Small and medium size self-propelled corncob-stem both-gaining corn combine harvester

A combine harvester, self-propelled technology, applied in the direction of harvesters, agricultural machinery and implements, threshing equipment, etc., can solve the problems of unsuitable structure, low operation efficiency, high price, etc., and achieve low device cost and generalization. The effect of high and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

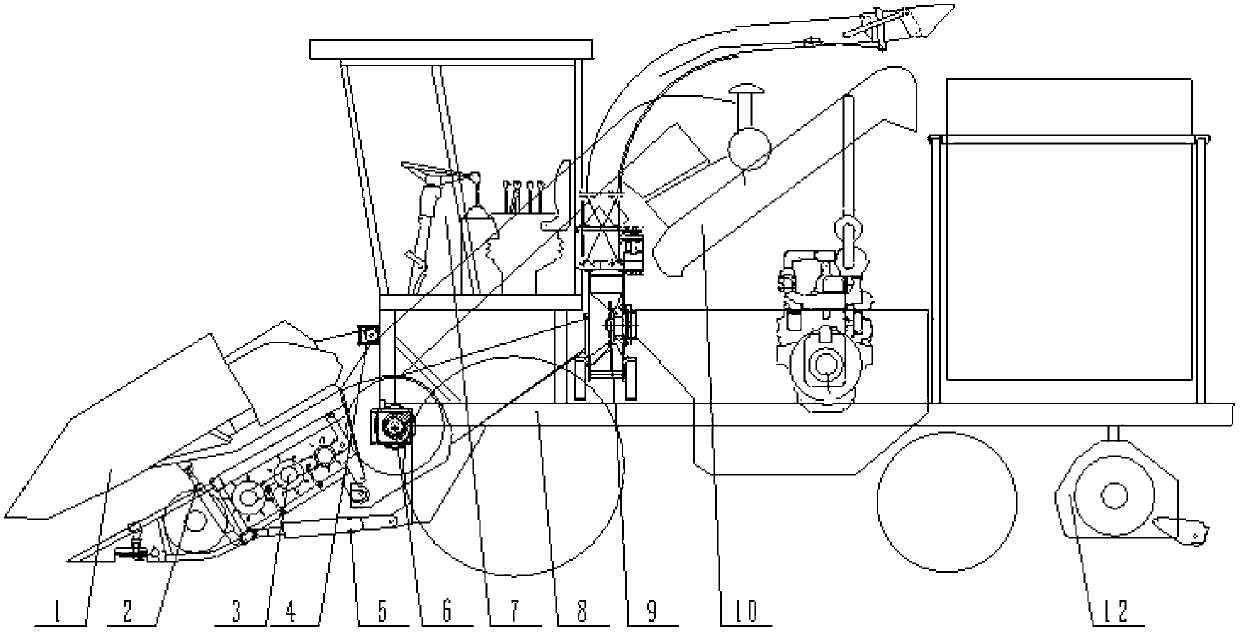

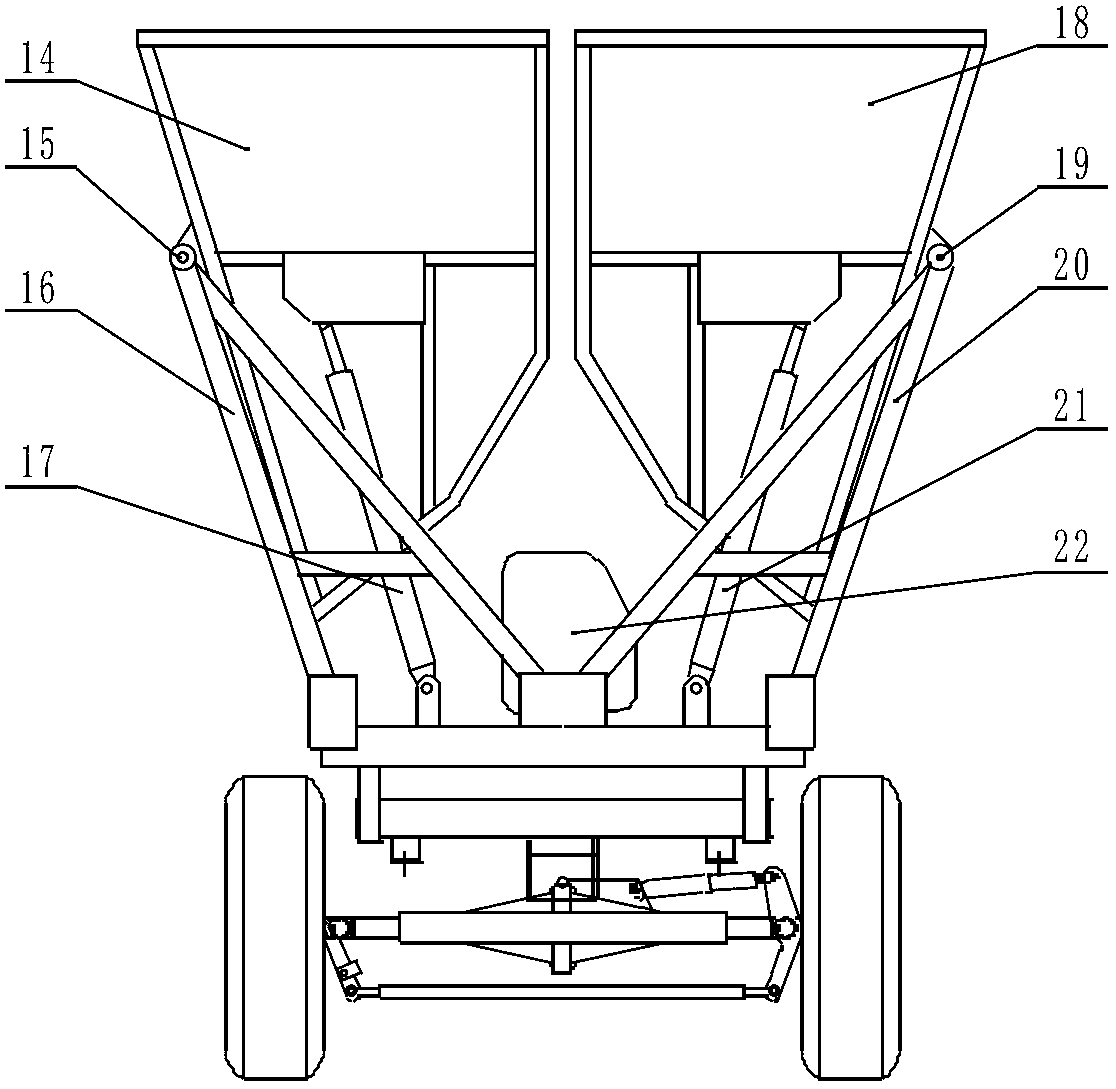

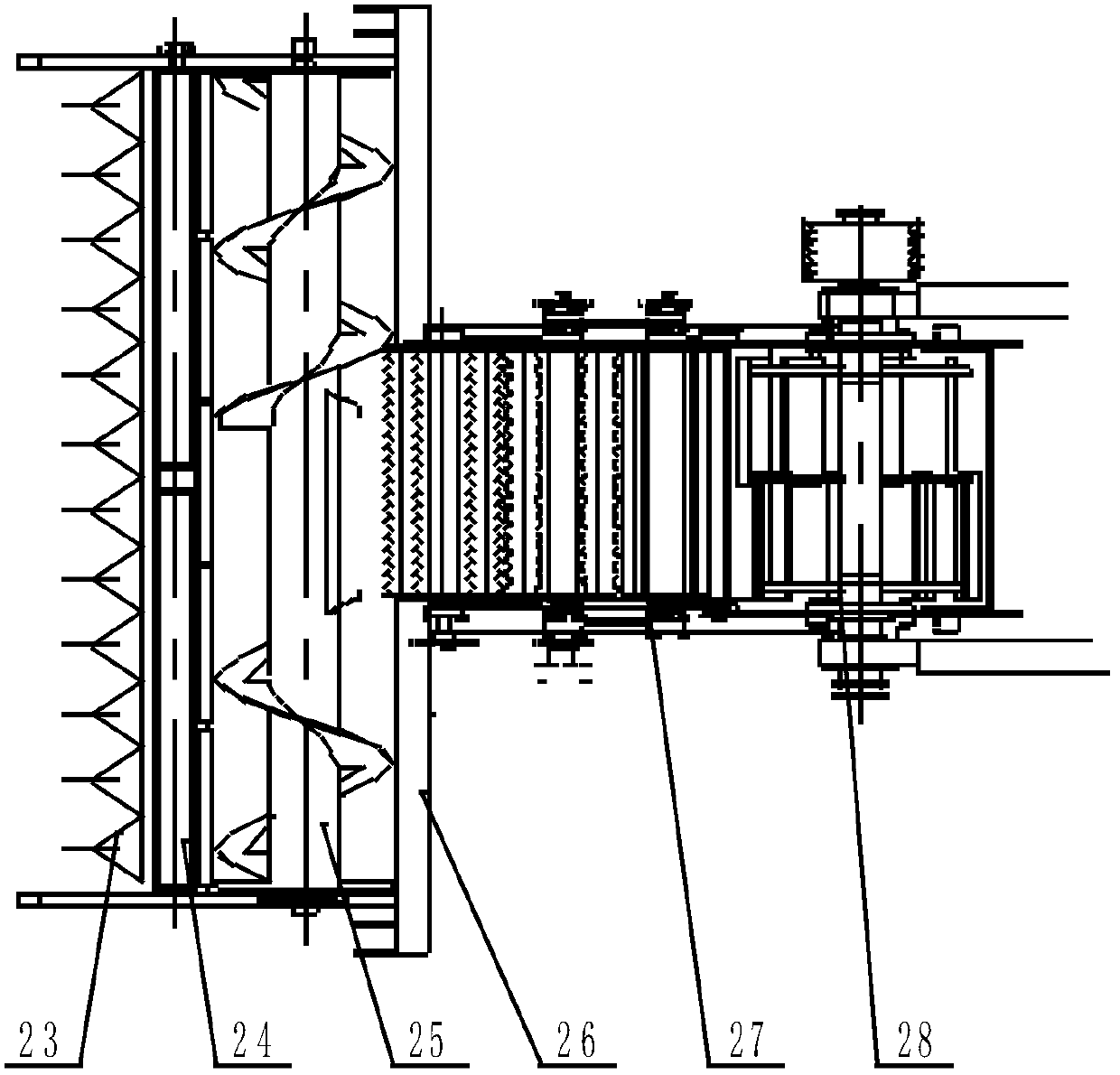

[0028] A small and medium-sized self-propelled ear and stem corn combine harvester, such as Figure 1 to Figure 3 Shown, comprise walking chassis 8, be provided with upper floor cutting platform 1, lower floor cutting platform 3, driver's cab 7, ear conveyer 10, engine 12, grass box 14, grain box 18, oil tank 22, dial wheel assembly on walking chassis 8 forming, straw feeding device, thrower 9; one end of the upper header 1 is hooked on the upper header mounting base 4, and the lower end is connected with the lower header 3 through the upper header oil cylinder 2; the lower header is located below the upper header, One end is articulated on the lower header mounting base 6, and the lower end is connected with the walking chassis 8 through the lower header oil cylinder 5, and the lower header mounting base 6 and the upper header mounting base 4 are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com