A method of manufacturing a printed circuit board

A technology of printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of unfavorable electrical connection reliability between inner and outer layers, difficulty in removing glass fibers, etc., to ensure the lamination effect, Effects of improving reliability and stabilizing dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

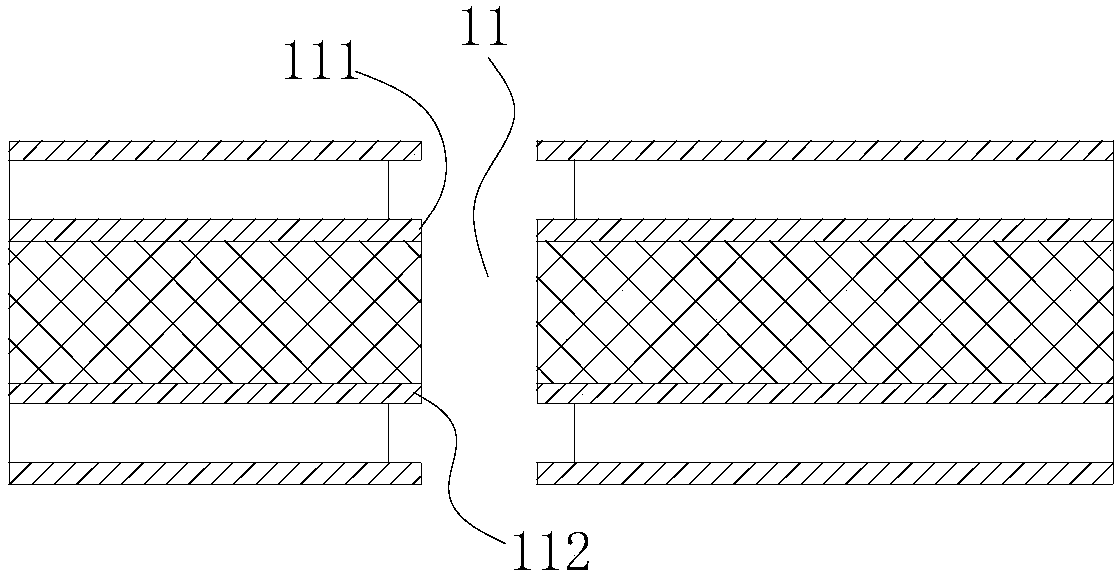

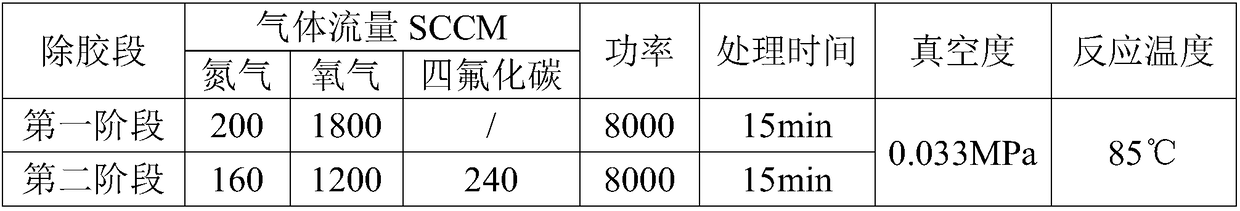

[0021] This embodiment provides a method for manufacturing an etched printed circuit board. The etched printed circuit board includes metallized etch holes, and the metallized etch holes are formed by metallizing the etch holes. The etch-back hole is formed after the through-hole is etched back.

[0022] The specific production steps are as follows:

[0023] (1) Making the inner core board

[0024] First, the base material is cut to obtain a core board of a predetermined size. Then bake the board, that is, place the core board at 150-175° C. to bake the core board for 4 hours. Next, according to the prior art, the inner layer circuit is made on the core board through the negative process to obtain the inner layer core board.

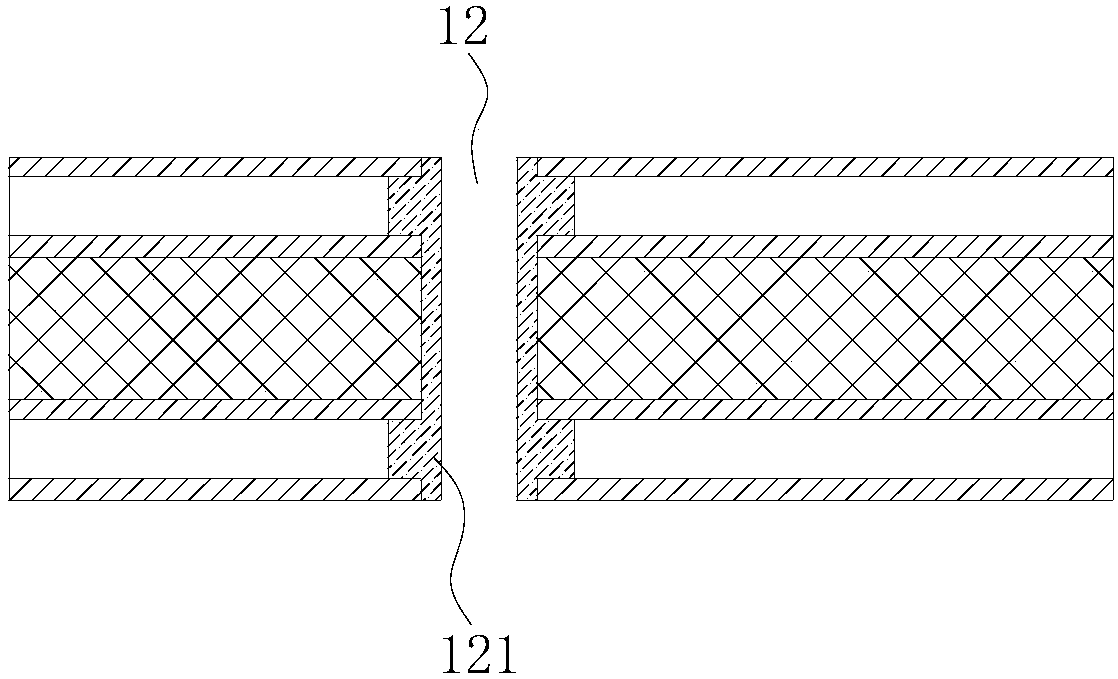

[0025] (2) Drill preset holes

[0026] Drill preset holes on the prepreg, the drilled preset holes correspond to the through holes to be made in the subsequent process and the center of the preset hole overlaps with the center of the through hole; in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com