Thermoplastic elastomer for frosted-sense wire and preparation method of thermoplastic elastomer

A technology of thermoplastic elastomer and matte feeling, applied in the field of polymer materials, can solve the problems of poor matte effect, poor tear strength, poor dispersion, etc., to avoid component migration, good matte matte surface, and appearance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

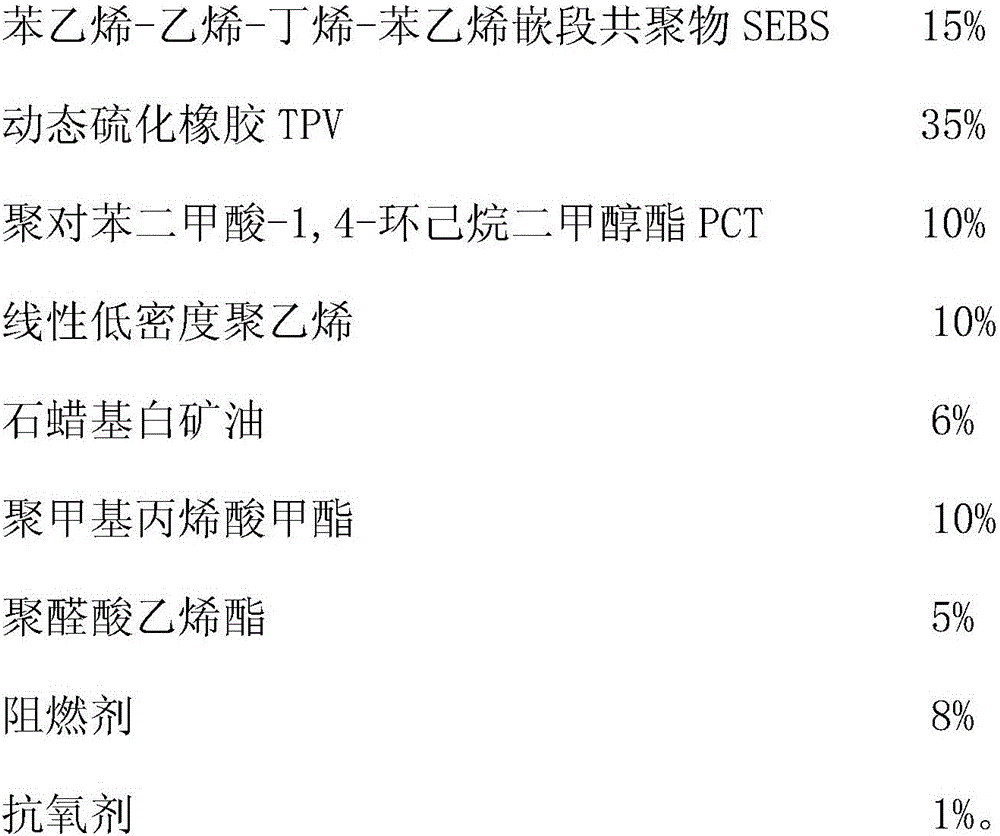

[0025] Embodiment 1: The thermoplastic elastomer for frosted electric wire provided in this embodiment, by weight percentage, includes:

[0026]

[0027] Among them, the flame retardant is composed of melamine cyanurate and organic hypophosphite in a mass ratio of 1:1, and the organic hypophosphite can be organic zinc hypophosphite; the antioxidant is antioxidant 1076 and antioxidant Agent 168 is compounded at a mass ratio of 2:1.

[0028] This embodiment also provides a preparation method of the above-mentioned thermoplastic elastomer for frosted electric wires, comprising the following steps:

[0029] S1: Weigh each raw material component according to weight percentage;

[0030] S2: Styrenic block copolymer, dynamic vulcanized rubber TPV, poly(1,4-cyclohexanedimethylene terephthalate) PCT, polyolefin, plasticizer, polymethyl methacrylate, polyoxymethylene acid Add vinyl ester, flame retardant and additives into the mixer, stir at high speed for 30 minutes and then stop ...

Embodiment 2

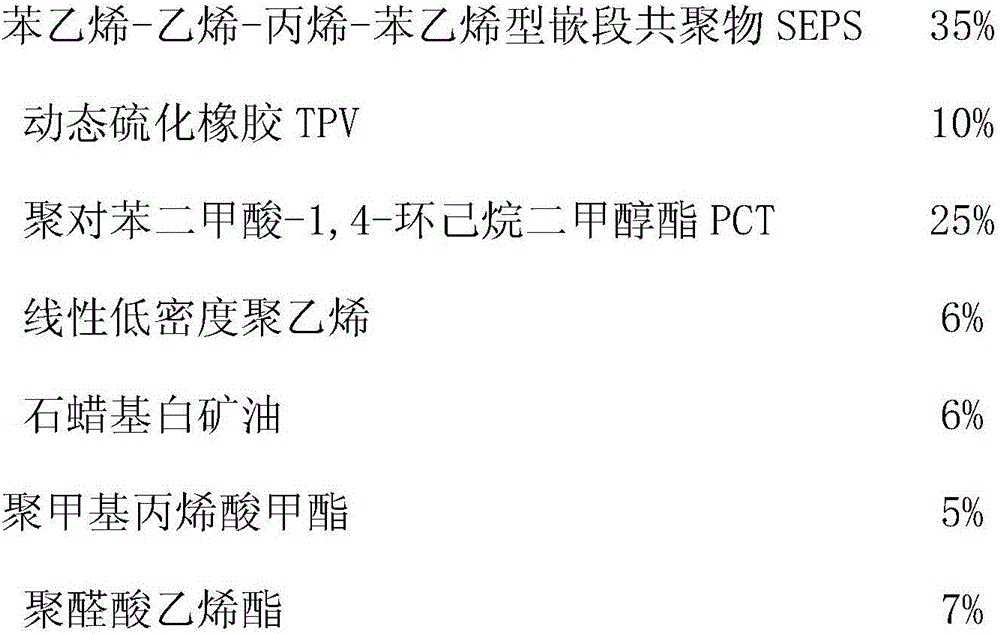

[0032] Example 2: The thermoplastic elastomer for frosted sensing wire and its preparation method provided in this example are basically the same as in Example 1, except that: a thermoplastic elastomer for frosted sensing wire, by weight percentage, includes :

[0033]

[0034]

[0035] Among them, the flame retardant is a compound of melamine cyanurate and organic hypophosphite in a mass ratio of 1:3; the antioxidant is a compound of antioxidant 1076 and antioxidant 168 in a mass ratio of 2:1 .

[0036] During its preparation process: mixing and stirring for 10 minutes, extrusion temperature at 220° C., and screw rotation speed at 300 rpm.

[0037] Others are the same as in Embodiment 1, and will not be redundant here.

Embodiment 3

[0038] Example 3: The thermoplastic elastomer for frosted electric wires provided in this example and its preparation method are basically the same as in Example 1, except that: a thermoplastic elastomer for frosted electric wires, by weight percentage, includes :

[0039]

[0040] Among them, the flame retardant is a compound of melamine cyanurate and organic hypophosphite in a mass ratio of 2:1; the antioxidant is a compound of antioxidant 1076 and antioxidant 168 in a mass ratio of 3:1 .

[0041] During its preparation process: mixing and stirring for 20 minutes, extrusion temperature at 180° C., and screw rotation speed at 600 rpm.

[0042] Others are the same as in Embodiment 1, and will not be redundant here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com