Deep drawing technology of deep-drawing-shaped simple pressure vessel

A pressure vessel and deep drawing technology, applied in calculation, geometric CAD, computer-aided design, etc., can solve problems such as unobtainable optimal solution, complicated design process, complex design, etc., to reduce debugging time, improve quality, and design cycle Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described below.

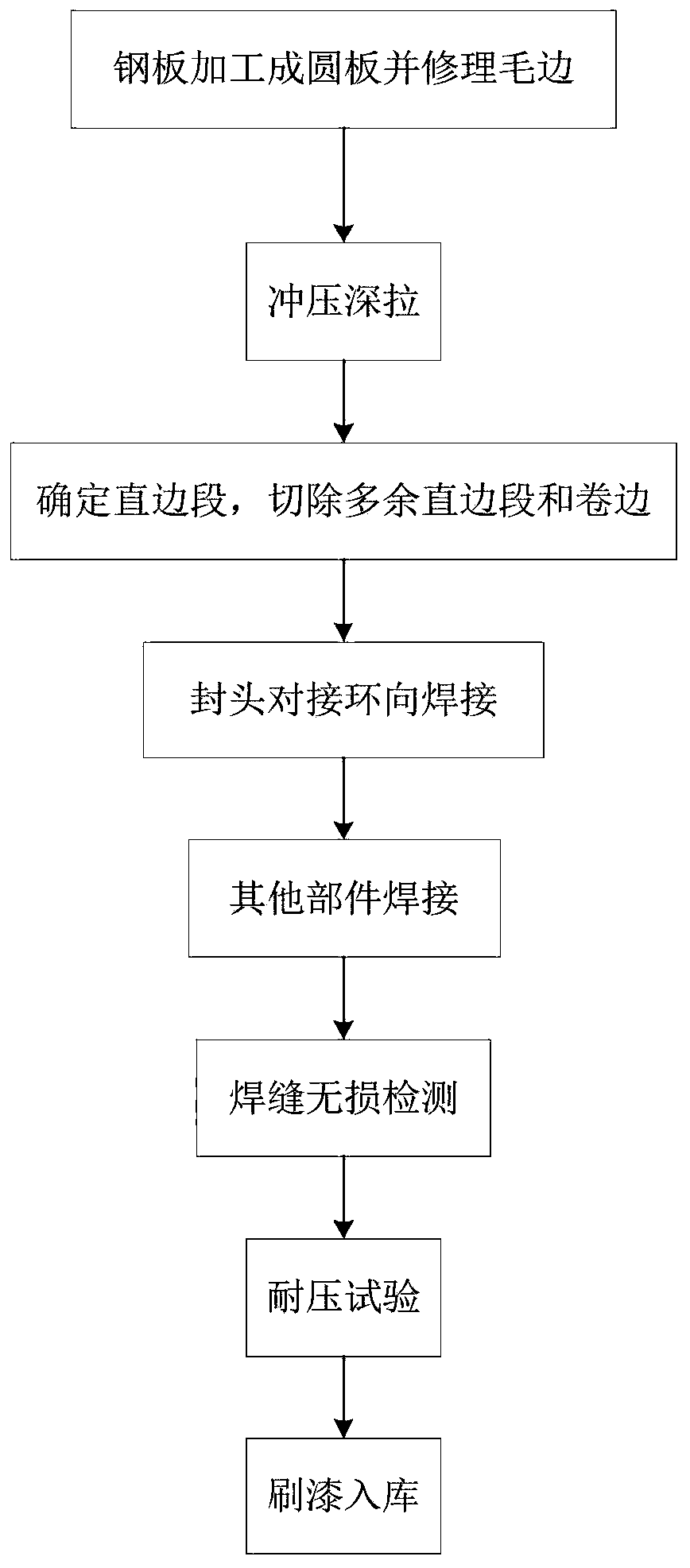

[0036] Such as figure 1 As shown, the present invention proposes a deep drawing process for a simple pressure vessel in deep drawing, comprising the following steps:

[0037] Step 1: Optimizing the deep drawing process parameters by establishing an optimal design method through computer software;

