Desizing agent for viscose-based wood carbon fibers and preparation and use method of desizing agent

A carbon fiber and viscose-based technology, applied in carbon fiber, dry-cleaning fiber products, fiber treatment, etc., to achieve the effects of small surface damage, avoid a large amount of waste water, and reduce treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

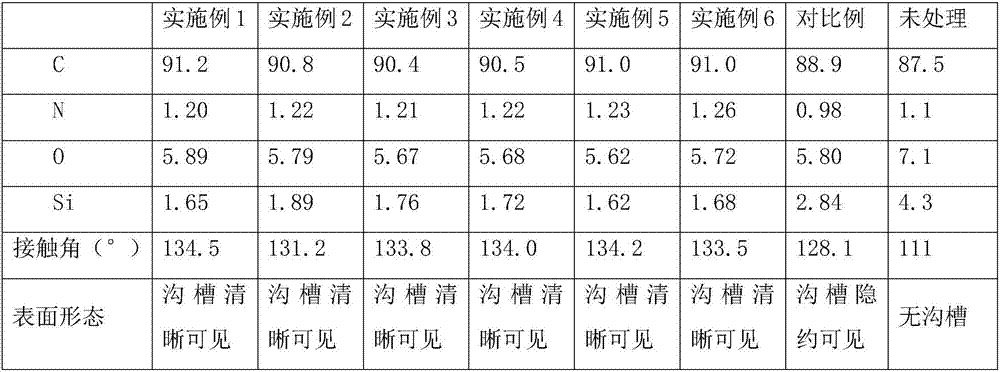

Examples

Embodiment 1

[0024] Mix isopropanol and water evenly, add lecithin, sodium dioctyl maleate sulfonate and cetyltrimethylammonium bromide, then add cellulase, pectinase, α-amylase Add the mixture with alkaline protease, fully stir until clarification, then add alkali lignin and sodium carbonate, after fully mixing, stir 10min at 200W ultrasonic to form a desizing agent for viscose-based woody carbon fiber, wherein, for The components of the desizing agent for viscose-based wood carbon fiber, in parts by weight, include 10 parts of alkaline substances, 8 parts of desizing enzymes, 5 parts of surfactants, 15 parts of polyols and 60 parts of water, in alkaline substances The mass ratio of alkali lignin and sodium carbonate is 1:2, and the mass ratio of cellulase, pectinase, alpha-amylase and alkaline protease in the described desizing enzyme is 1:1:1:1, surface activity The mass ratio of lecithin, maleic acid di-sec-octyl sodium sulfonate and cetyltrimethylammonium bromide in the agent is 1:0.3...

Embodiment 2

[0027] Mix isopropanol and water evenly, add lecithin, sodium dioctyl maleate sulfonate and cetyltrimethylammonium bromide, then add cellulase, pectinase, α-amylase Add the mixture with alkaline protease, fully stir until clarification, then add alkali lignin and sodium carbonate, after fully mixing, 300W ultrasonic stirring for 30min, form the desizing agent for viscose-based woody carbon fiber, wherein, for The components of the desizing agent for viscose-based wood carbon fiber, in parts by weight, include 20 parts of alkaline substances, 12 parts of desizing enzymes, 10 parts of surfactants, 25 parts of polyols and 80 parts of water, in alkaline substances The mass ratio of alkali lignin and sodium carbonate is 1:4, and the mass ratio of cellulase, pectinase, alpha-amylase and alkaline protease in the described desizing enzyme is 1:1:1:1, surface activity The mass ratio of lecithin, maleic acid di-sec-octyl sodium sulfonate and cetyltrimethylammonium bromide in the agent i...

Embodiment 3

[0030] Mix isopropanol and water evenly, add lecithin, sodium dioctyl maleate sulfonate and cetyltrimethylammonium bromide, then add cellulase, pectinase, α-amylase Add the mixture with alkaline protease, fully stir until clarification, then add alkali lignin and sodium carbonate, after fully mixing, 250W ultrasonic stirring for 20min, form the desizing agent for viscose-based woody carbon fiber, wherein, for The components of the desizing agent for viscose-based wood carbon fiber, in parts by weight, include 15 parts of alkaline substances, 9 parts of desizing enzymes, 7 parts of surfactants, 19 parts of polyols and 75 parts of water, in alkaline substances The mass ratio of alkali lignin and sodium carbonate is 1:3, and the mass ratio of cellulase, pectinase, alpha-amylase and alkaline protease in the described desizing enzyme is 1:1:1:1, surface activity The mass ratio of lecithin, maleic acid di-sec-octyl sodium sulfonate and cetyltrimethylammonium bromide in the agent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com