A construction method of lime-soil filling

A construction method and lime-soil technology, which can be applied to buildings, roads, roads, etc., can solve the problems of high maintenance costs, high prices, and difficulty in compensating for the inconsistency of the depth of new and old tools, so as to ensure the depth of construction, smooth lime paving, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

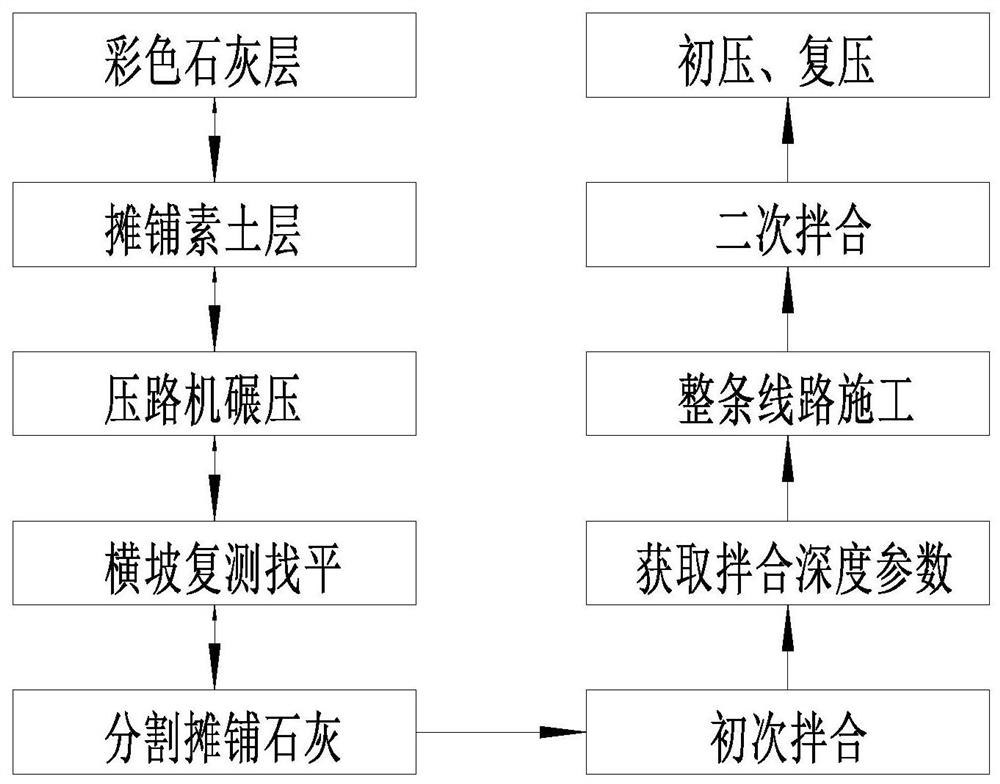

[0037] like figure 1 As shown, a lime-soil filling construction method is characterized in that, comprises the following steps:

[0038] A1. Pave colored lime with a thickness of 1cm at the starting point of the route construction on the lower bearing layer, and the length is 10-15m;

[0039] A2. Pave the plain soil layer, turn the soil to the required water content, and the soil blocks are all less than 15mm, and the plough can be used for the construction;

[0040] A3. Light-duty road roller for rolling;

[0041] A4. The cross slope is re-measured and leveled, and wavy surfaces are not allowed;

[0042] A5. Draw lime grids and spread lime, and use scraper 1 to level the upper surface of lime. After the surface is flat, the lime blocks should not exceed 5mm;

[0043] A6. The road mixer is in place, and firstly, the trial mixing is carried out at 10-15m from the starting route;

[0044] A7. According to the drawing, set the thickness of the lime soil layer plus the thickne...

