Silicon-based inverted microstrip line structure and manufacturing method therefor

A technology of inverting microstrip and line structures, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as difficult accuracy, dielectric loss, and limited applications, so as to reduce the emission of secondary electrons, reduce the Small insertion loss and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

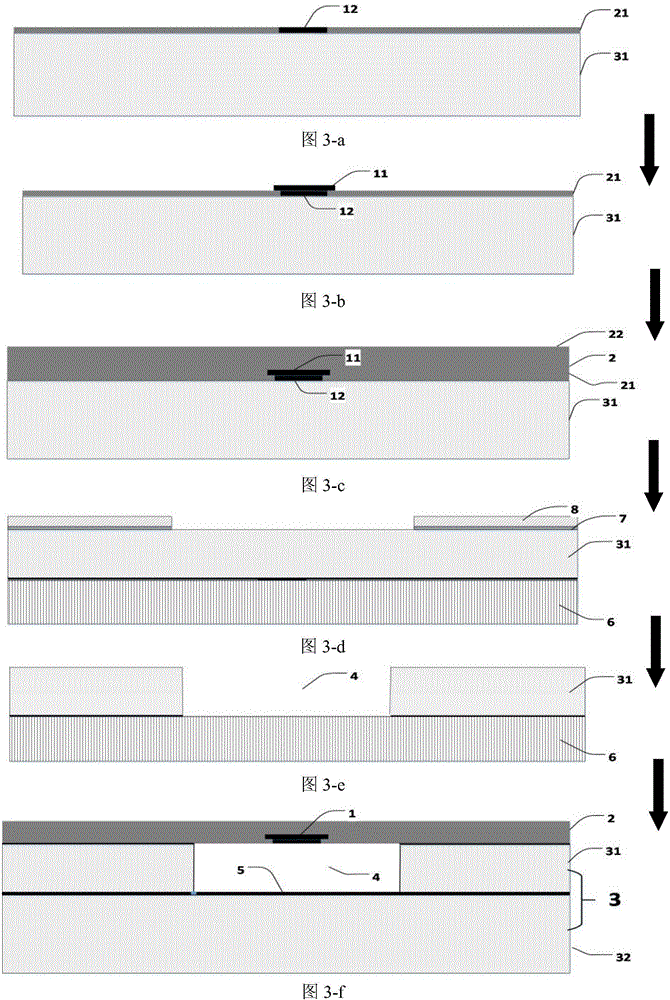

[0051]The present invention will be described in further detail below in conjunction with the accompanying drawings. Described embodiment is only a part of embodiment of the present invention, not all embodiment, the present invention can also adopt other different modes to implement, those skilled in the art can do similar promotion under the situation of not violating connotation of the present invention, Therefore, the present invention is not limited by the specific examples disclosed below.

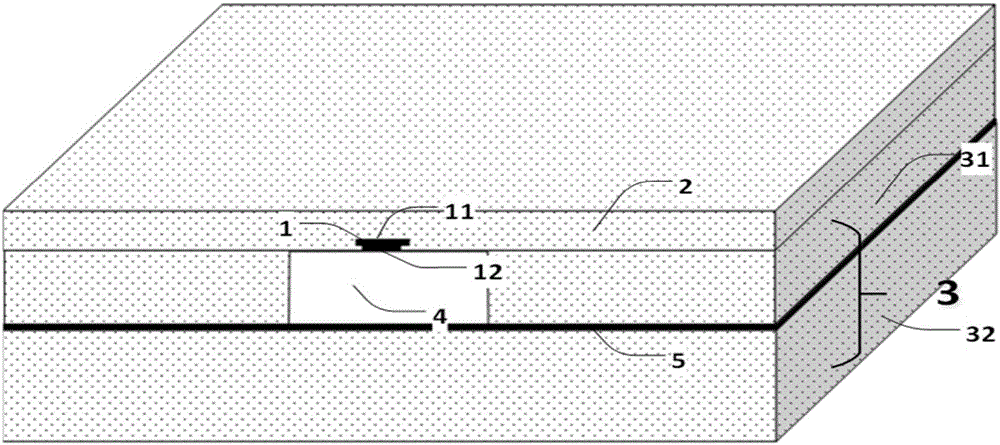

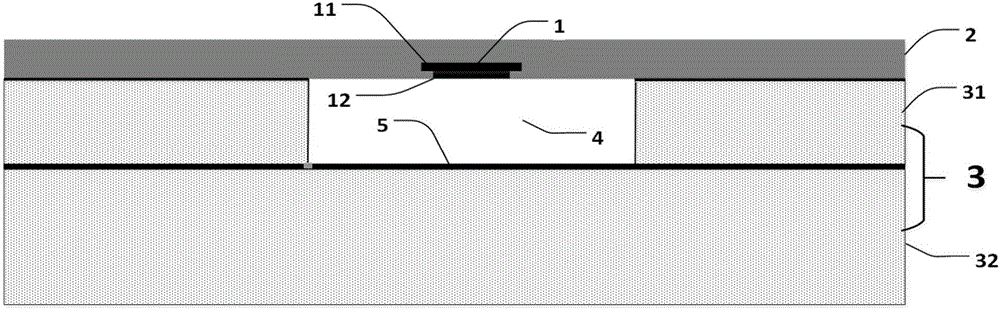

[0052] see figure 1 , 2. The silicon-based inverted microstrip line structure of the present invention includes a lower silicon substrate 32 , an upper silicon substrate 31 and an inversion layer 2 arranged in sequence from bottom to top. The inversion layer 2 is prepared by using SU8 photoresist, and its thickness is between 10 μm and 20 μm. The upper silicon substrate 31 is made of 110 silicon, the width of the upper metal layer 11 is 1.2 to 1.4 times that of the lower metal laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com