Method for extracting fiber from straw

A straw and fiber technology, which is applied in fiber raw material treatment, microbial/enzymatic cellulose treatment, textile and paper making, etc., can solve problems that do not conform to the production concept of energy saving and environmental protection, shortage of wood resources, and non-compliance with sustainable development. Achieve good removal effect, high purity, and reduce wood consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

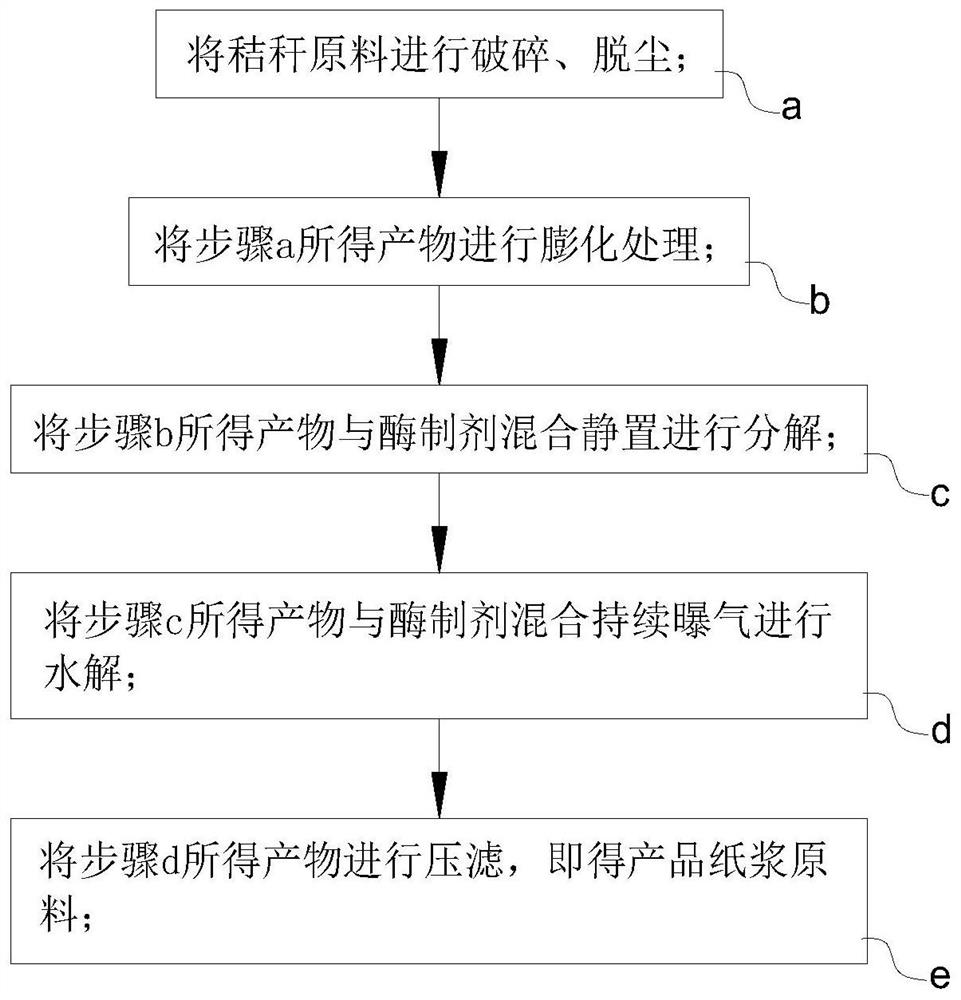

[0037] Such as figure 1 Shown, a kind of method for extracting fiber from straw described in the present disclosure, comprises the following steps:

[0038] a: Crushing and dedusting the straw raw materials; specifically, crushing the collected and transported straw raw materials through a crusher, breaking them into wood chips, and then dedusting through a six-roller dust remover to remove the straw fragments. dust and other sundries to improve the purity of straw;

[0039] b: The product obtained in step a is subjected to puffing treatment; specifically, the product obtained in step a (that is, crushed and dedusted straw fragments) is sent to an extruder for puffing, and after appropriate heating and pressure, decompression is performed to make the straw The starch material in the starch material expands, and the expansion is to increase the volume of the straw fragments and prepare for the subsequent fermentation and degradation process. When the expanded straw fragments r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com