A drilling platform mud recovery and drill pipe thread cleaning and oiling device

A technology for mud recovery and thread cleaning, which is applied to cleaning methods and appliances, cleaning methods using tools, removing smoke and dust, etc., can solve the problems of low oiling work efficiency, high labor intensity and low degree of automation of drill pipe threads. To achieve the effect of cleaning and oiling work, reducing labor intensity and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the present invention and actual conditions.

[0020] For the convenience of description in the present invention, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 For example, the positional relationship of front, back, left, right, top, bottom and middle is based on the attached figure 1 determined by the layout method.

[0021] Below in conjunction with embodiment and accompanying drawing, the present invention is further described:

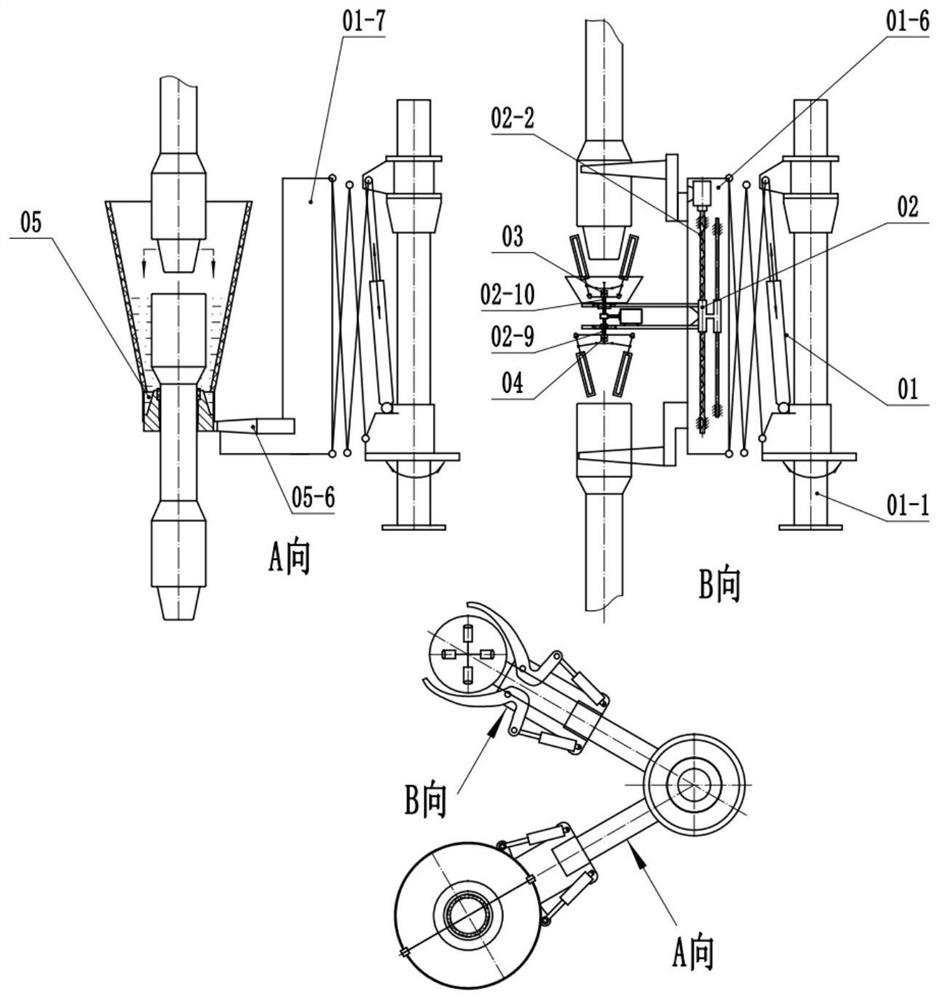

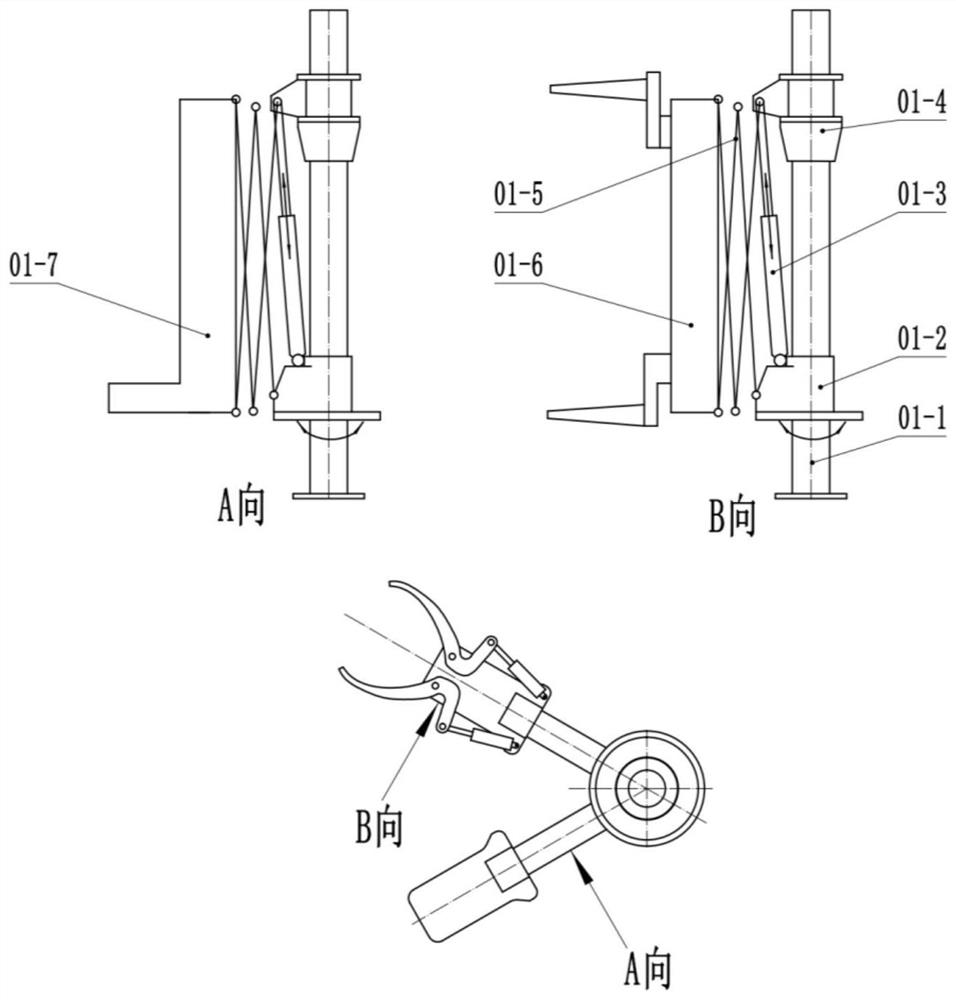

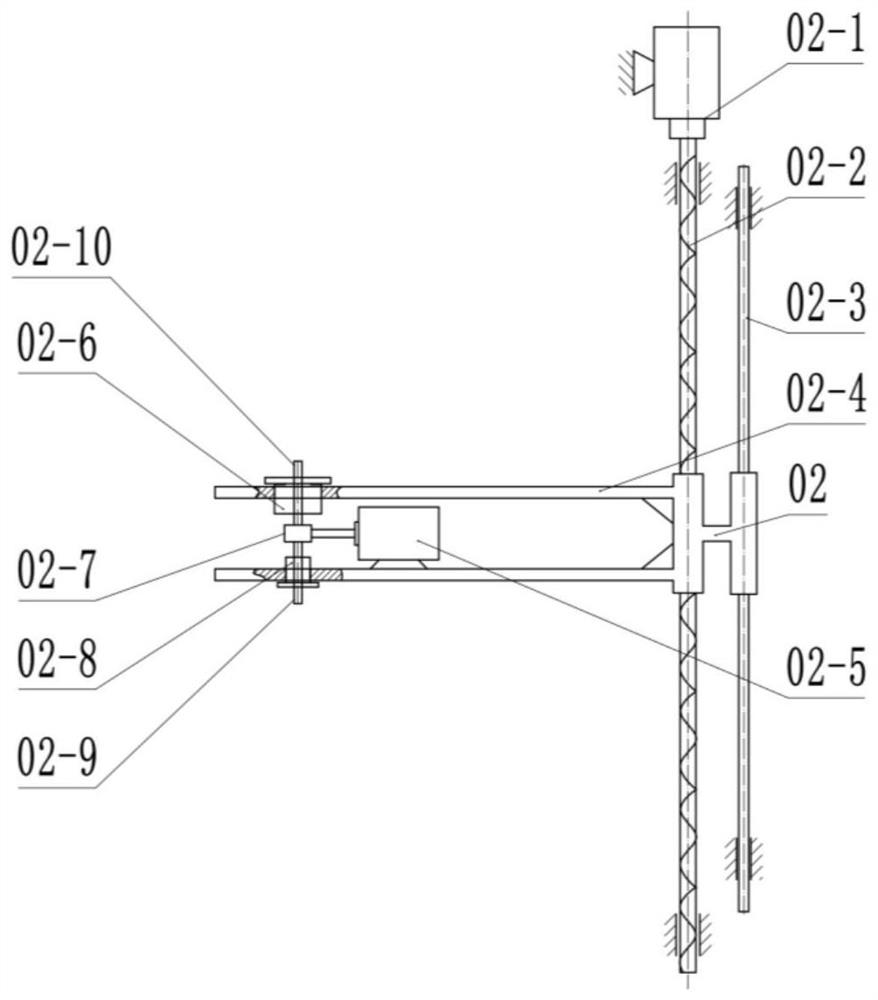

[0022] as attached figure 1As shown, the automatic mud recovery and drill pipe thread cleaning and oiling device includes a plane motion positioning mechanism 01, a working lifting mechanism 02, a male thread cleaning and oiling mechanism 03, a female thread cleaning mechanism 04, and a drilling fluid receiving mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com