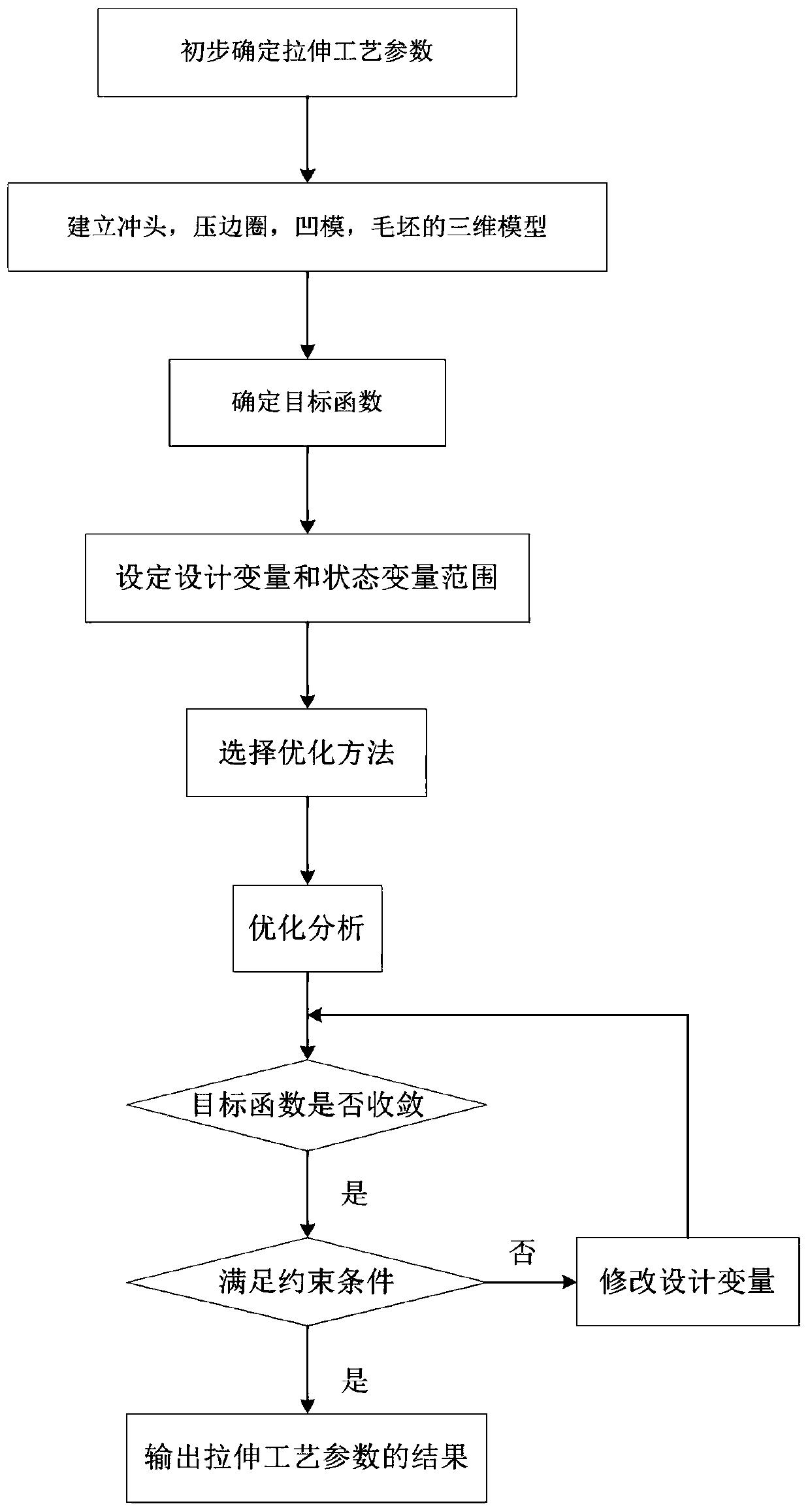

[0038] Among them, the flow chart of the optimal design method is as follows: image 3 shown, including:

[0039] Step 1.1: Determine the initial value of the deep drawing design parameters;

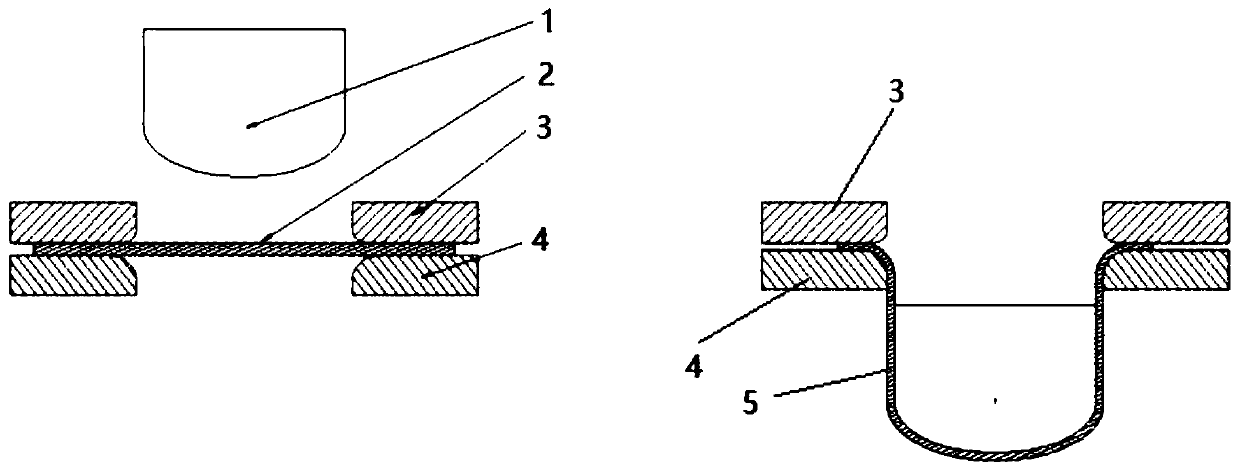

[0040] Step 1.2: Establish a three-dimensional geometric model of the punch 1, the blank holder 3, the die 4 and the blank 2;

[0041] Step 1.3: Determine the objective function for deep drawing process optimization;

[0042] Step 1.4: Set the variable range of design parameters and state variables;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com