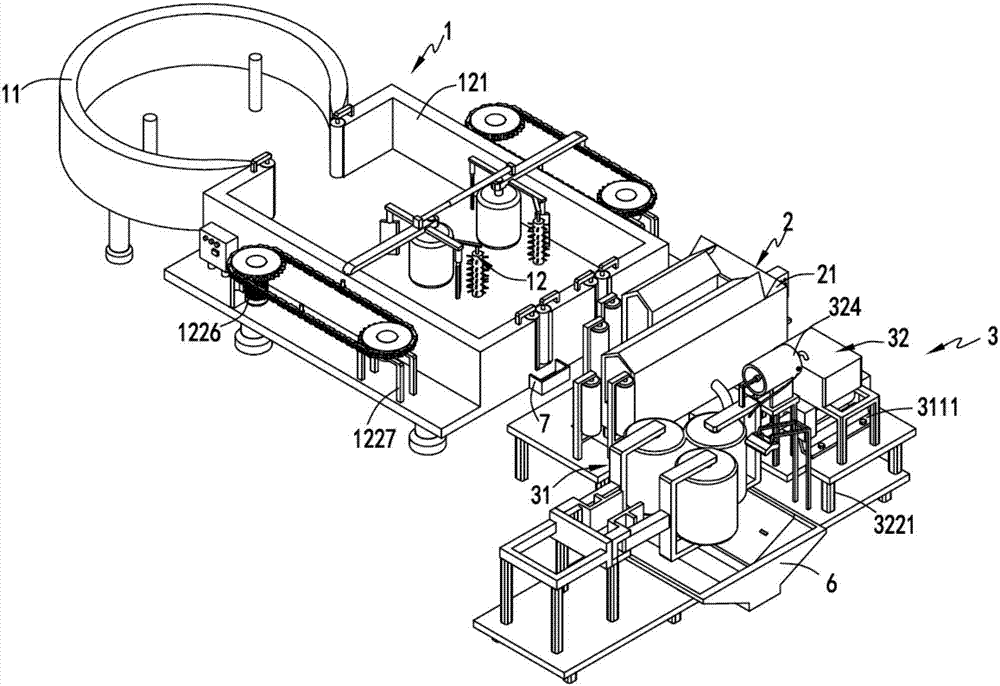

[0074] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, a textile fabric post-processing production line, including

[0075] Desizing part 1, said desizing part 1 comprises the soaking tank 11 for putting amylase and the material to be desized and is arranged on the rear end of the soaking tank 11 for the material transported backward by the soaking tank 11 a collation agency 12 for collation;

[0076] A steaming part 2, the steaming part 2 is arranged at the rear end of the finishing mechanism 12, and the steaming part 2 is used for steaming while transporting the fabrics finished by the finishing mechanism 12;

[0077] The rubbing and washing part 3, the rubbing and washing part 3 is arranged at the rear end of the steaming part 2, the rubbing and washing part 3 includes a rubbing mechanism 31 and a water washing mechanism 32, and the rubbing mechanism 31 is along ...

Embodiment 3

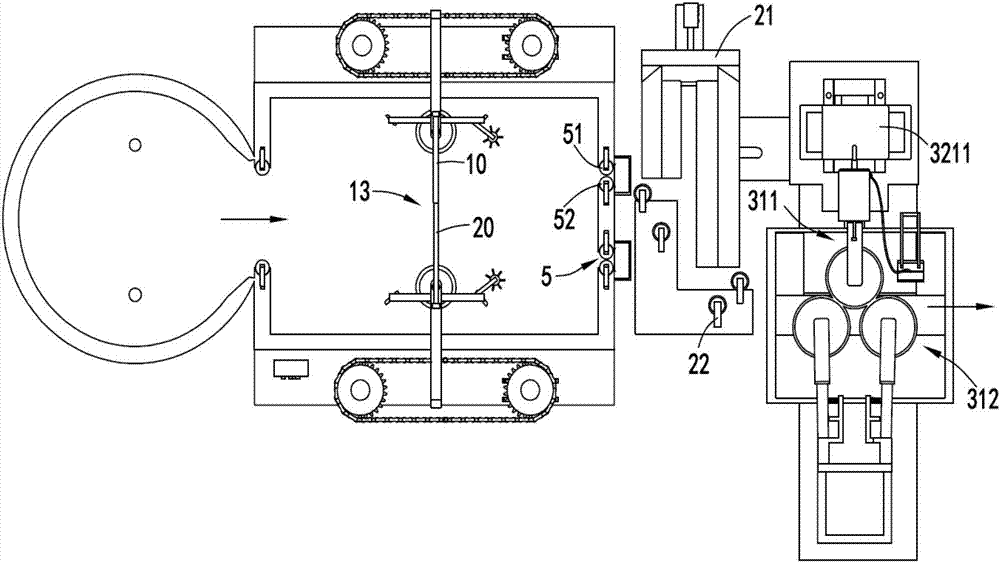

[0103] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is that the steaming part 2 includes a steaming box 21, and several guide rollers 22 arranged at the inlet end, the outlet end and the inside of the steaming box 21, the steaming The box 21 is arranged in a U-shape.

[0104] Firstly, by arranging the steaming part 2, the cloth with amylase attached can promote the decomposition of amylase under the action of heat. In addition, by arranging the steaming box 21, it is set to a U-shape so that the cloth can be improved as much as possible u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com