Embodiment 2

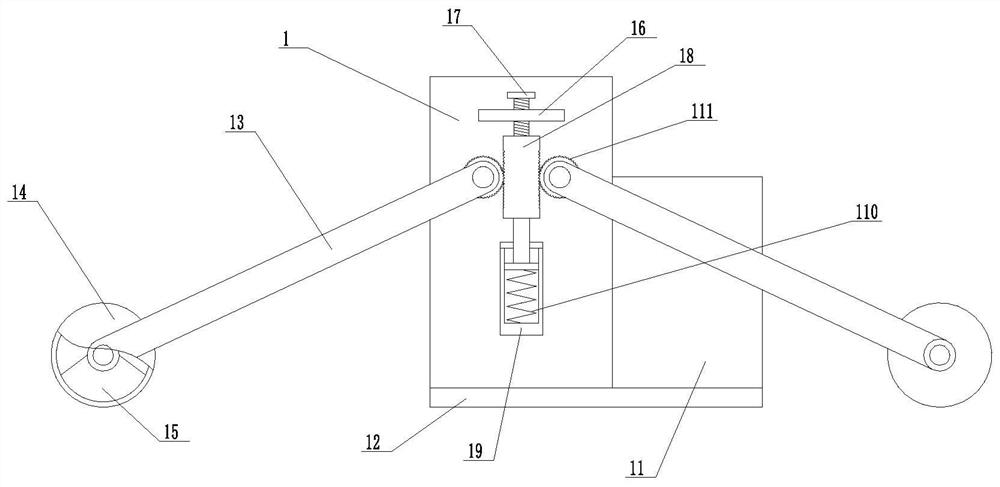

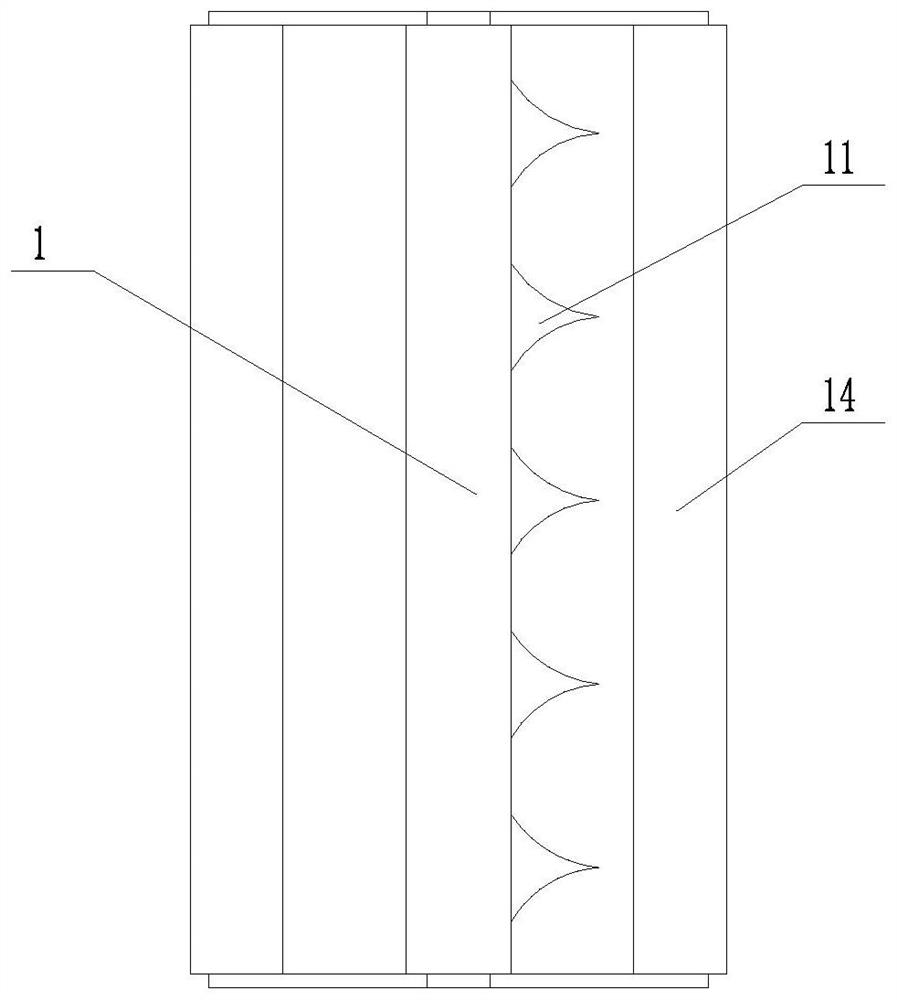

[0053] like figure 2 and image 3 As shown, a further improved solution on the basis of Embodiment 1, the front side of the scraper 1 is integrally connected with a breaking part 11, and the bottom of the breaking part 11 and the bottom of the scraper 1 are integrally connected with the same horizontal part 12, Both sides of the breaking part 11 are inwardly concave arc structures. The horizontal part 12 can be used to smooth the path of the demolition part 11 first, and the demolition part 11 will be raised higher than the design height to remove the arc structure and move to both sides and evenly spread, effectively improving the efficiency and construction quality of tiling.

[0054] In a further improved solution in this embodiment, the scraper 1 is rotatably connected with two sets of connecting rods 13 at the front and rear, and both sets of connecting rods 13 are connected with rolling rollers 14 , and one set of rolling rollers 14 is located behind the scraper 1 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com