Method of heating jacket of retaining ring of steam turbine generator rotor

A technology for turbogenerators and rotor guard rings, which is applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc. It can solve problems such as falling below the thermal expansion temperature, difficult to control the temperature, and cumbersome lifting process. Achieve the effects of reducing elastic expansion, easy temperature control, and safe lifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

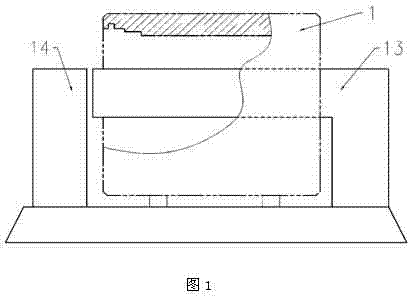

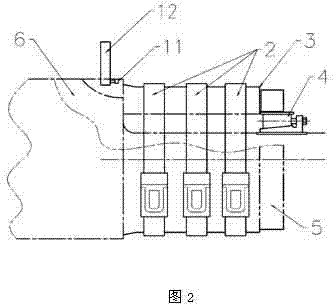

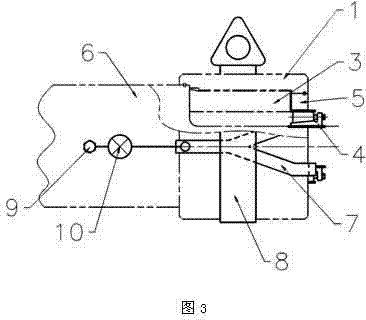

[0018] A kind of technology method of thermal sleeve of turbogenerator rotor retaining ring, such as figure 1 , figure 2 , image 3 Shown, its technical scheme is:

[0019] a. Preparations before heat-shrouding ring: use tensioning band 2 to tighten the coil end 3 at three axial positions of the coil end 3, assemble the ring key 11 into the ring keyway of the rotor body, and use the ring key clip 12 Tighten the ring key 11, use the center ring radial positioning tool 4 to fix the center ring 5 on the coil end 3, and adjust the center ring radial positioning tool 4 to align the center ring 5 and the rotor 6 concentrically;

[0020] b. Guard ring induction heating: lift the rotor guard ring 1 to the intermediate frequency induction heating machine 13 for the retaining ring, turn off the intermediate frequency induction heating machine 13 to move the iron core 14, turn on the intermediate frequency induction heating machine 13 to heat the guard ring 1, and monitor the guard ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com