Capacitor guide pin and manufacturing method thereof

A capacitor and guide needle technology, applied in the direction of capacitor manufacturing, capacitors, capacitor terminals, etc., can solve the problems of the size of the explosion point, the appearance is difficult to control, the incision has burrs and acute angles, and the plastic sleeve is punctured and cracked, and the structure is simple and reasonable. , High bending strength, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

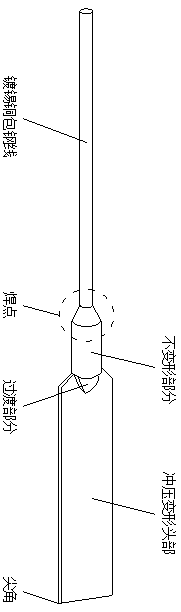

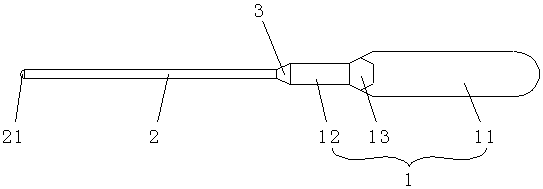

[0027] see image 3 , a capacitor guide pin, which are respectively a positive guide pin and a negative guide pin. The positive guide pin is 5-8mm longer than the negative guide pin. Composed of steel-clad wire 2, part of the aluminum wire 1 is stamped to form a flat head 11 with a thickness of 0.2-0.3mm, and the other part is a cylinder 12 with a diameter of 1.0-2.5mm, and the cylinder 12 is located in the flat On the transverse centerline of the flat head 11, a transition part 13 is formed between the flat head 11 and the cylinder 12, the transition part 13 is square R-shaped, and the length is 1.0-1.3mm, and the maximum width is 1.0-1.5mm. The transition part 13 is in the shape of a square R, which has high bending strength and can withstand three times of 90° bending with a load of 800g to avoid damage and breakage during container assembly; the flat head 11 is an arc-shaped structure; tin-plated The copper-clad steel wire 2 is welded to the cylinder 12 of the aluminum wi...

Embodiment 2

[0028] Embodiment 2, in order to reduce the probability of internal piercing of the pole foil and improve product quality, the flat head 11 has an arc-shaped structure, and the radius of the front end of the flat head 11 is 1 / 2 of the width of the flat head 11 one.

Embodiment 3

[0029] Embodiment 3, in order to enable the size and appearance of the solder joint 3 to be well controlled, to avoid the rubber plug being inserted into the hole or to expose the rubber, the length of the solder joint 3 should be controlled between 0.5-0.8 mm, and The outer diameter of the welding spot 3 is smaller than or equal to the diameter of the aluminum wire 1 . .

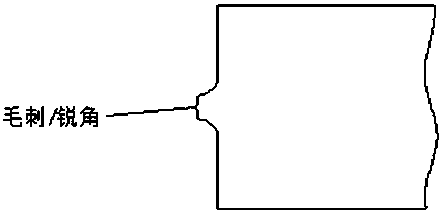

[0030] It also includes the manufacturing method of the capacitor guide pin, which respectively undergoes stamping, sharp angle removal, welding and electrochemical deburring, and the specific steps are as follows:

[0031] Stamping forming: a part of the aluminum wire is stamped to form a flat head with a thickness of 0.2-0.3mm, and the other part is not stamped and is a cylinder with a diameter of 1.0-2.5mm, and the cylinder is located in the flat head On the transverse center line of 11, a transition part is formed between the flat head and the cylinder, the transition part is in the shape of a square R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com