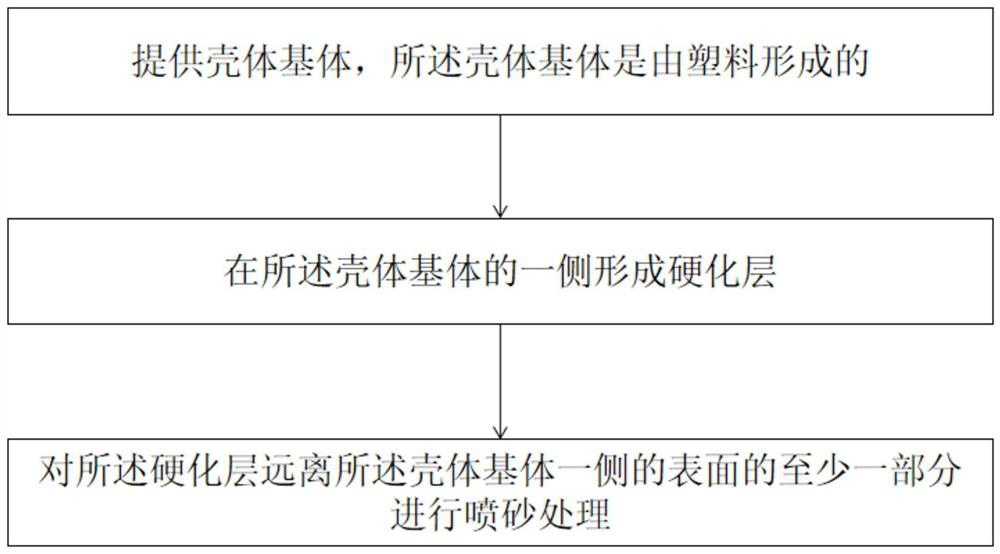

Method for preparing shell assembly, shell assembly and electronic equipment

A shell assembly and shell technology, applied in electrical equipment shell/cabinet/drawer, metal processing equipment, chassis/box/cabinet/drawer parts, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

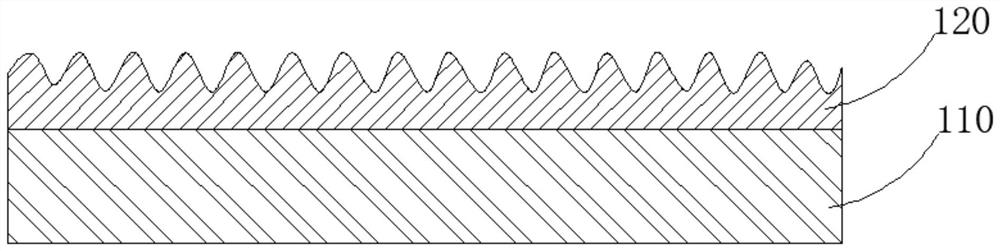

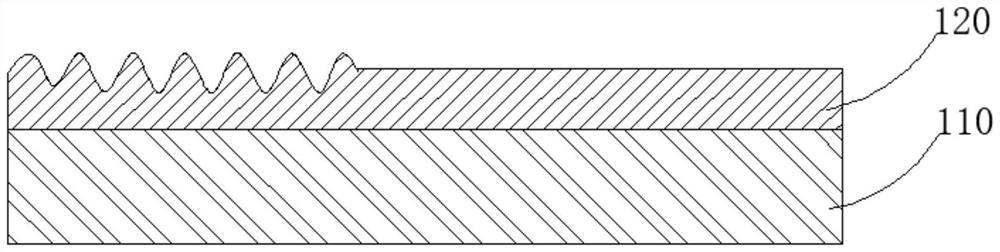

[0044] The shell base is made of a composite sheet made of co-extruded PC and PMMA plastic particles, or a plastic shell injection-molded with co-polymerized PC to form a hardened layer on one side of the shell base. Then sandblasting is performed on the surface of the hardened layer away from the base of the shell, wherein the shape of the alumina sand used in the sandblasting includes at least one of polygonal column shape and polygonal pyramid shape. The specific parameters of the blasting treatment are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com