Laminating device for double-sided double-glazed photovoltaic assembly

A dual-glass photovoltaic and module layer technology, applied in the direction of lamination devices, lamination, and layered products, etc., can solve problems such as increasing tooling placement and picking processes, battery string offset, and reducing production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

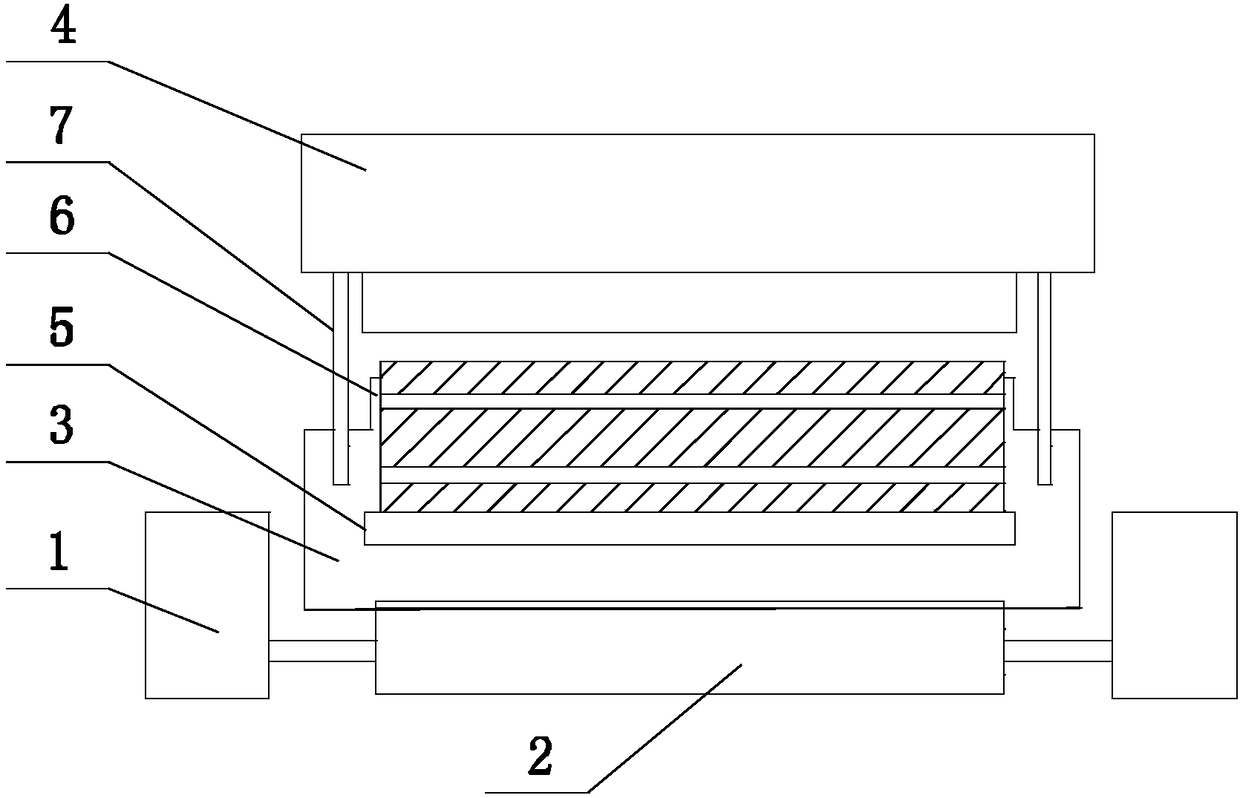

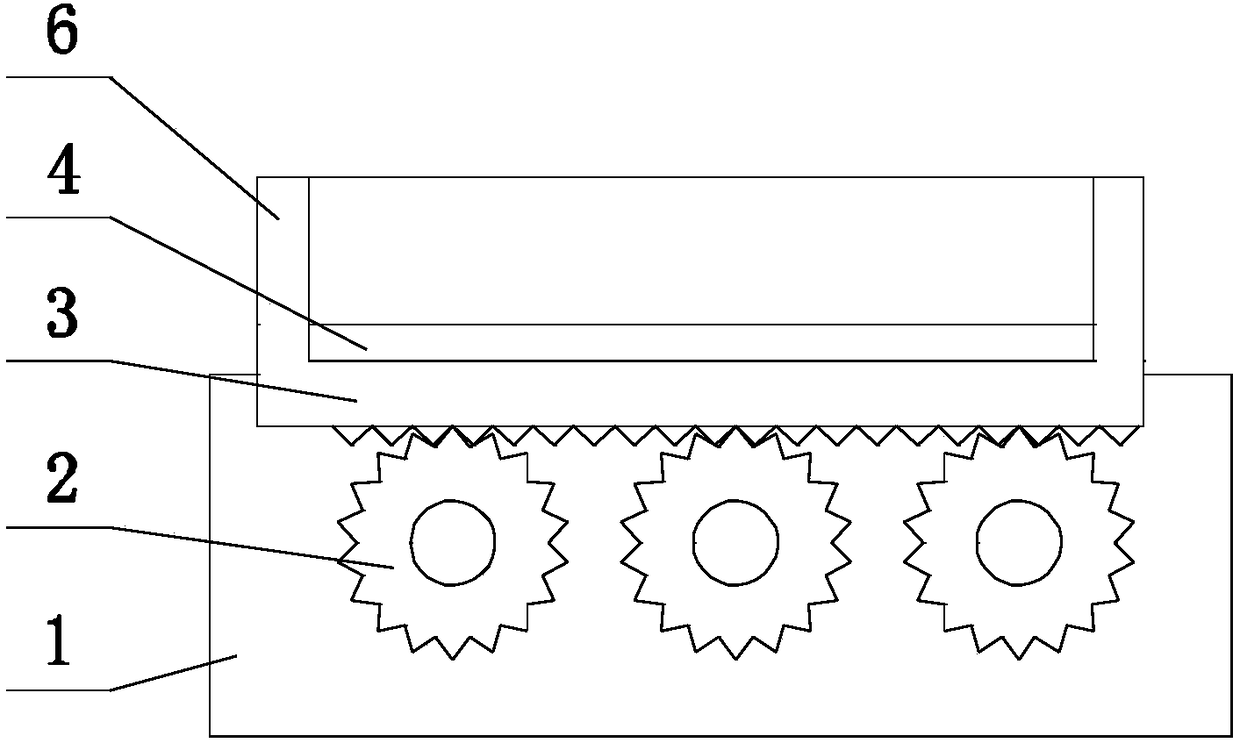

[0015] Such as figure 1 with 2 as shown, figure 1 It is a structural schematic diagram of a double-sided double-glass photovoltaic module lamination device proposed by the present invention, figure 2 It is a schematic diagram of the cooperation structure of the installation seat and the transmission mechanism of a double-sided double-glass photovoltaic module lamination device proposed by the present invention.

[0016] refer to figure 1 with 2 , a double-sided double-glass photovoltaic module lamination device proposed by the present invention, comprising: a support frame 1, a transmission mechanism, a mounting seat 3, a pressure applying mechanism 4, a first driving mechanism, and a second driving mechanism;

[0017] The transmission mechanism is arranged on the support frame 1, and the transmission mechanism includes a plurality of transmission rollers 2 arranged in sequence. The transmission rollers are rotatably mounted on the support frame 1, and the outer wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com