Environment-friendly and energy-saving cloth printing and dyeing process

A printing and dyeing process, environmental protection and energy-saving technology, applied in the field of textile printing and dyeing, can solve the problems of consuming raw materials, consuming large desizing agents, increasing pollution, etc., to achieve the effects of saving a lot of energy, improving dyeing effect, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

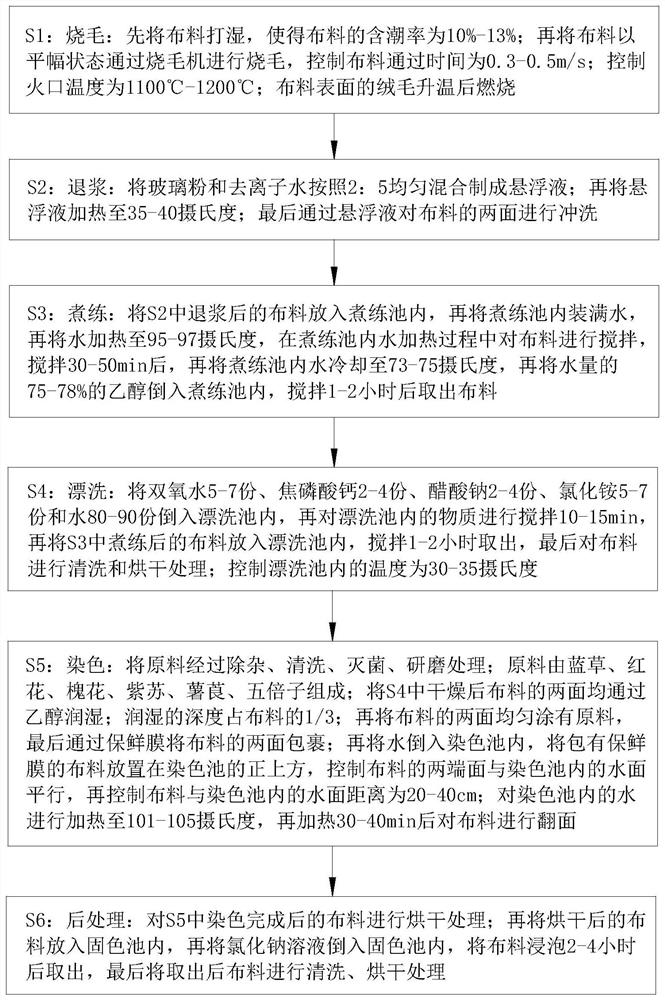

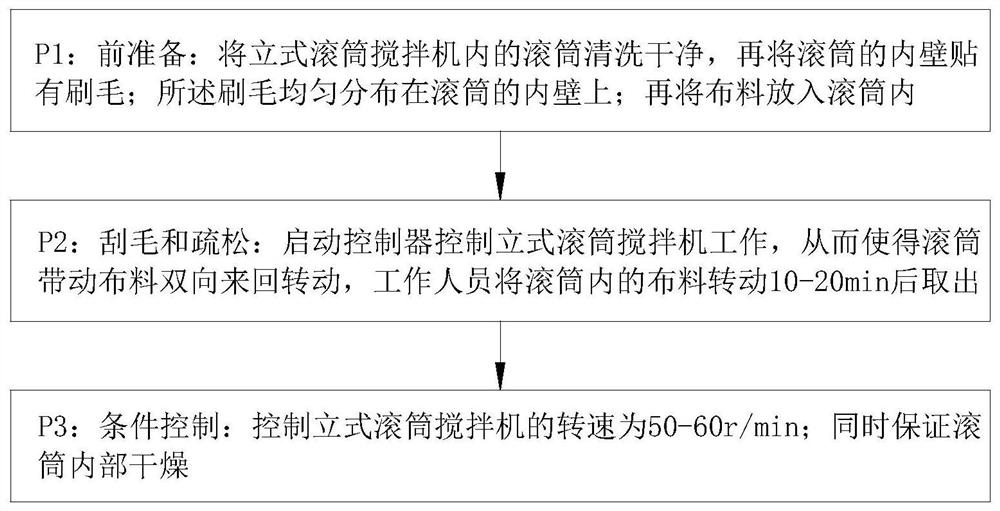

[0037] A kind of environmental protection and energy-saving cloth printing and dyeing process of the present invention, comprises the following steps:

