Patents

Literature

46 results about "Chilled beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

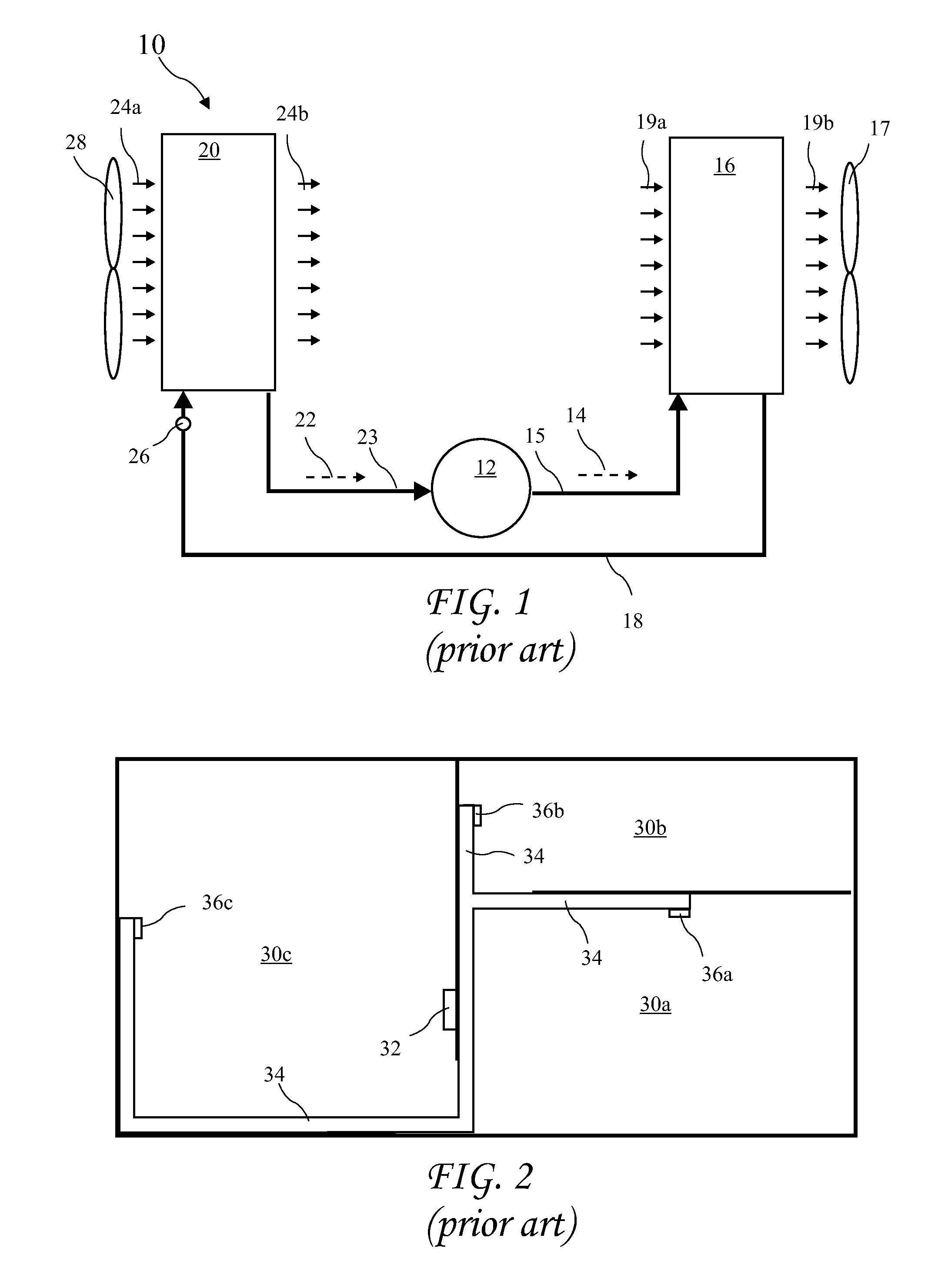

A chilled beam is a type of radiation/convection HVAC system (as is an alternative design known as "chilled ceiling") designed to heat and cool large buildings. Pipes of water are passed through a "beam" (a heat exchanger) either integrated into standard suspended ceiling systems or suspended a short distance from the ceiling of a room. As the beam chills the air around it, the air becomes denser and falls to the floor. It is replaced by warmer air moving up from below, causing a constant passive air movement called convection, which cools the room. Heating works in much the same fashion, similar to a steam radiator. There are two types of chilled beams. Some passive types rely solely on convection, while there is a "radiant"/convective passive type that cools through a combination of radiant exchange (40%) and convection (60%). The passive approach can provide higher thermal comfort levels, while the active type (also called an "induction diffuser") uses the momentum of ventilation air entering at relatively high velocity to induce the circulation of room air through the unit (thus increasing its heating and cooling capacity).

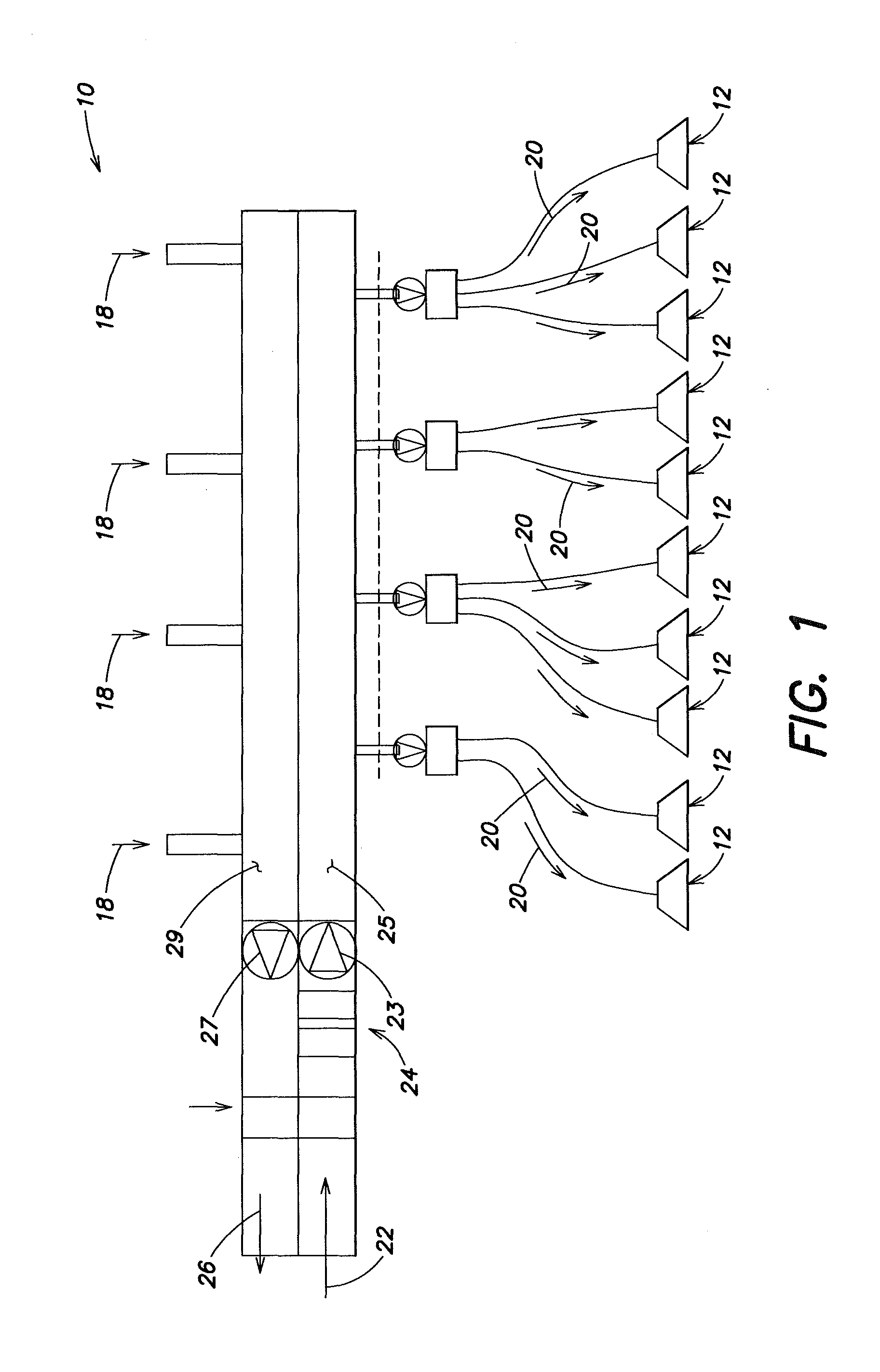

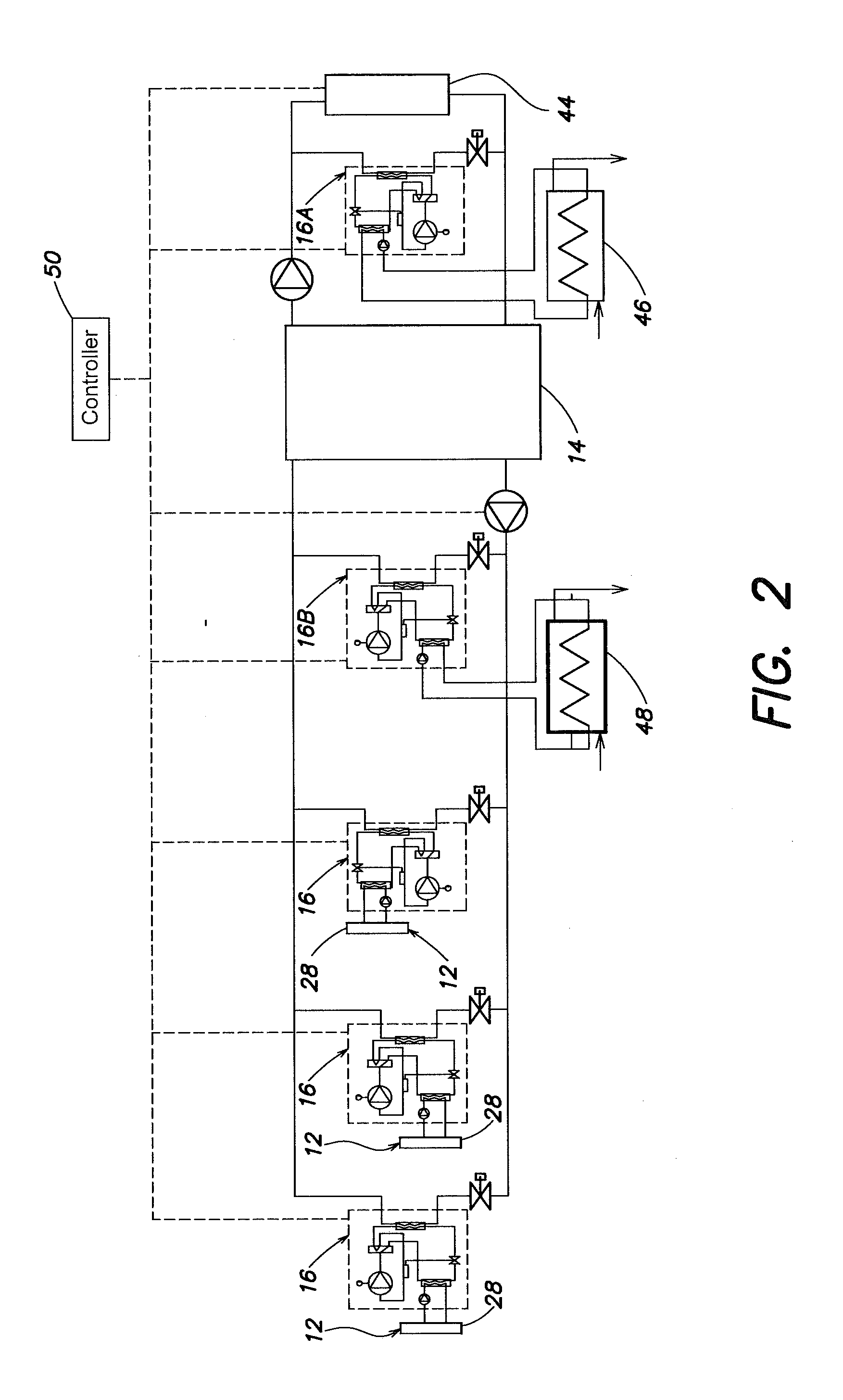

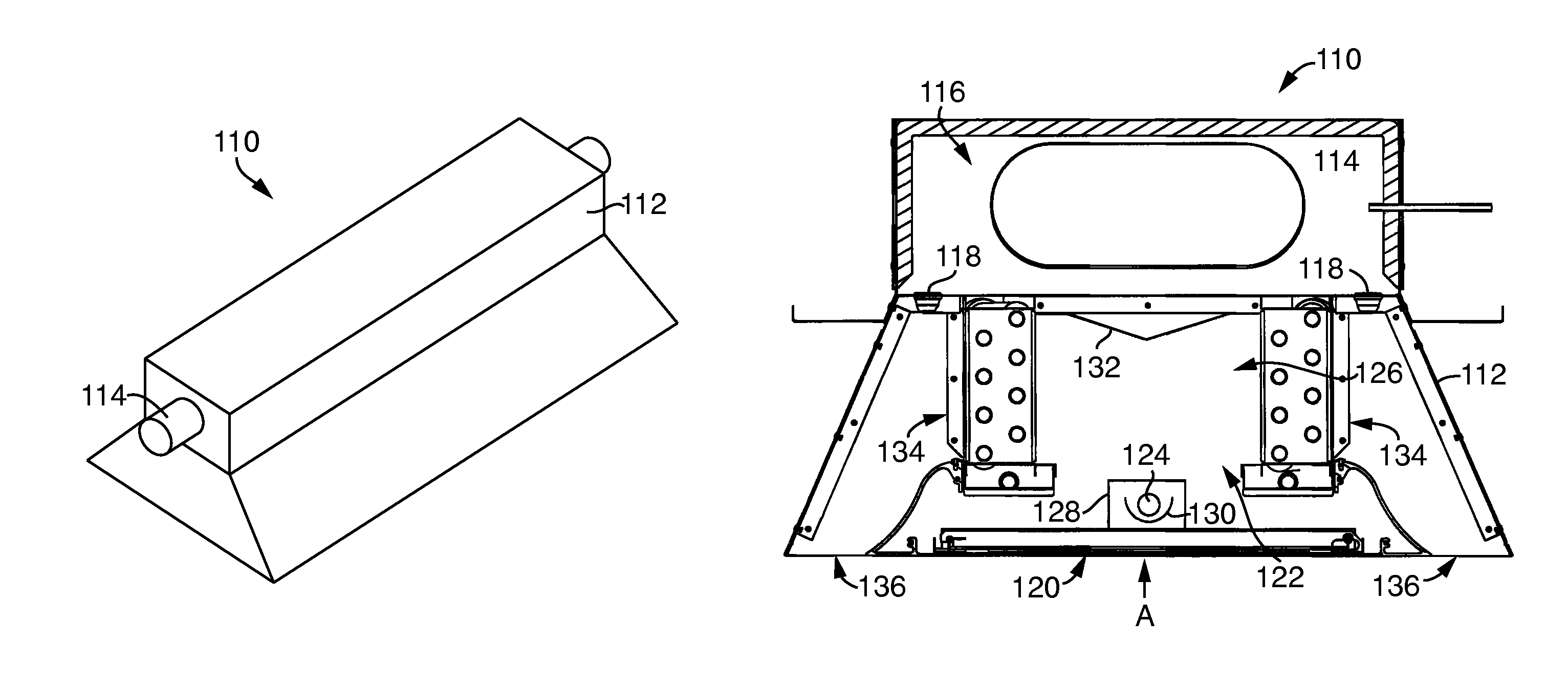

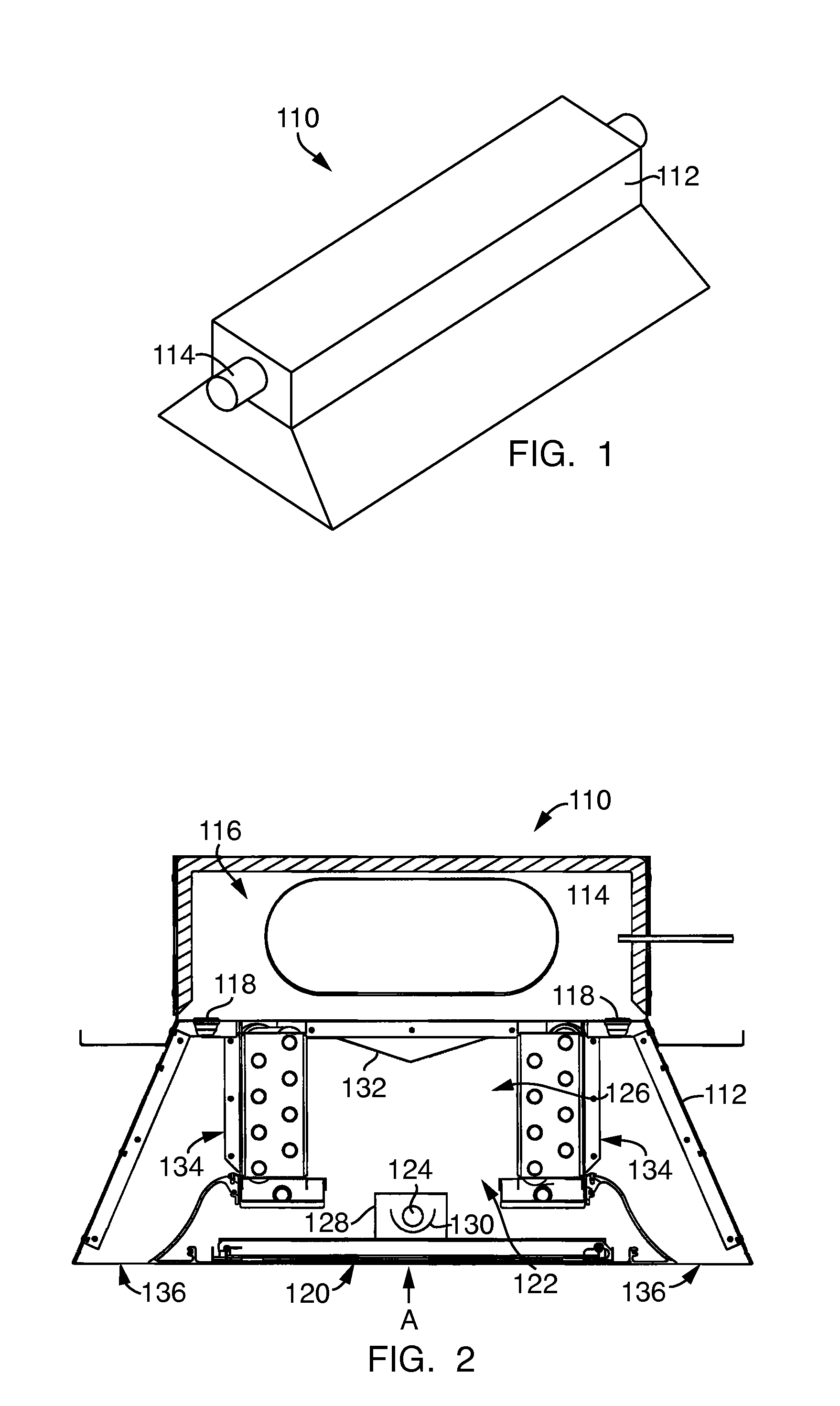

Chilled beam pump module, system, and method

ActiveUS20130199772A1Improve performanceSimple design and installationTemperatue controlHeat exchange apparatusWarm waterComputer module

