Method for preparing porous composite polymer electrolyte film through gas volatilization

An electrolyte film and porosity technology, which is applied in the field of polymer electrolyte film preparation, can solve the problems of limited popularization, poor mechanical properties of polymer films, and poor processability, so as to improve ionic conductivity and accelerate film curing Speed, the effect of improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

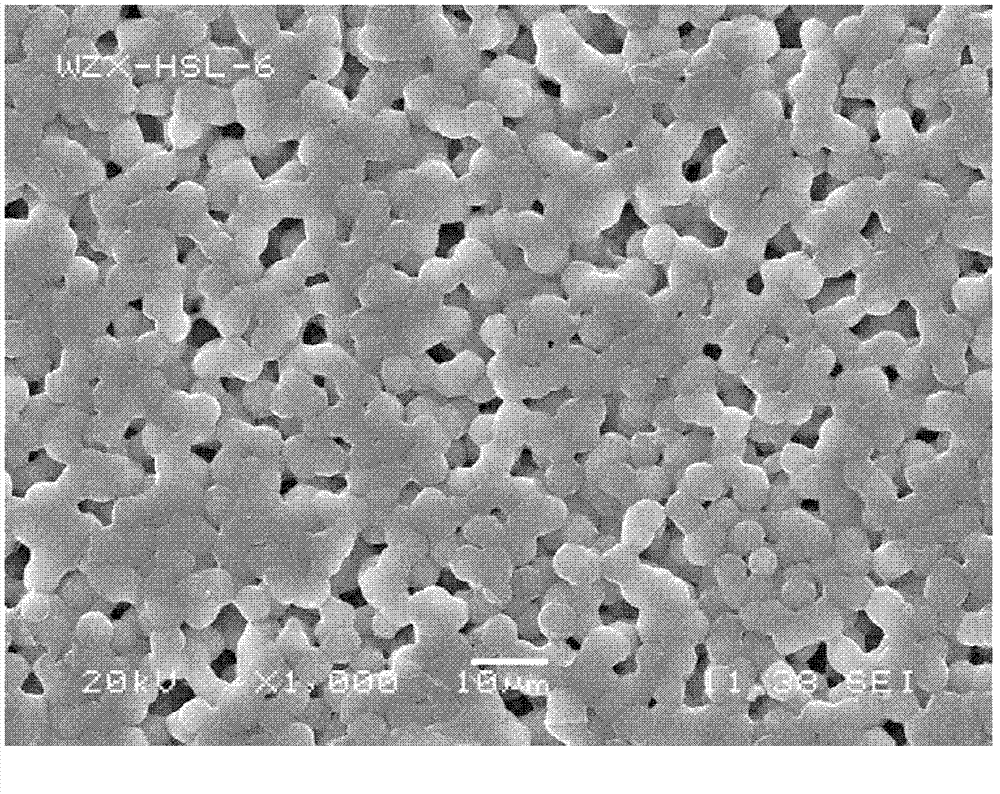

Image

Examples

Embodiment 1

[0024] An appropriate amount of ammonium bicarbonate solution (W NH4HCO3 =5%), nano-Al 2 o 3 Add to dimethylacetamide (DMAC) and shake evenly, then add polyvinylidene fluoride (PVDF), where NH 4 HCO 3 :Al 2 o 3 : PVDF: DMAC mass ratio is 0.1:0.05:1:6; Stir at 30°C for 2 hours to obtain a uniform gel, stand to remove air bubbles, apply the gel evenly on a glass plate, evaporate the solvent at 80°C to form Membrane, ammonium bicarbonate decomposed into water, ammonia and carbon dioxide pore modified PVDF / Al 2 o 3 polymer electrolyte membrane.

[0025] The resulting PVDF / Al 2 o 3 The polymer electrolyte film was treated with 1mol / L LiPF 6 After soaking and activating the EC-DMC-EMC solution, its ionic conductivity was tested by AC impedance method to be 2.3mS / cm. Cyclic voltammetry tests showed that PVDF / Al 2 o 3 The electrochemical stability window of the electrolyte film is >5.5V, the breaking strength is >15MPa, and the porosity is 57%.

Embodiment 2

[0027] An appropriate amount of ammonium carbonate solution (W (NH4)2CO3 =2.5%), nano-SiO 2 Add to dimethylformamide (DMF) and shake evenly, then add polyvinylidene fluoride (PVDF), where (NH 4 ) 2 CO 3 : SiO 2 : PVDF:DMF ratio is 0.3:0.3:1:4; Stir at 15°C for 2 hours to obtain a uniform gel, stand to remove air bubbles, apply the gel evenly on a glass plate, and evaporate the solvent at 90°C to form a film , to obtain ammonium carbonate decomposed into water, ammonia and carbon dioxide pore-forming PVDF / SiO 2 polymer electrolyte membrane.

[0028] The resulting PVDF / SiO 2 The polymer electrolyte film was treated with 1mol / L LiPF 6 After the EC-DMC-EMC solution was soaked, activated and plasticized, its ion conductivity was tested by AC impedance method to be 2.4mS / cm. Cyclic voltammetry tests showed that PVDF / SiO 2 The electrochemical stability window of the electrolyte film is >5.5V, the breaking strength is >22MPa, and the porosity is 60%.

Embodiment 3

[0030] Appropriate amount of ammonium carbamate solution (W NH2COONH4 =5%), Nano TiO 2 Add to acetone and shake evenly, then add hexafluoropropylene copolymer (PVDF-HFP), in which NH 2 COONH 4 : TiO 2 : PVDF-HFP: Acetone ratio is 0.1:0.1:1:5; Stir at 10°C for 5 hours to obtain a uniform gel, let it stand to remove air bubbles, spread the gel evenly on a glass plate, and place it under vacuum at 90°C Volatile solvent is formed into a film, and ammonium carbamate is decomposed into ammonia and carbon dioxide to form pores and modify PVDF-HFP / TiO 2 polymer electrolyte membrane.

[0031]The resulting PVDF-HFP / TiO 2 The polymer electrolyte film was treated with 1mol / L LiPF 6 After the EC-DMC-EMC solution was soaked, activated and plasticized, the ionic conductivity was tested by AC impedance method to be 2.8mS / cm. Cyclic voltammetry tests showed that PVDF-HFP / TiO 2 The electrochemical stability window of the electrolyte film is >5.5V, the breaking strength is >11MPa, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrochemical stability window | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com