Hole fabric and method for making same

A fabric and hole cloth technology, applied in the direction of dyeing method, fabric surface trimming, textile and papermaking, etc., can solve the problems of complex production process, and achieve the effect of improving coloring degree, improving desizing efficiency and improving dyeing uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

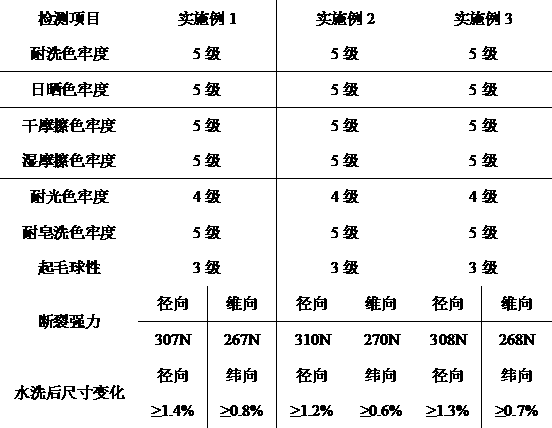

Embodiment 1

[0036] Hole fabric, the gray fabric of the hole fabric is formed by interweaving T / R fibers, and the hole fabric is provided with a plurality of evenly distributed holes.

[0037] The manufacturing process of the hole cloth fabric comprises the following steps:

[0038] Step 1, distribution:

[0039] Unroll the gray cloth and distribute it to the cloth car;

[0040] Step 2, continuous desizing and washing:

[0041] Arrange the blanks in a continuous desizing machine for continuous desizing and water washing to obtain washed gray fabrics. The desizing aids include the following ingredients: tea saponin, tea soap powder and liquid alkali. During the desizing process, add them in sequence according to the amount of water The following components are calculated: tea saponin 18g ⁄ L, tea soap powder 1g ⁄ L and liquid caustic soda 19g ⁄ L, the desizing temperature is 85°C, the washing temperature is 75°C, the padding pressure is 1.5kg, the tension bar pressure is 2kg, The rolling...

Embodiment 2

[0057]Hole fabric, the gray fabric of the hole fabric is formed by interweaving T / R fibers, and the hole fabric is provided with a plurality of evenly distributed holes.

[0058] The manufacturing process of the hole cloth fabric comprises the following steps:

[0059] Step 1, distribution:

[0060] Unroll the gray cloth and distribute it to the cloth car;

[0061] Step 2, continuous desizing and washing:

[0062] Arrange the blanks in a continuous desizing machine for continuous desizing and water washing to obtain washed gray fabrics. The desizing aids include the following ingredients: tea saponin, tea soap powder and liquid alkali. During the desizing process, add them in sequence according to the amount of water The following components are calculated: tea saponin 20g ⁄ L, tea soap powder 2g ⁄ L and liquid caustic soda 20g ⁄ L, the desizing temperature is 90°C, the washing temperature is 80°C, the padding pressure is 2.0kg, the tension rod pressure is 2kg, The rolling ...

Embodiment 3

[0078] Hole fabric, the gray fabric of the hole fabric is formed by interweaving T / R fibers, and the hole fabric is provided with a plurality of evenly distributed holes.

[0079] The manufacturing process of the hole cloth fabric comprises the following steps:

[0080] Step 1, distribution:

[0081] Unroll the gray cloth and distribute it to the cloth car;

[0082] Step 2, continuous desizing and washing:

[0083] Arrange the blanks in a continuous desizing machine for continuous desizing and water washing to obtain washed gray fabrics. The desizing aids include the following ingredients: tea saponin, tea soap powder and liquid alkali. During the desizing process, add them in sequence according to the amount of water The following components are calculated: tea saponin 22g ⁄ L, tea soap powder 3g ⁄ L and liquid caustic soda 21g ⁄ L, the desizing temperature is 95°C, the washing temperature is 85°C, the padding pressure is 2.5kg, the tension bar pressure is 3kg, The rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com