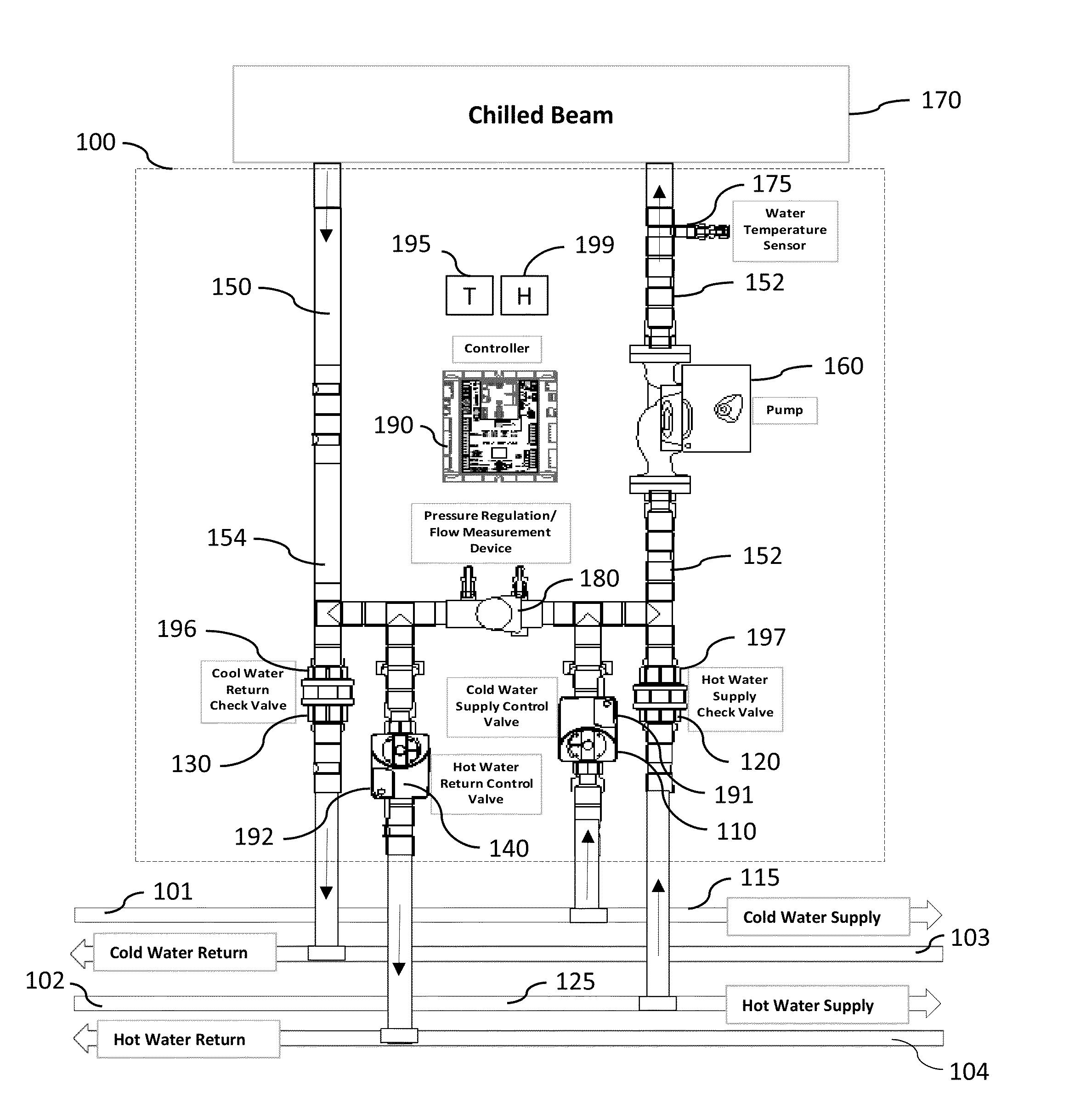

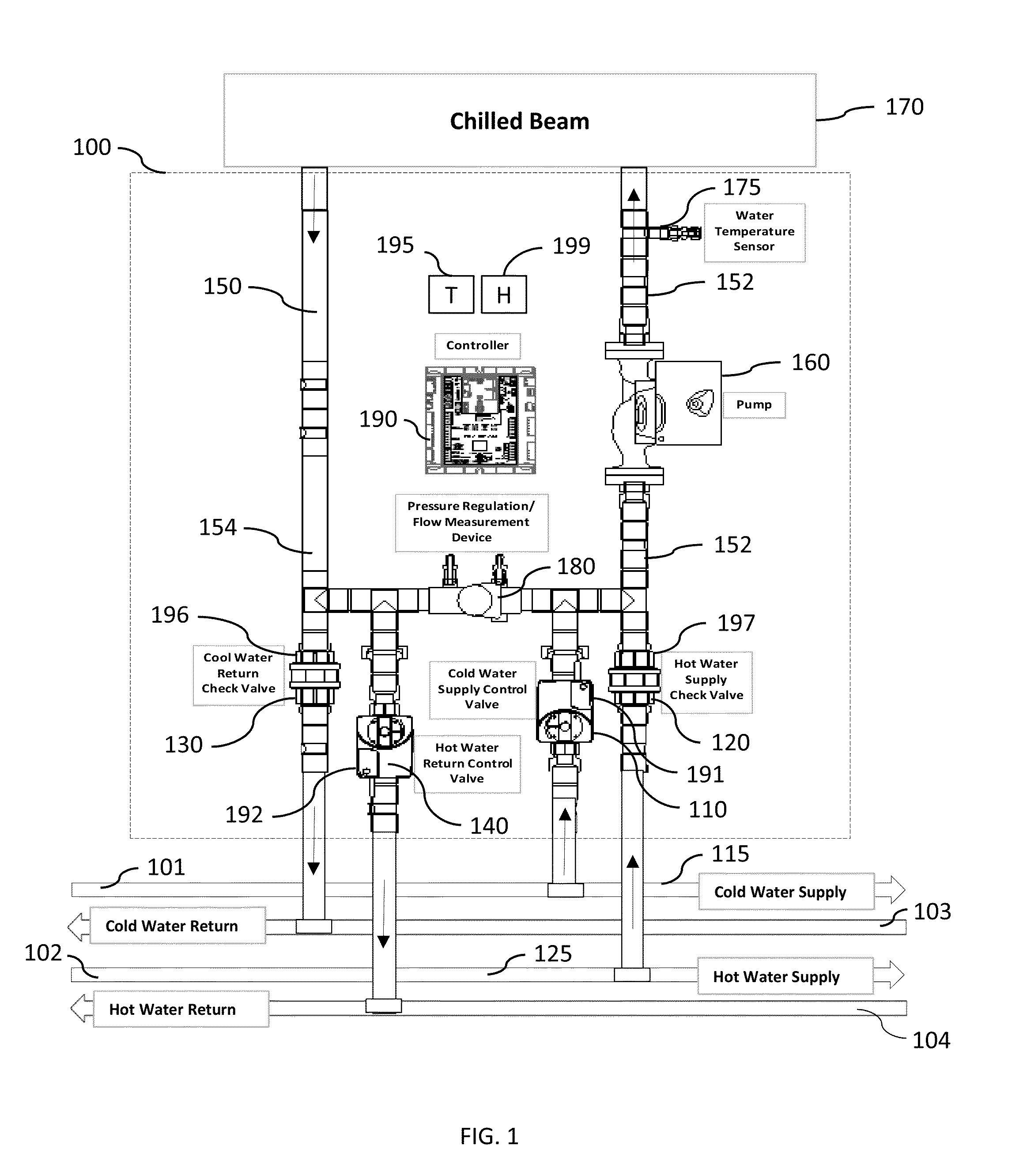

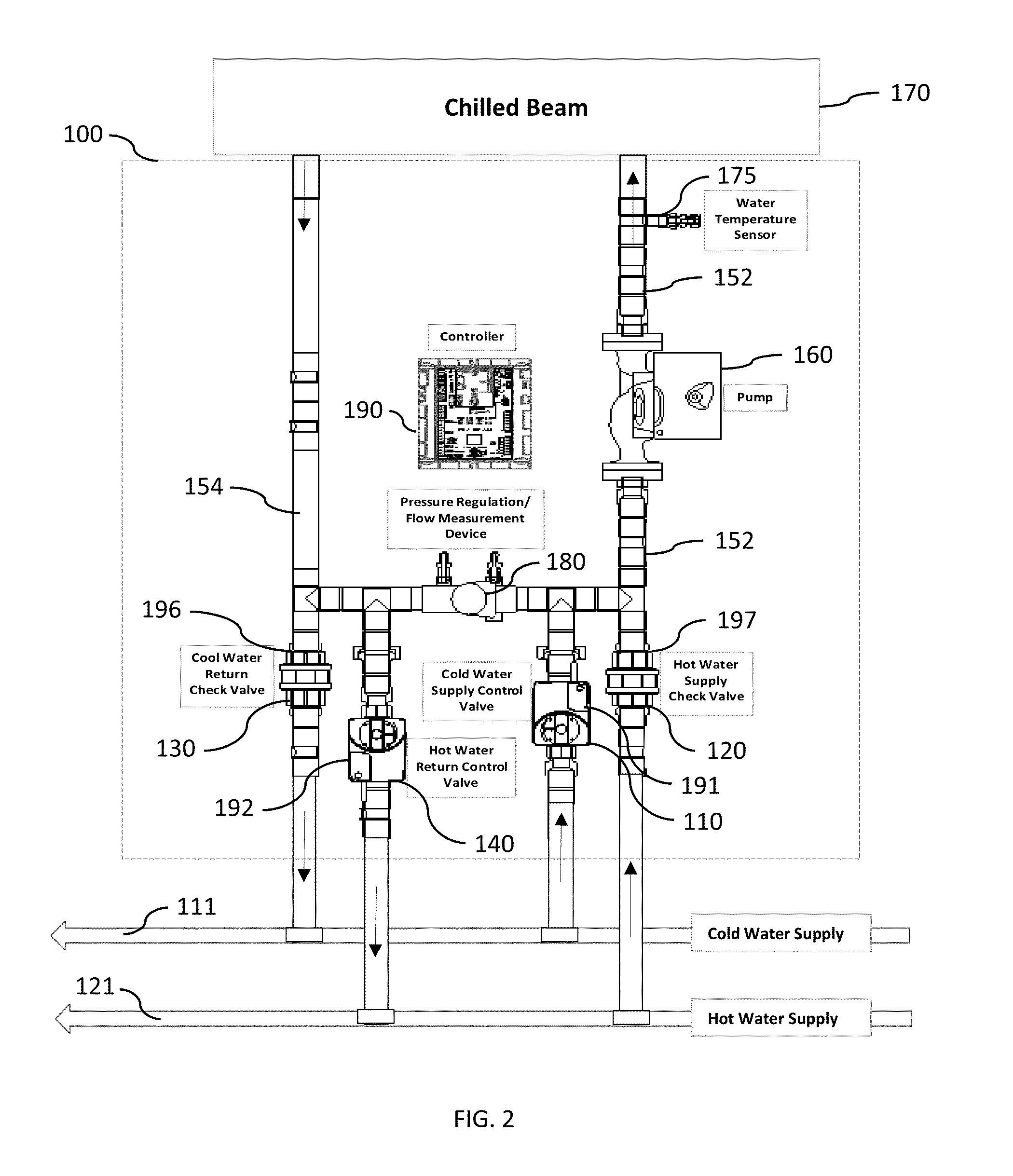

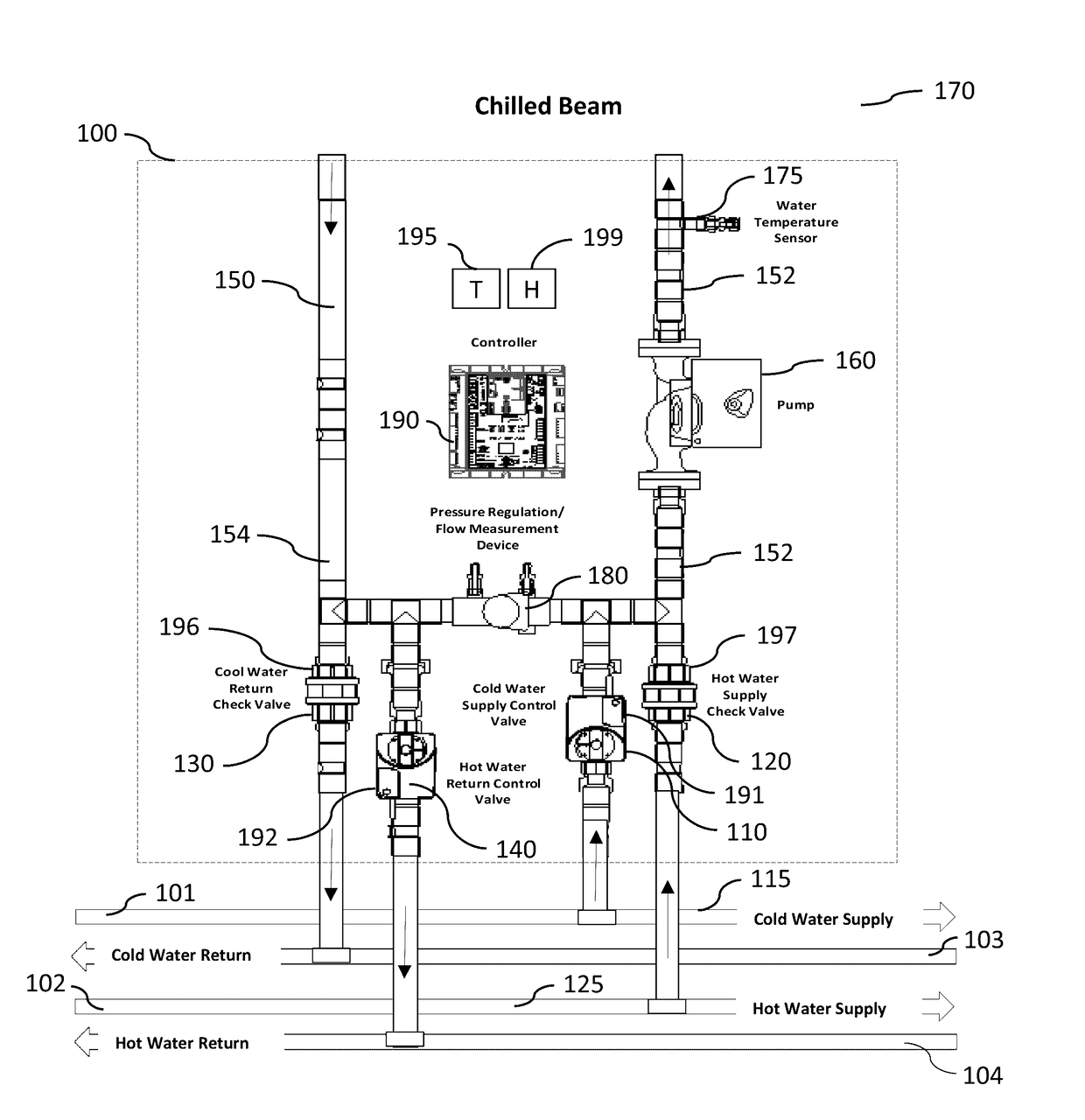

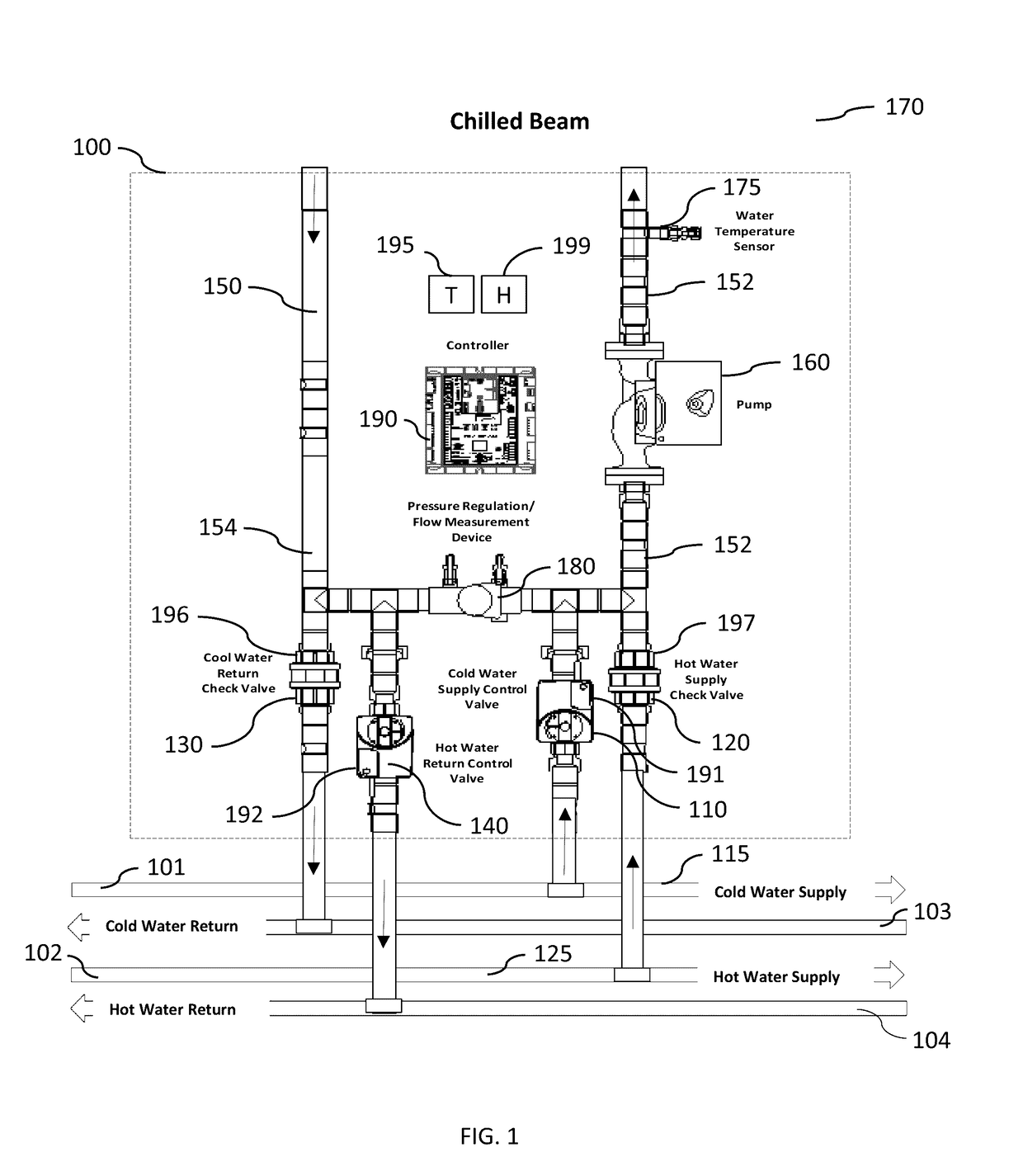

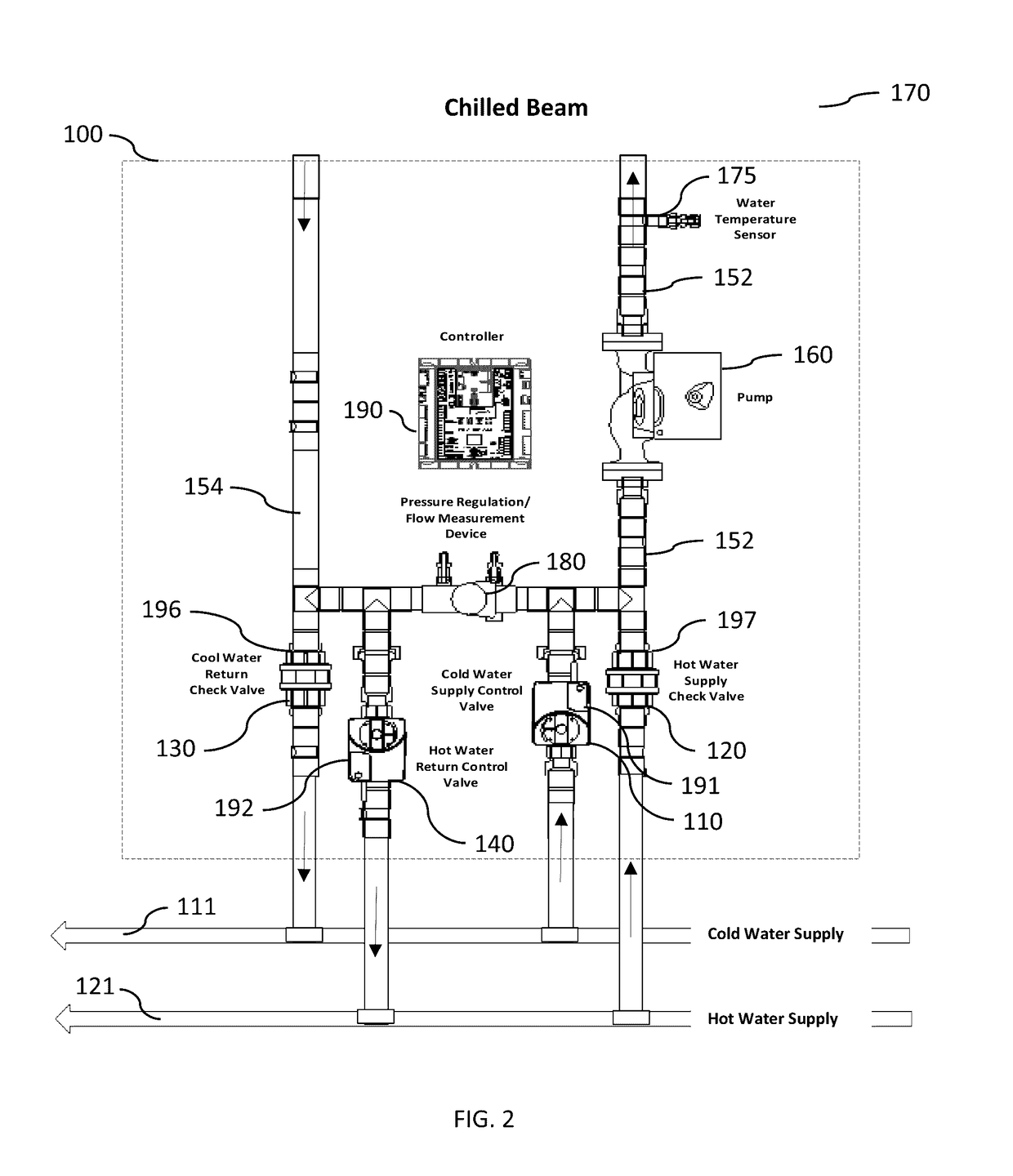

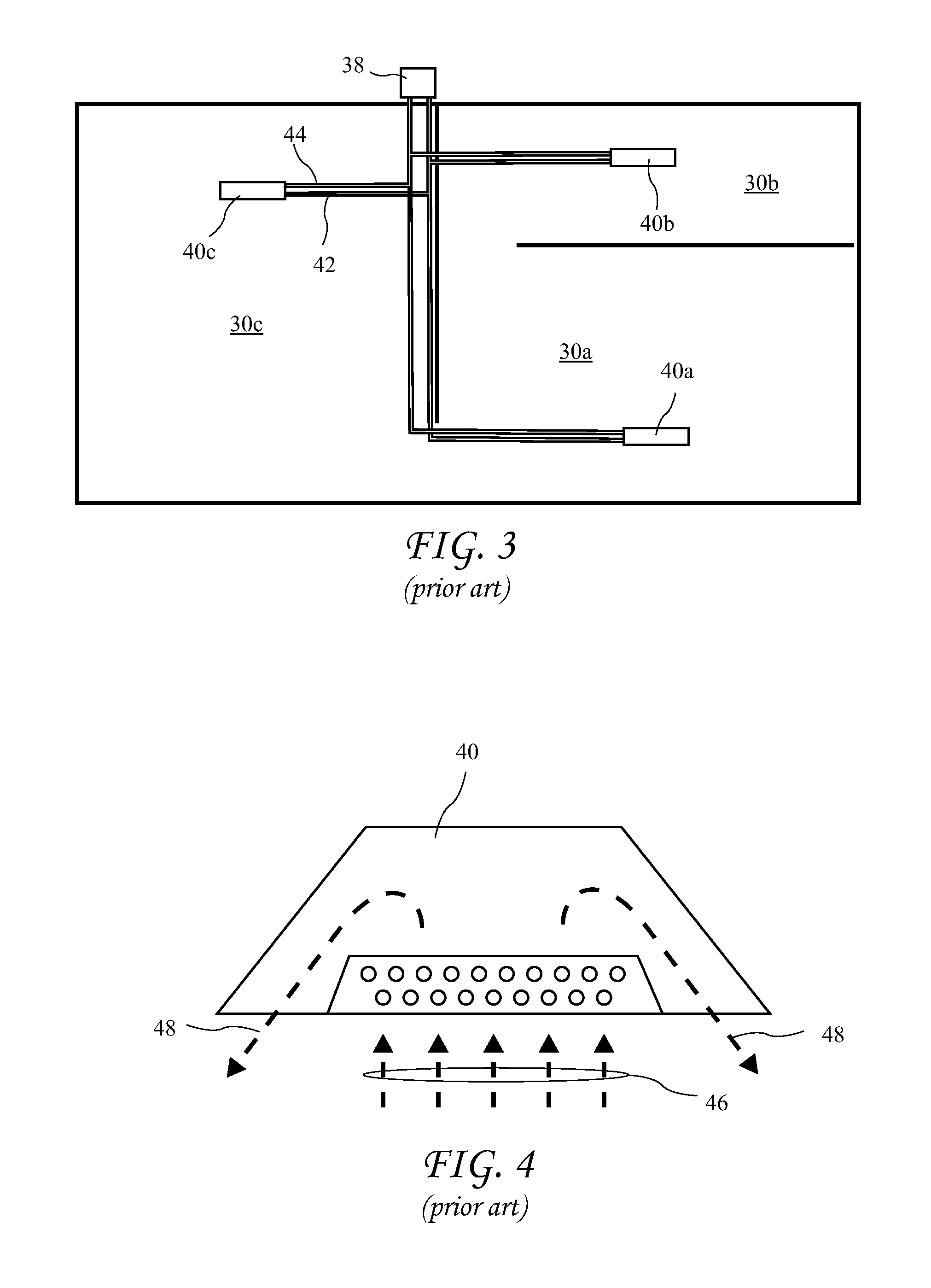

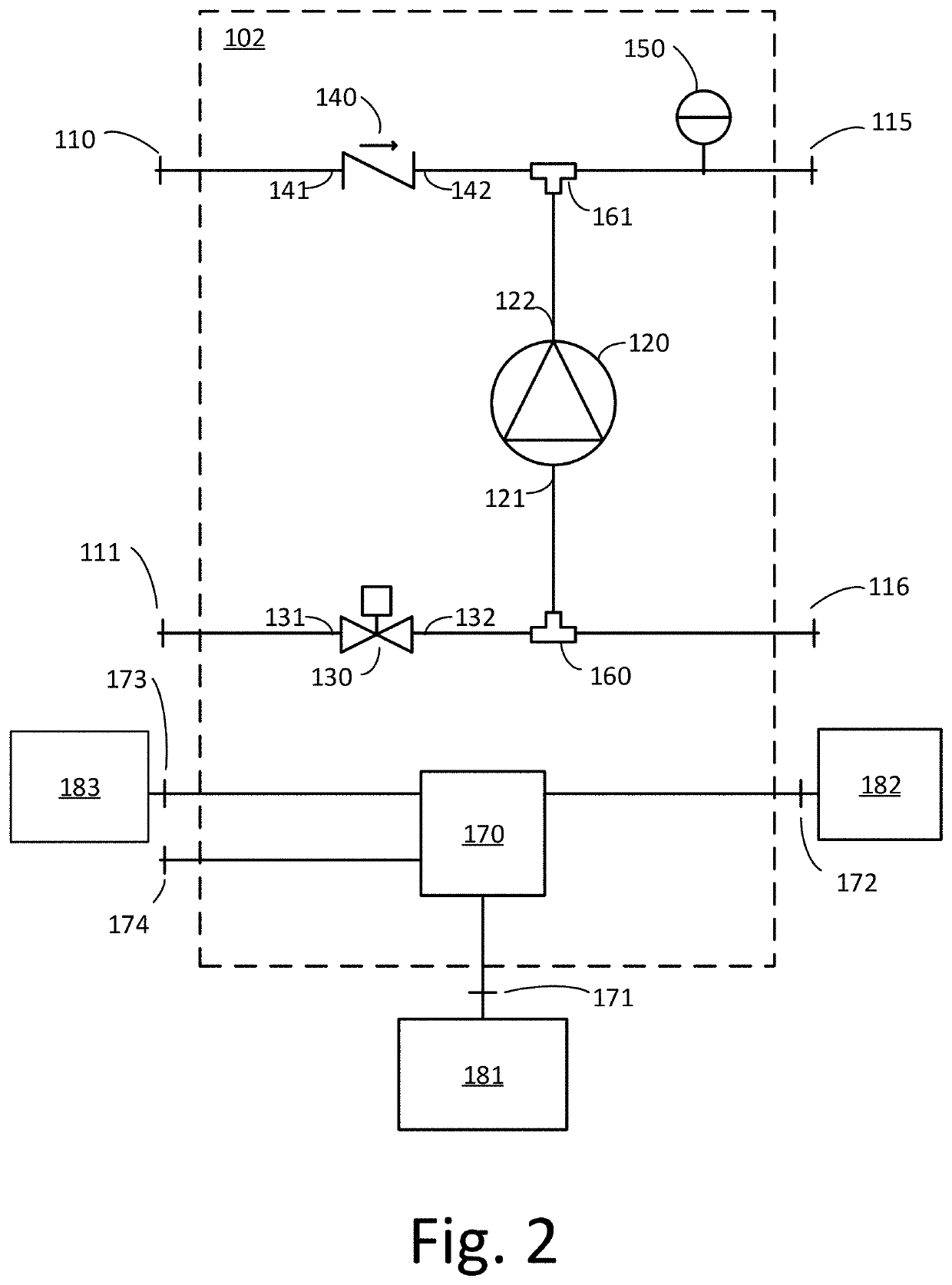

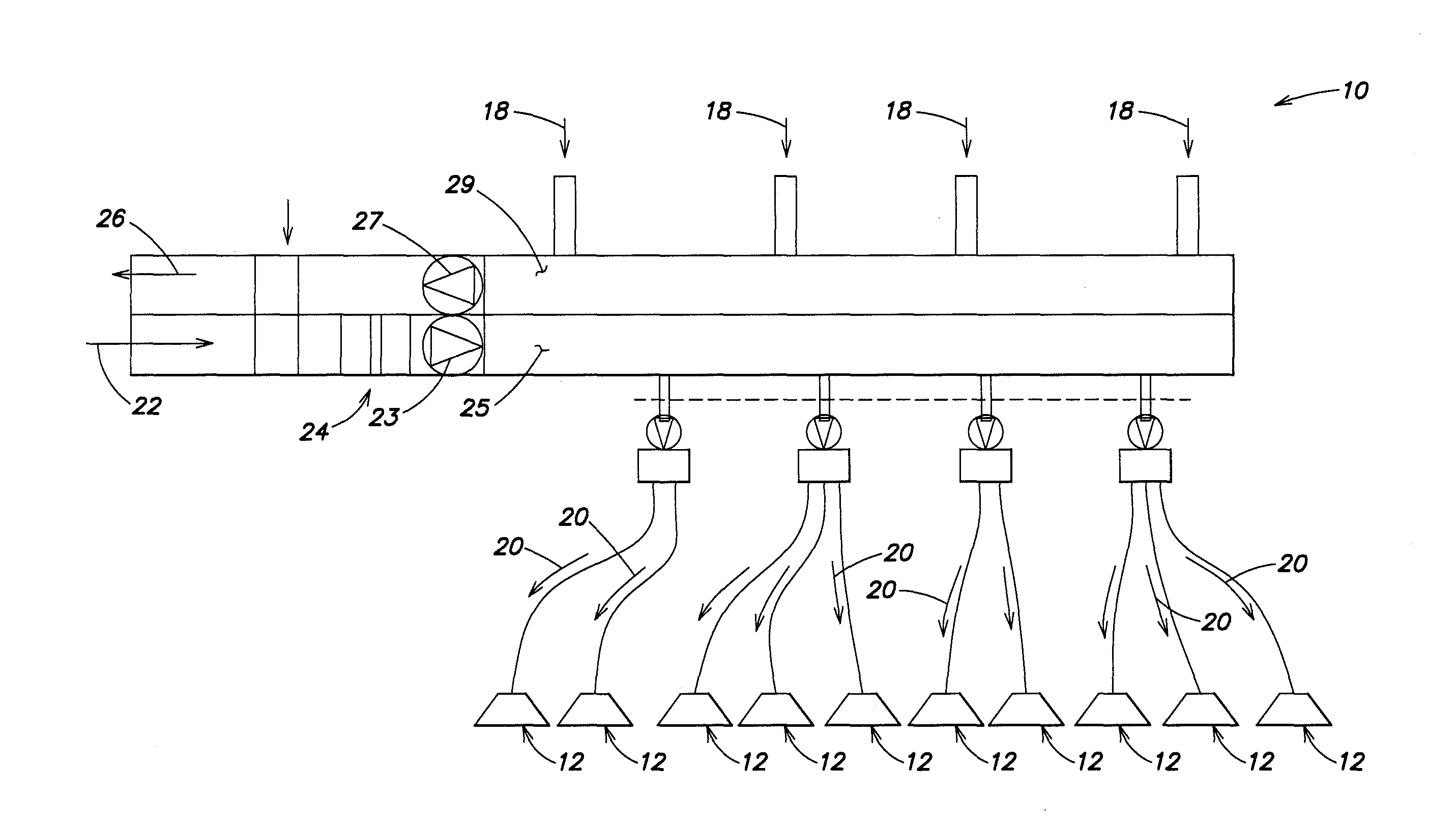

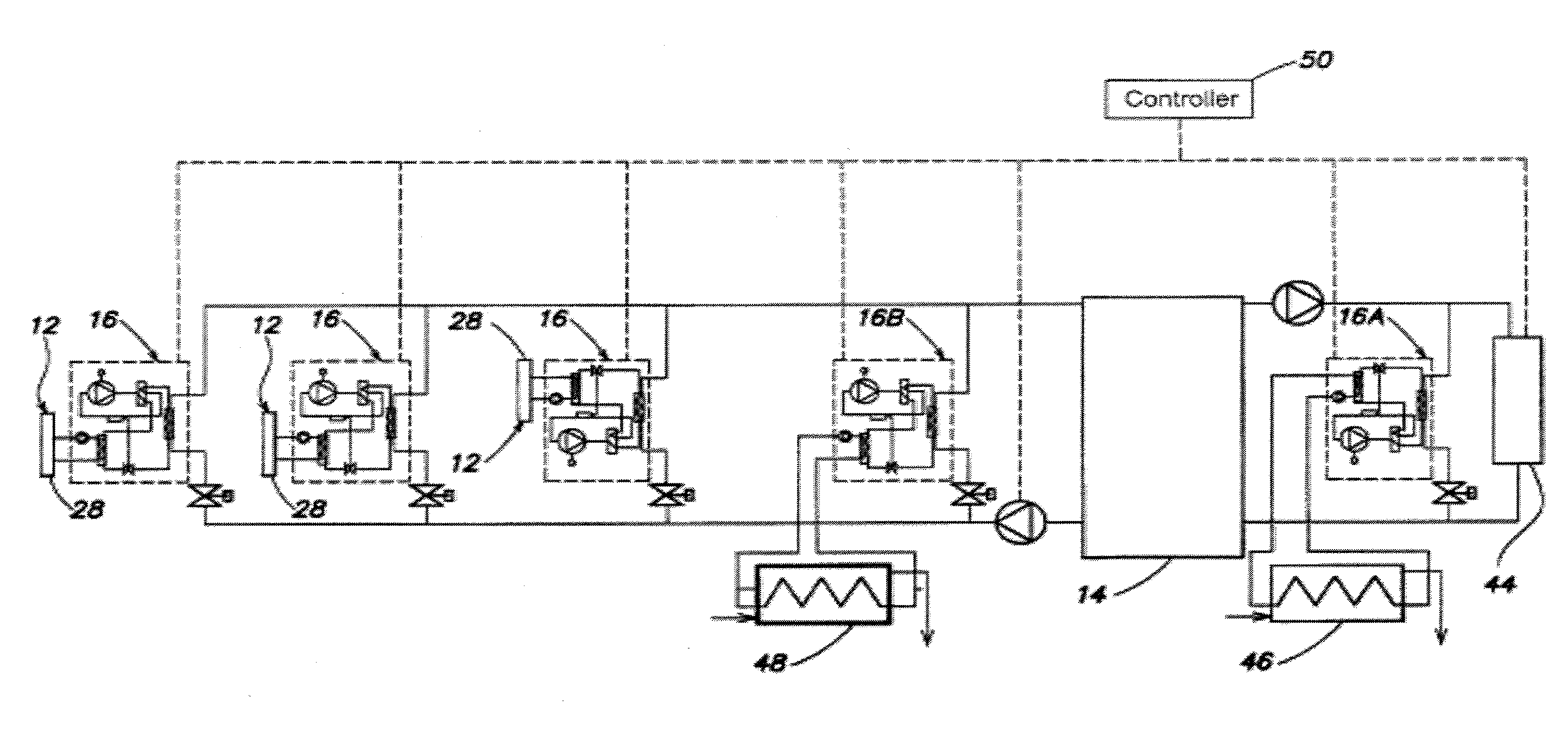

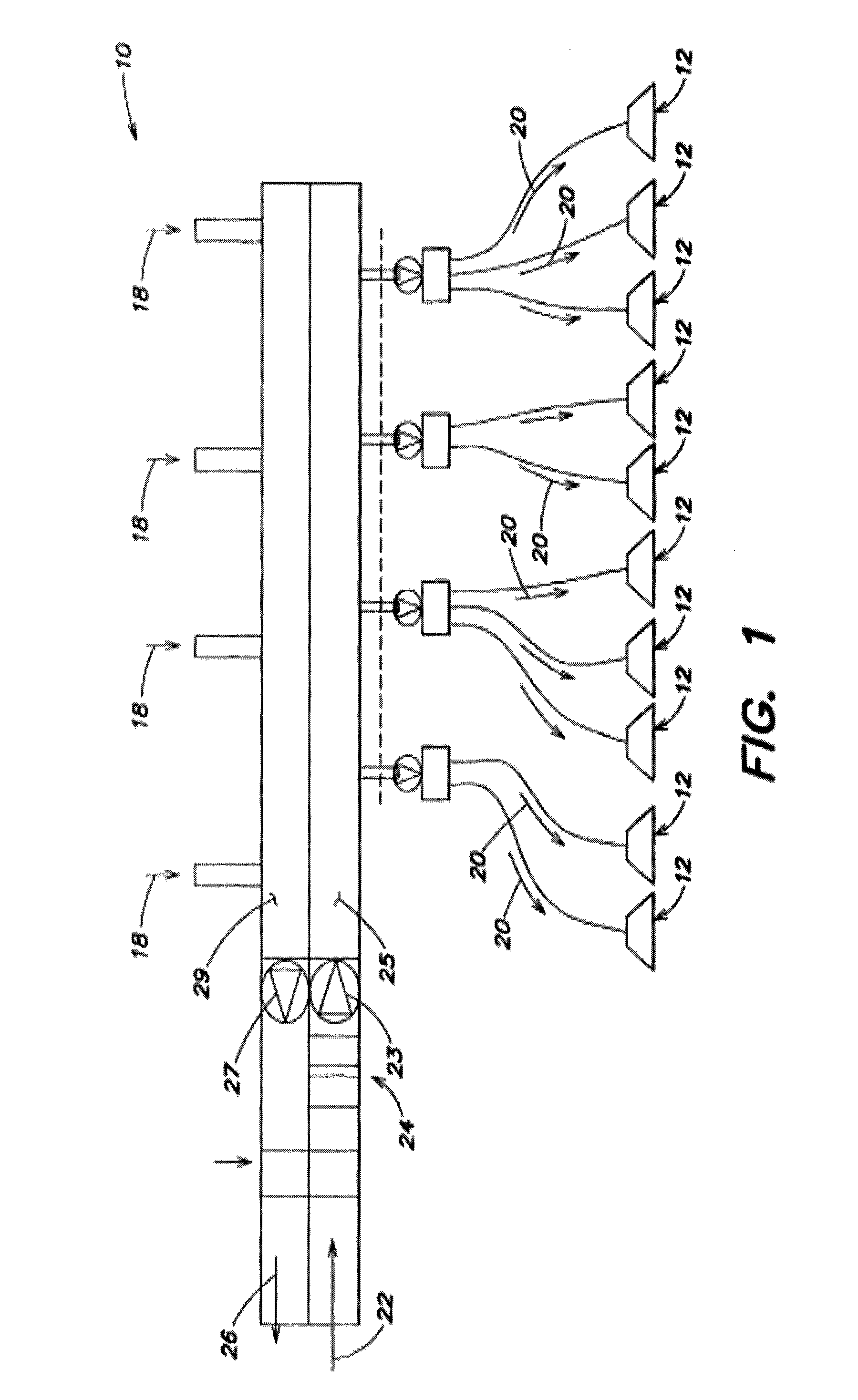

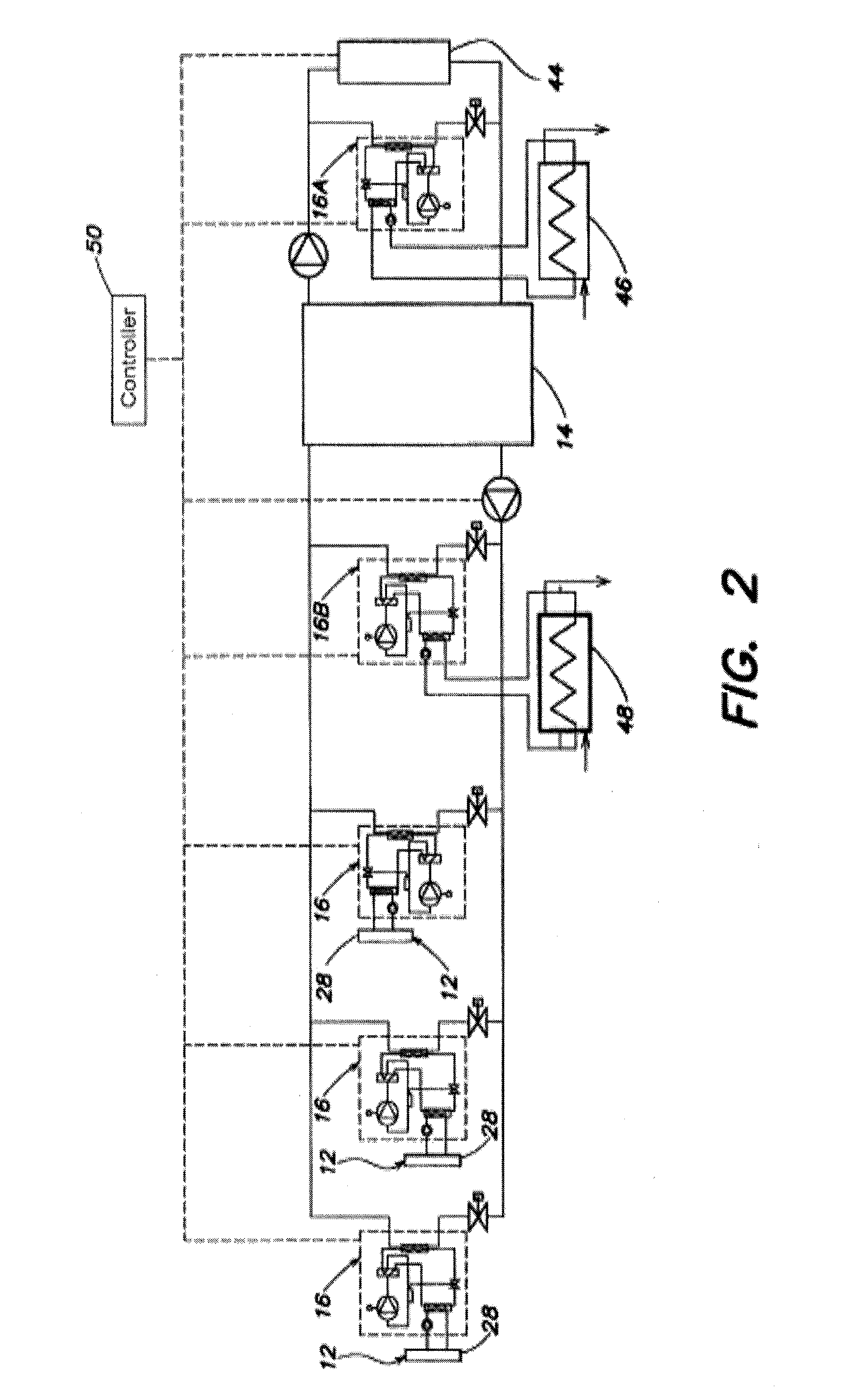

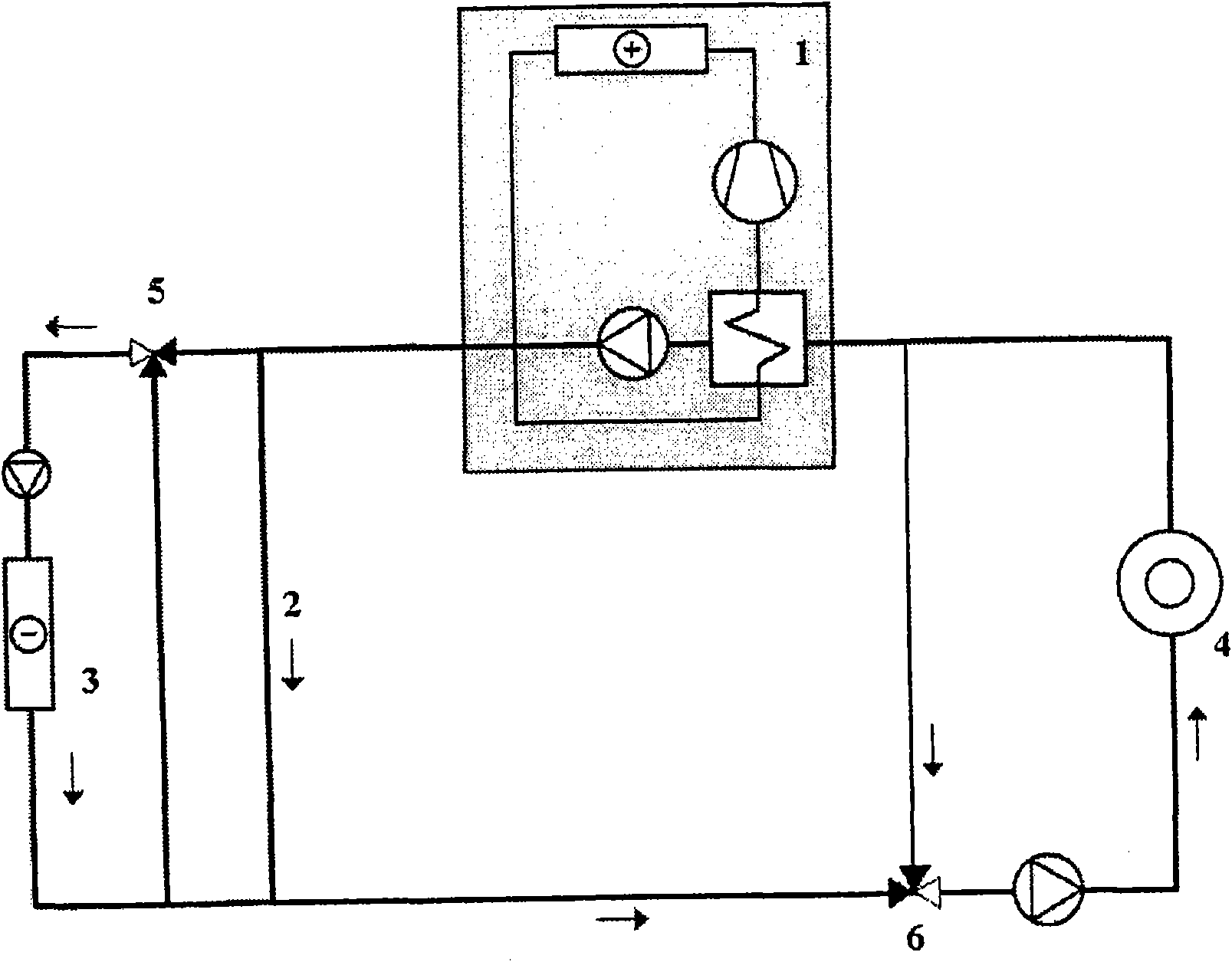

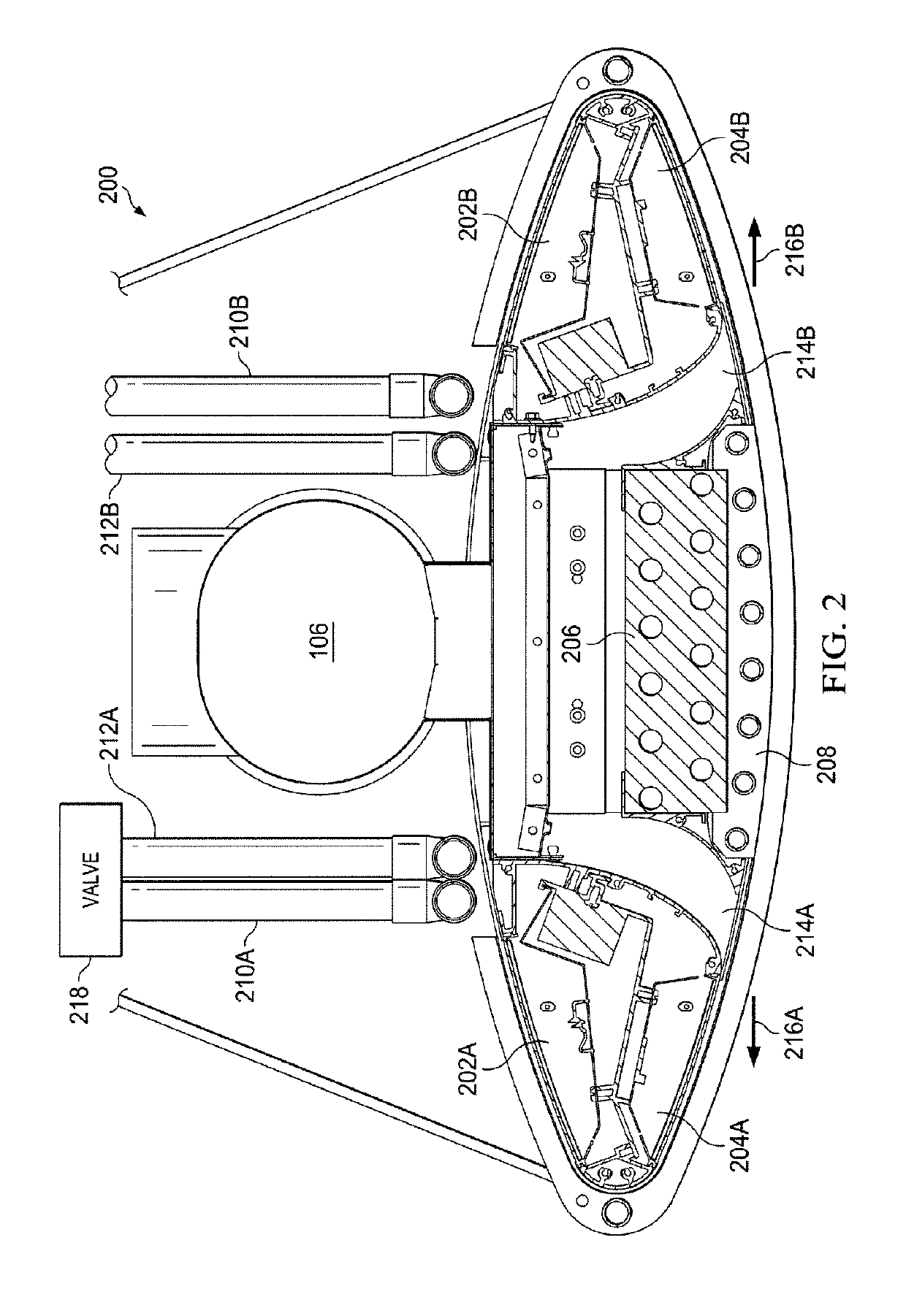

Chilled-beam zone pump modules for controlling zones of a chilled-beam heating and air conditioning system, multiple-zone chilled beam air conditioning systems for cooling multiple-zone spaces, and methods of controlling chilled beams in multi-zone air conditioning systems. Embodiments include a pump serving each zone that both recirculates water within the module and chilled beam and circulates water in and out of a chilled or warm water distribution system through valves to control temperature. Different embodiments provide heating as well as cooling, use check valves to reduce the number of control valves required, adjust the temperature of the beam to avoid condensation, change pump speed to save energy or increase capacity, can be used in two- or four-pipe systems, allow for lower installation cost, provide better performance or control, improve reliability, overcome barriers to the use of chilled beams, or a combination thereof.

Owner:SEMCO INC

Chilled beam pump module, system, and method

ActiveUS9625222B2Improve performanceSimple design and installationTemperatue controlHeat exchange apparatusWarm waterDistribution system

