Preparation method of starch-grafted composite glutin sizing

A technology of grafting starch and gelatin protein, applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problems of affecting the adhesion performance of serosal strong yarns, affecting the sizing process, and the environmental protection of emulsifiers. The effect of film forming, improving sizing rate and easy hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

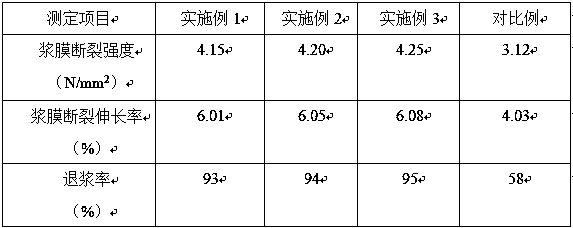

Examples

Embodiment 1

[0038] In terms of parts by weight, weigh 60 parts of cornstarch, 120 parts of methanol, and 15 parts of deionized water respectively, add methanol to deionized water, and stir at a speed of 200r / min for 10min at room temperature to obtain a methanol solution, and add cornstarch to methanol In the solution, stir at a speed of 100r / min for 20min at room temperature to obtain a starch dispersion, put the starch dispersion in a water bath at 50°C and stir at 120r / min for 1h, vacuum filter, and place the filter cake at 60°C Dry for 1 hour, pass through an 80-mesh sieve after grinding to obtain refined starch, and weigh 60 parts of refined corn starch, 6 parts of polymaleic anhydride, 120 parts of deionized water, and 15 parts of Hydrogen peroxide solution, 0.2 parts of ferric sulfate, 0.3 parts of ammonium sulfate, add the refined starch into deionized water, stir at 120r / min for 20min at room temperature to obtain a refined starch dispersion, and place the refined starch dispersio...

Embodiment 2

[0040] In terms of parts by weight, weigh 70 parts of cornstarch, 135 parts of methanol, and 17 parts of deionized water, add methanol to deionized water, and stir at a speed of 220r / min for 13 minutes at room temperature to obtain a methanol solution. Add cornstarch to methanol In the solution, stir at a speed of 110r / min for 25min at room temperature to obtain a starch dispersion, put the starch dispersion in a water bath at 55°C and stir at 130r / min for 1.5h, vacuum filter, and place the filter cake at 70°C After drying for 1.5 hours, pass through a 90-mesh sieve after grinding to obtain refined starch, and weigh 70 parts of refined cornstarch, 7 parts of polymaleic anhydride, 150 parts of deionized water, and 17 parts of mass concentration 1 % hydrogen peroxide solution, 0.3 parts of ferric sulfate, 0.4 parts of ammonium sulfate, add the refined starch into deionized water, stir at 140r / min at room temperature for 25min to obtain a refined starch dispersion, and place the r...

Embodiment 3

[0042]In terms of parts by weight, weigh 80 parts of cornstarch, 150 parts of methanol, and 20 parts of deionized water respectively, add methanol to deionized water, and stir at a speed of 240r / min for 15 minutes at room temperature to obtain a methanol solution. Add cornstarch to methanol In the solution, stir at a speed of 120r / min for 30min at room temperature to obtain a starch dispersion, put the starch dispersion in a water bath at 60°C and stir at 140r / min for 2h, vacuum filter, and place the filter cake at 80°C Dry for 2 hours, pass through a 100-mesh sieve after grinding to obtain refined starch, and weigh 80 parts of refined corn starch, 8 parts of polymaleic anhydride, 180 parts of deionized water, and 20 parts of Hydrogen peroxide solution, 0.4 parts of ferric sulfate, 0.5 parts of ammonium sulfate, add the refined starch into deionized water, stir at 160r / min for 30min at room temperature to obtain a refined starch dispersion, and place the refined starch dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com