Tire type tunnel track laying crane and construction method

A crane and tire-type technology, applied in the directions of walking bridge cranes, cranes, traveling mechanisms, etc., can solve the problems of low construction efficiency and segment damage, and achieve the goal of simplifying construction steps, reducing construction costs, and reducing construction workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

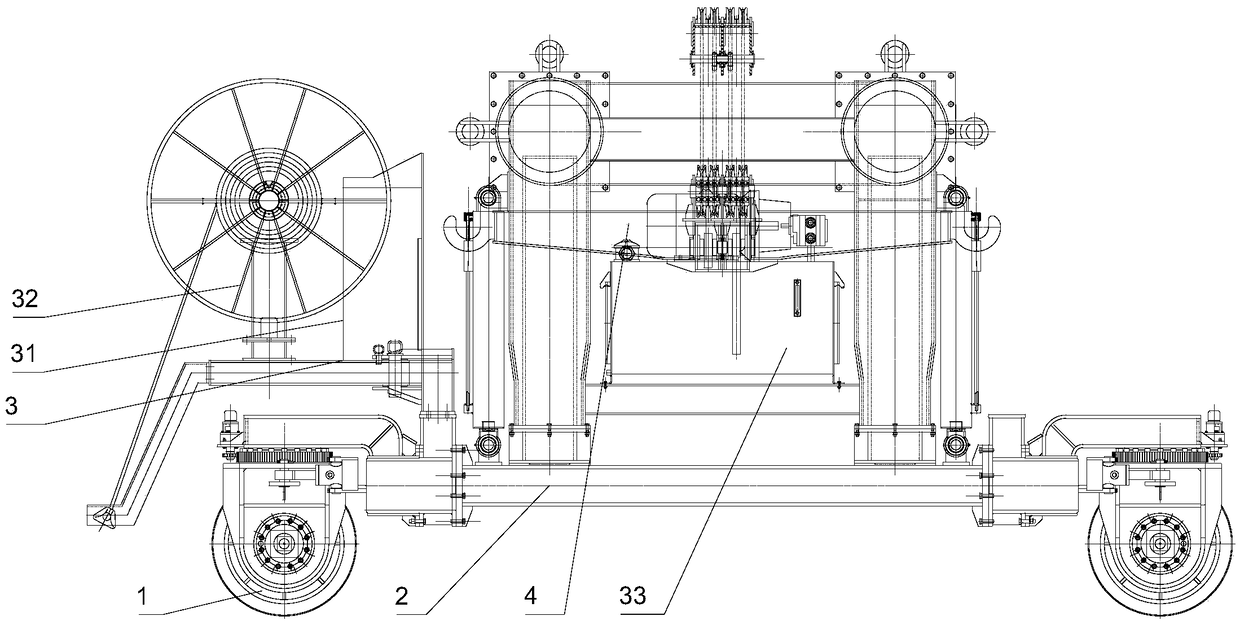

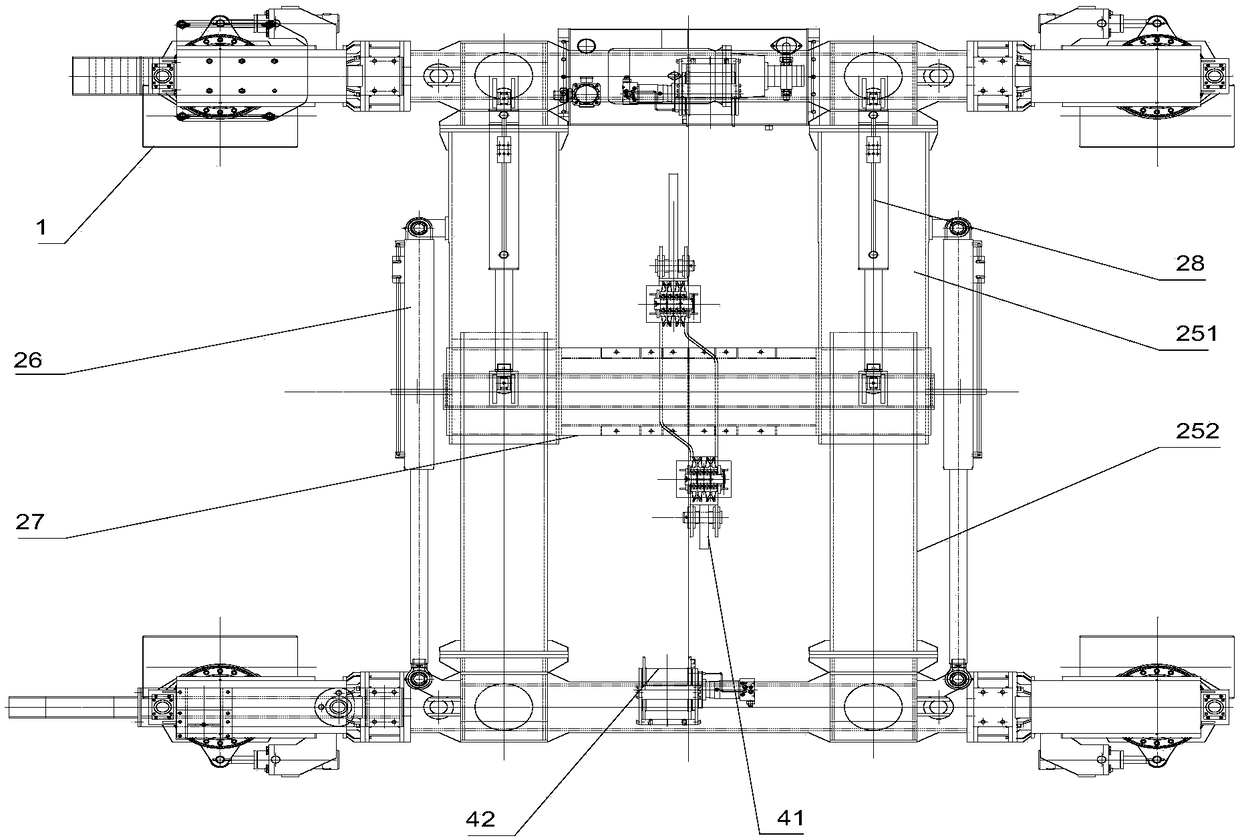

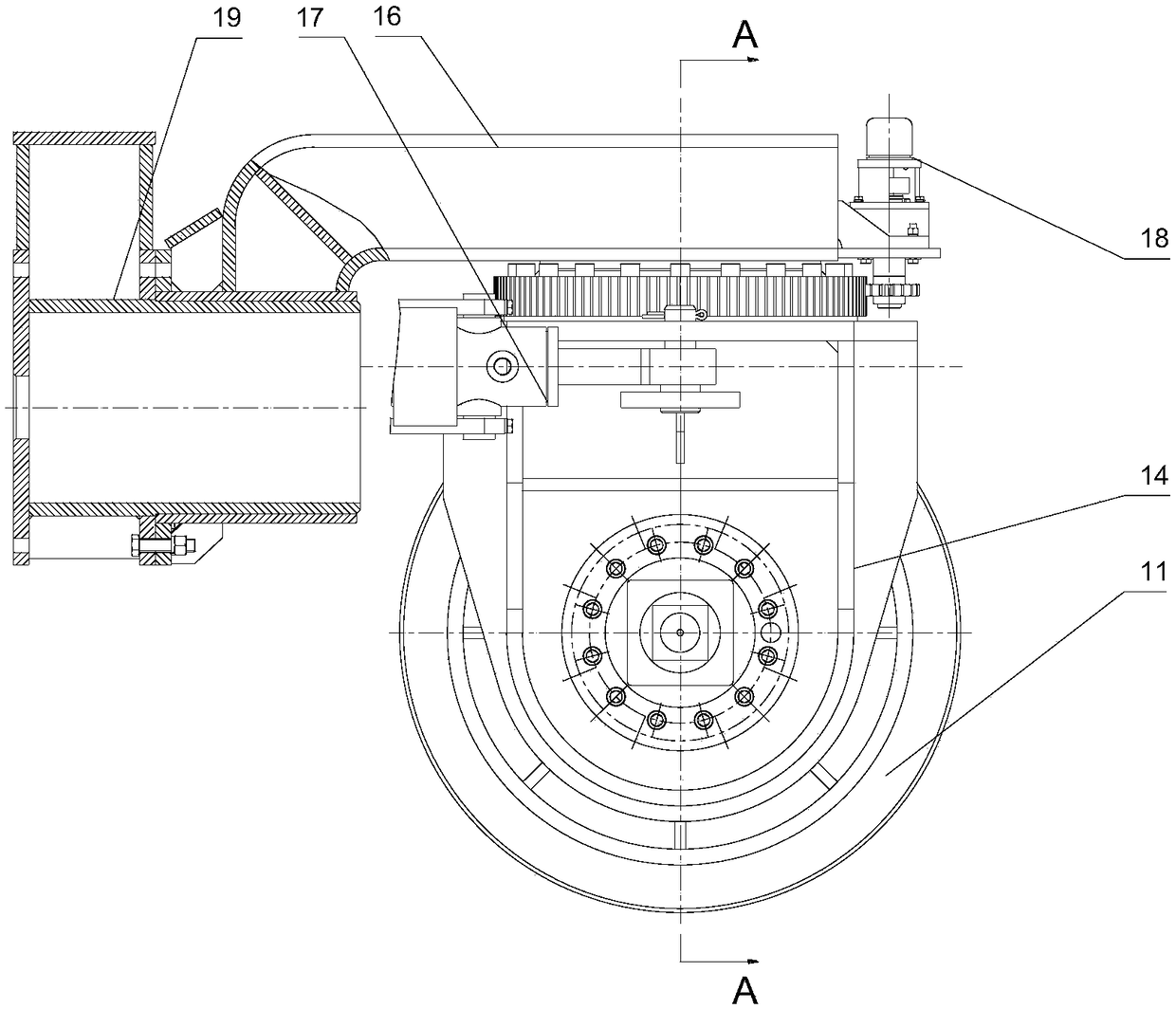

[0039] like Figure 1 to Figure 6 As shown, the present invention discloses a tire-type tunnel track-laying crane, which may include a wheel set 1, a door frame 2, a workbench 3 and a lifting device 4, and the wheel sets 1 are multiple and are respectively arranged on the door frame 2 Around the bottom, the door frame 2 is operated by each wheel set 1, and the workbench 3 can include a console 31, a power supply device 32 and a hydraulic device 33, and the console 31 and the power supply device 32 are installed on one of them respectively. On the wheel set 1, the hydraulic device 33 is installed and fixed on the door frame 2, the lifting device 4 includes a spreader 41 and a winch 42, and the winch 42 is fastened to the door frame 2, and connected by a wire rope. Said spreader 41.

[0040] Wherein, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com