[0038] S1: singeing: wet the fabric first, so that the moisture content of the fabric is 10%; then singe the fabric through the singeing machine in the open width state, control the passing time of the fabric to 0.3m / s; control the temperature of the burner to 1100°C; the fluff on the surface of the cloth burns after heating up;

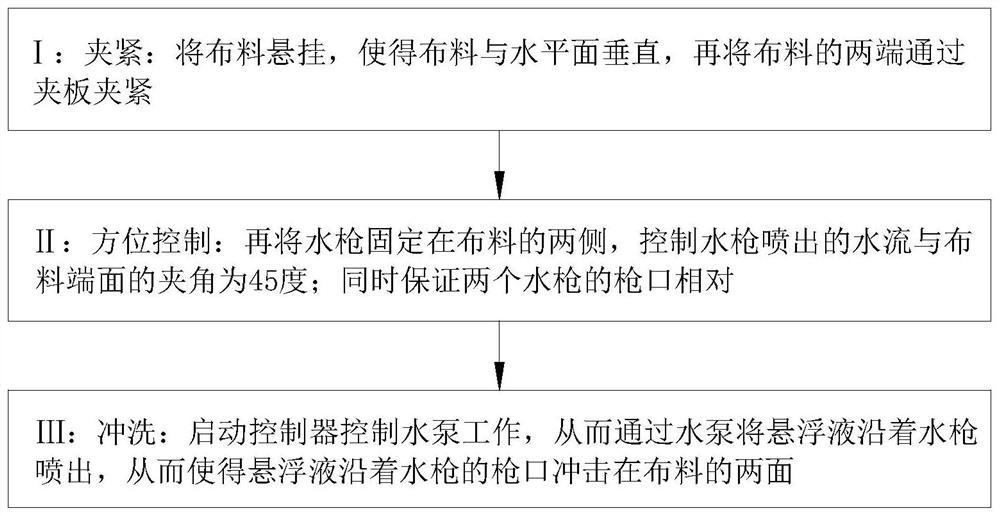

[0039] S2: Desizing: mix glass powder and deionized water at a ratio of 2:5 to make a suspension; then heat the suspension to 35 degrees Celsius; finally wash both sides of the fabric with the suspension;

[0040] S3: Scouring: Put the desized fabric in S2 into the scouring pool, fill the scouring pool with water, heat the water to 95 degrees Celsius, and stir the fabric for 30 minutes during the heating process of the water in the scouring pool Finally, cool the water in the scouring pool to 73 deg...

Embodiment 2

[0056] Include the following steps:

[0057] S1: singeing: wet the fabric first, so that the moisture content of the fabric is 12%; then singe the fabric through the singeing machine in the open width state, control the passing time of the fabric to 0.4m / s; control the temperature of the burner to be 1150°C; the fluff on the surface of the cloth burns after heating up;

[0058] S2: Desizing: Mix glass powder and deionized water at a ratio of 2:5 to make a suspension; then heat the suspension to 37.5 degrees Celsius; finally wash both sides of the fabric with the suspension;

[0059] S3: Scouring: put the desized fabric in S2 into the scouring pool, then fill the scouring pool with water, then heat the water to 96 degrees Celsius, and stir the fabric during the heating process of the water in the scouring pool for 40 minutes Finally, cool the water in the scouring pool to 74 degrees Celsius, then pour 76% ethanol into the scouring pool, and take out the cloth after stirring fo...

Embodiment 3

[0075] Include the following steps:

[0076] S1: singeing: wet the cloth first, so that the moisture content of the cloth is 13%; then singe the cloth through the singeing machine in the open width state, and control the passing time of the cloth to 0.5m / s; control the temperature of the burner to be 1200°C; the fluff on the surface of the cloth burns after heating up;

[0077] S2: Desizing: Mix glass powder and deionized water at a ratio of 2:5 to make a suspension; then heat the suspension to 40 degrees Celsius; finally wash both sides of the fabric with the suspension;

[0078] S3: Scouring: put the desized fabric in S2 into the scouring pool, fill the scouring pool with water, heat the water to 97 degrees Celsius, and stir the fabric for 50 minutes during the heating process of the water in the scouring pool Finally, cool the water in the scouring pool to 75 degrees Celsius, then pour 78% ethanol into the scouring pool, and take out the cloth after stirring for 2 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com