Flue-cured tobacco accurate intensive curing technology for tobacco high-temperature induced maturity

A technology of intensive baking and tobacco leaves, applied in the direction of tobacco, tobacco preparation, application, etc., can solve problems that have not been involved, and achieve the effects of strong pertinence, improved appearance quality, and precise craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

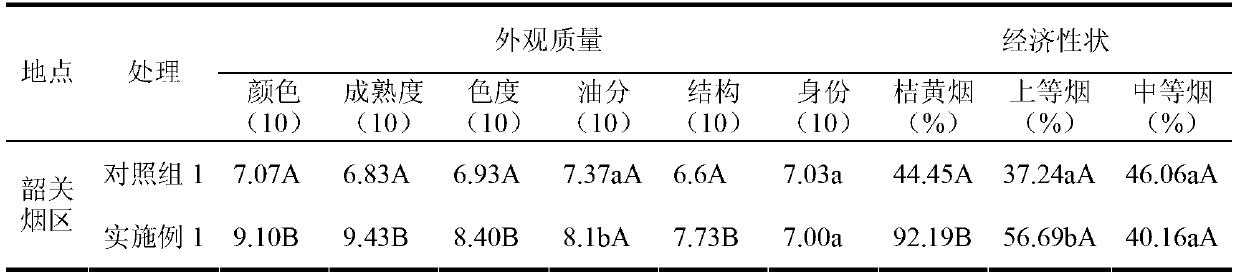

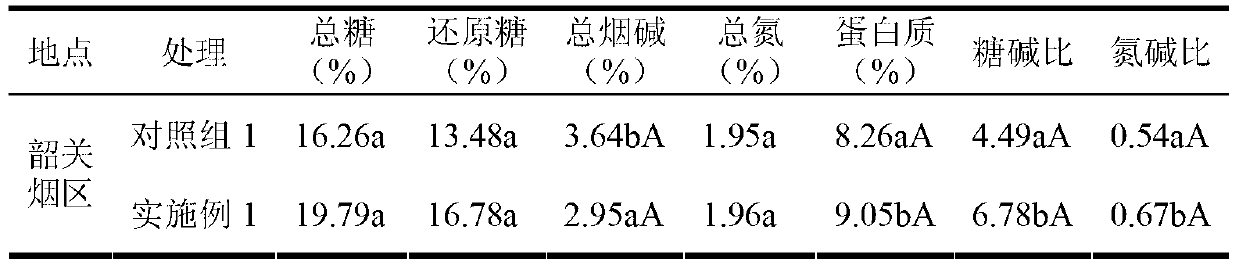

[0021] Harvesting, tying, curing and curing of high-temperature forced-ripened tobacco leaves.

[0022] In late June 2011, 100 mu of high-temperature forced-ripening tobacco fields with balanced growth were selected in the dry slope tobacco area of Nanxiong Ancient City, Guangdong Province, and 50 mu of tobacco leaves were processed according to the precise and intensive curing process of high-temperature forced-ripening tobacco leaves of the present invention.

[0023] The first step: Harvesting of high-temperature forced-ripe tobacco leaves: the upper second leaf (phyllotaxy is counted from bottom to top) is fully mature, that is, the leaf surface of the upper second leaf is fully yellowed, the basic color is yellow, and wrinkled. When the mature spots are obvious, and the yellow is white, 6-8 pieces are harvested at one time;

[0024] The second step: Tobacco clamping and roasting, clamping with a 12cm-long tobacco clamp, the upper leaf 18kg per clamp; each layer is evenl...

Embodiment 2

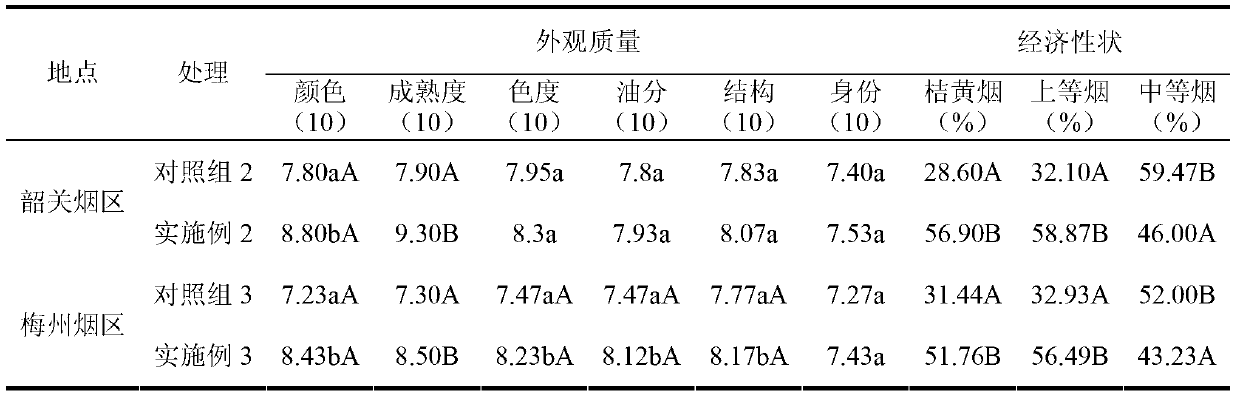

[0054] In late June 2012, the demonstration and popularization of the present invention was carried out in Shaoguan. In Xikou Village, Gushi Town, Nanxiong Tobacco Area, 1,000 mu of high-temperature forced-ripening tobacco fields were selected for 1000 mu of high-temperature forced-ripening tobacco fields in 3 natural groups of Xikou Village, Gushi Town, Nanxiong Tobacco Area. Invented high-temperature forced-ripening tobacco leaf precision and intensive baking process, after roasting, each natural group selects an intensive curing room for various index statistics; the other 500 mu is treated according to the tobacco farmers' customary method (control group 2), and after roasting, each natural group Choose a dense barn for statistics of various indicators. The appearance quality, economic properties and chemical components of the cured tobacco leaves of Example 2 were compared with those of the control group 2, and the results are shown in Table 3 and Table 4.

[0055] The hi...

Embodiment 3

[0062] In early June 2012, the demonstration and popularization of the present invention was carried out in Meizhou. In Anliu Town, Wuhua Tobacco Area, 3 natural groups were selected to select 1,000 mu of high-temperature forced-ripening tobacco fields in sand and mud fields, and 500 mu of upper tobacco leaves were used for high-temperature forced-ripening tobacco leaves. After roasting, each natural group selects one intensive curing barn for various index statistics; the other 500 mu is treated according to the tobacco farmers' customary method (control group 3), and each natural group selects one intensive curing barn after roasting The baking room conducts statistics on various indicators. The appearance quality, economic properties and chemical components of the cured tobacco leaves of Example 3 were compared with those of the control group 3, and the results are shown in Table 3 and Table 4.

[0063] For the high-temperature forced-cured tobacco leaves of this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com