Chilled-beam zone pump modules for controlling zones of a chilled-beam heating and air conditioning system, multiple-zone chilled beam air conditioning systems for cooling multiple-zone spaces, and methods of controlling chilled beams in multi-zone air conditioning systems. Embodiments include a pump serving each zone that both recirculates water within the module and chilled beam and circulates water in and out of a chilled or warm water distribution system through valves to control the temperature of the water delivered to the chilled beams. Different embodiments provide heating as well as cooling, use check valves to reduce the number of control valves required, adjust the temperature of the beam to avoid condensation, change pump speed to save energy or increase capacity, can be used in two- or four-pipe systems, or a combination thereof.

Owner:SEMCO INC

Chilled Beam Air Conditioning System

InactiveUS20120118535A1Good effectAvoid condensationIndirect heat exchangersAir conditioning systemsPositive pressureEngineering

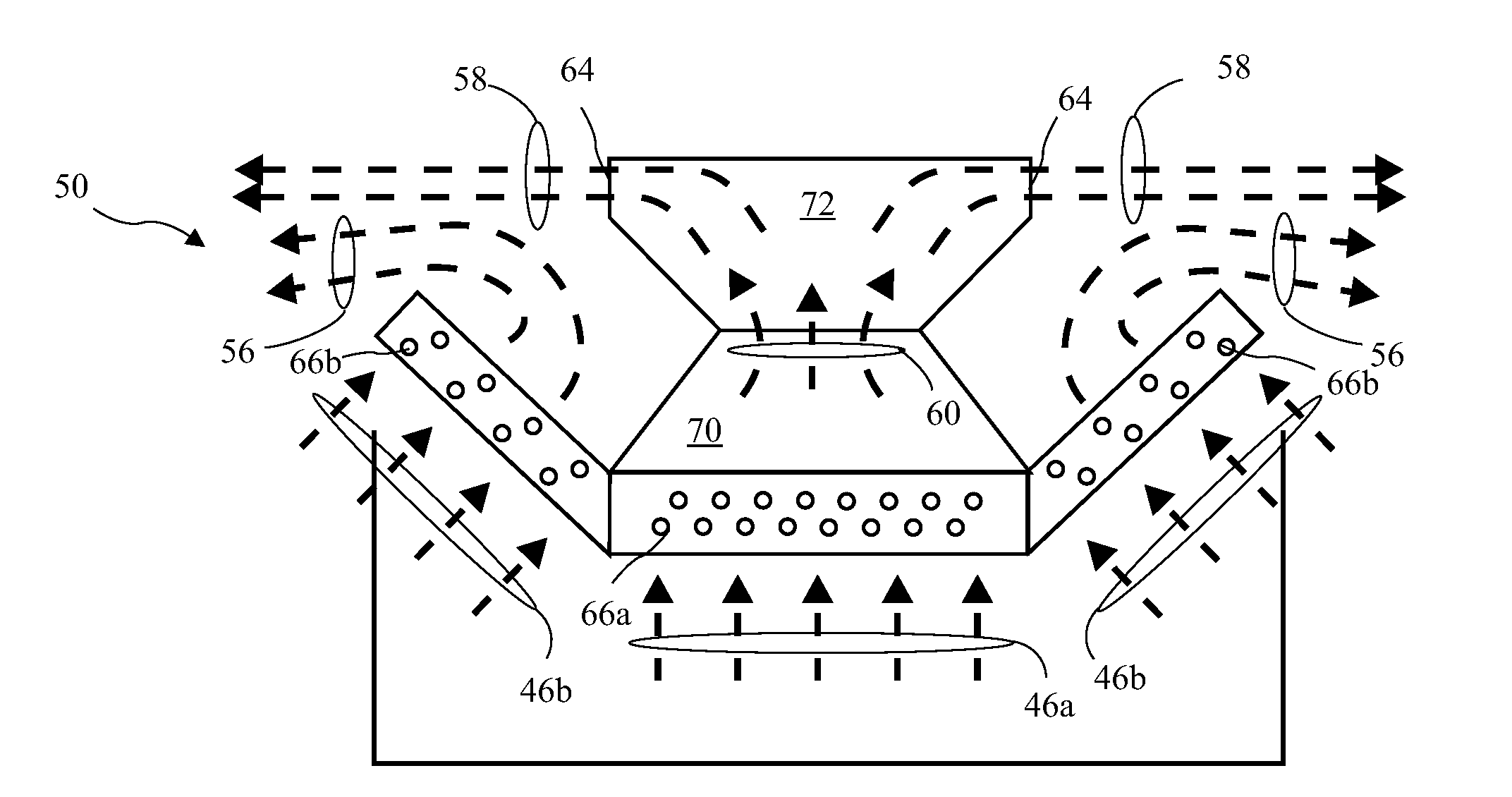

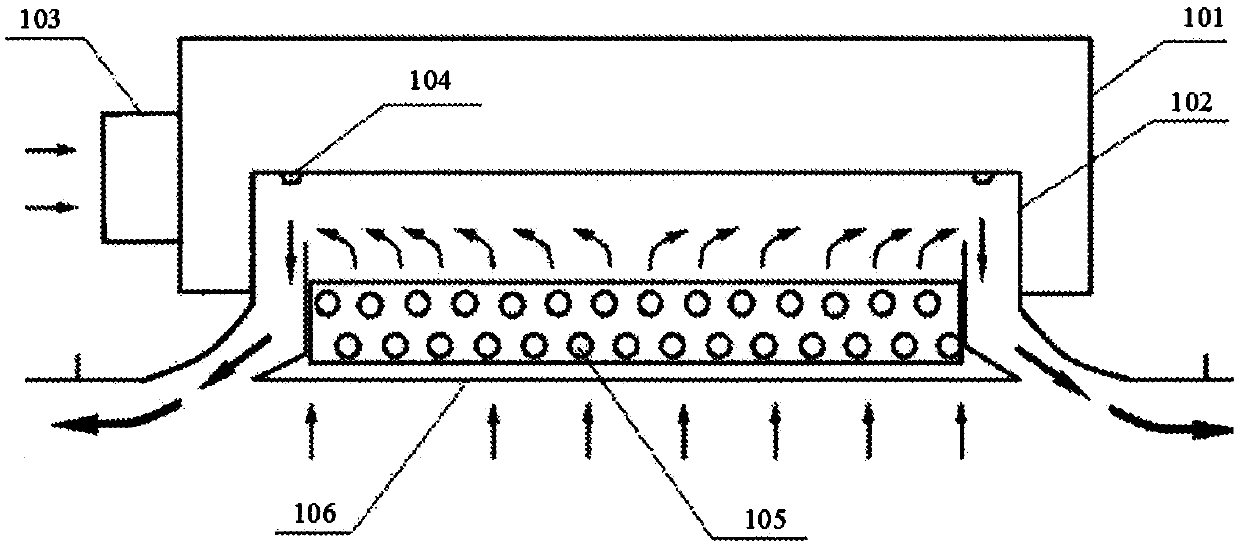

An improved chilled beam refrigeration and / or air conditioning systems uses a first chilled air flow to induce a second chilled air flow. Ambient air is drawn through first coils to produce a primary cooled air flow into an intake plenum on the suction side of a fan. The primary cooled air is drawn from the intake plenum, through the fan, and is exhausted into a discharge plenum at a positive pressure. Discharge nozzles along discharge face(s) of the discharge plenum direct the primary cooled air outward inducing a negative pressure in an area behind (or above) second coils. The negative pressure induces additional ambient air to be drawn through the second coils and cooled to provide additional cooled air. The additional cooled air mixes with the primary cooled air providing a larger refrigeration and / or air conditioning effect which would otherwise require additional motorized fans.

