Anchor cable pressure bowl composite mould

A compound mold and pressure technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unfavorable safety production, frequent punching times, low production efficiency, etc., to reduce safety hazards and labor intensity, and high yield , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

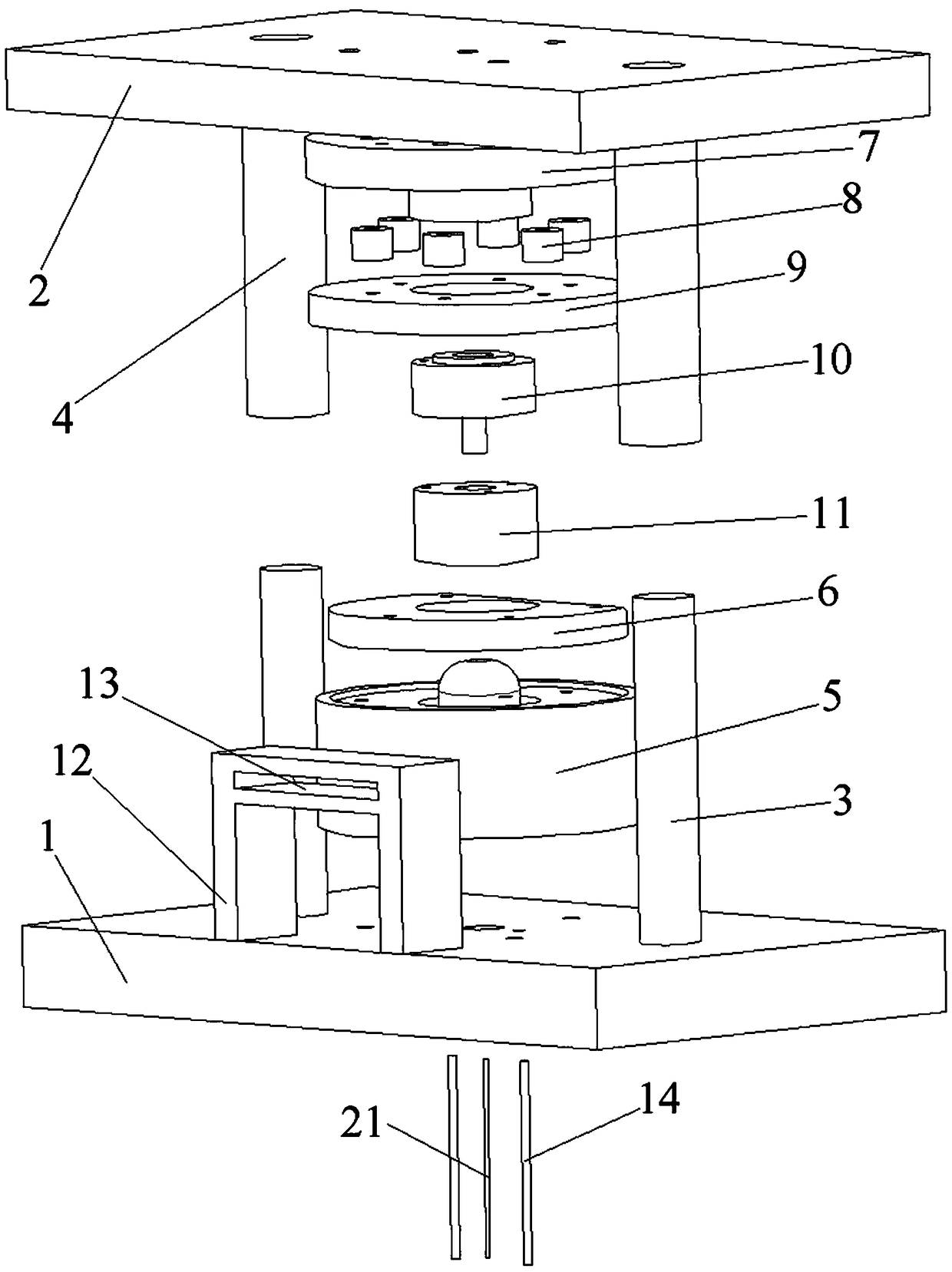

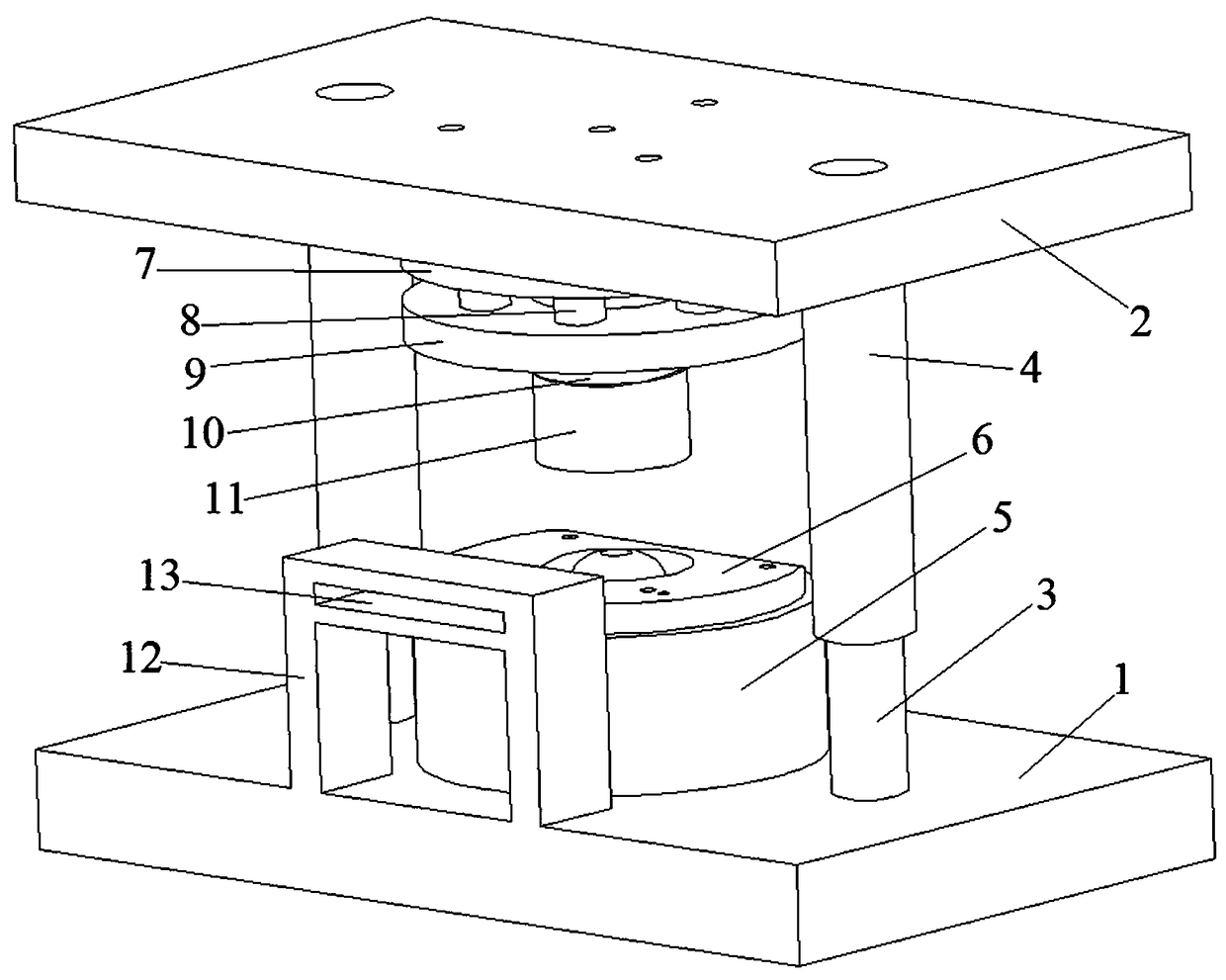

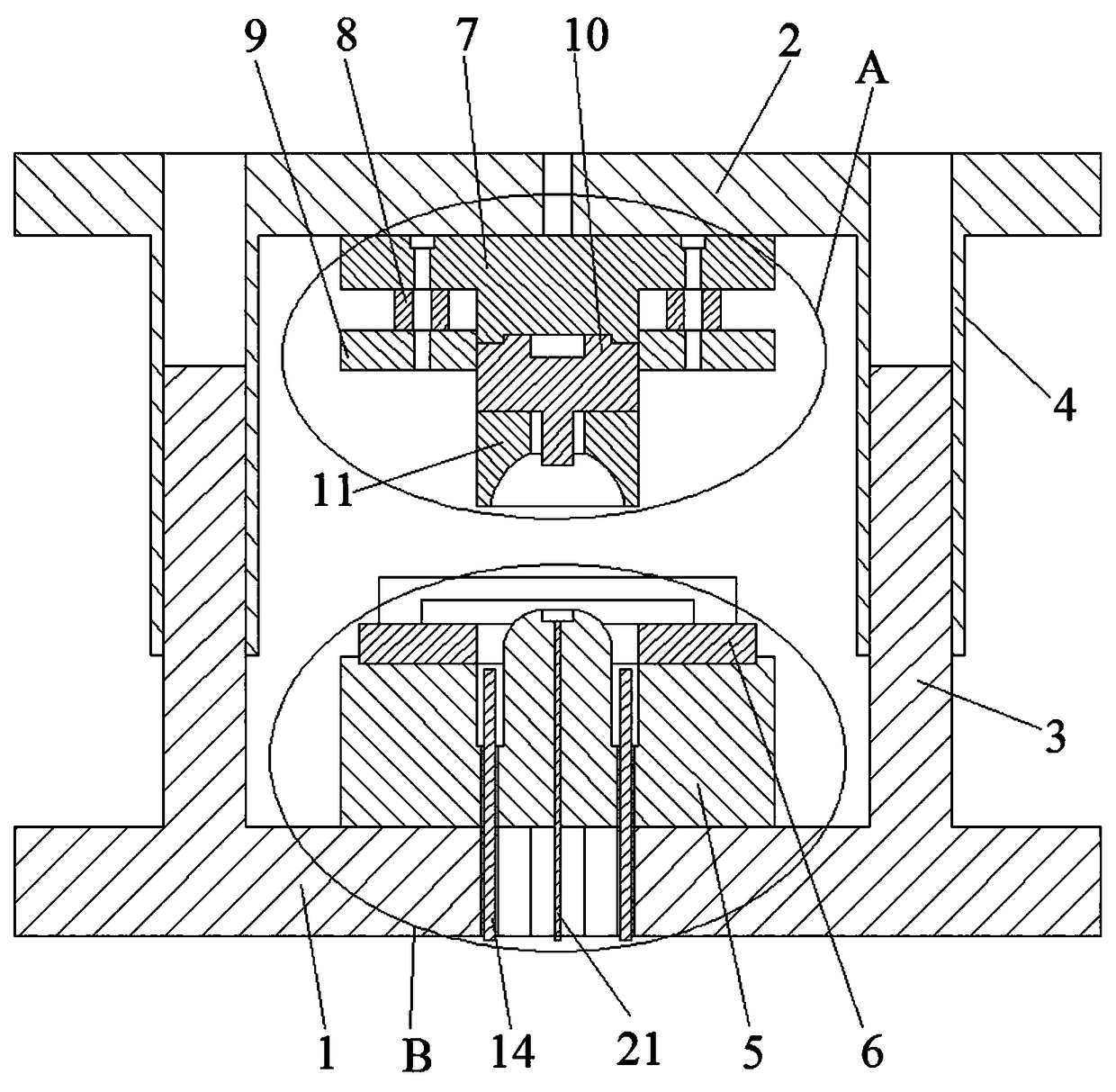

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] As shown in the figure, a compound mold for anchor cable pressure bowl includes a rectangular base 1 at the bottom and a rectangular upper seat 2 at the top. The left and right sides of the base 1 are fixed with cylindrical guide posts 3, and the middle part of the base 1 is passed through three bolts. The lower mold 5 of conical shape is installed and fixed, and the upper surface middle part of described lower mold 5 is provided with cylindrical sinking groove 22, and the middle part of sinking groove 22 is integrally formed with cylindrical protruding shaft 19, and the top surface of protruding shaft 19 It has an arc-shaped surface (adapted to the inner surface of the anchor cable pressure bowl), and the center of the top surface of the protruding shaft 19 has a circular inner ring groove 20 (adapted to the middle hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com