Guide blade shaft sleeve assembling and disassembling tool

A guide vane shaft sleeve and tool technology, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of aggravation of out-of-synchronization, personal injury, insufficient rigidity and easy deformation, etc., and achieve reasonable cost and construction period, control cost and construction period , The effect of improving the process precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

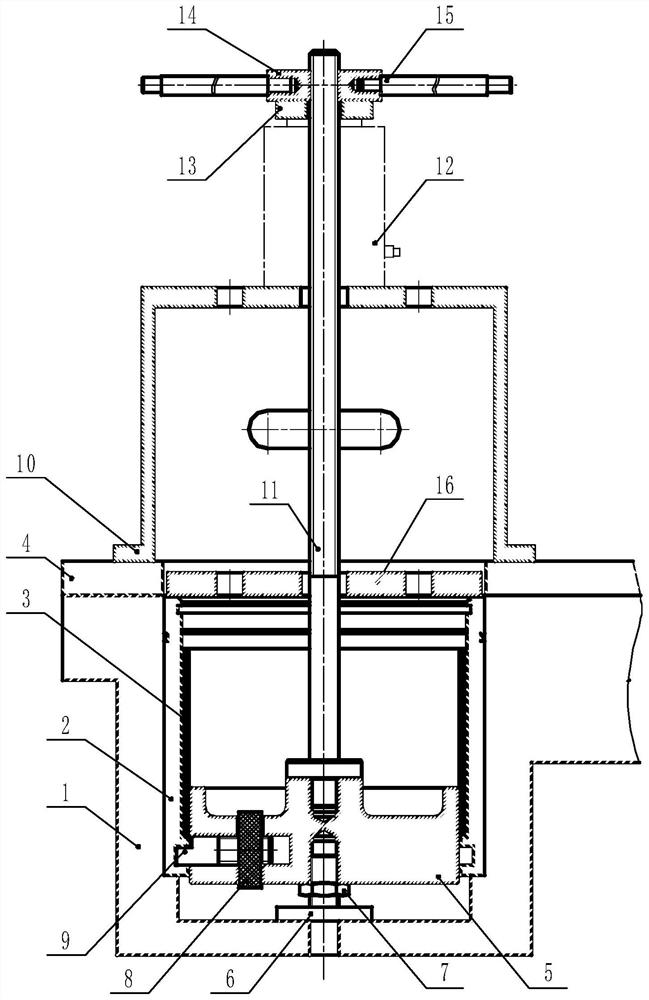

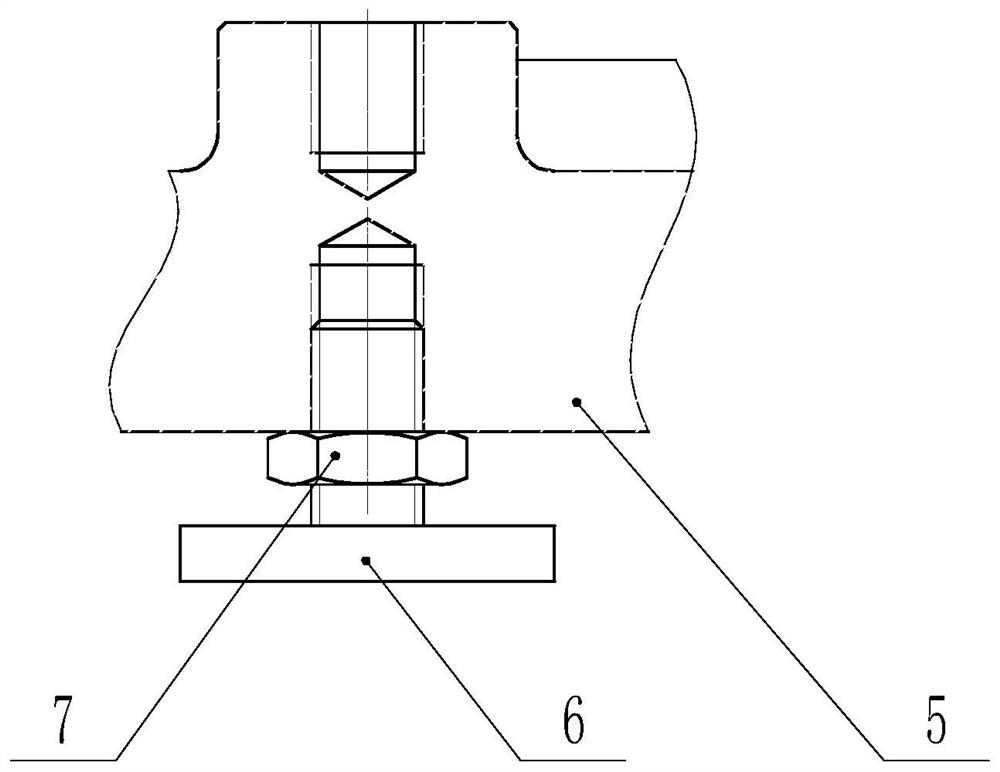

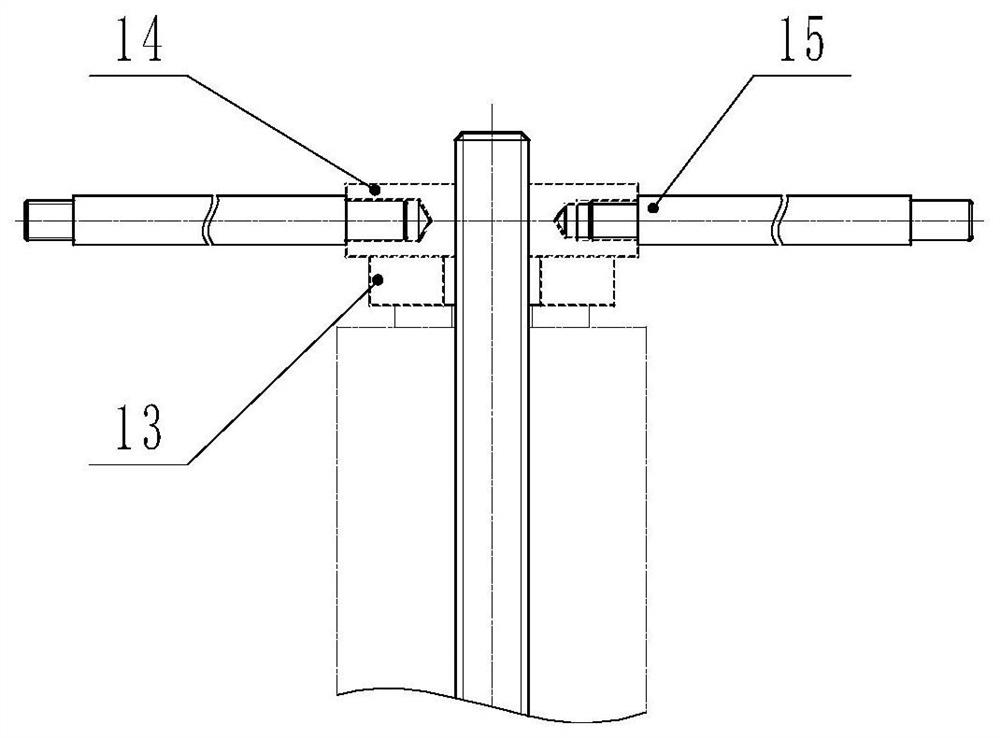

[0032] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a tool for removing and installing a guide vane shaft sleeve, which includes a sleeve 10 , a hollow jack 12 , a lead screw 11 and a chuck 5 . The lower end of the sleeve 10 is open and the upper end is closed. The lower end of the sleeve 10 abuts against the wear-resistant plate 4 on the upper end of the bottom ring 1 . The sleeve 10 has an accommodation space for accommodating the shaft sleeve 2 to be disassembled. The hollow jack 12 is arranged coaxially with the sleeve 10 , and the lower end of the hollow jack 12 abuts against the top wall of the sleeve 10 . The lead screw 11 is coaxially instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com