Owner:WILLIAMS MICHAEL

Active chilled beam and chilled beam air conditioner system

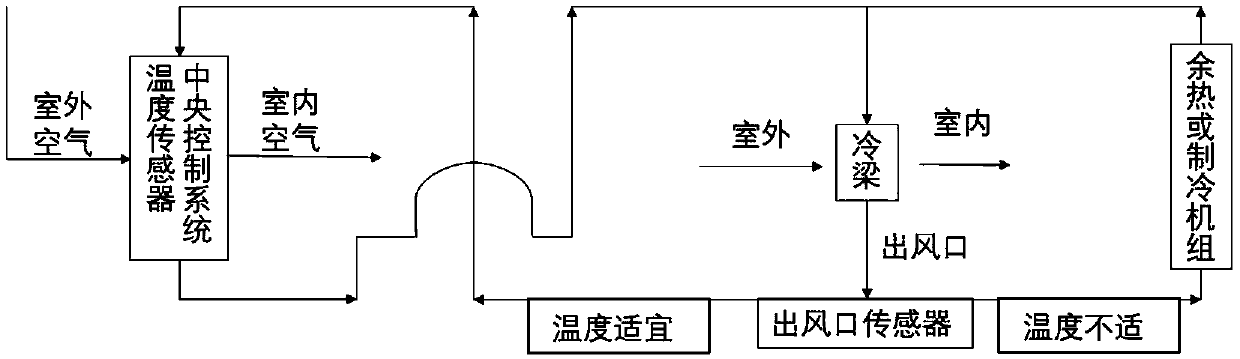

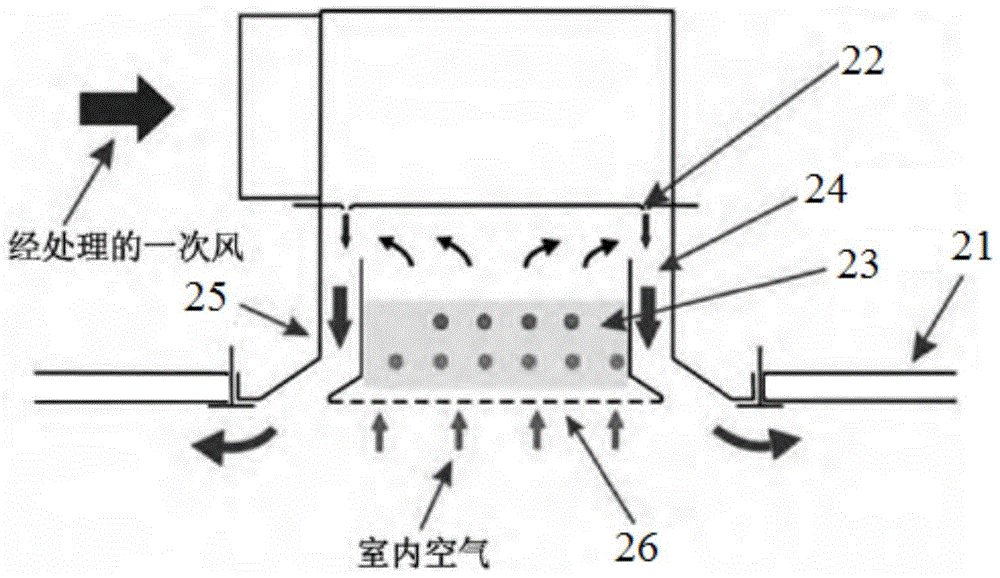

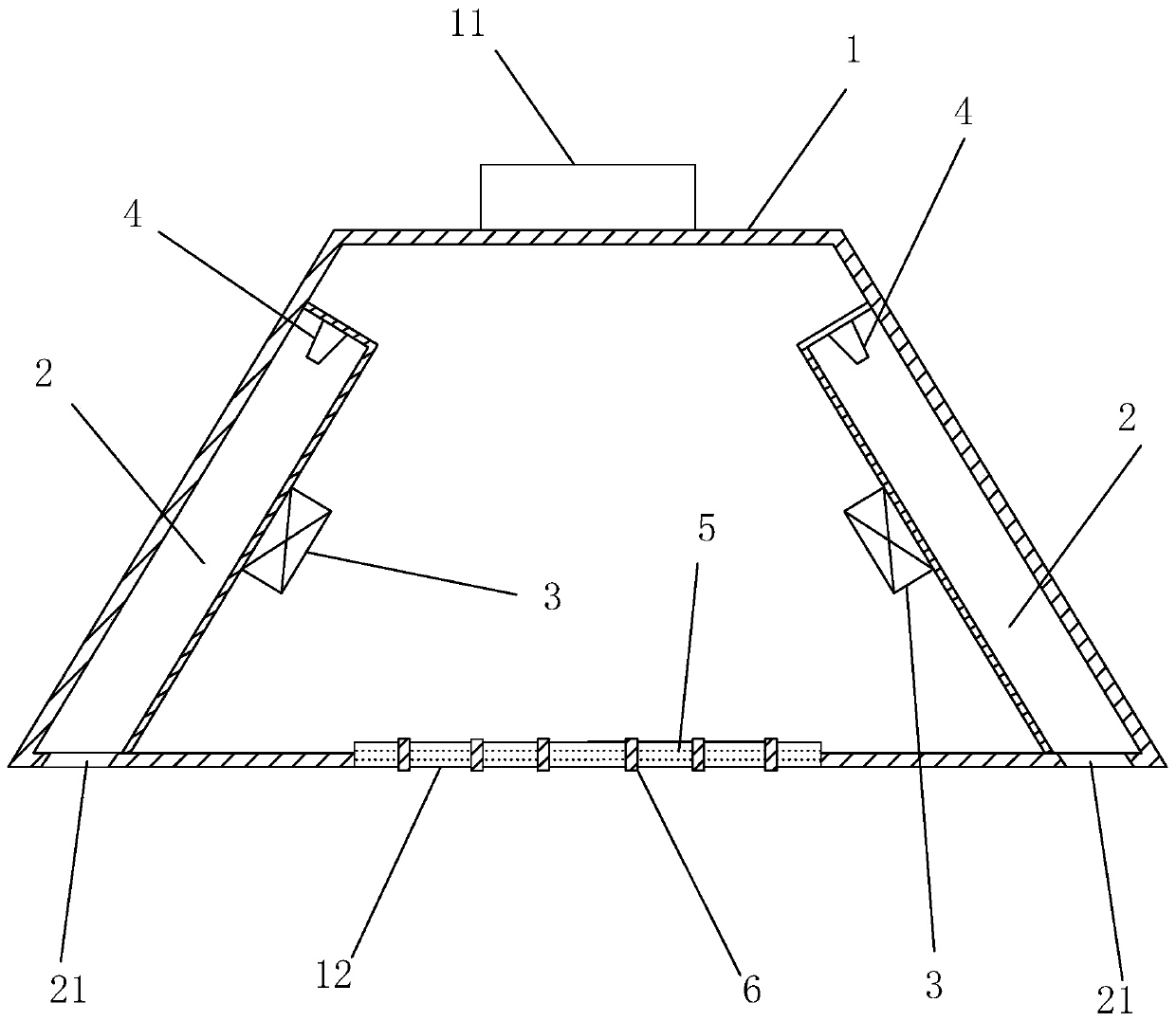

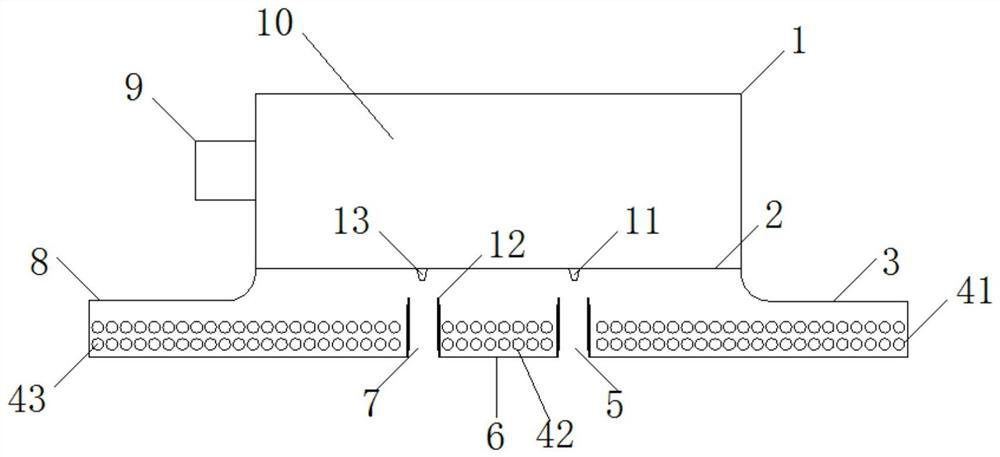

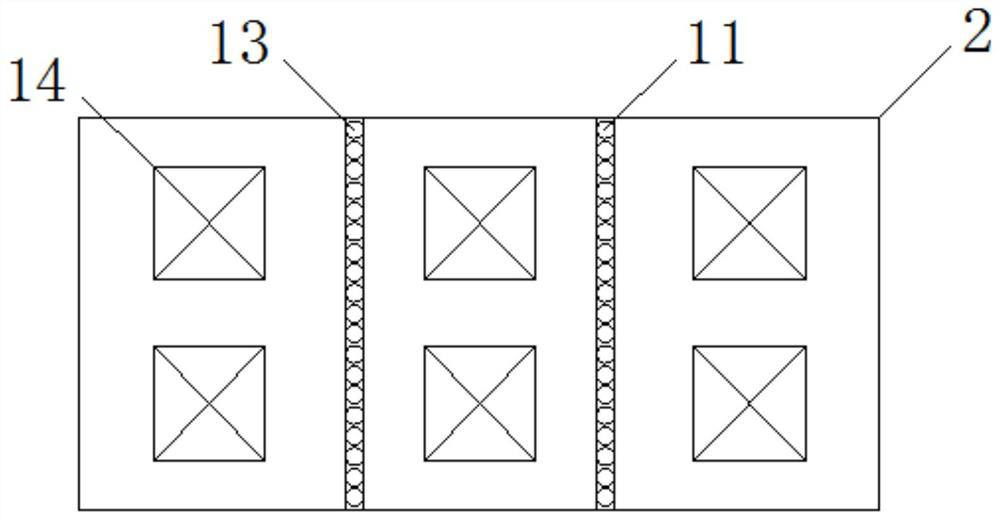

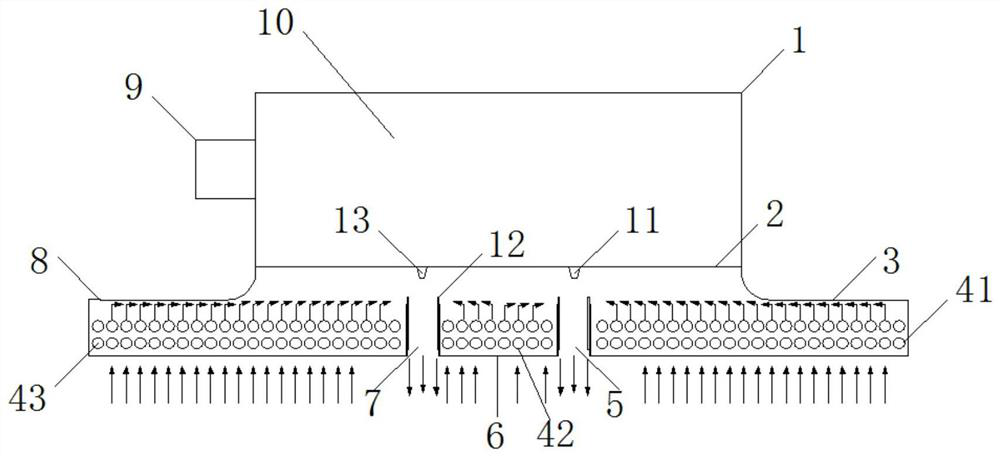

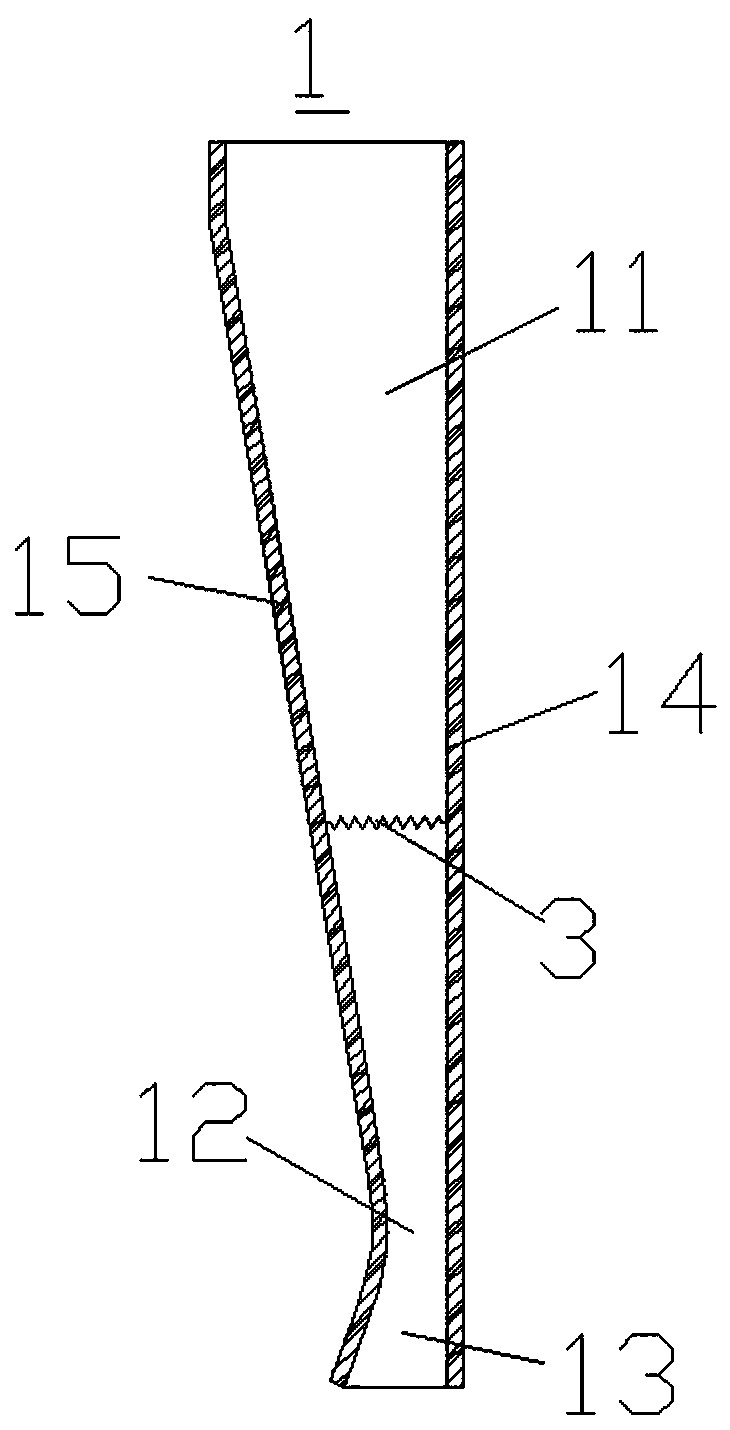

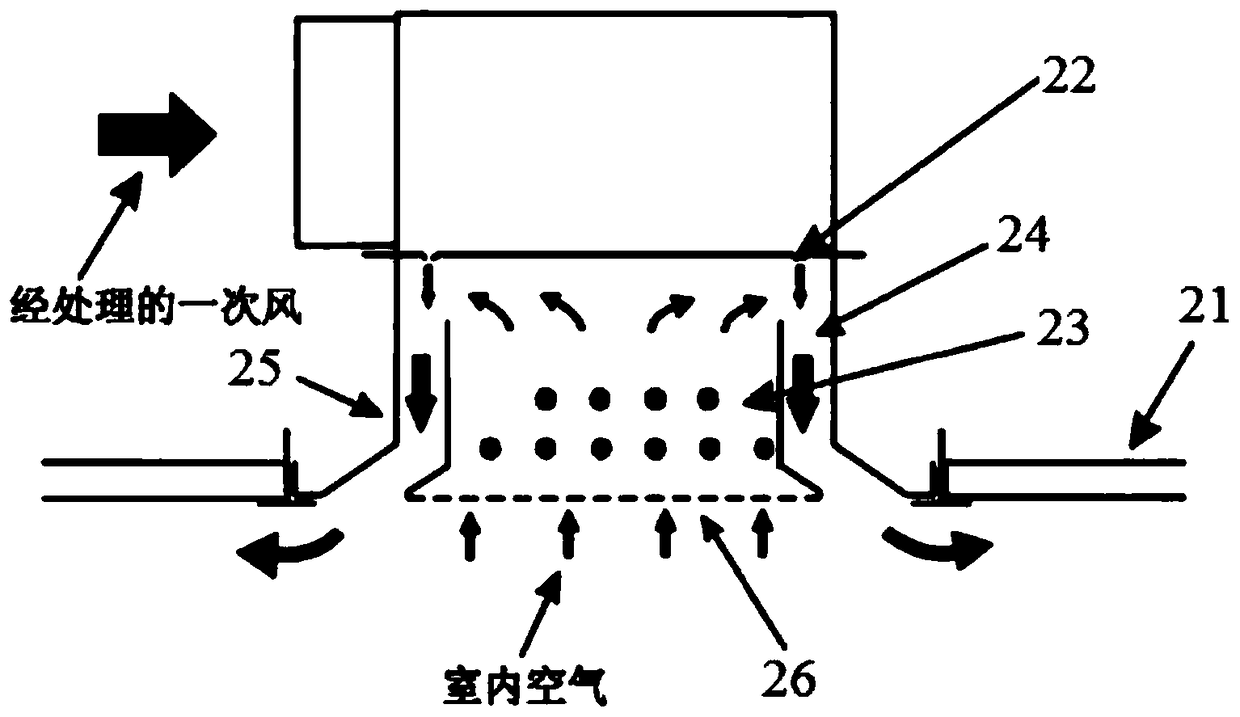

PendingCN107816755ARealize personalized air supplyNo cooling load requiredMechanical apparatusSpace heating and ventilation safety systemsEngineeringChilled beam

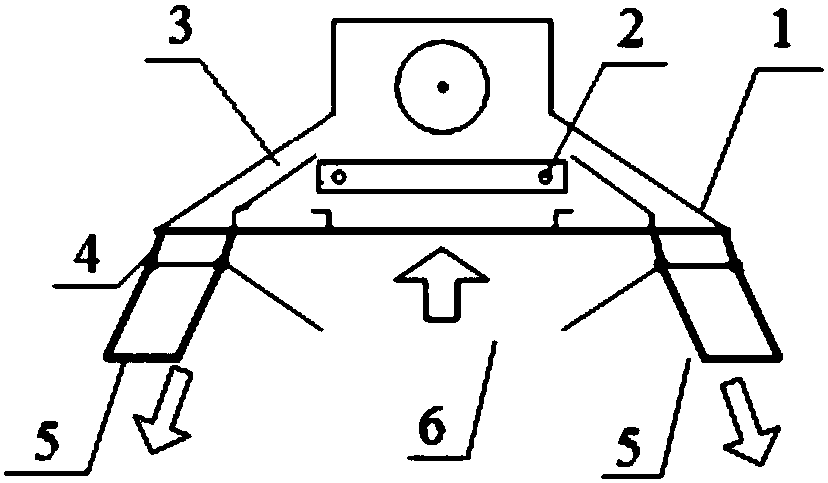

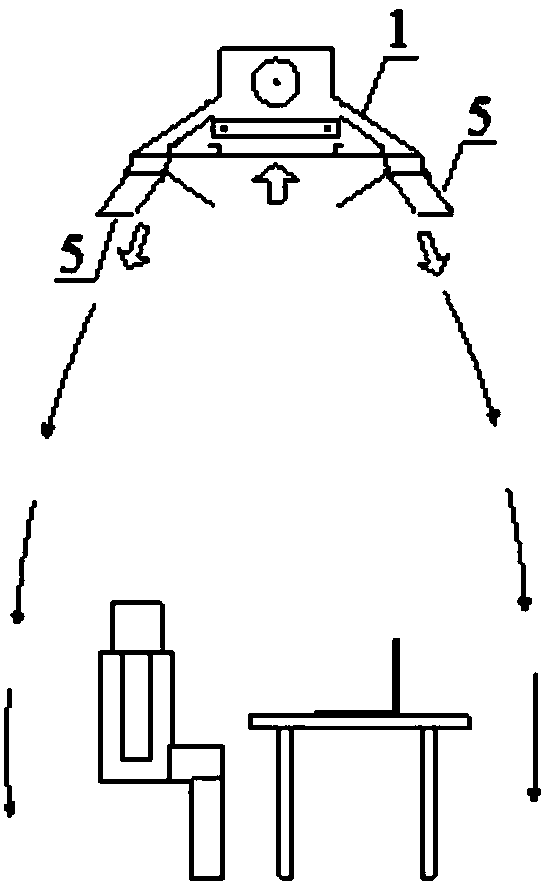

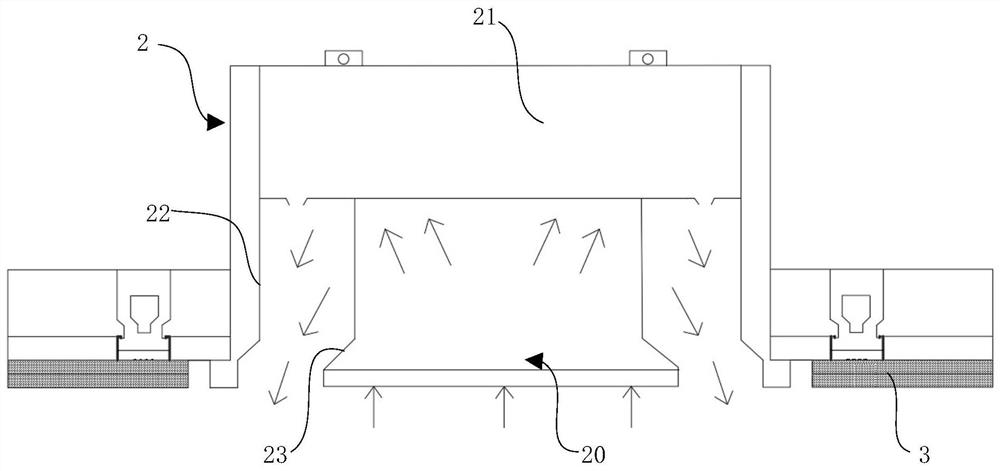

The invention provides an active chilled beam. The active chilled beam comprises a shell body, an air inlet is formed in the bottom of the shell body, and air outlets are formed in the two sides of the shell body; the shell body is internally provided with air outlet channels and heat exchanging coils, wherein the air outlet channels and the heat exchanging coils communicate with the air outlets;and rotatable air guiding wing plates are arranged at the air outlets. On the one hand, the cooling load of all indoor areas is not required to be borne, and the active chilled beam only acts on the indoor specific guaranteed area, so that energy consumption is saved; and on the other hand, the size and the position of the indoor specific guaranteed area can be adjusted by changing the angles of the air guiding wing plates so that the indoor specific guaranteed area can be changed along with indoor personnel activities, and comfortableness is ensured. The invention further provides a chilled beam air conditioner system. The chilled beam air conditioner system comprises a natural energy collecting device and the active chilled beam; and water outlet pipes of the natural energy collecting device are connected with water inlets of the heat exchanging coils, and the natural energy collecting device is used for providing cold water to the heat exchanging coils. Natural energy resources canbe fully utilized to save energy, and the requirement of indoor thermal comfortableness is met.

