Starch removing device special for blue print cloth

A printed cloth and metal strip technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of time-consuming and laborious work efficiency, low efficiency, affecting the development of blue printed cloth, etc., to improve production efficiency, reduce damage, and improve production efficiency. The effect of pulp efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

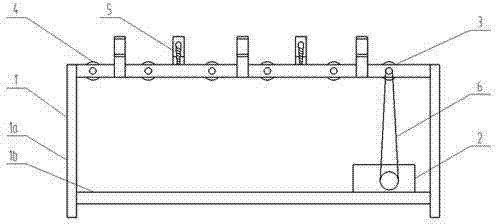

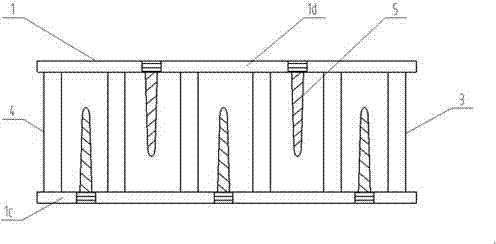

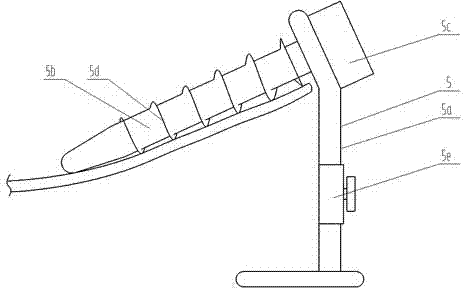

[0023] like figure 1 , figure 2 As shown, the special desizing device for blue calico includes support 1, main motor 2, driving roller 3, driven roller 4 and desizing tool 5, support 1 is a cubic frame structure, and the bottom of support 1 is fixed with 4 Legs 1a, each leg 1a is connected by metal strip A1b, two metal strips B1c and metal strip C1d are arranged in parallel on the top of support 1, the gap between one end of metal strip B1c and metal strip C1d is movable in the vertical direction. Roller 3, the driving roller 3 is connected with the drive shaft of the main motor 2 through the belt 6, and several driven rollers 4 are movable in the same plane where the driving roller 3 is arranged on the bracket 1, and the metal strips ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com