Accelerated converging device for cigarette box conveying

A smoke box and main conveying technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of reducing work efficiency, affecting production volume, and long processing cycle, so as to reduce waiting time, improve work efficiency, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

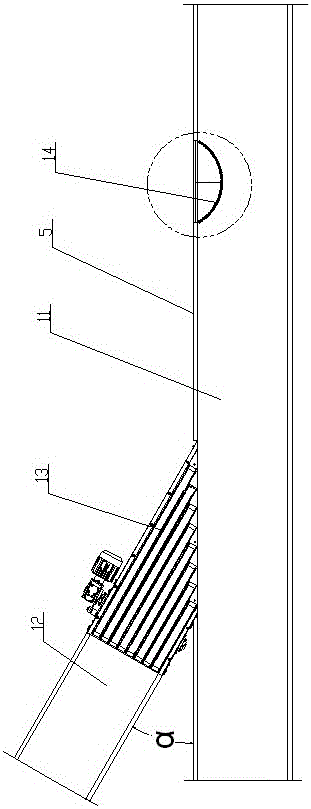

[0032] Such as Figure 1 to Figure 5 As shown, an accelerated merging device for cigarette case transportation according to the present invention includes a main conveying path 11 and a branch conveying path 12, the conveying direction of the branch conveying path 12 and the conveying direction of the main conveying path 11 form an acute angle, and the acute angle α The size is 30°. An accelerating merging structure 13 is provided between the outlet of the branch conveying path 12 and the main conveying path 11 , and the branch conveying path 12 merges with the main conveying path 11 through the accelerating merging structure 13 .

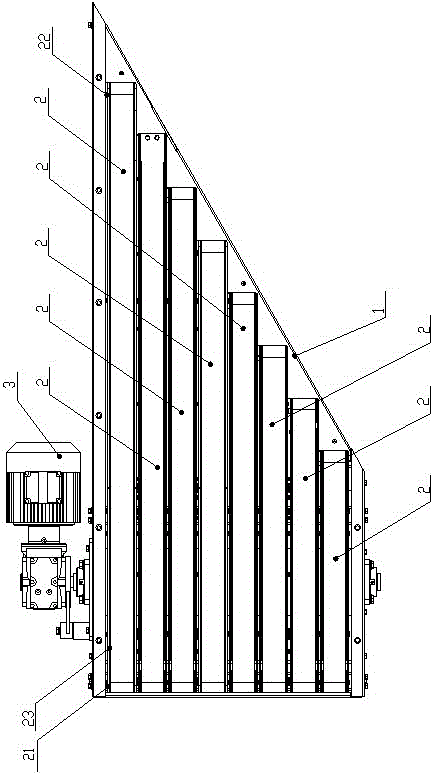

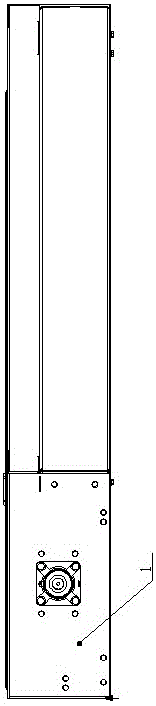

[0033] The acceleration confluence structure 13 includes a drive bracket 1, a drive unit 2 and a drive motor 3. The drive unit 2 is composed of a drive wheel 21, a tail wheel 22 and a drive belt 23 slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com