Owner:TSINGHUA UNIV

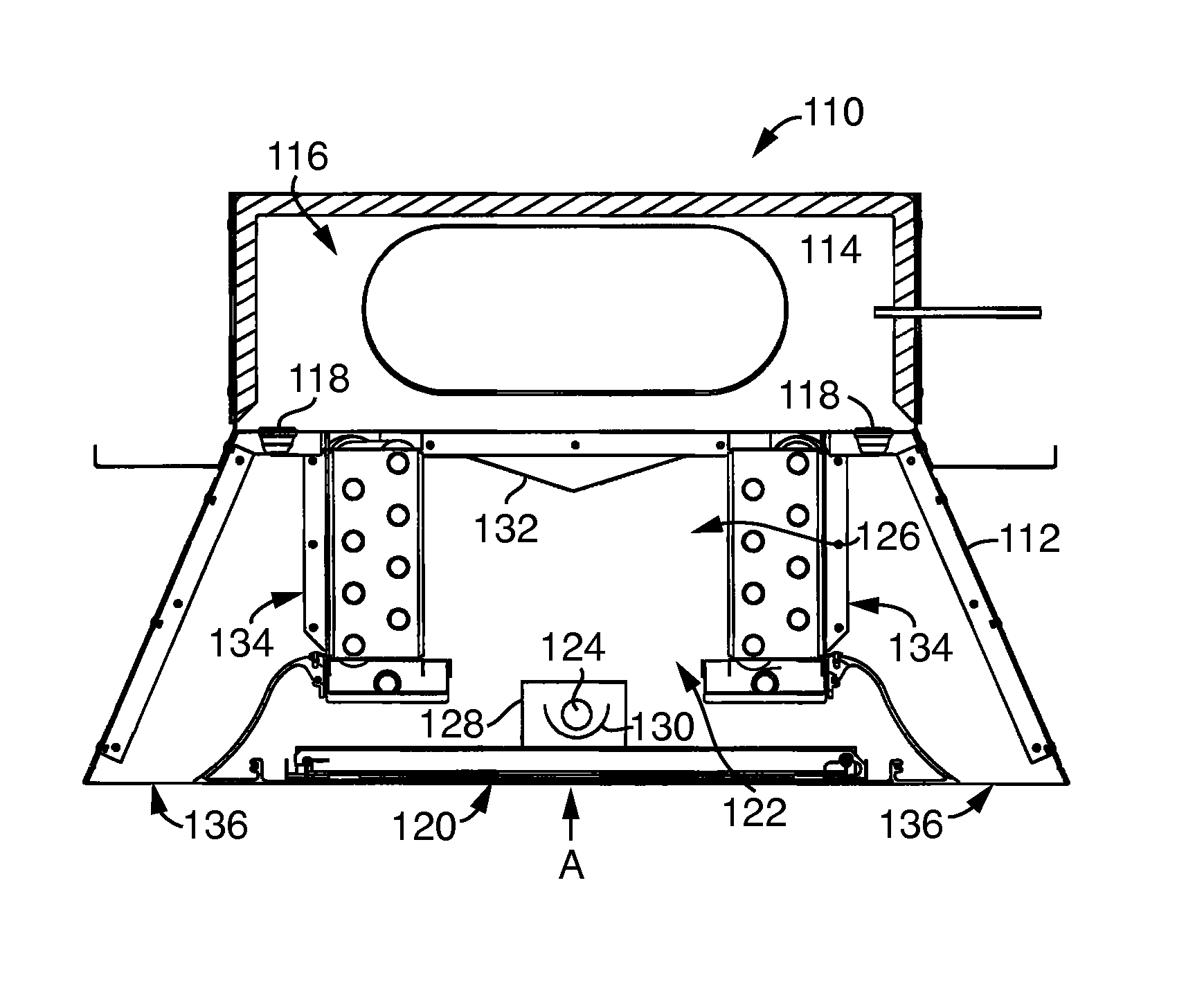

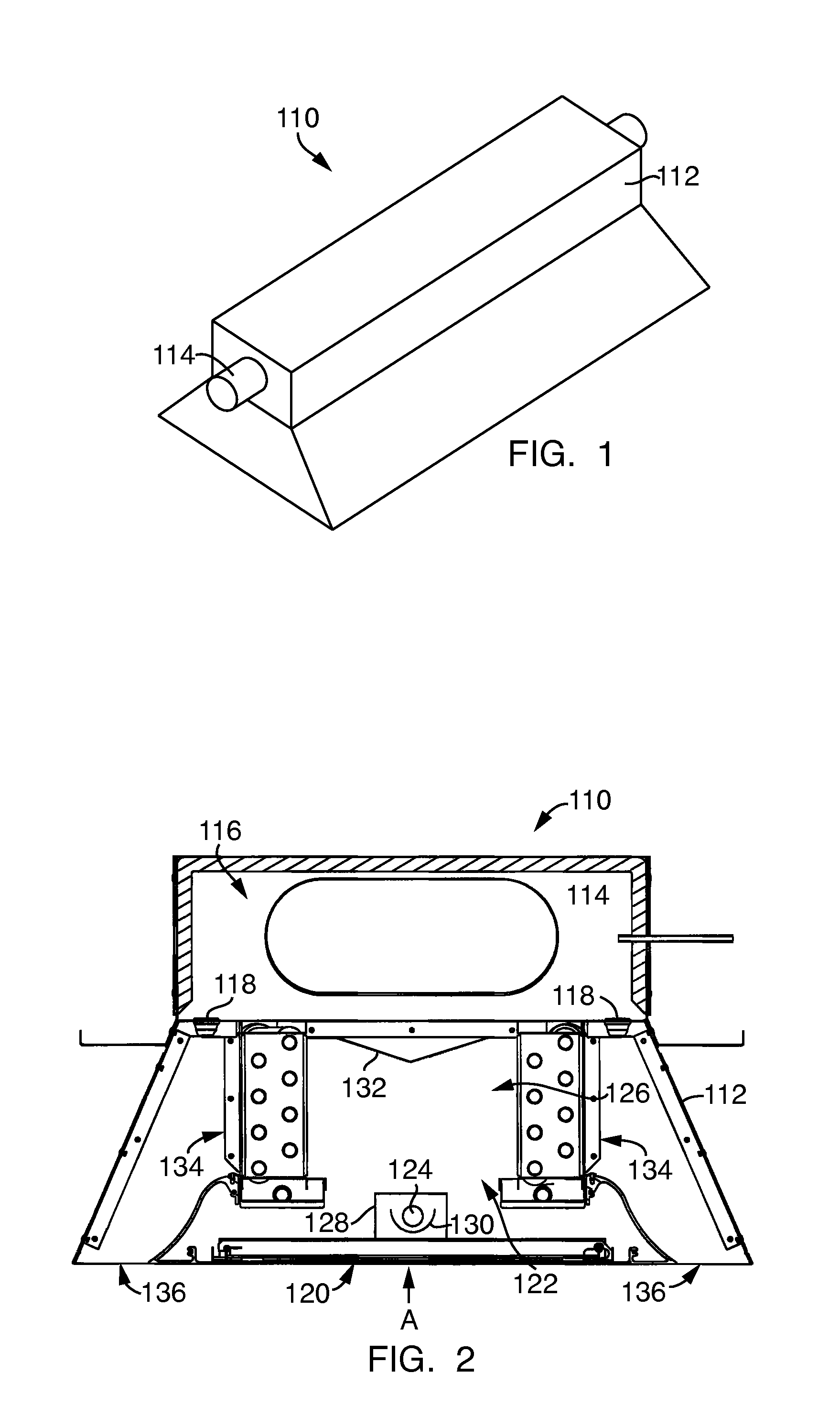

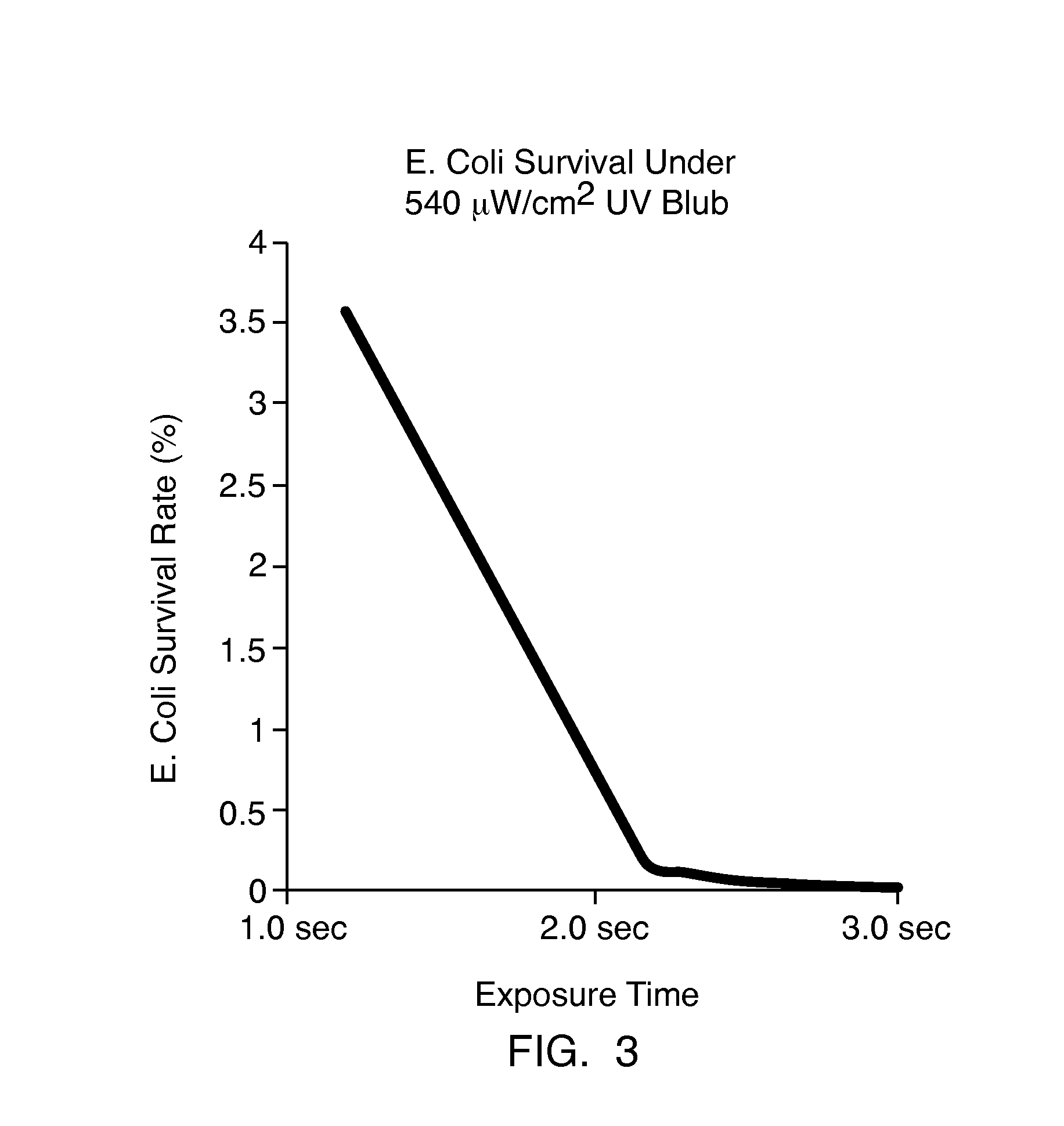

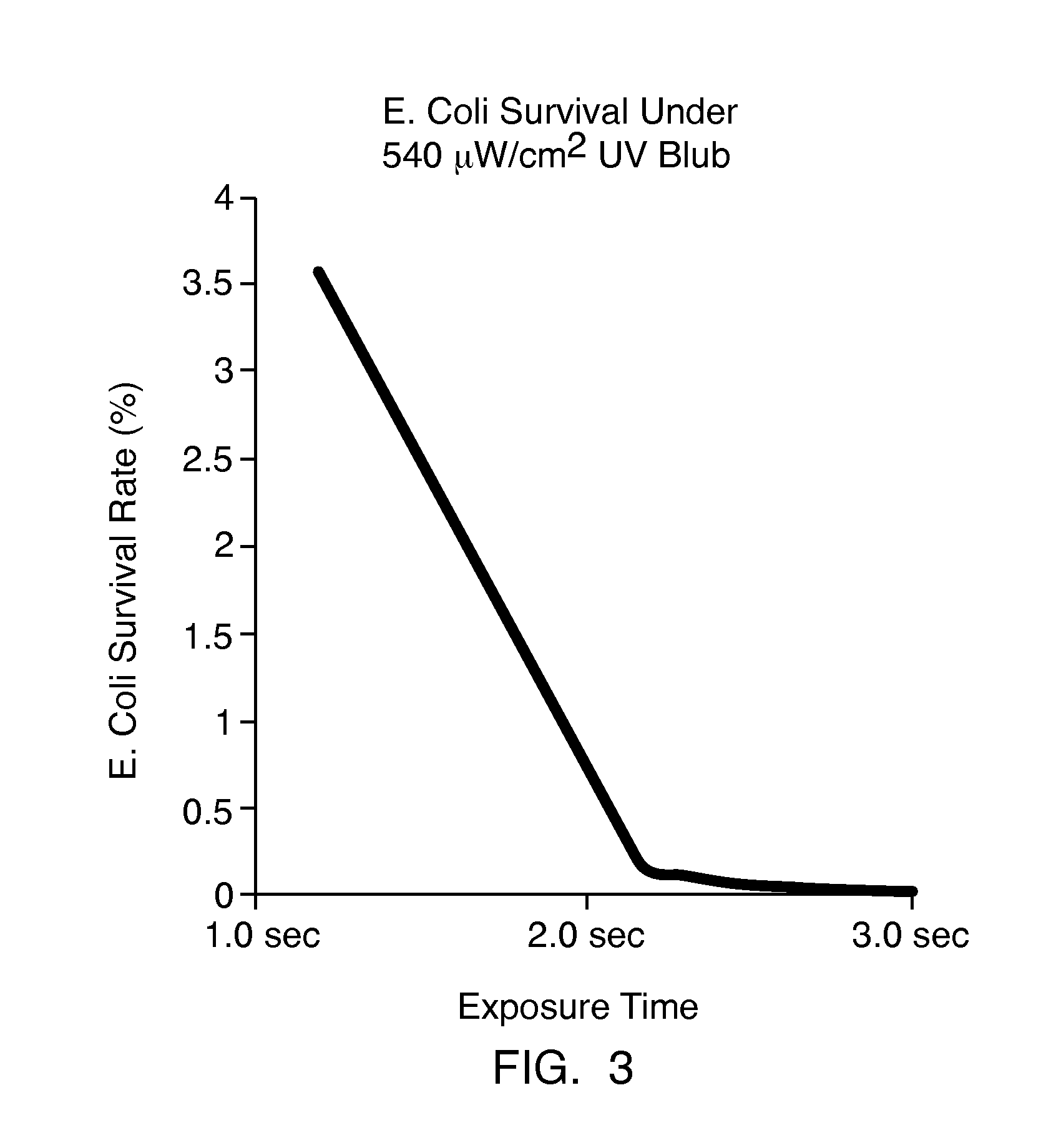

Active chilled beam with sterilization means

InactiveUS20130213061A1Extended stayReduce leakageMechanical apparatusDomestic cooling apparatusChilled beamWaste management

