Round disc type plant straw uprooting device

A crop straw and disc-type technology, applied in collectors, agricultural machinery and implements, applications, etc., can solve the problems of easy loss of soil moisture, low production efficiency, and large soil disturbance, so as to reduce soil erosion and increase operational productivity. , the effect of small soil disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

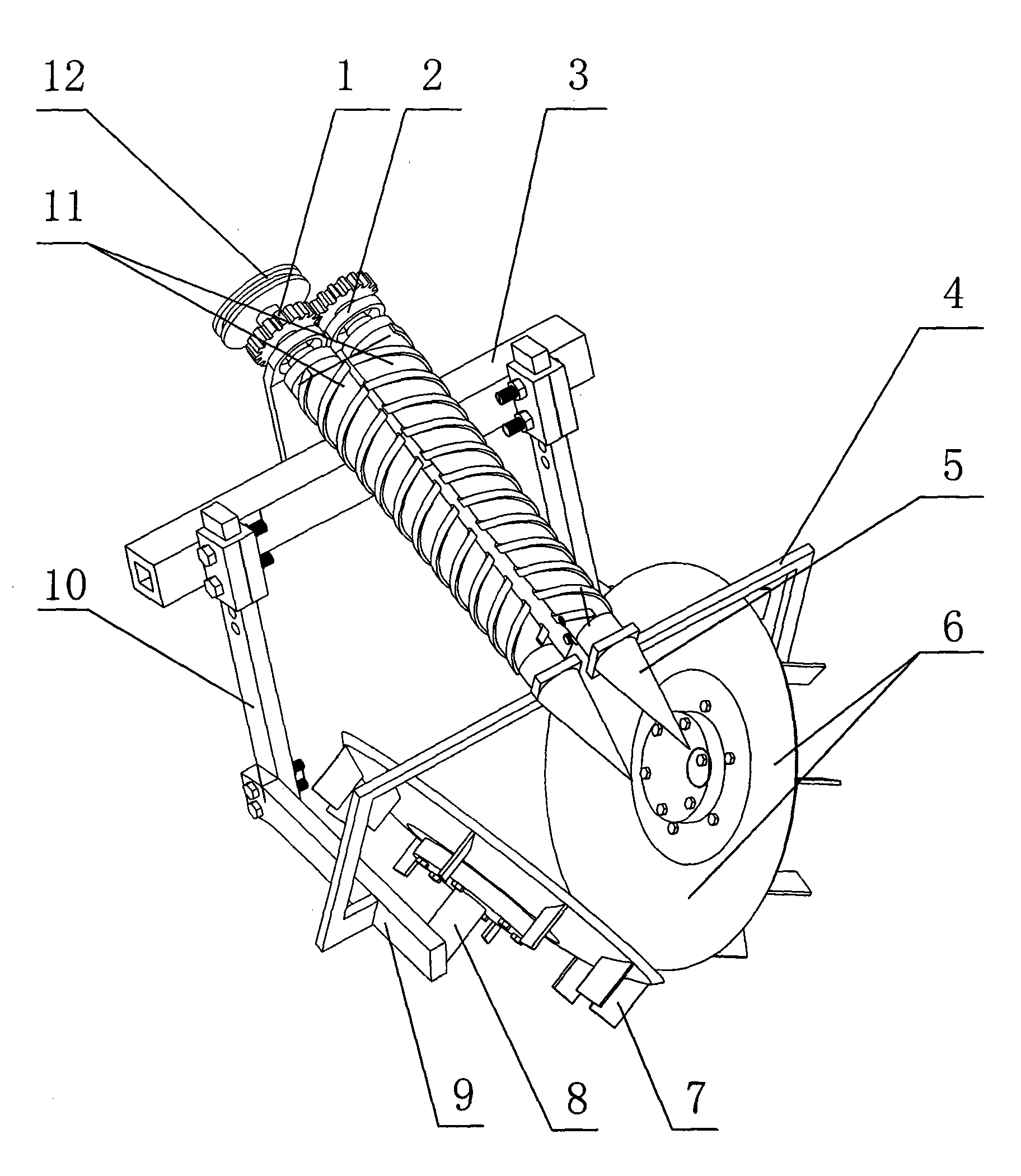

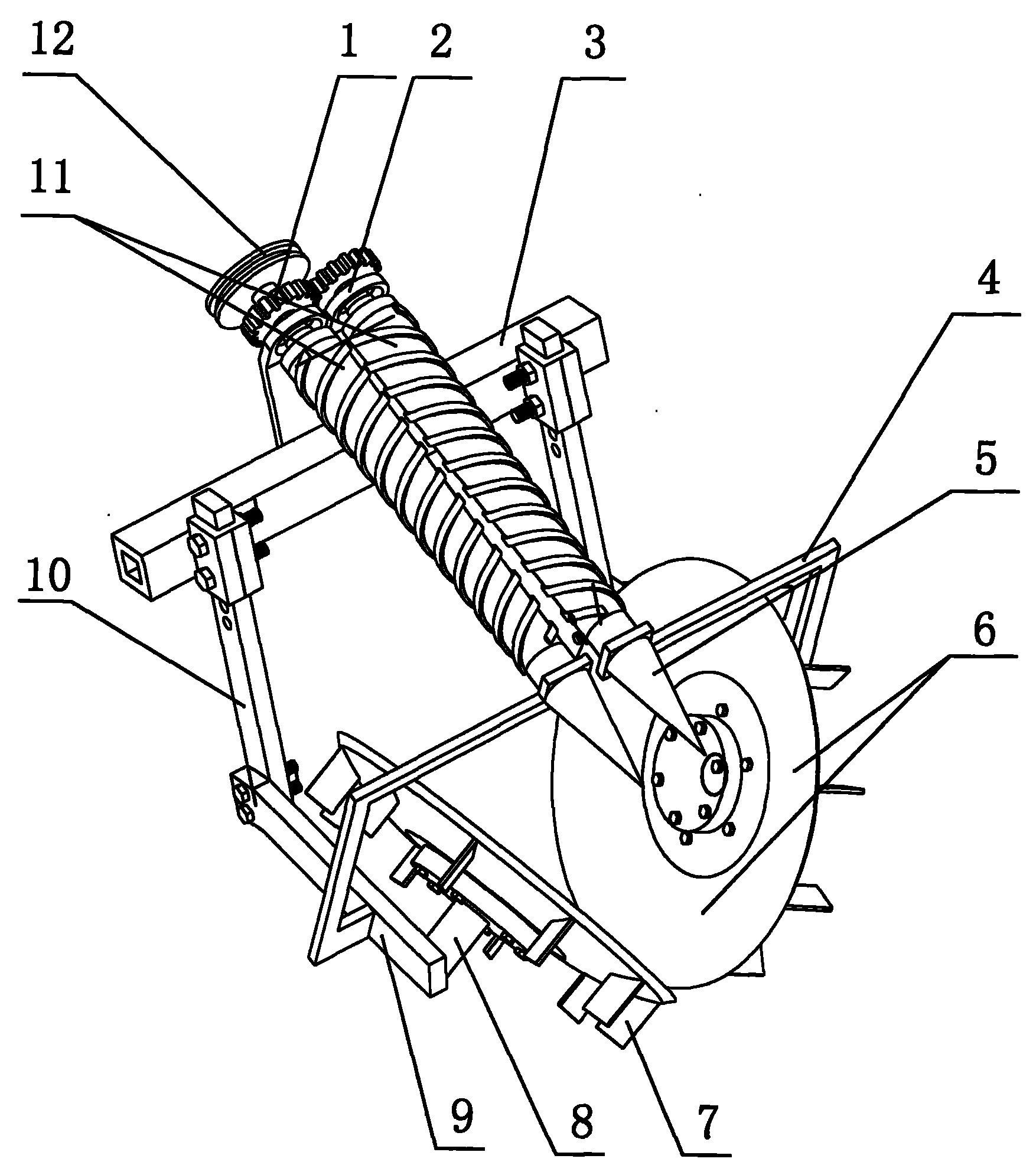

[0017] Such as figure 1 As shown, the disk-type crop straw rooting device of the present invention includes a frame 3, and left and right push rods 9 are symmetrically arranged on the left and right sides of the frame. Among them, a straw clamping device is arranged on the upper part of the frame 3, and a disc rooter is arranged on the lower front of the frame 3, and the disc rooter is composed of two discs whose front ends are at a certain angle. It consists of slices 6. The lower part of the angle between the two disc slices 6 is kept at a certain distance. During the operation, the angle between the two disc slices and the distance between the lower part of the angle are designed according to the depth of the crop rhizome and the diameter of the rhizome.

[0018] The outer edge of the disc slice 6 is provided with a blade 7, and a disc cutter shaft 8 is arranged at the front end of the left and right push rods. The left and right disc slices 6 are respectively assembled on the ...

