Desizing equipment for spinning fabric

A technology for desizing equipment and textile fabrics, which is applied in the direction of processing textile material equipment configuration, textile material processing, and continuous processing of textile materials, etc., and can solve problems such as poor desizing effect, low desizing efficiency, and uneven contact , to achieve the effect of improving water spraying efficiency, good wetting performance and sufficient water spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

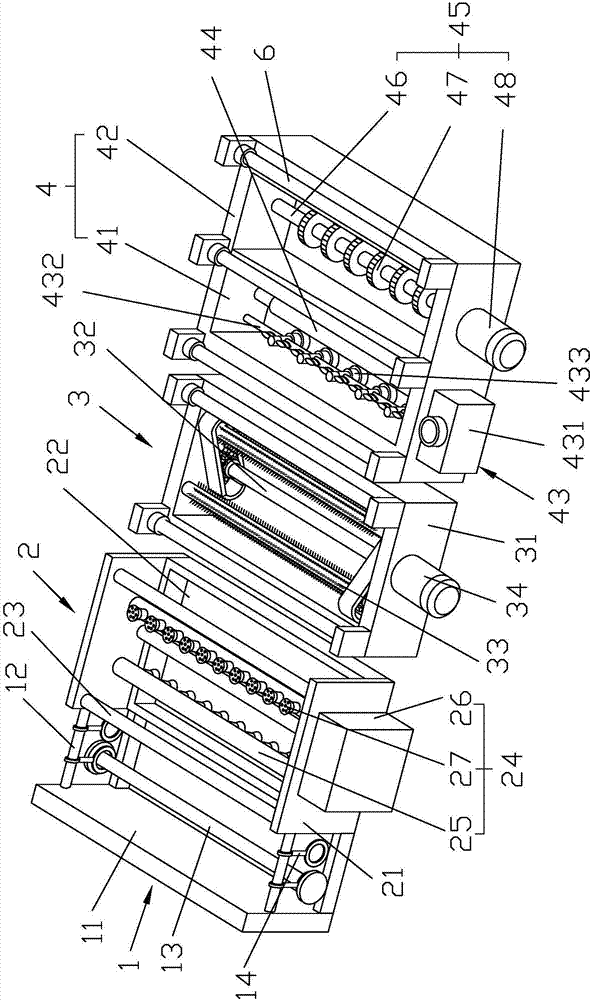

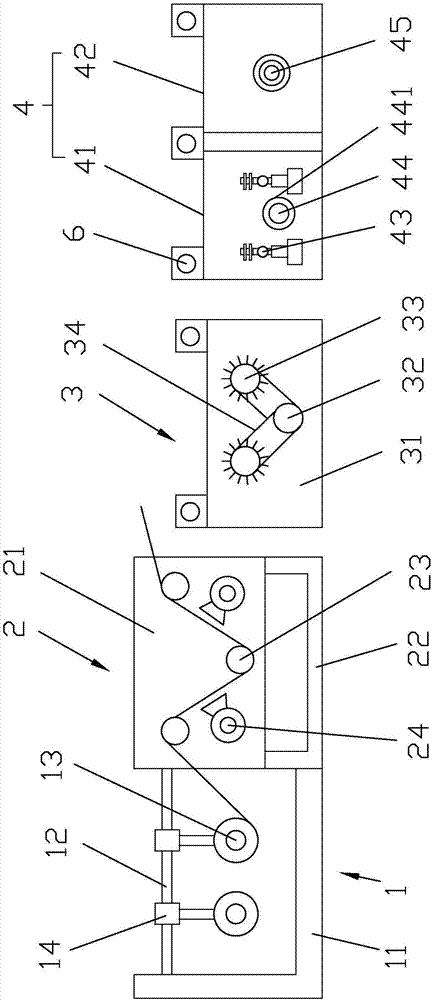

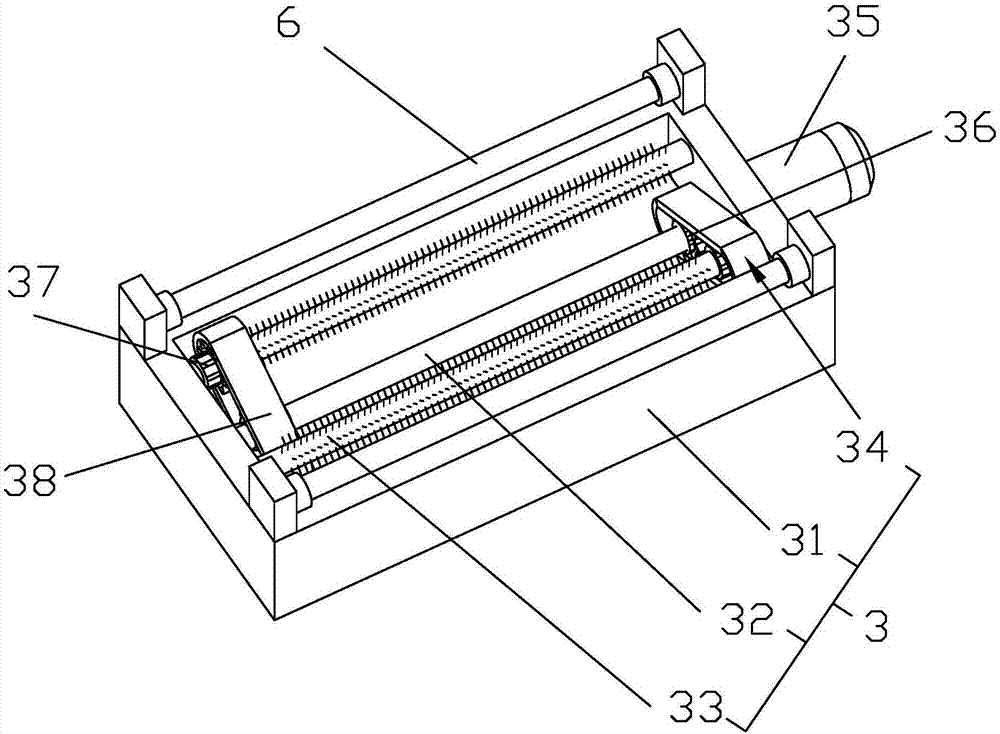

[0025] Such as Figure 1-5 As shown, it is a kind of desizing equipment for textile fabrics of the present invention, including a cloth rack 1, a pretreatment device 2, a scraping device 3 and a desizing box 4, and the cloth rack 1 includes a support plate 11, a connecting rod 12 and the distribution shaft 13, the left and right sides of the support plate 11 are connected with the pretreatment frame 21 by the connecting rod 12, the connecting rod 12 is provided with at least two connecting rings 14, and the cloth releasing shaft 13 is hung on the connecting ring 14 superior. Wind the cloth that needs to be desized on the cloth release shaft 13, and then place the cloth release shaft 13 on the cloth release rack 1 through the connecting ring 14, which is convenient for cloth feeding and speeds up the desizing speed, and can be placed on the cloth release rack 1 at the same time Many cloth putting shafts 13 save the time of getting cloth back and forth.

[0026]Pretreatment de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com