Owner:MESTEK

System and apparatus for conditioning of indoor air

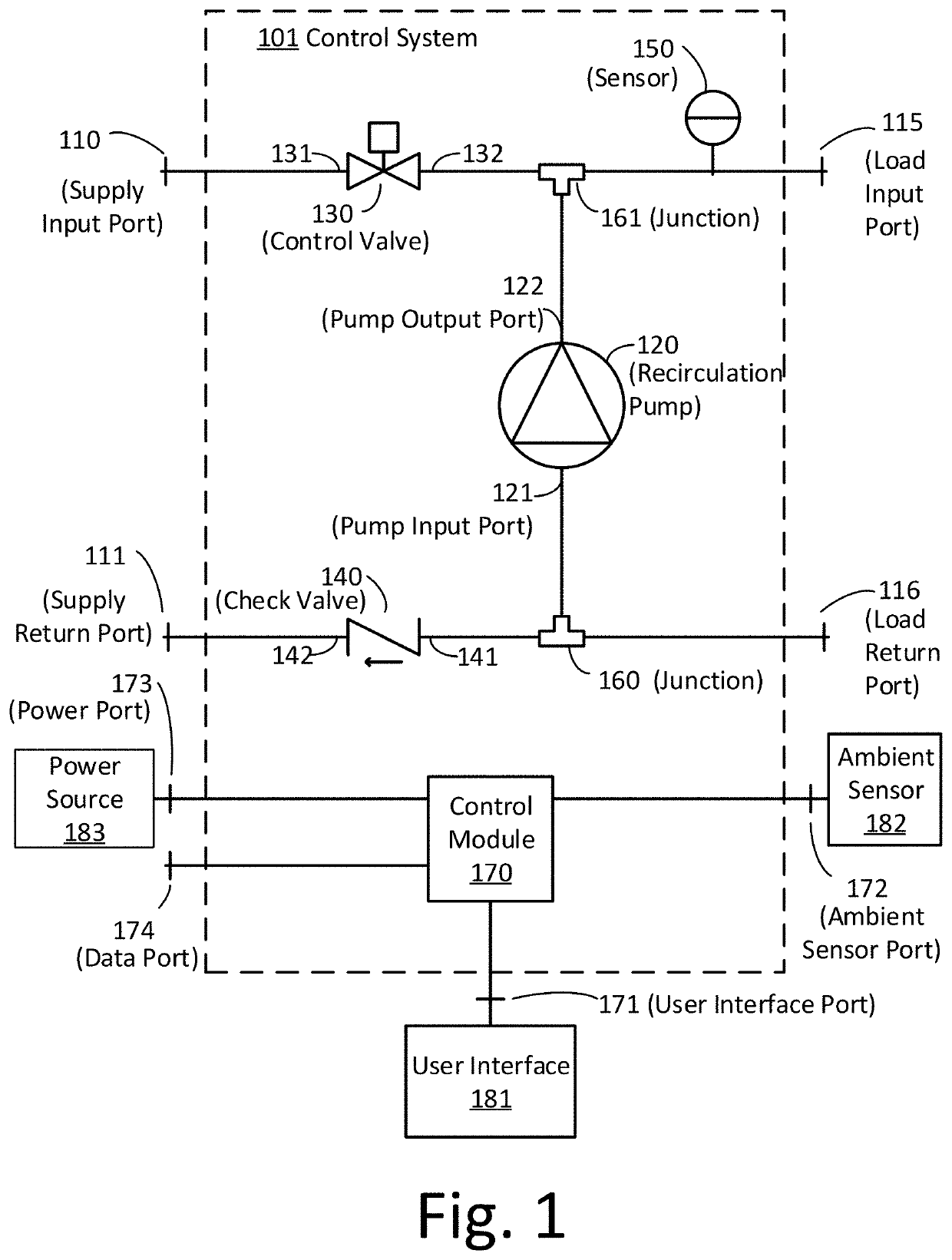

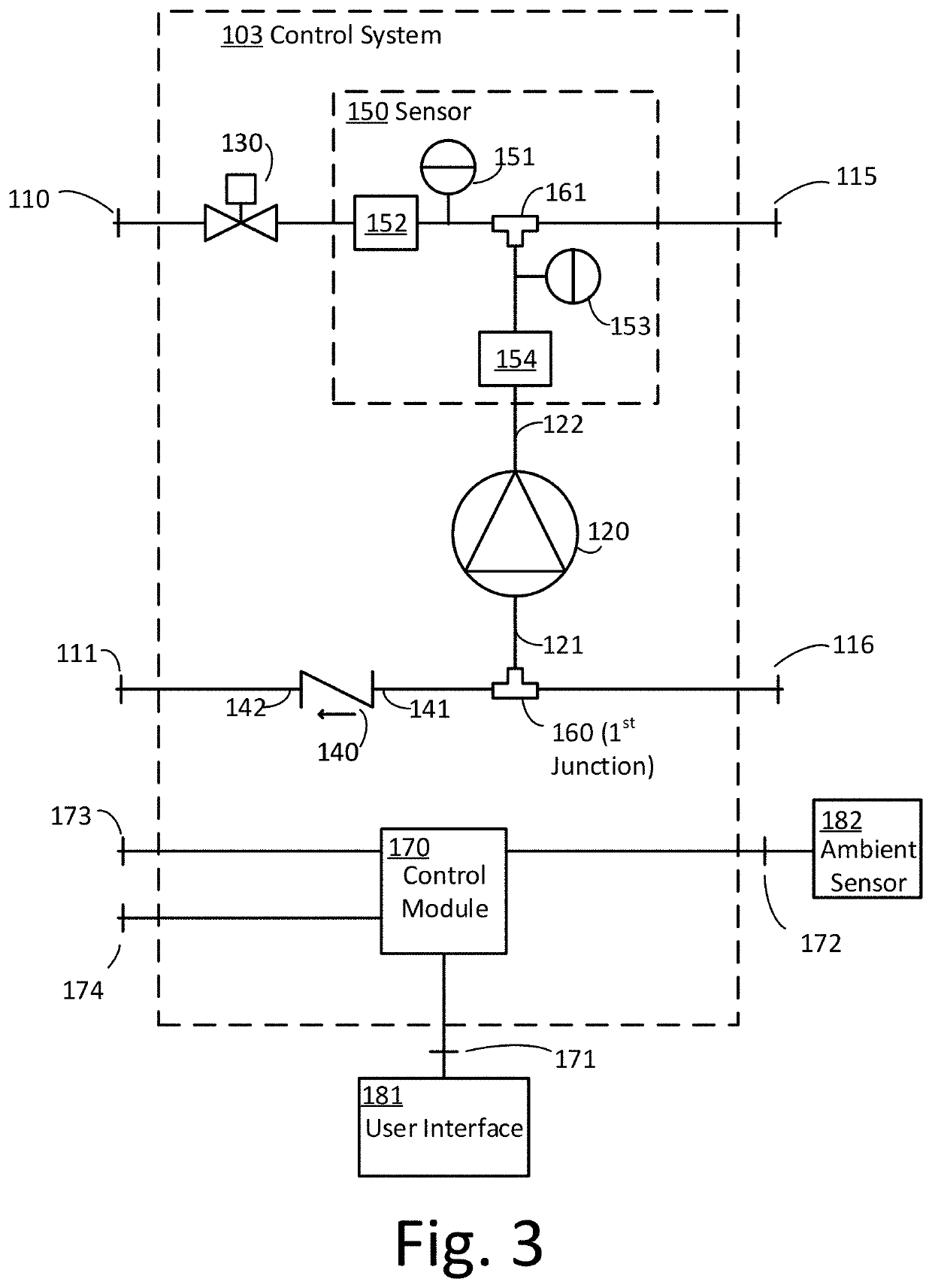

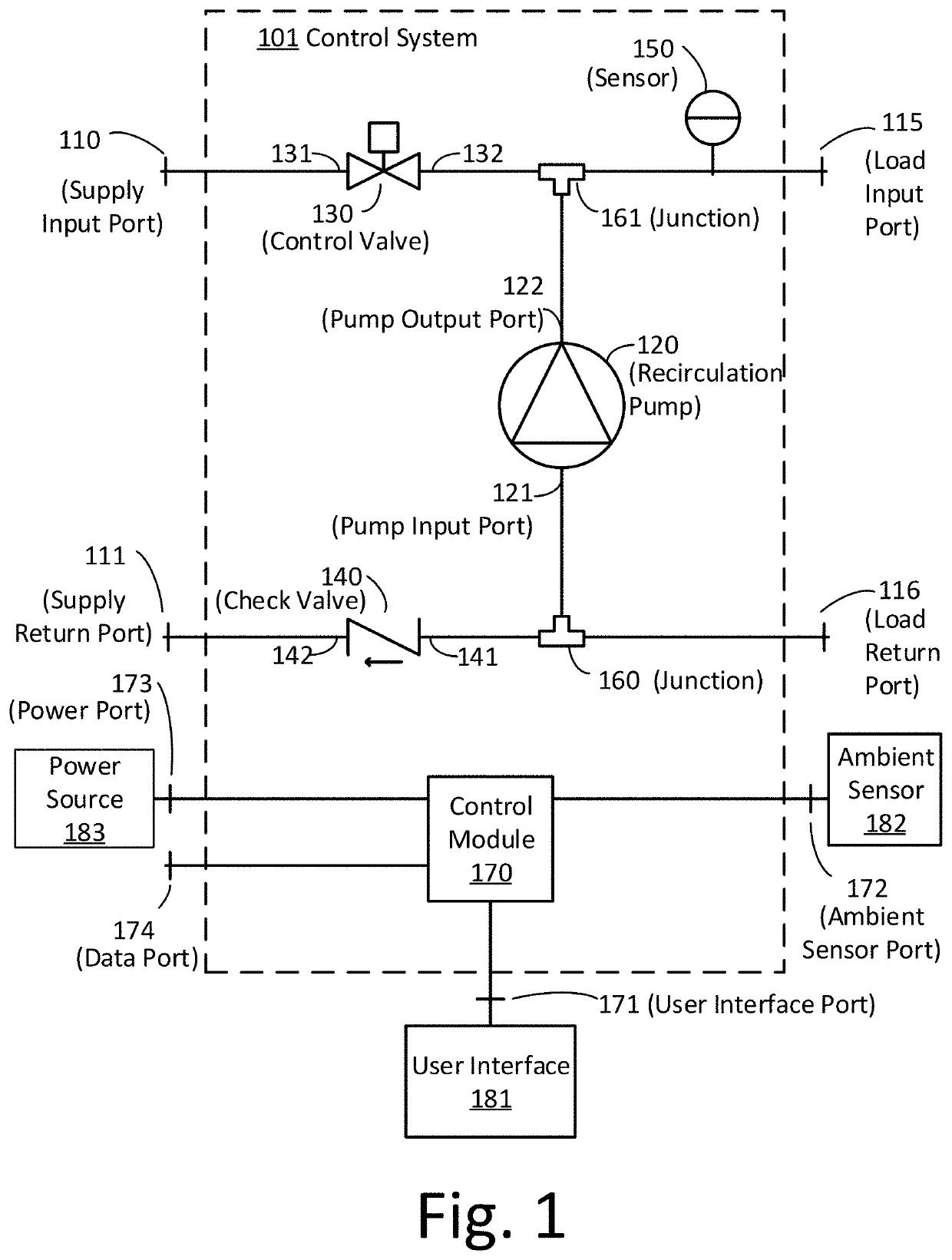

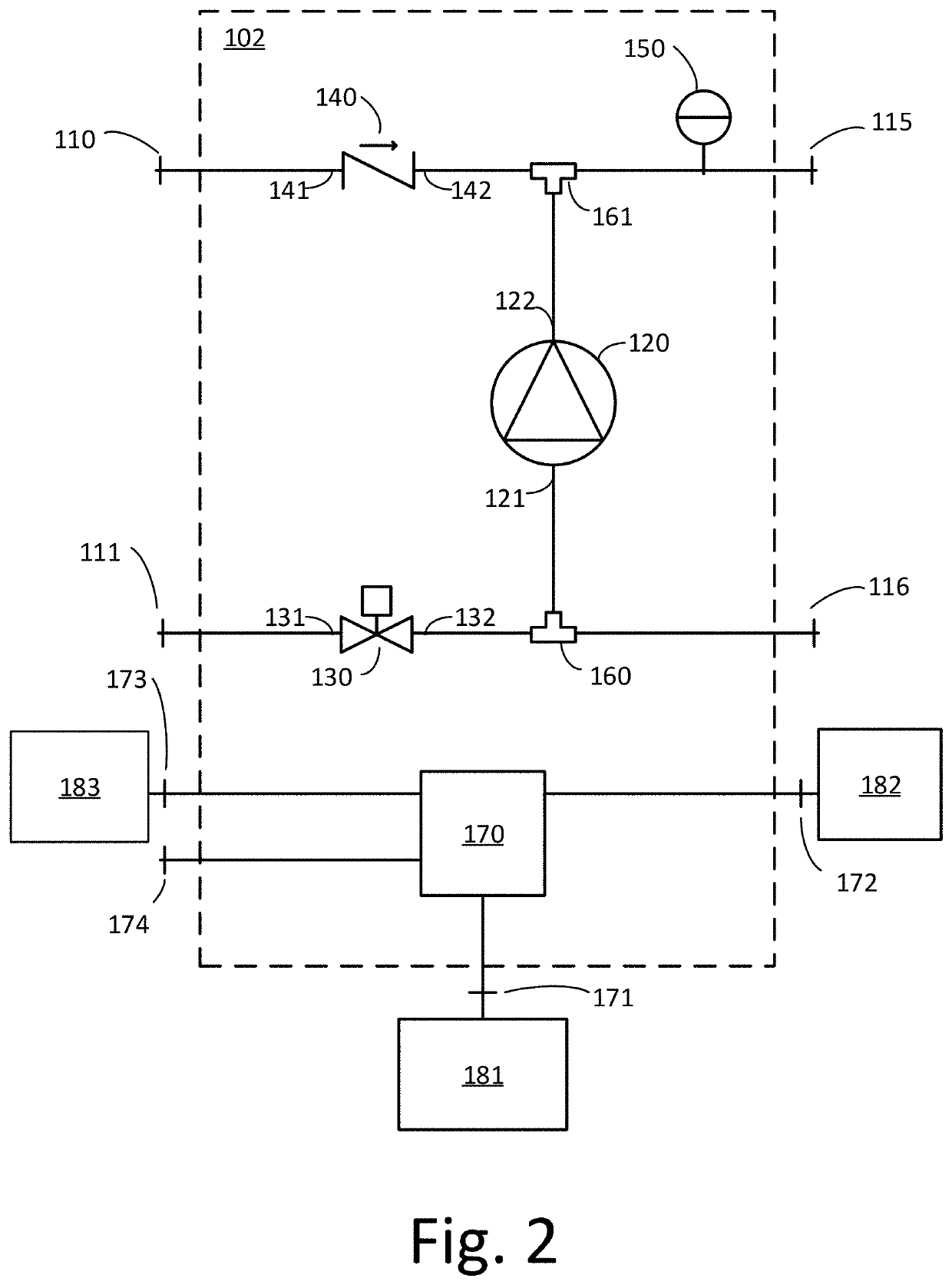

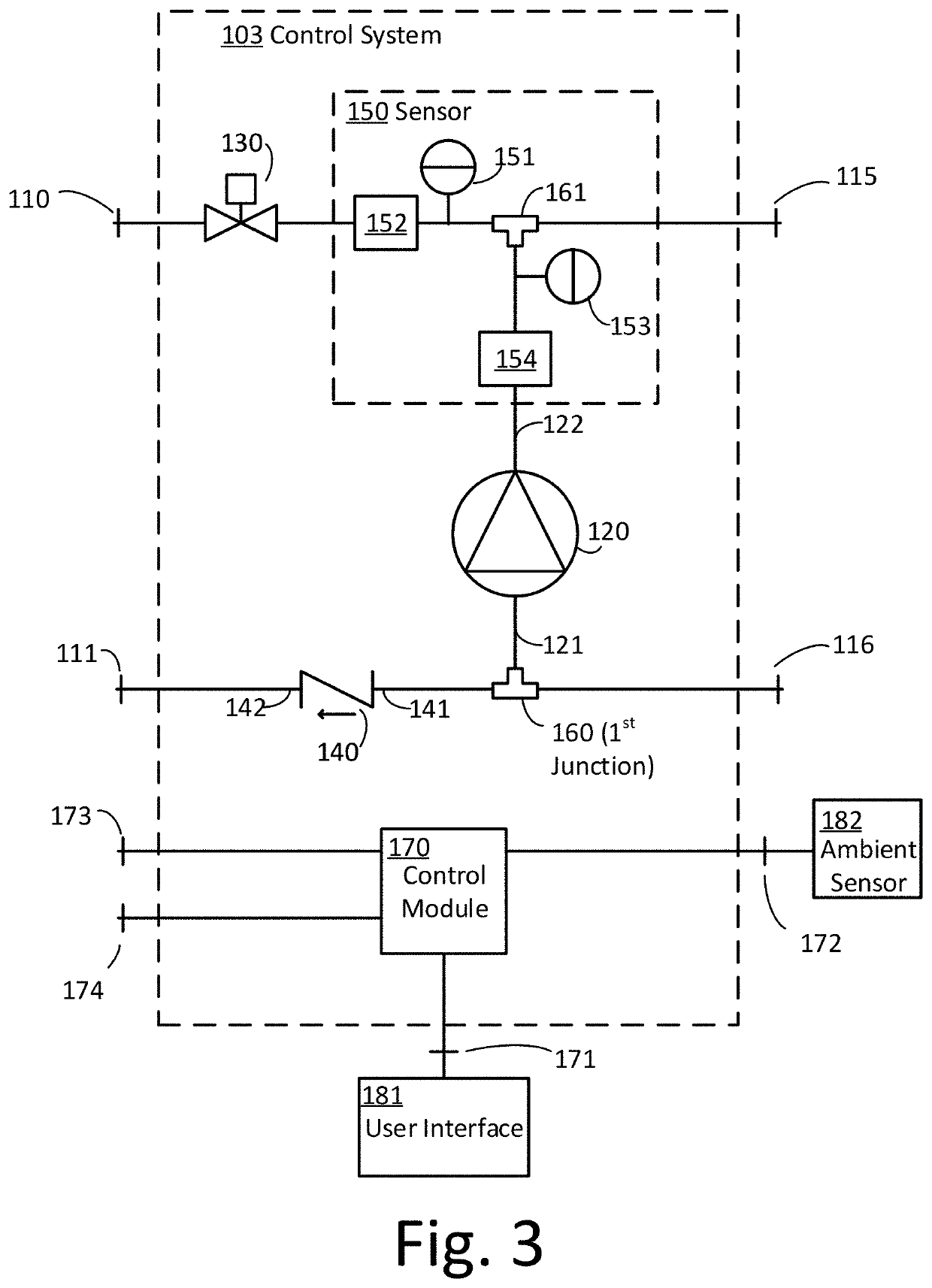

ActiveUS11054167B2Shorten the timeControl flowMechanical apparatusSpace heating and ventilation safety systemsTemperature controlControl system

A control system is provided for controlling heating and / or cooling with a conditioning load such as fan coils and chilled beams. Based on user input and ambient conditions, the control system determines a desired temperature for the liquid entering the load and combines fresh supply liquid (e.g., from a chiller or boiler) with a portion of the liquid that has passed through the load, to achieve the target load input temperature for the liquid. A recirculation pump may be used to return a portion of the liquid exiting the load for mixing with the fresh supply liquid and a control valve may be used to adjust the ratio of fresh supply liquid and recirculated liquid to achieve the targeted temperature. The control systems can be compatible with a variety of liquid supply systems such as two- and four-pipe systems.

Owner:CHILLED BEAM CONTROLS LLC

Method for using outdoor air to cool room devices

InactiveCN101576304AEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsChilled beamWaste management

Owner:FLKT WOODS AB

System and method for maintaining air temperature within a building HVAC system

ActiveUS20120245739A1Temperatue controlStatic/dynamic balance measurementWater storageControl system

A system and method for conditioning air within an air handling system of a building is provided. The building has a hot water source and a cold water source. The conditioning system includes at least one heating-cooling unit connected to the air handling system, a primary water storage device, at least one heat pump, and a controller. The heating-cooling unit, which includes at least one chilled beam, is operable to transfer heat into or out of air passing within the air handling system of the building. The primary water storage device is operable to store a volume of water within a predetermined temperature range. The primary water storage device is in communication with the hot water source and the cold water source. The heat pump is connected to the primary water storage device and the chilled beam. The controller is adapted to selectively drive the heat pump to transfer heat between the primary water storage device and the chilled beam. The controller is also adapted to selectively control the system to transfer heat into or out of the primary water storage device to maintain the water within the primary storage device within the predetermined temperature range.

Owner:CARRIER CORP

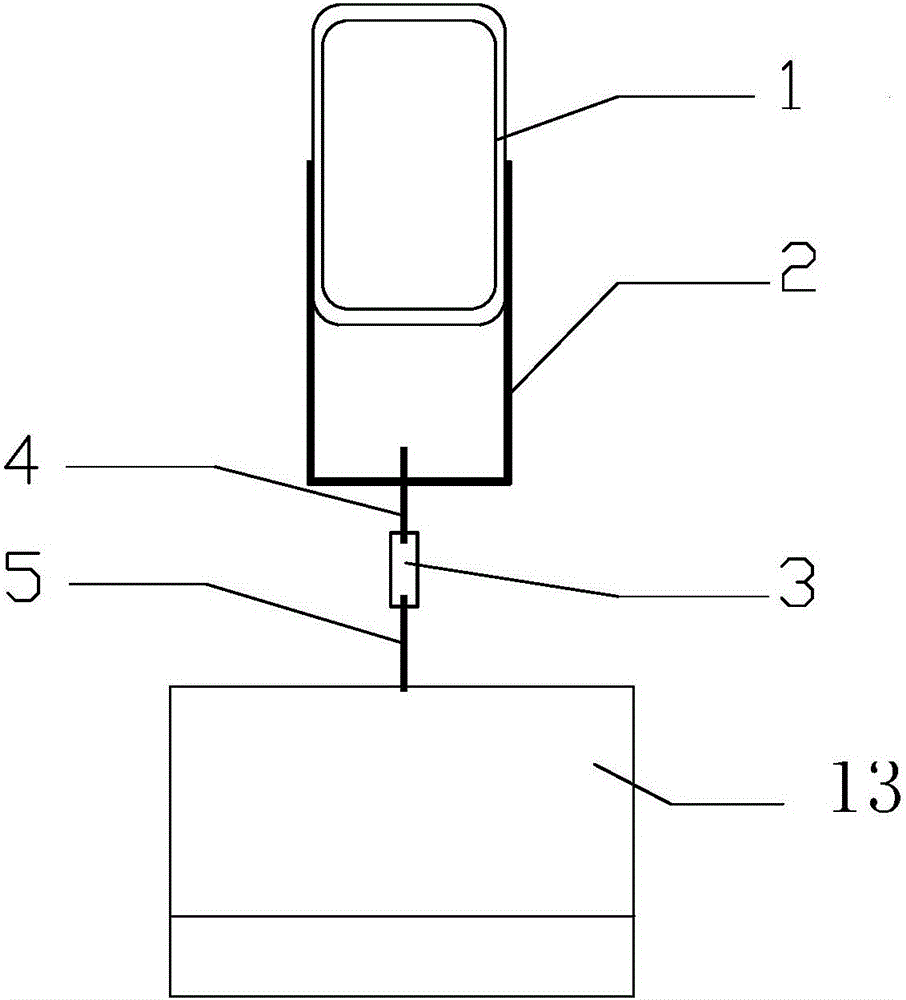

Temperature and humidity adjusting system and active cooing beam joint construction structure and method

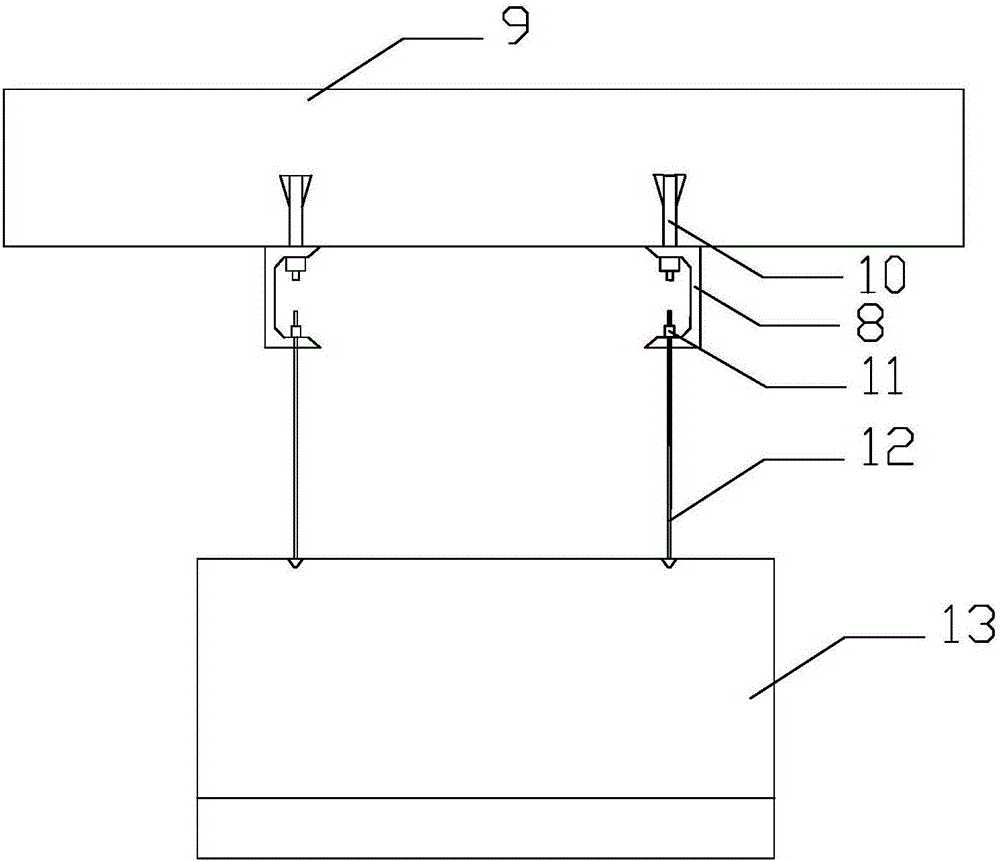

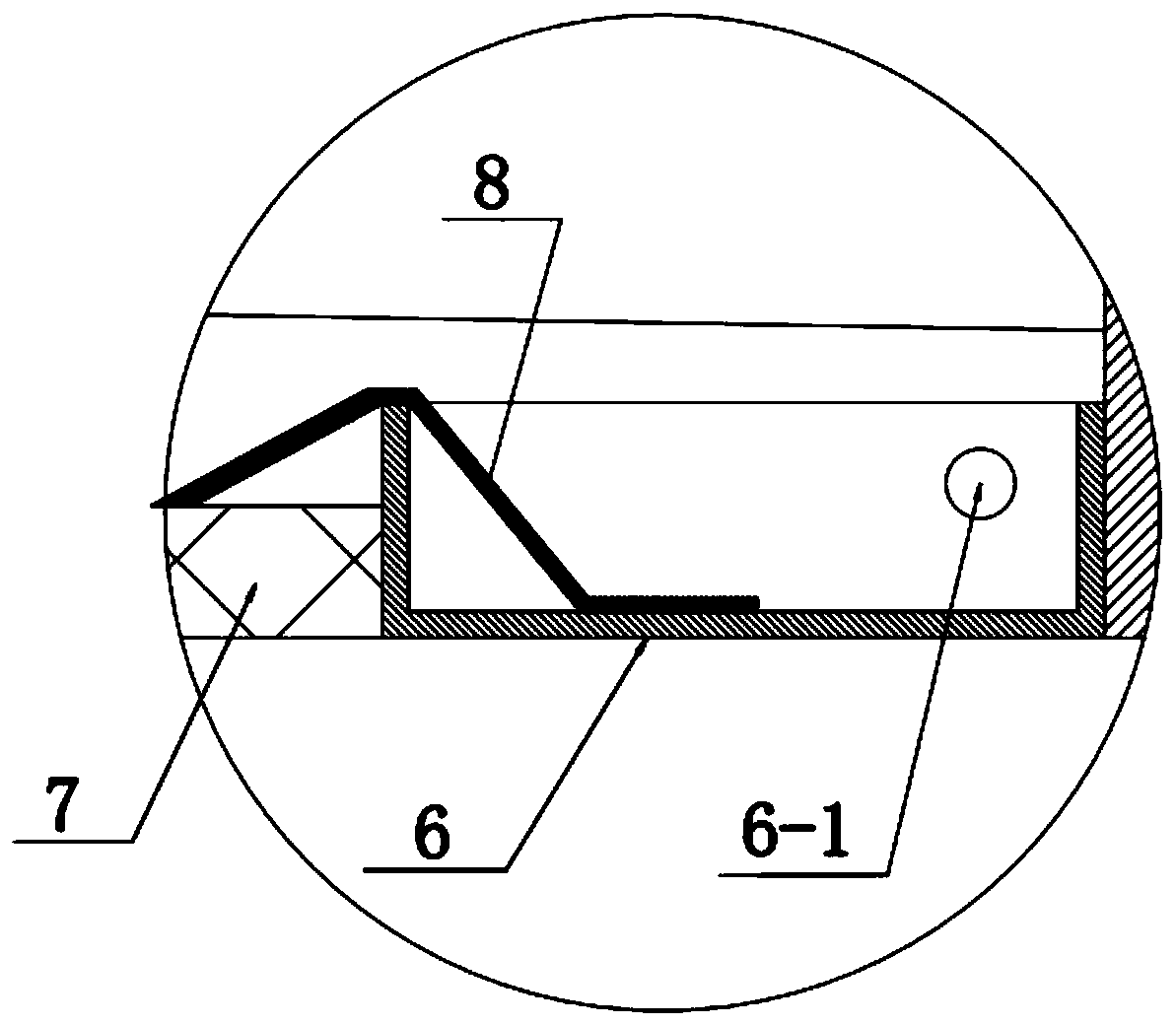

PendingCN106524363ASimple structureReasonable designDucting arrangementsMechanical apparatusWater volumeKeel

The invention discloses a temperature and humidity adjusting system and active cooing beam joint construction structure which comprises an active cooling beam mounting device, a temperature and humidity independent adjustment pipeline and a temperature and humidity independent adjustment device. The active cooling beam mounting device comprises a keel mounting structure and a top plate mounting structure. The temperature and humidity independent adjustment pipeline comprises an air pipeline and an air conditioner water pipeline. The temperature and humidity independent adjustment air conditioner device comprises a PLC, the input end of the PLC is connected with a control panel, a temperature sensor and a dew point detection sensor, and the output end of the PLC is connected with a constant air volume valve and a water volume adjusting valve. The invention further discloses a temperature and humidity adjusting system and active cooing beam joint construction method. An active cooling beam is installed through the keel mounting structure and the top plate mounting structure, the air conditioner water pipeline and the air pipeline are distributed through combination with the characteristics of the active cooling beam, a comfort, safe and sanitary indoor environment is provided for buildings in a hidden mode, and broad application prospects are achieved.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

System and method for maintaining air temperature within a building HVAC system

A system and method for conditioning air is provided. A building has a hot water source and a cold water source. The system includes at least one heating-cooling unit, a primary water storage device, at least one heat pump, and a controller. The heating-cooling unit transfers heat into or out of air passing within an air handling system of the building. The primary water storage device stores a volume of water within a predetermined temperature range. The primary water storage device is in communication with the hot water source and the cold water source. The heat pump is connected to the primary water storage device and a chilled beam. The controller selectively drives the heat pump to transfer heat between the primary water storage device and the chilled beam. The controller selectively controls the system to transfer heat into or out of the primary water storage device.