Embodiment 2

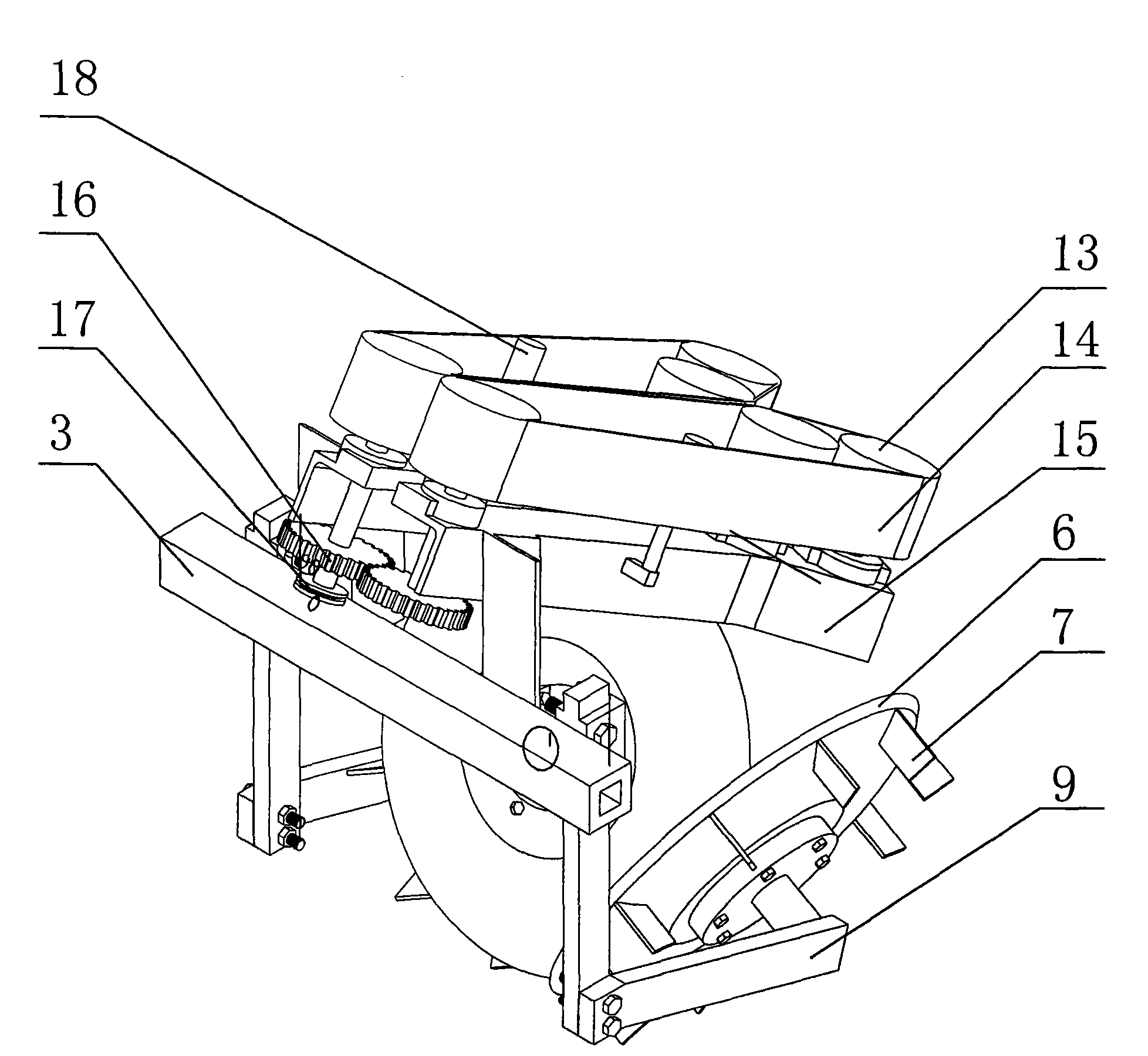

[0022] Such as figure 2 As shown, the disk-type crop straw rooting device of the present invention includes a frame 3, and left and right push rods 9 are symmetrically arranged on the left and right sides of the frame. Among them, a straw clamping device is arranged on the upper part of the frame 3, and a disc rooter is arranged on the lower front of the frame 3, and the disc rooter is composed of two discs whose front ends are at a certain angle. It consists of slices 6. The lower part of the angle between the two disc slices 6 is kept at a certain distance. During the operation, the angle between the two disc slices and the distance between the lower part of the angle are related to the depth of the crop rhizome and the diameter of the rhizome.

[0023] The outer edge of the disc slice 6 is provided with a blade 7, and a disc cutter shaft 8 is arranged at the front end of the left and right push rods. The left and right disc slices 6 are respectively fixed on the left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com