Sand-containing colorful environment-friendly coating and preparation method of same

An environmentally friendly coating and colorful technology, applied in the field of coatings, can solve the problems of non-flexibility, gelatinization, and unevenness of materials, and achieve good steric hindrance effects, good construction stability, and good storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1

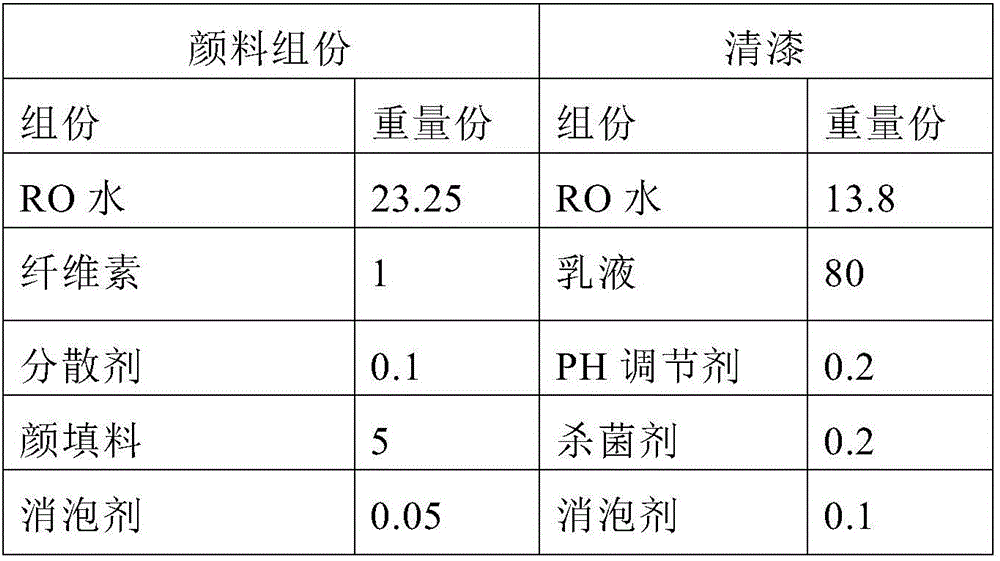

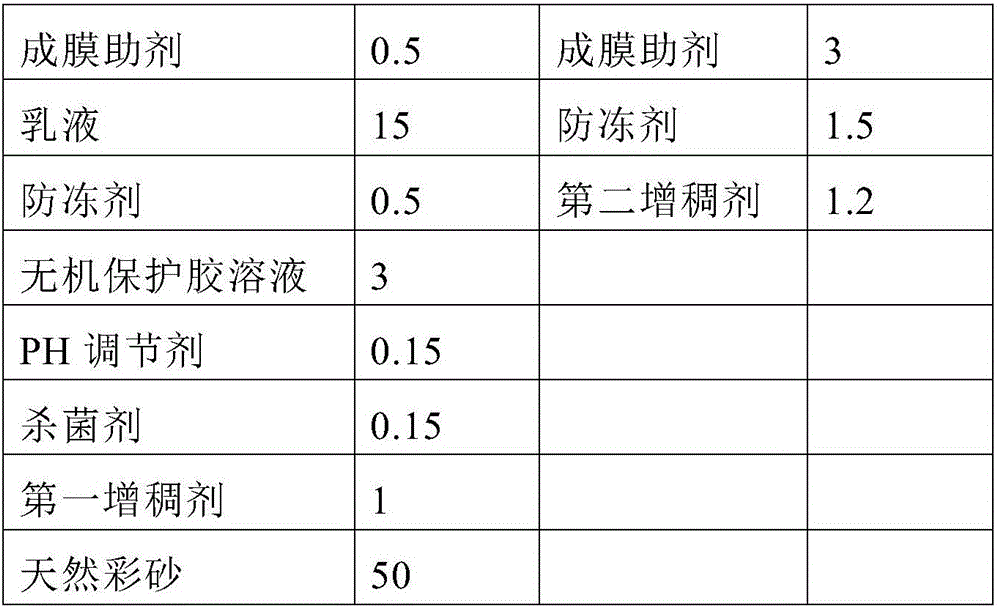

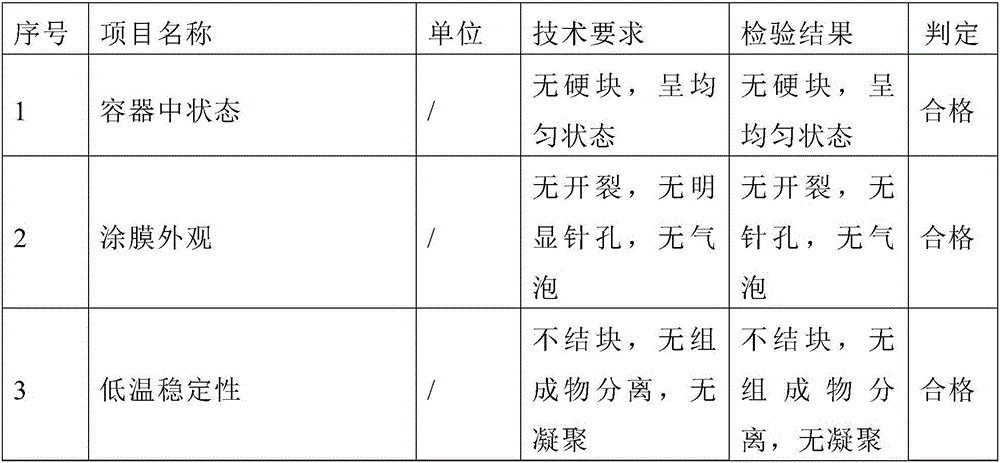

[0030] The ingredients of Examples 1-3 and Comparative Example 1 are shown in Table 1 and Table 2. Among them, the cellulose adopts ethyl cellulose ether; the dispersant is the hydrophobic copolymer sodium salt dispersant; the pigment and filler are calcined kaolin, heavy Calcium, mica powder, talc powder or rutile titanium dioxide; antifoaming agent is modified polysiloxane; film forming aid is dodecyl alcohol ester; emulsion is water-based acrylic resin; antifreeze is propylene glycol; PH regulator It is 2-amino-2-methyl-1-propanol; the bactericide is a nitrogen-sulfur heterocyclic compound without organic volatiles; the rheological agent is silicon dioxide; the coupling agent is a titanate coupling agent; The inorganic protective glue solution is