Owner:CARRIER CORP

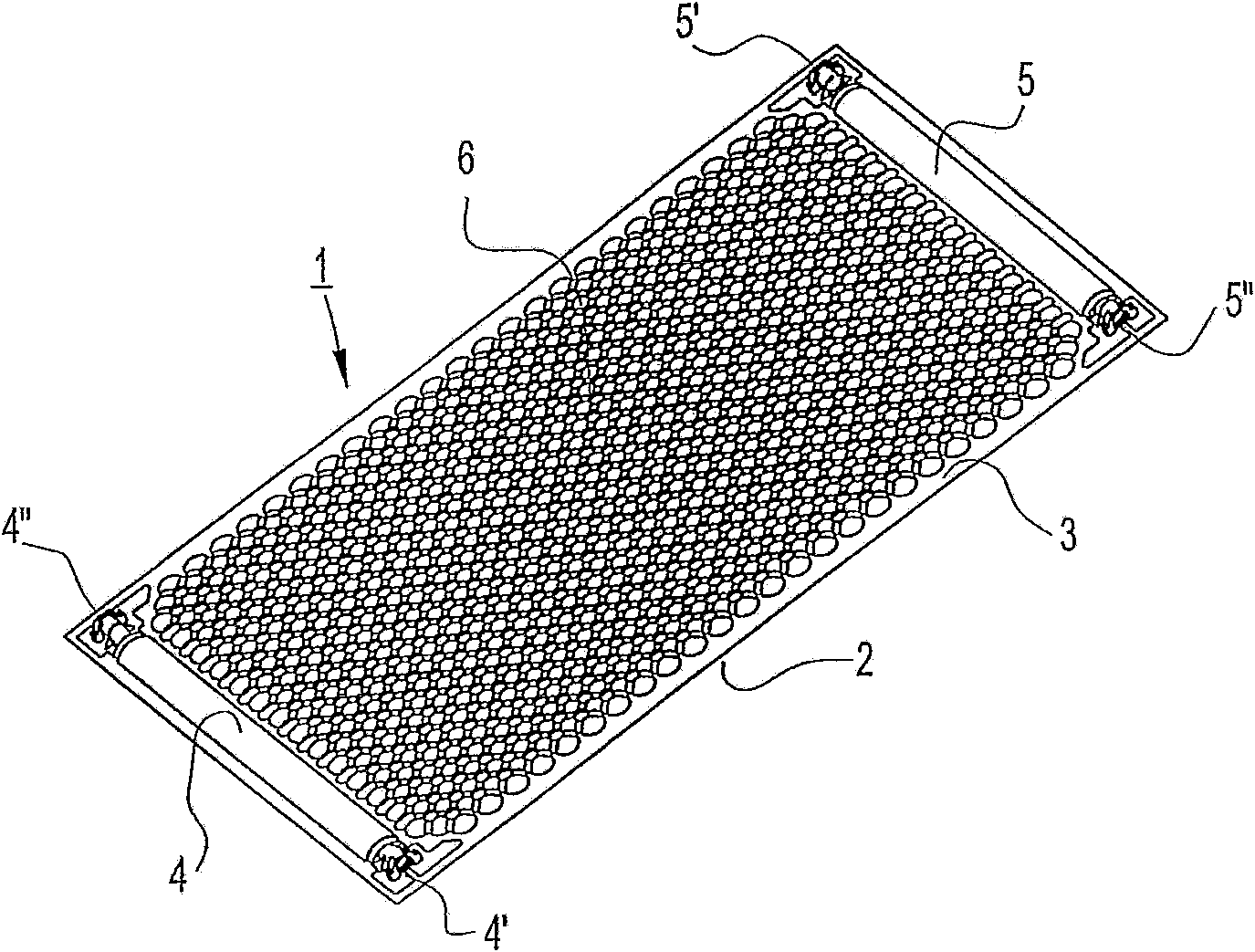

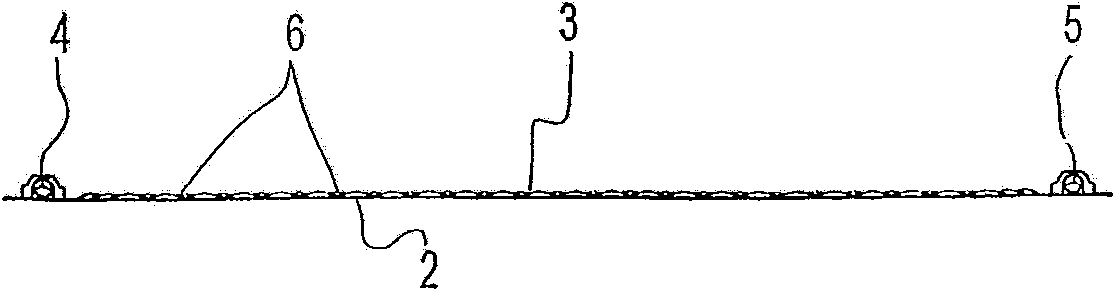

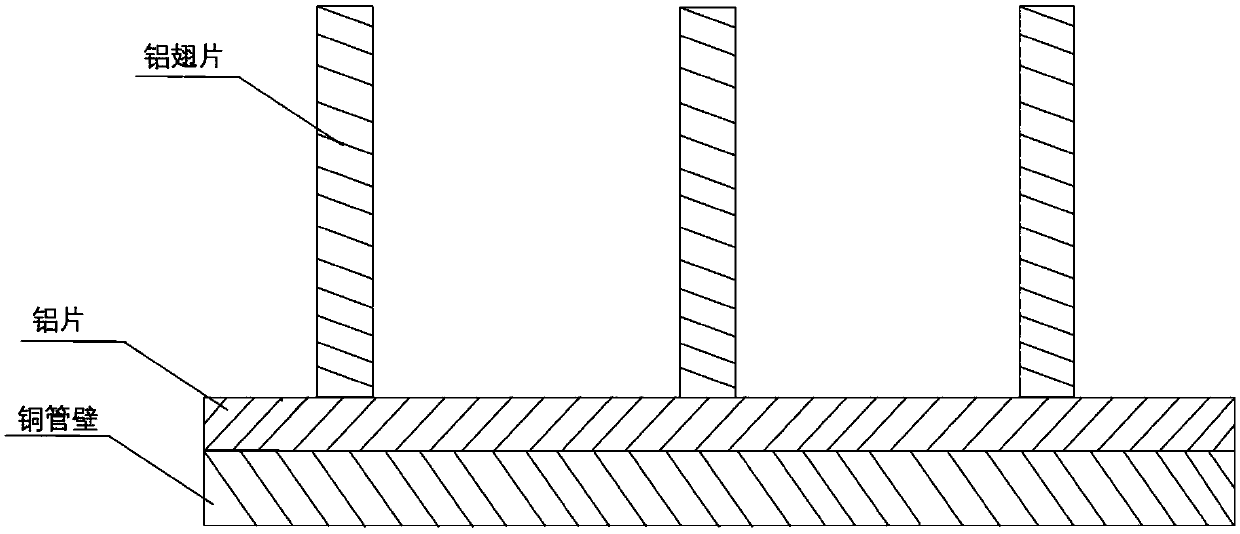

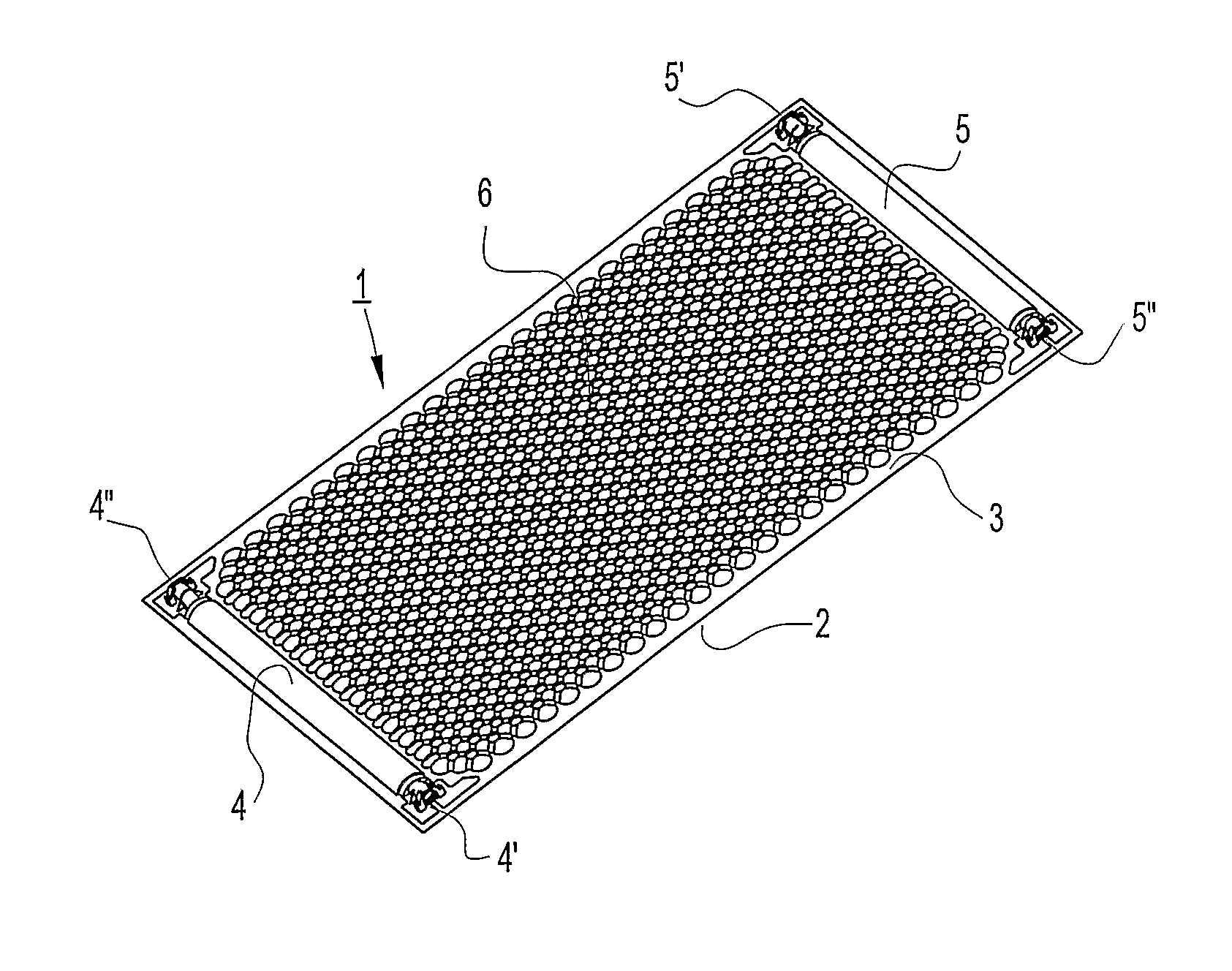

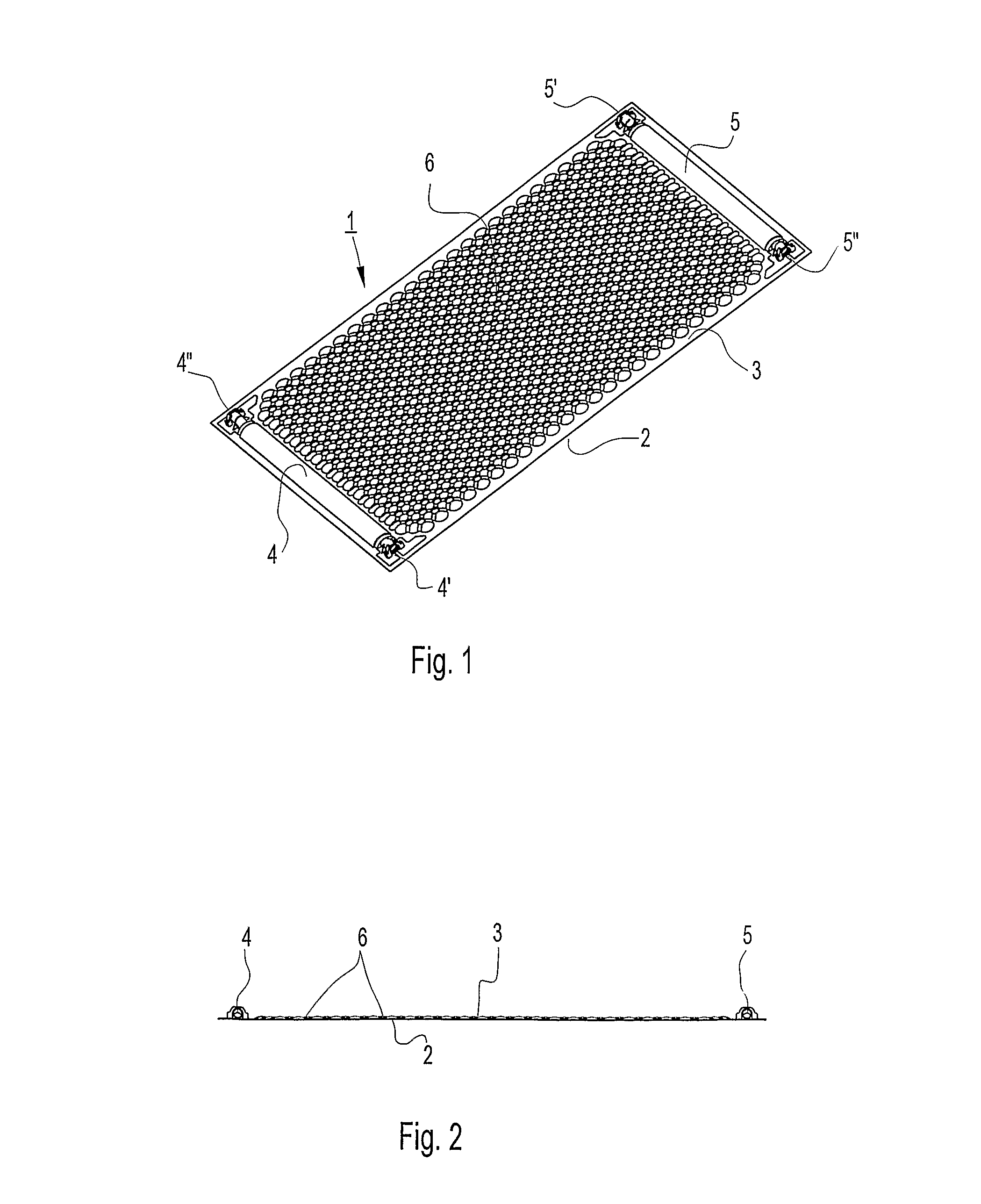

Heat exchanger element

The invention relates to an heat exchanger element of a plate type, with one internal flow passage, comprising two plates defining an inlet, an outlet and an internal passage extending between said inlet and said outlet, whereas said passage is between two generally parallel plates of self supporting polymer material. The present invention also relates to the use of such an exchanger element as collector in a solar energy arrangement, as chilled beam, as hear distributing element, as subterranean collector, as exchange element in industrial processes and as heat absorber in arrangements for cooling electrical components that are negatively affected by being close to or next to elements having electrical conductivity.

Owner:SUNCORE

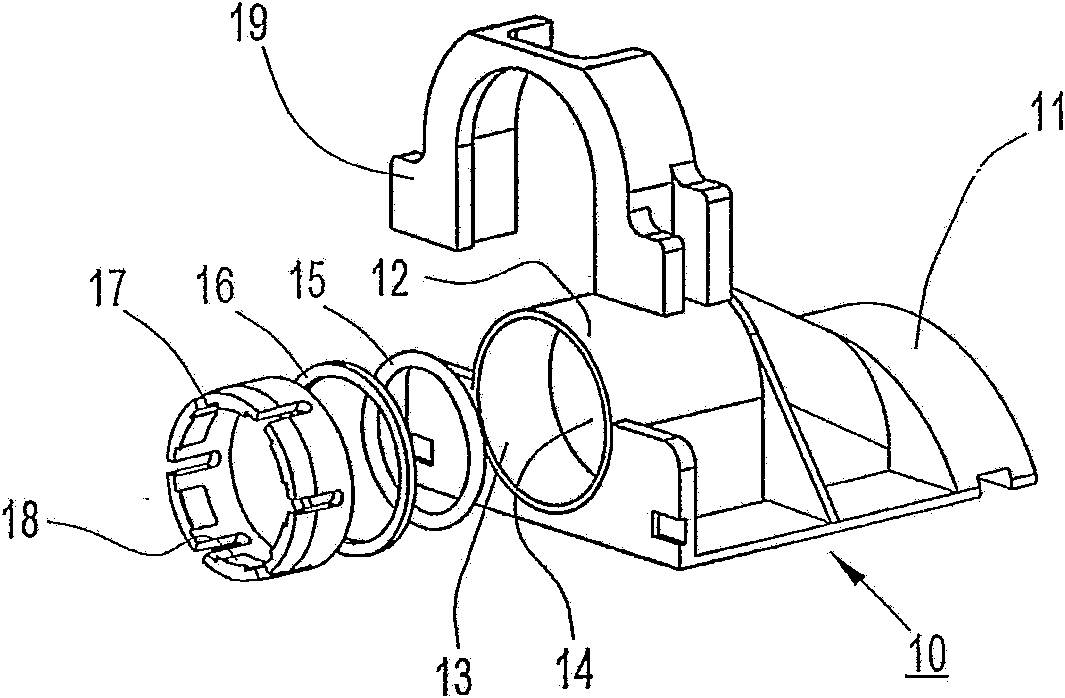

Method for cooling supply air

InactiveCN101576299AMechanical apparatusSpace heating and ventilation safety systemsNuclear engineeringChilled beam

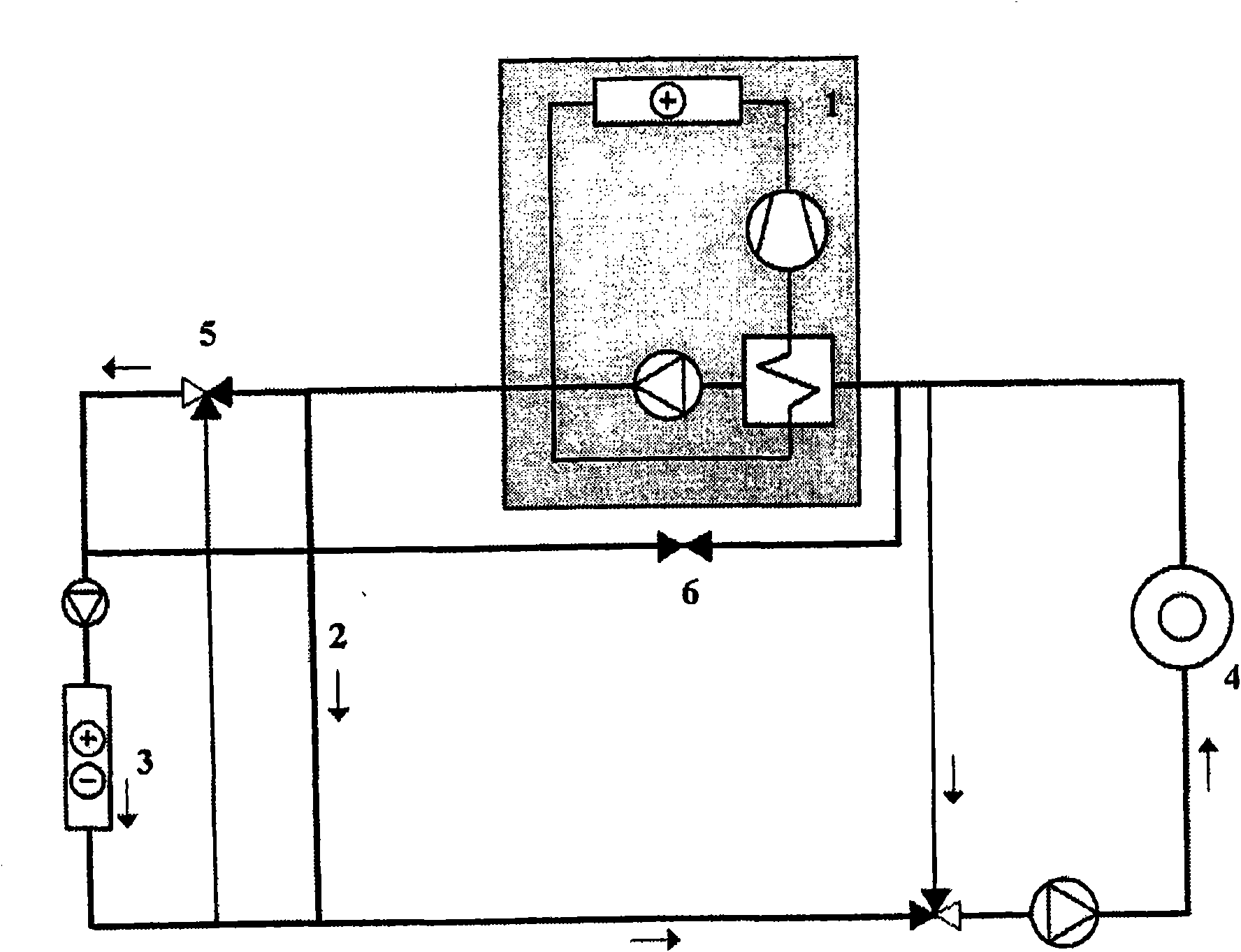

Method for cooling supply air in the cooling system of a building, in which method the cooling water in the main circulation circuit (2) is cooled with a cooling compressor (1), and in which method cooling water is taken to the cooling radiator (3) from the main circulation circuit (2) for cooling the supply air, and in which method cooling water is taken to the room unit, such as to the chilled beam network (4) from the main circulation circuit (2) and mixed to the desired temperature, e.g. approx. 15 DEG C. The invention is implemented such that in an operating situation the cooling water of the main circulation circuit (2) is cooled to a temperature of over 7 DEG C, preferably to a temperature of approx. 12 DEG C, and such that in an exceptional situation such as when the supply air is humid, the temperature of the room unit, such as of the chilled beam network (4), is raised higher to prevent condensation and at the same time the temperature of the water of the main circulation circuit (2) is reduced lower.

Owner:FLKT WOODS AB

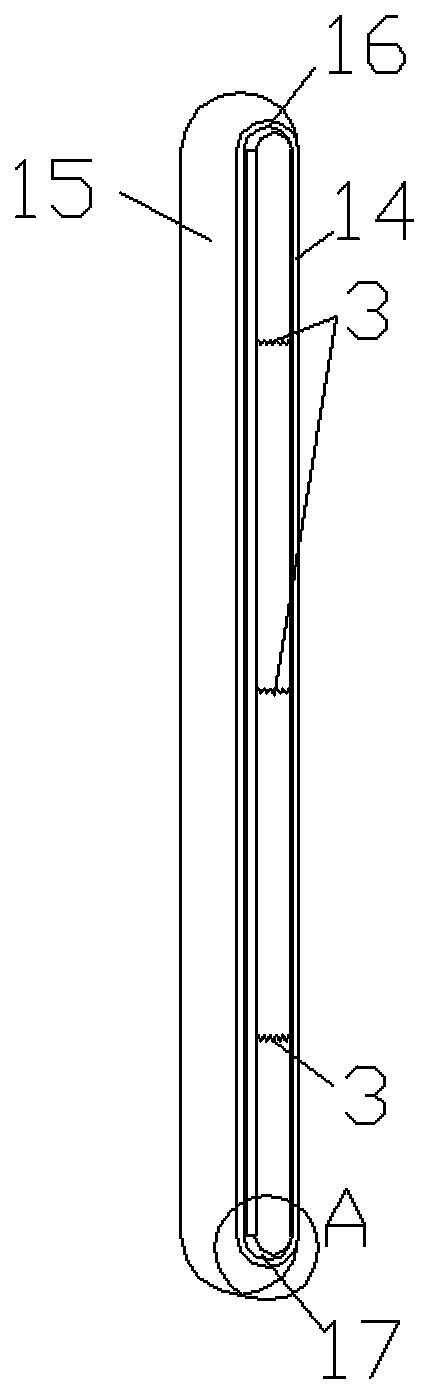

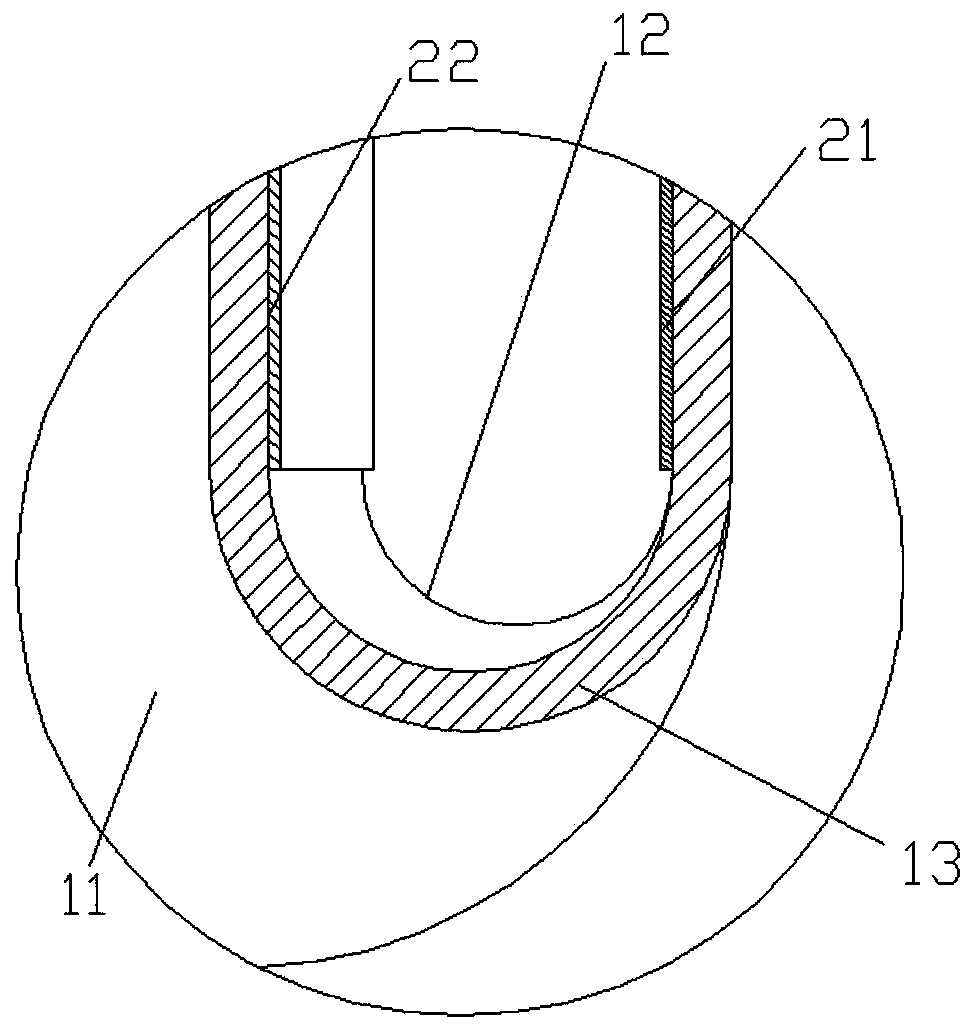

Prefabricated air feeding cooling beam and production method thereof

ActiveCN106760188ASimple designReduce noiseDucting arrangementsLighting and heating apparatusReinforced concreteEngineering

The invention provides a prefabricated air feeding cooling beam and a production method thereof and relates to the field of air-conditioning systems. The prefabricated air feeding cooling beam comprises a cooling beam main body, an air feeding piece and an air returning piece; and the cooling beam main body is a hollow box type beam, and an air pipe is installed in the cooling beam main body, of a hollow frame structure and embedded into the cooling beam main body. The cooling beam main body is integrated with the air pipe through reinforced concrete. An air inlet communicating with the air pipe is formed in the side wall of the cooling beam main body, and at least four ventilation openings communicating with the air pipe are formed in the bottom of the cooling beam main body in the length direction of the cooling beam main body; and the air feeding piece communicates with the ventilation openings, and the air returning piece communicates with the air inlet. By combining a normal air feeding pipeline, a tail end heat exchanging coil pipe and a building prefabricated beam, a system can achieve the air-conditioning aim through convection and radiation between indoor air and the coil pipe, noise generated by the air pipe during running can be effectively reduced while beam loading is not influenced, maintenance cost is low, more energy is saved, and people feel comfortable.

Owner:SICHUAN UNIV

Marine chilled beam air purification device and temperature adjustment device

InactiveCN110498032AReduce energy consumptionIncrease profitAuxillariesVessel ventillation/heating/coolingParticulatesEngineering

The invention discloses a marine chilled beam air purification device and a temperature adjustment device. The marine chilled beam air purification device mainly comprises a chilled beam system, a waste heat recovery system, an information transmission system, a control system and a purification system. A heat source and a cold source required by the chilled beam system come from the waste heat generated by a marine main engine and a marine refrigeration unit, the characteristics of the chilled beam device and the marine main engine are combined, and the cold and heat sources generated by theship are rationally used, so that the energy efficiency is improved. Existing marine pipelines do not need to be upgraded, so that resources are saved, and the pollution problem caused by a refrigerant is reduced; and the temperature is stabilized in the setting range, the secondary use of waste heat is also realized, the energy consumption of the ship is reduced, and the return air generated by the spray principle of a chilled beam guide plate is adopted to drive indoor air flow for adsorption of air particulate matter and impurities, so that air quality is improved, and the purposes of bringcomfort to human and saving energy are realized.

Owner:WUHAN UNIV OF TECH

Heat exchanger element

ActiveUS20110220340A1Well formedEasy to joinSolar heating energyOther heat production devicesPlate heat exchangerParallel plate

The invention relates to an heat exchanger element of a plate type, with one internal flow passage, comprising two plates defining an inlet, an outlet and an internal passage extending between said inlet and said outlet, whereas said passage is between two generally parallel plates of self supporting polymer material. The present invention also relates to the use of such an exchanger element as collector in a solar energy arrangement, as chilled beam, as hear distributing element, as subterranean collector, as exchange element in industrial processes and as heat absorber in arrangements for cooling electrical components that are negatively affected by being close to elements having electrical conductivity.

Owner:ECOCLIME GRP AB

Active chilled beam with sterilization means

InactiveUS9222687B2Extended stayReduce leakageMechanical apparatusLighting and heating apparatusChilled beamWaste management

Owner:MESTEK

System and Apparatus for Conditioning of Indoor Air

ActiveUS20200348040A1Shorten the timeSpeed maximizationMechanical apparatusSpace heating and ventilation safety systemsControl systemCirculator pump

A control system is provided for controlling heating and / or cooling with a conditioning load such as fan coils and chilled beams. Based on user input and ambient conditions, the control system determines a desired temperature for the liquid entering the load and combines fresh supply liquid (e.g., from a chiller or boiler) with a portion of the liquid that has passed through the load, to achieve the target load input temperature for the liquid. A recirculation pump may be used to return a portion of the liquid exiting the load for mixing with the fresh supply liquid and a control valve may be used to adjust the ratio of fresh supply liquid and recirculated liquid to achieve the targeted temperature. The control systems can be compatible with a variety of liquid supply systems such as two- and four-pipe systems.

