A constant pressure valve device for oil and gas field wellheads

A constant pressure valve, gas field technology, applied in valve device, valve details, control valve and other directions, can solve the problems of affecting the pressure regulating and constant pressure performance of the constant pressure valve, the consumption of human resources, and the loss of the regulating function of the constant pressure valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below with reference to the accompanying drawings.

[0019] It should be noted that the directional terms or qualifiers "upper", "lower", "inner", "outer" and the like used in the present invention are all for the referenced drawings. They are not intended to define the absolute position of the components involved, but can vary on a case-by-case basis.

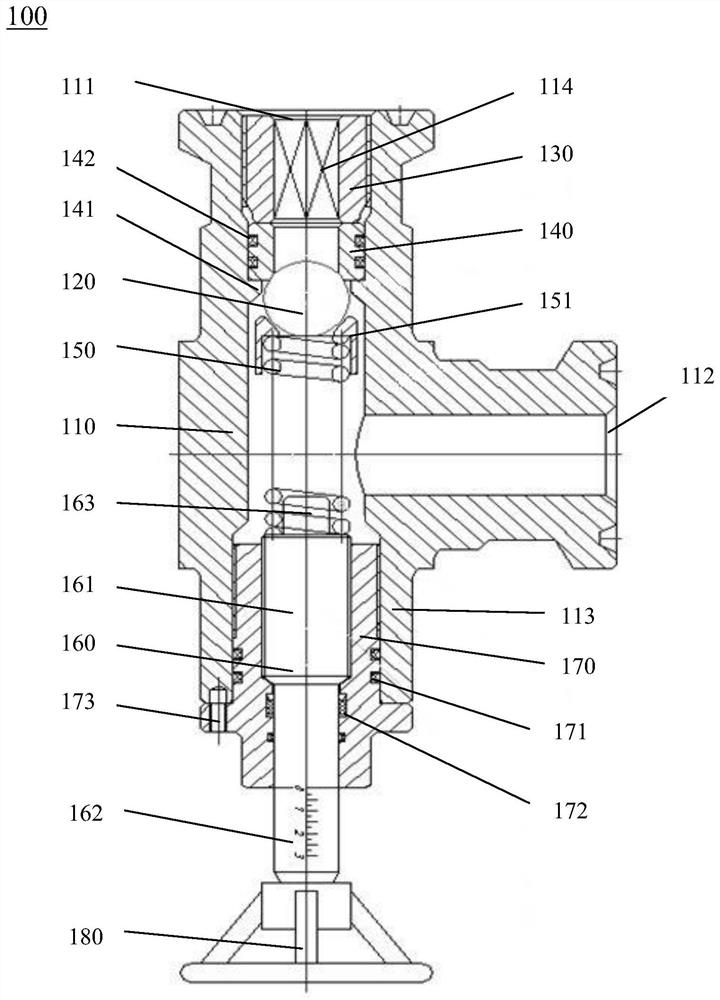

[0020] figure 1 The structure of a constant pressure valve device 100 for oil and gas field wellheads according to the present invention is shown. like figure 1 As shown, the constant pressure valve device 100 includes a valve body 110 . The valve body 110 is configured as a three-way structure, including the valve body inlet end 111 for injecting oil and gas, the valve body outlet end 112 for discharging oil and gas, and the pressure regulating end 113 for installing pressure regulating parts. The outlet end 112 of the valve body extends along the radial direction of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com