an aqueous solution of lithium magnesium silicate; the first thickener is hydroxypropyltrimethylammonium chloride; the second thickener is a hydrophobically modified alkali-soluble emulsion thickener; the organic protective glue solu...

Embodiment 4-6

[0055] The preparation method of Example 4-6 is the same as that of Example 1, and the specific formula is shown in Table 5-7:

[0056] Table 5 Example 4-6 Pigment component formula

[0057]

[0058] Table 6 Example 4-6 Dispersion Medium Formula

[0059]

[0060]

[0061] Table 7 Example 4-6 Varnish Formula

[0062]

[0063] Above, cellulose is ethyl cellulose ether; dispersant is hydrophobic copolymer sodium salt dispersant; pigment and filler are calcined kaolin, heavy calcium, mica powder, talc or rutile titanium dioxide; defoamer is organic silicon modified Mineral oil; film-forming aid is dodecyl alcohol ester; emulsion is silicone water-based acrylic resin; antifreeze is propylene glycol; PH regulator is 2-amino-2-methyl-1-propanol; bactericide is Nitrogen-sulfur heterocyclic compounds without organic volatiles; rheological agent is silicon dioxide; coupling agent is titanate coupling agent; first thickener is hydroxypropyl trimethyl ammonium chloride; second The thickener is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com