Long grained seed steering precision seeding device and seeding method thereof

A technology of precision seeding and seeding, which is applied in the field of precision seeding devices, can solve the problems of time-consuming, laborious, and restricting the promotion and use of automatic equipment for crops, and achieve the effects of stable operation quality, smooth transportation, and high operation productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

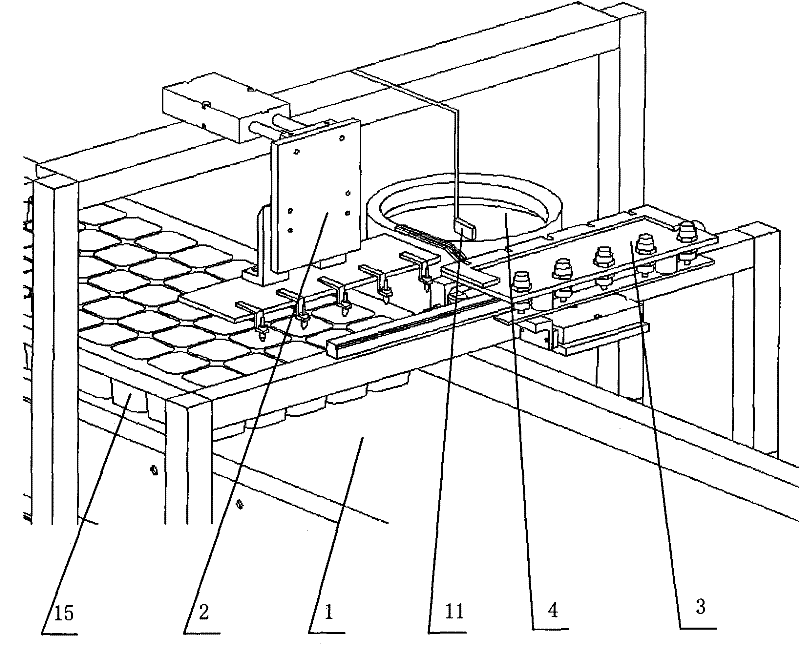

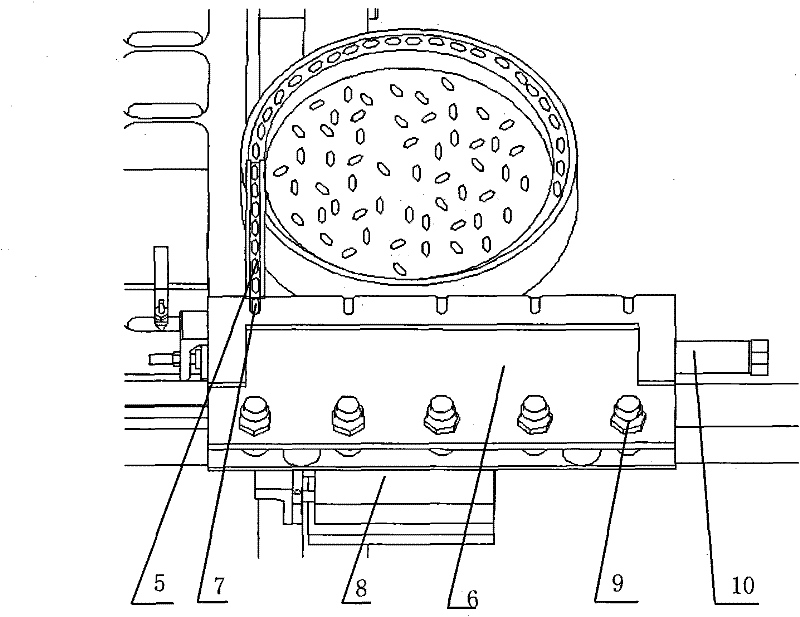

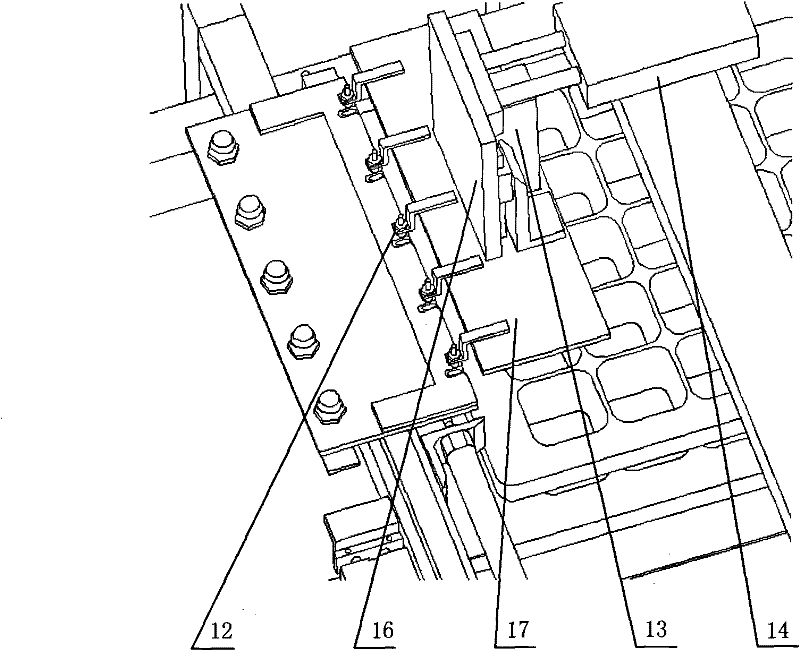

[0035] Figure 1~3 Show the specific structural diagram of sowing device of the present invention, as figure 1 As shown, the long-grained seeds are adjusted to the precision seeding device, including a tray conveyor belt 1, a directional seed feeder 4, a positioning and sorting mechanism 3 and an air suction sowing mechanism 2, and the directional seed feeding device 4 and the positioning and sorting mechanism 3 connected and arranged on the same side of the tray conveyor belt 1, the air suction sowing mechanism 2 is arranged above the tray conveyor belt 1; the directional seed feeder 4 is provided with a seed feeding Slideway 5, described kind delivery slideway 5 is connected with positioning sorting mechanism 3, as figure 2 As shown; the tray conveyor belt 1, the directional seed feeder 4, the positioning sorting mechanism 3 and the air suction seeding mechanism 2 are all fixed on the frame.

[0036] Such as figure 2As shown, the positioning and sorting mechanism 3 incl...

Embodiment 2

[0052] The present embodiment is the same as embodiment 1 except the following features: the number of negative pressure suction nozzles, positioning grooves, needle-shaped stop pin cylinders is all corresponding to the number of holes in each row on the tray, which is 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com