Multi-connected chilled beam air conditioning system with variable refrigerant flow

A technology of variable refrigerant flow and multi-connected air conditioner, which is applied in air conditioning system, heating mode, noise suppression, etc. It can solve problems such as troublesome maintenance, high water supply temperature, and damage to the ceiling of condensed water, so as to reduce the initial investment cost , Piping design is simple, the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

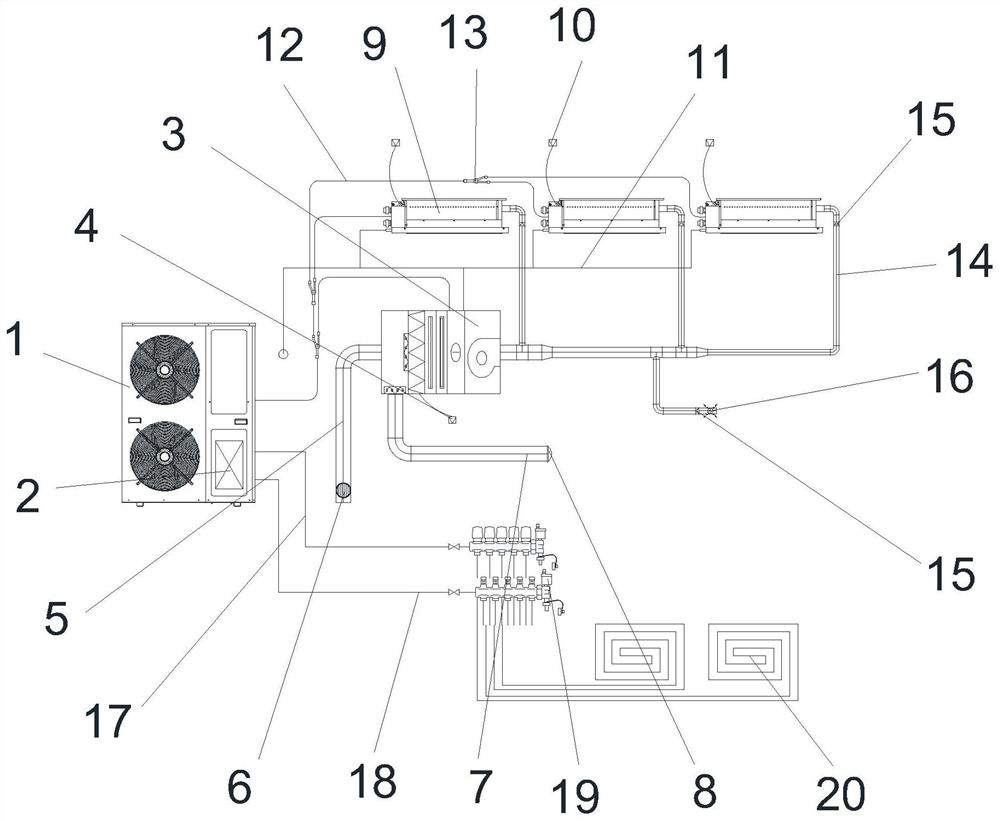

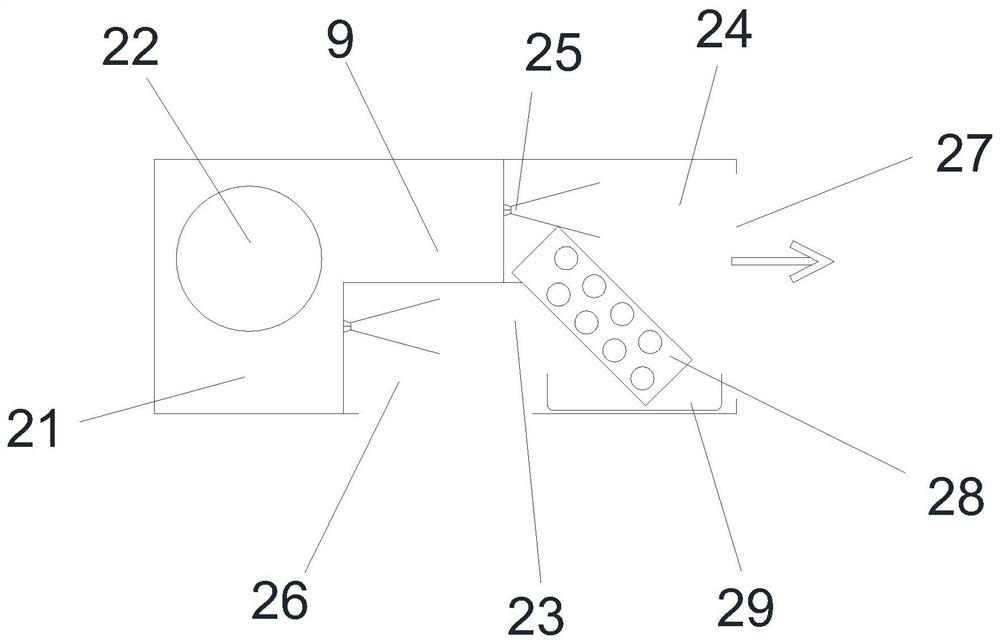

[0031] Embodiment: Variable refrigerant flow multi-connected chilled beam air conditioning system, such as Figure 1-Figure 2 As shown, it includes DC inverter multi-connected air conditioner external unit 1, refrigeration system and heating system. The refrigeration system includes multifunctional air conditioning box 3, chilled beam 9, thermostat 10, refrigerant copper pipe 12 and branch pipe 13. Both the air conditioning box 3 and the chilled beam 9 are connected to each other with the DC frequency conversion multi-connected air conditioner external unit 1 through the refrigerant copper pipe 12 and the branch pipe 13, and the multi-group refrigerant copper pipes 12 are connected to each other through the branch pipe 13. Both the functional air-conditioning box 3 and the chilled beam 9 are equipped with electronic expansion valves, the input end of the electronic expansion valve and the control end of the thermostat 10 are electrically connected to each other through an elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com