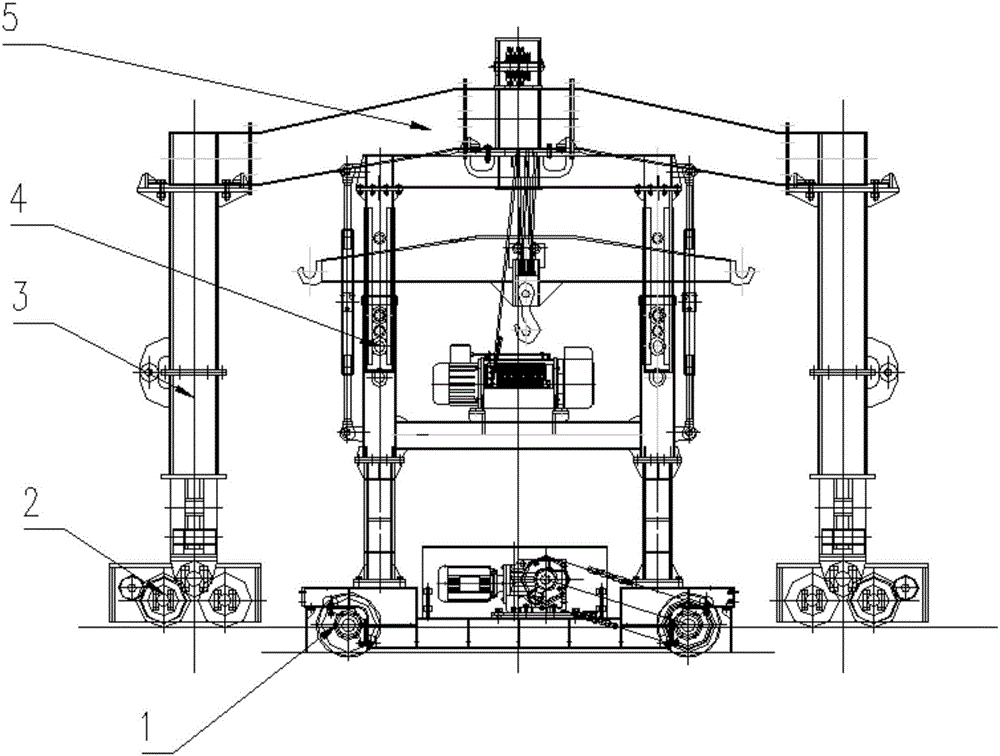

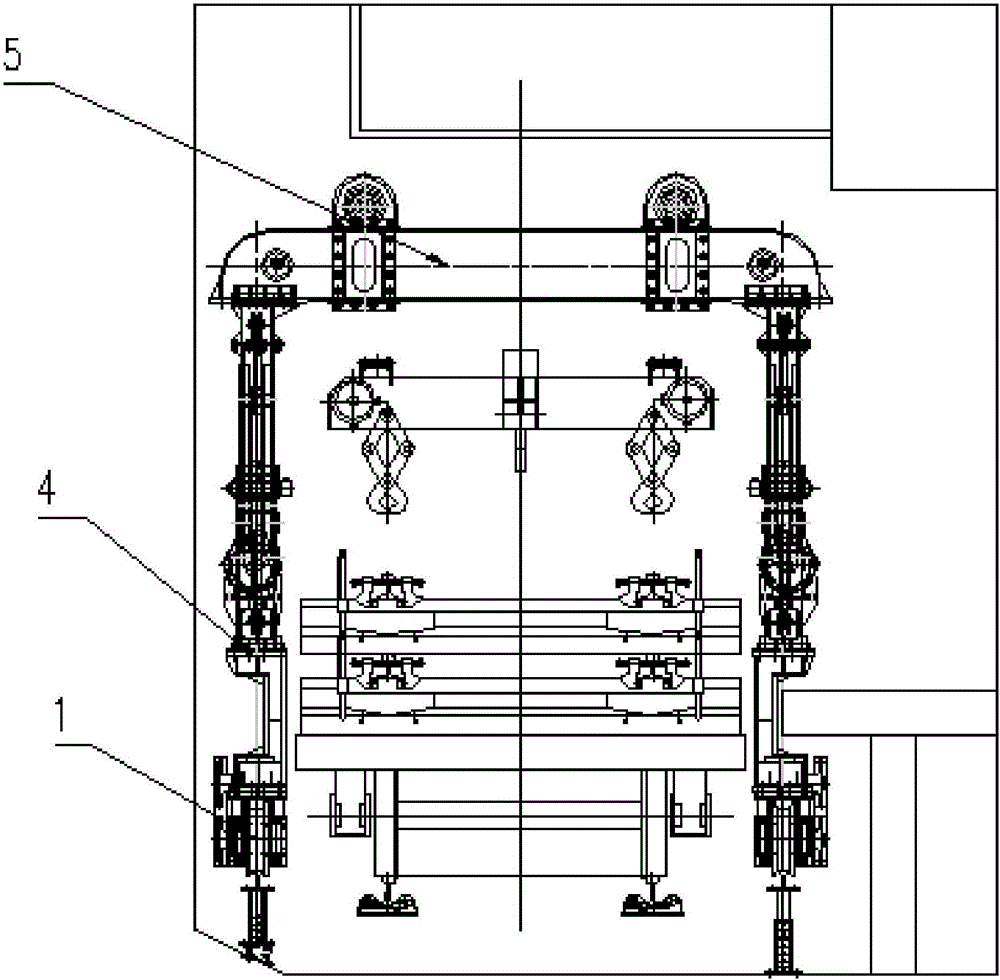

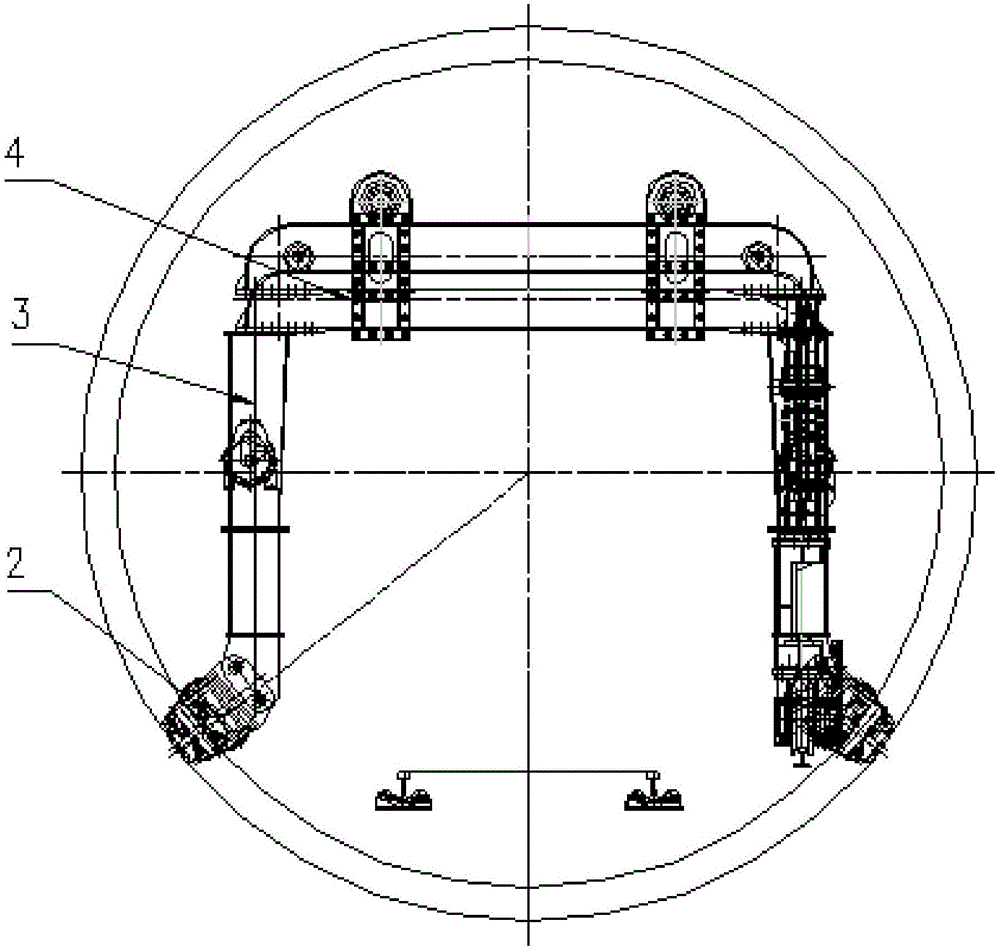

Rail-mounted and wheel-mounted combined type tunnel track-laying crane and construction method thereof

A crane and combined technology, applied in the direction of cranes, trolley cranes, track systems, etc., can solve problems such as low construction efficiency and segment damage, and achieve the effects of reducing damage, quick switching, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: In the construction condition in the tunnel, the construction in the tunnel is the most important working condition of the track laying operation. Under this working condition, tires are used throughout the whole process to avoid damage to the tunnel segments. The specific construction process is as follows: Before entering the tunnel section, the running span and height of the tires need to be adjusted to adapt to the width of the rail row and the height of the tunnel section. Under the action of the rail support legs 4 of the crane, the wheel support legs 3 are stretched and adjusted in order to adjust the height, and then the span of the whole machine is adjusted through the connecting beam 5 . After the adjustment is basically in place, drive the whole machine into the tunnel section, adjust the support angle of the wheel and wheel set 2 according to the adjusted height and position in the tunnel, so that the tires are positively pressed on the segment,...

Embodiment 2

[0030] Embodiment 2: In the construction condition of the platform section, the construction of the platform section is the most complicated operation condition of the track laying operation, and the wheel-rail is used for the whole process under this condition. The specific construction process is as follows: Before entering the platform section, the wheel-rail running span and height need to be adjusted to adapt to the width of the rail row and the height and width of the platform section. Under the action of the wheeled outriggers 3 of the crane, the wheeled outriggers 4 expand and contract in order to adjust the height, and then the telescopic connecting beam 5 adjusts the span of the whole machine, and then is supported on the temporary track. After the track wheel group 1 is supported in place, adjust the wheel leg 3 and the connecting beam 5 to avoid affecting the track laying operation of the platform section. Then the whole machine drives into the platform section for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com