A fully automatic wire stripping machine wire feeding and pressing mechanism and operation method

A technology of pressing mechanism and wire stripping machine, applied in recycling technology, electrical components, circuits, etc., can solve the problems of unsustainable operation and insufficient controllability of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

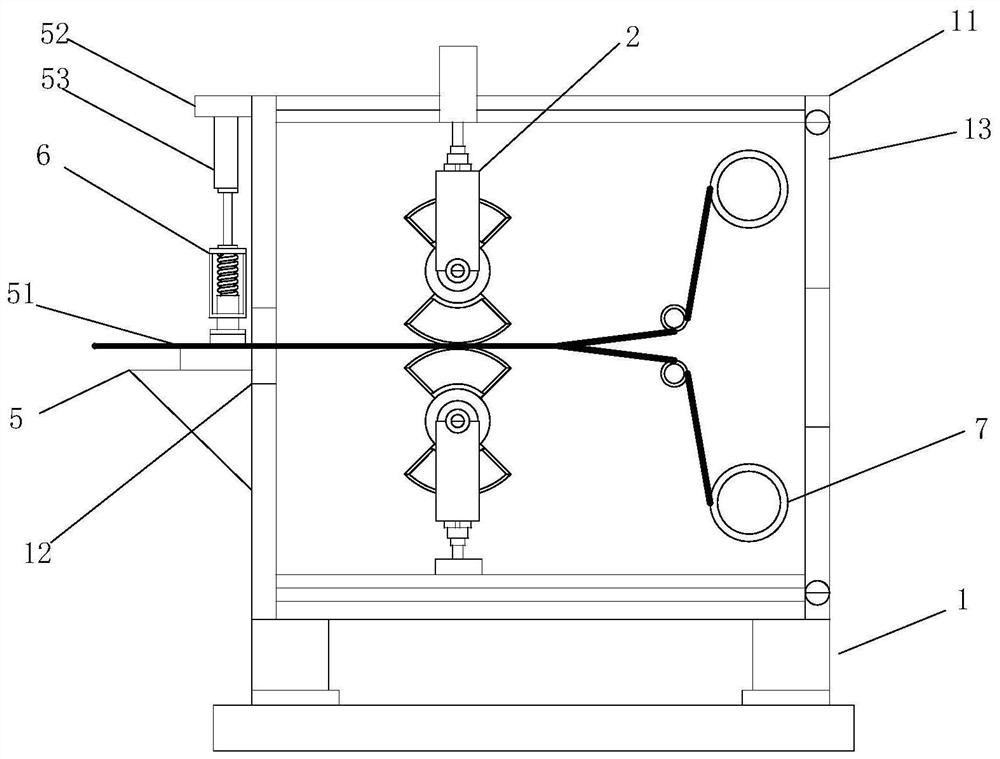

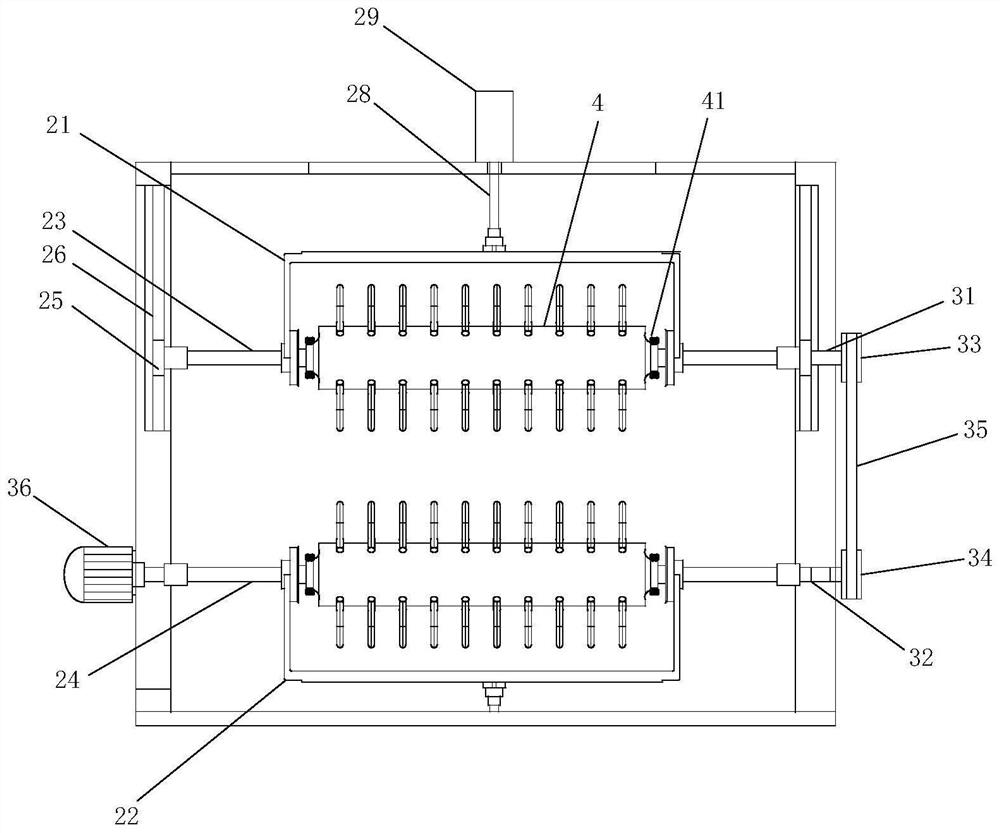

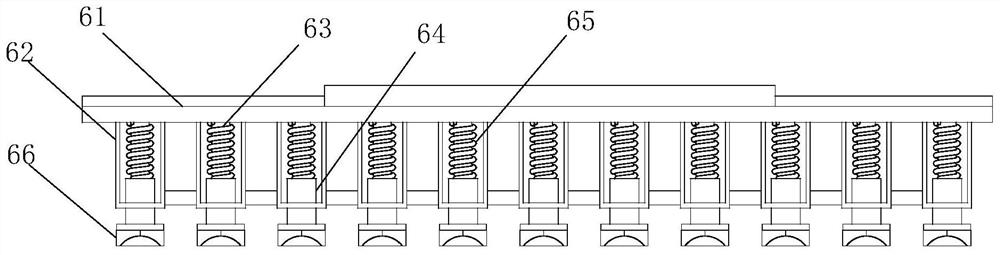

[0036] see figure 1 and figure 2 , a fully automatic wire stripping machine wire feeding and pressing mechanism, including a working frame 1, the top of the working frame 1 is provided with a working cabinet 11, and the front side of the working cabinet 11 is provided with a wire inlet 12, so The rear side of the operation cabinet 11 is provided with an opening and closing cover plate 13, and the wire stripping and pressing mechanism 2 is arranged in the operation cabinet 11, and the wire stripping and pressing mechanism 2 includes a movable frame 21 and a fixed frame 22. The frame 21 and the fixed frame 22 are all arranged in the inner cavity of the operation cabinet 11, and the movable shaft 23 and the fixed shaft 24 are installed horizontally on the movable frame 21 and the fixed frame 22 respectively, and the movable shaft 23 and the fixed shaft 24 are equipped with Stripping tool holder 4, vertical guide rails 26 are provided on the left and right side inner walls of th...

Embodiment 2

[0043] see figure 1 and Figure 5 , this embodiment is a further optimization of the first embodiment, on the basis of which, the rear side of the operation machine box 11 is provided with a material receiving mechanism 7, and the material receiving mechanism 7 includes a distribution roller 71 and a material receiving roller 72, so A plurality of receiving roller discs 73 are installed on the receiving roller 72, and the receiving roller discs 73 are arranged in a staggered manner. External driving wheels 74 are installed on the outer ends of the receiving rollers 72 , and the external driving wheels 74 are connected by a second synchronous belt 75 .

[0044] In this application, the cut and peeled wire sheaths are stored by the receiving roller 72, and the receiving roller discs 73 are arranged in a staggered manner. On the one hand, the wire sheath on the same cable can be separated, and on the other hand, the wire sheath is laterally Pulling force, the auxiliary thread s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com