Owner:CHILLED BEAM CONTROLS LLC

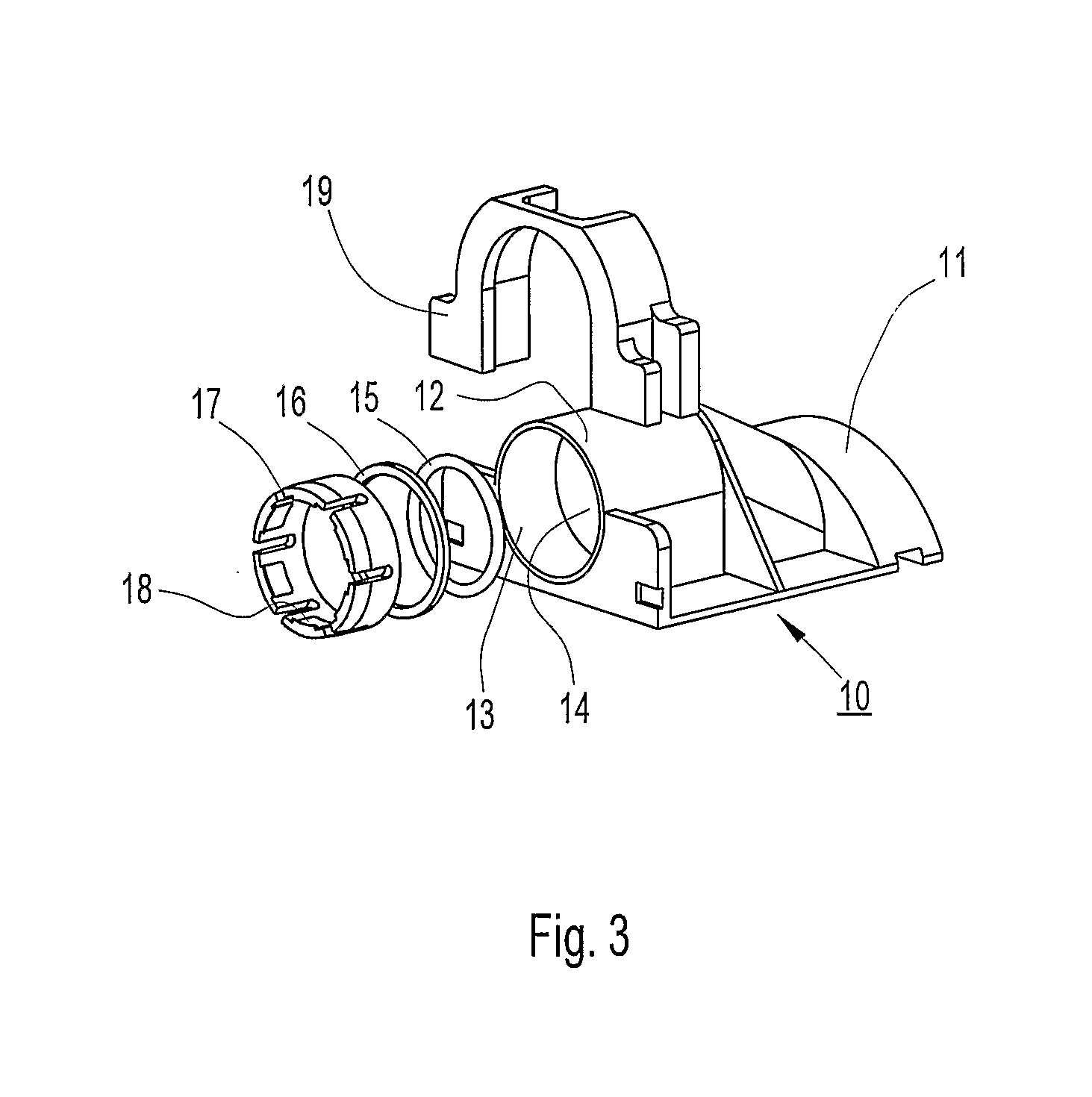

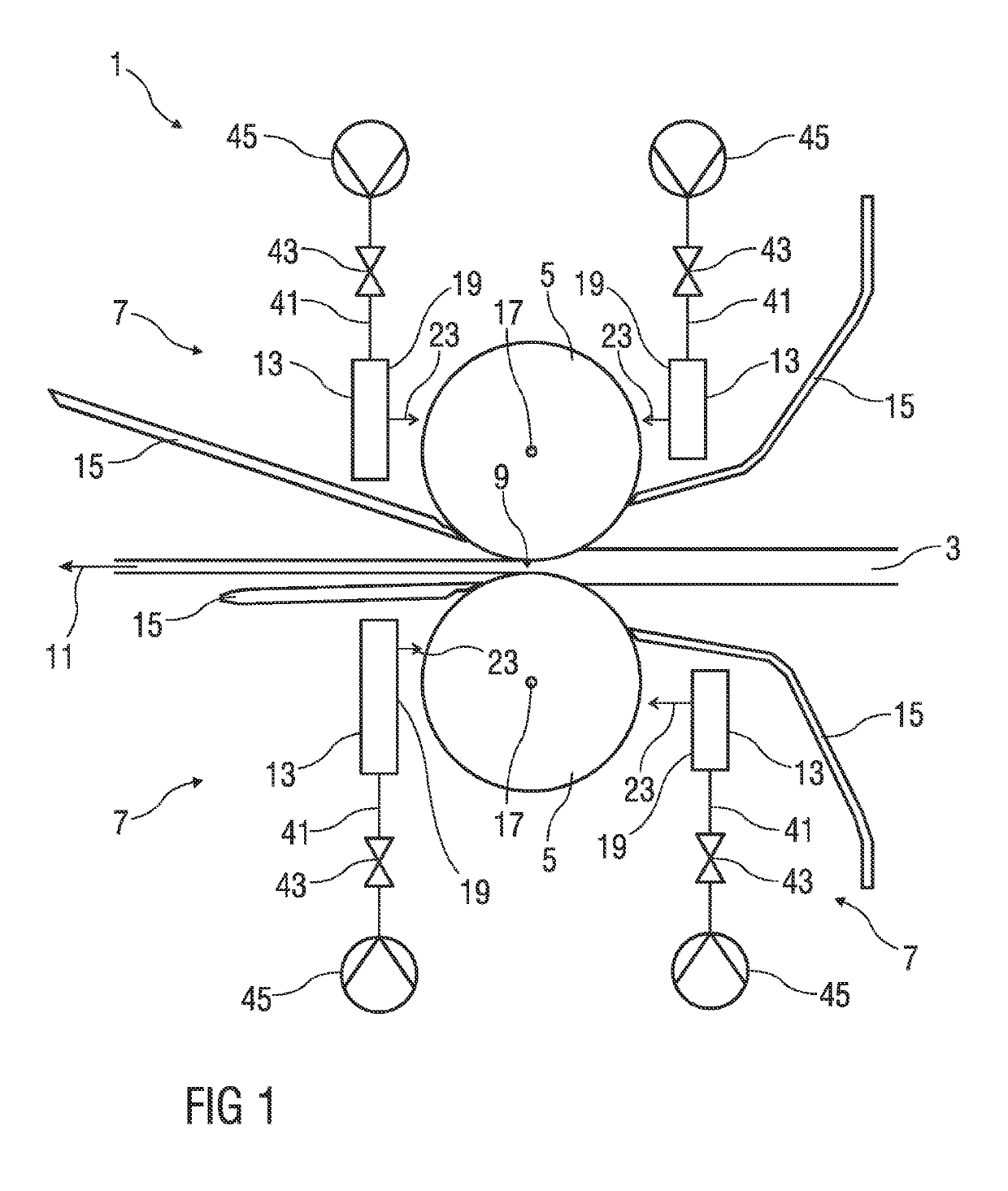

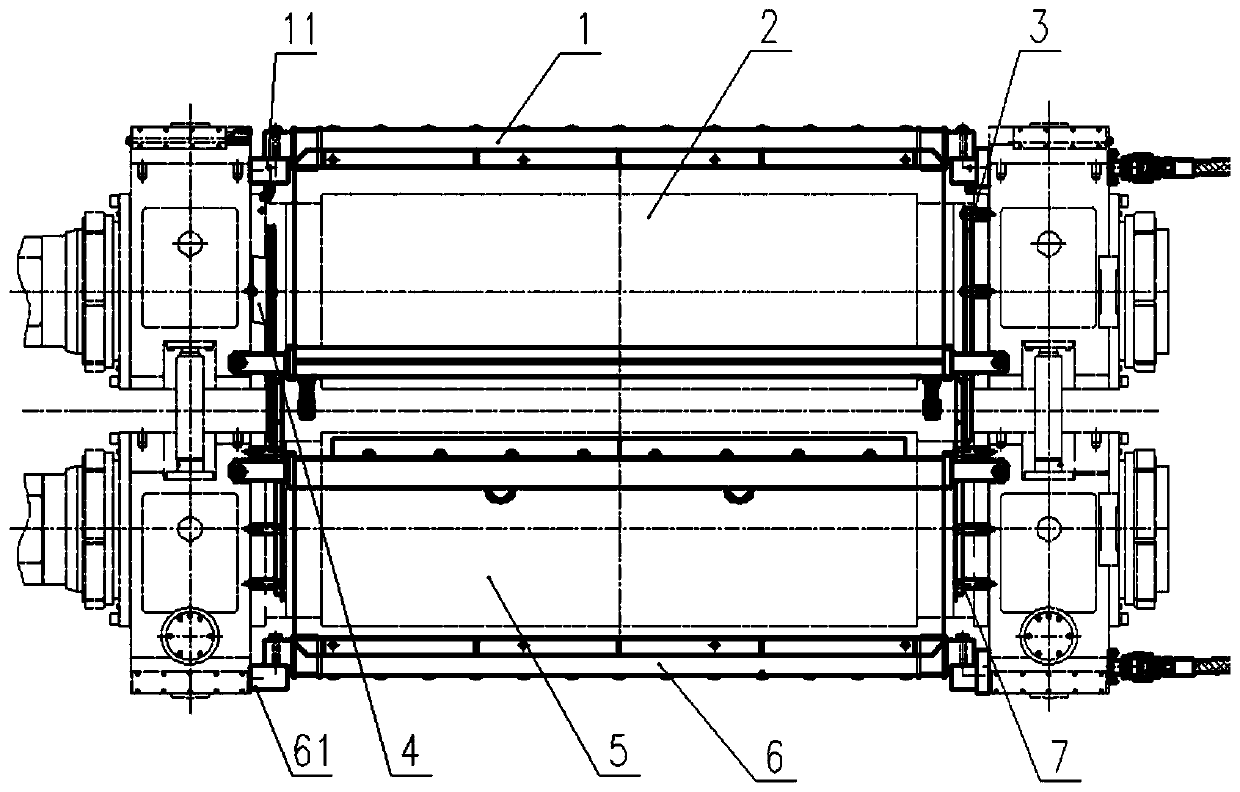

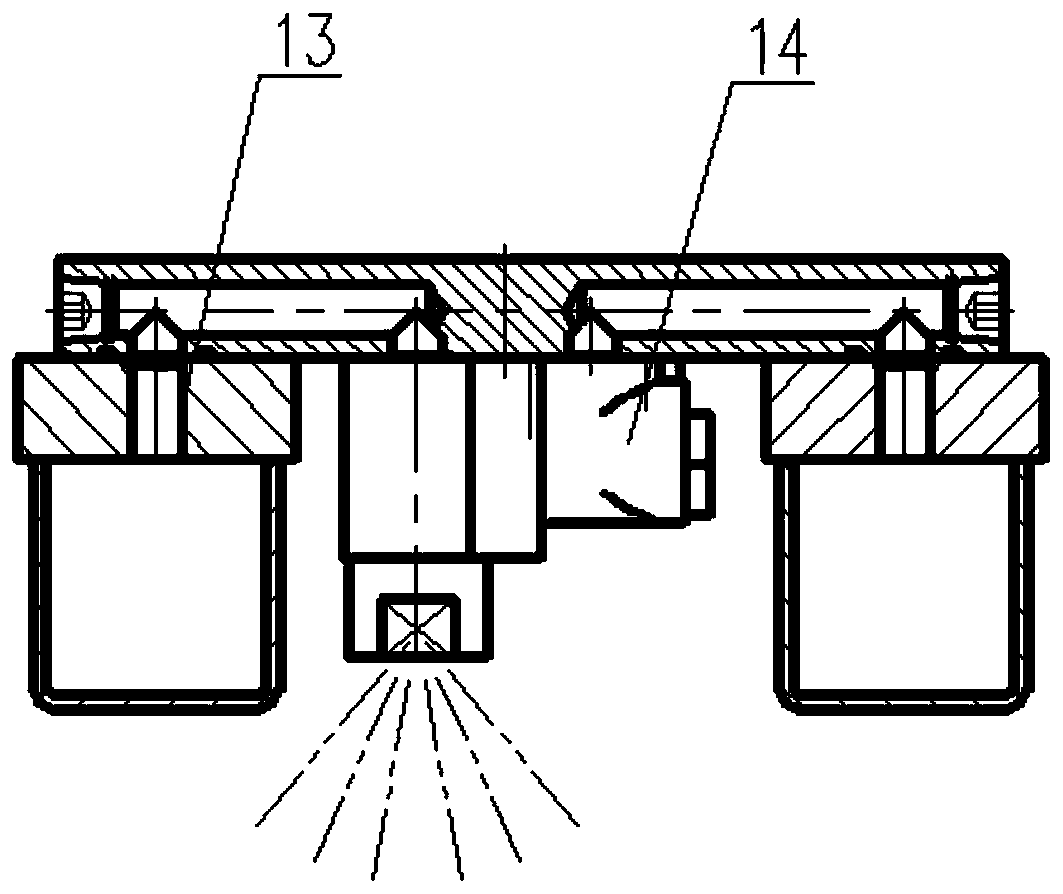

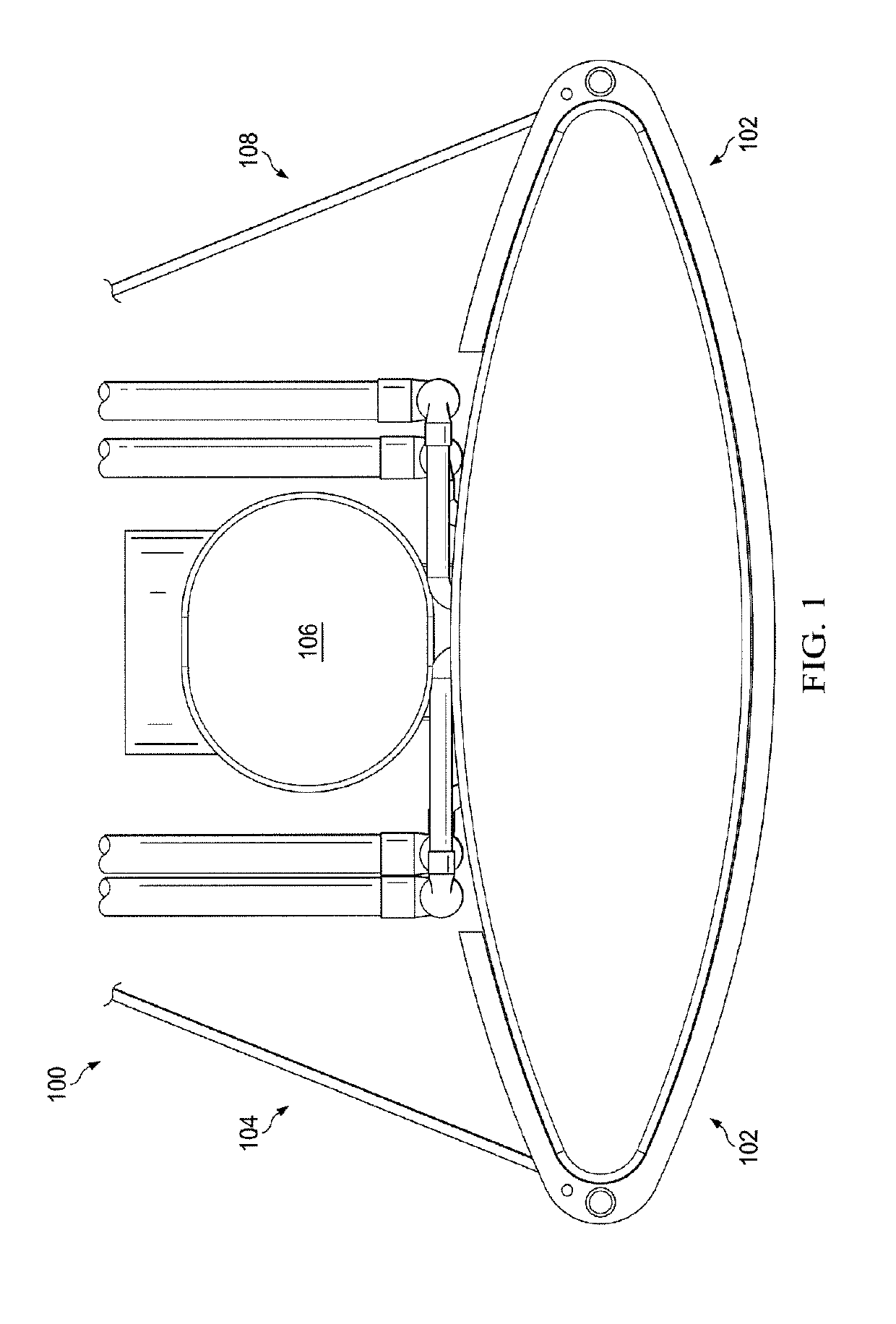

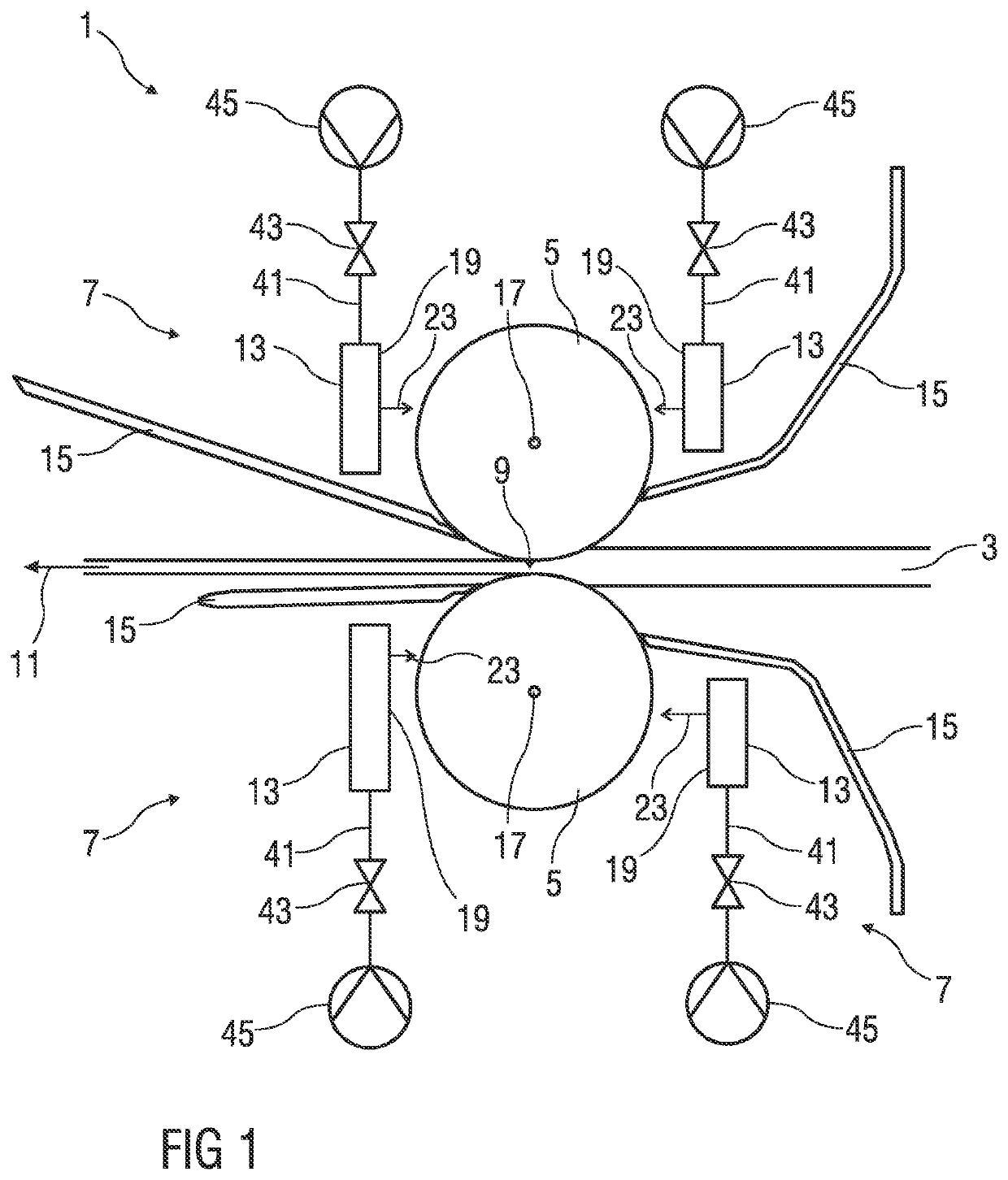

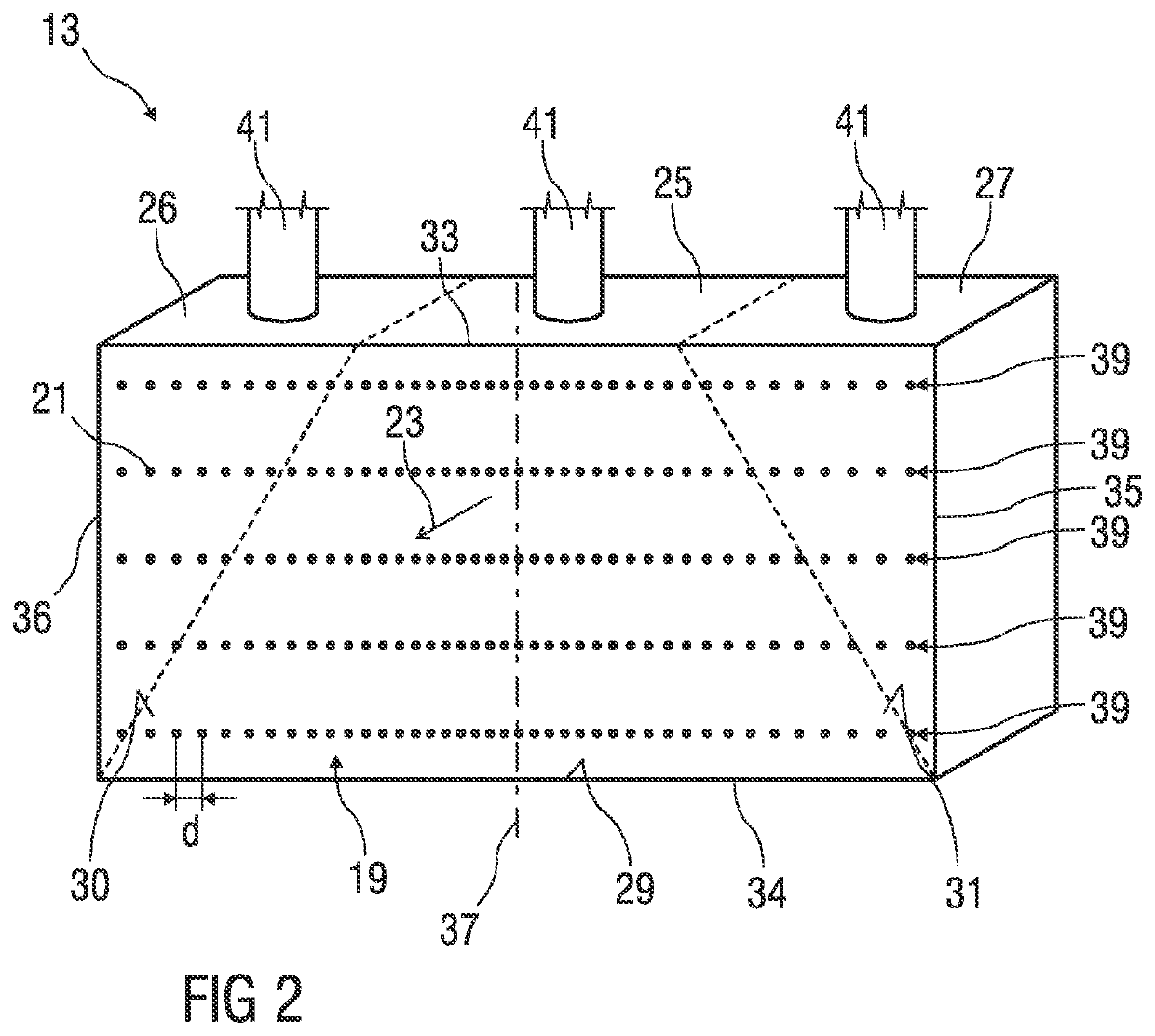

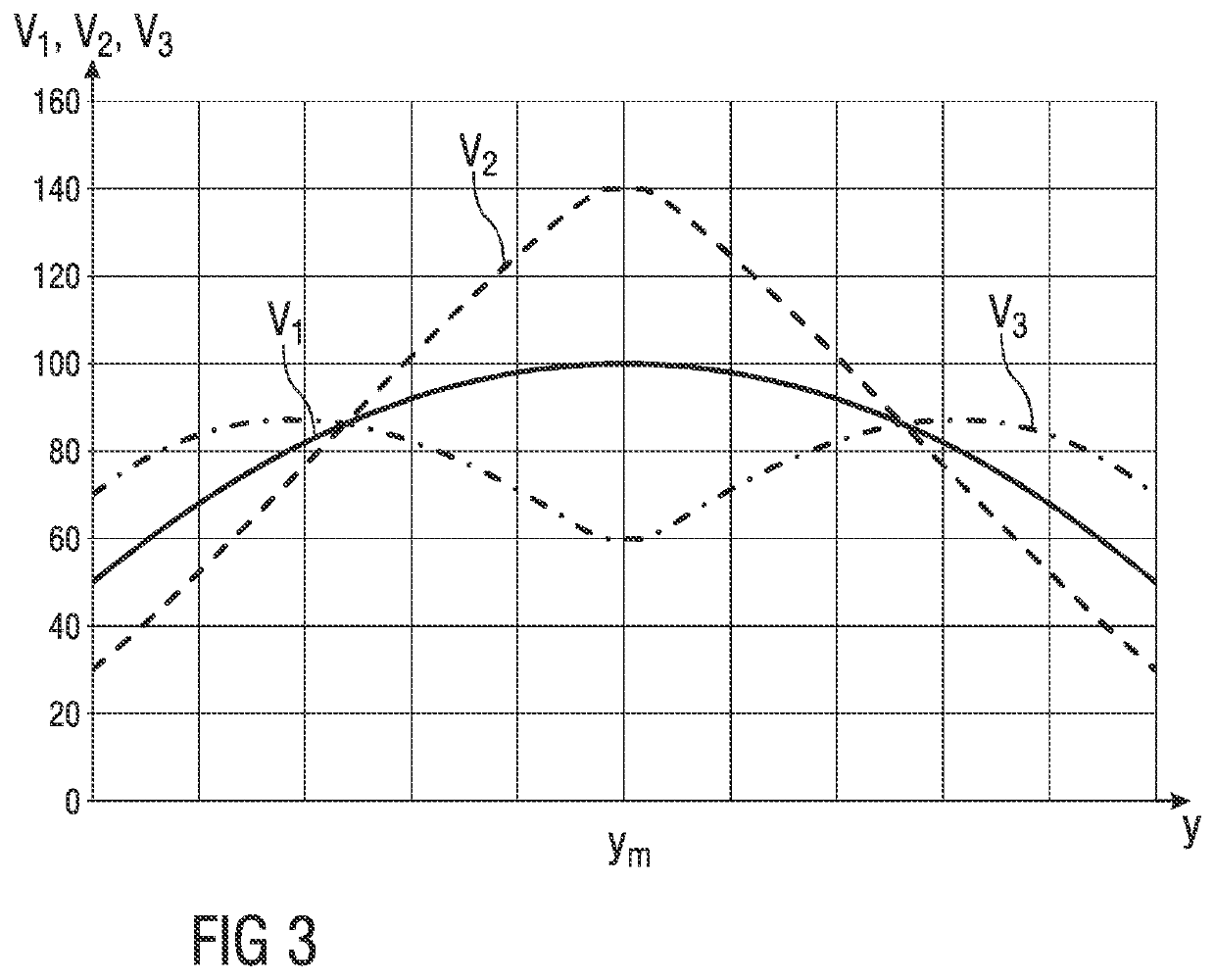

Cooling a roll of a roll stand

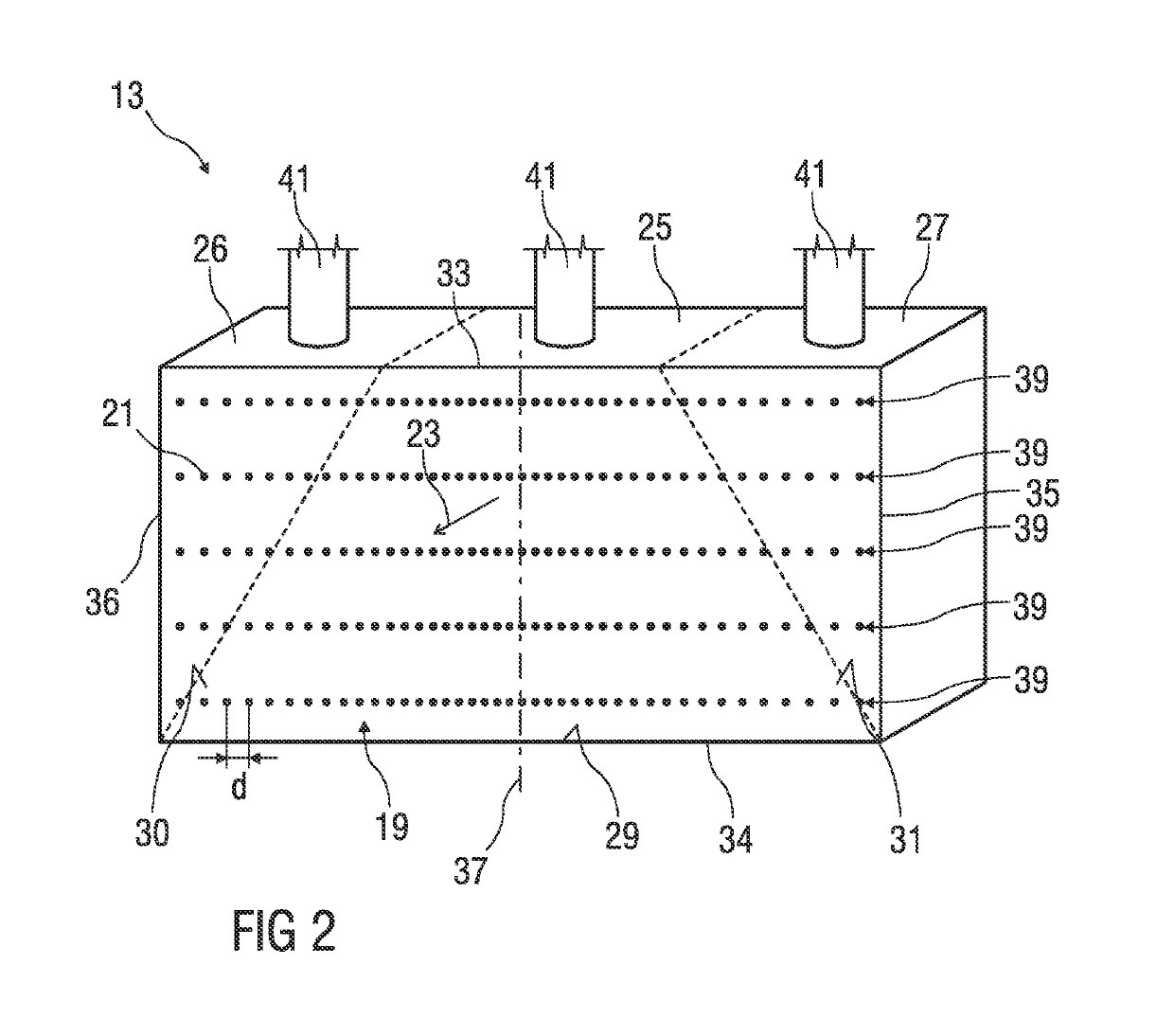

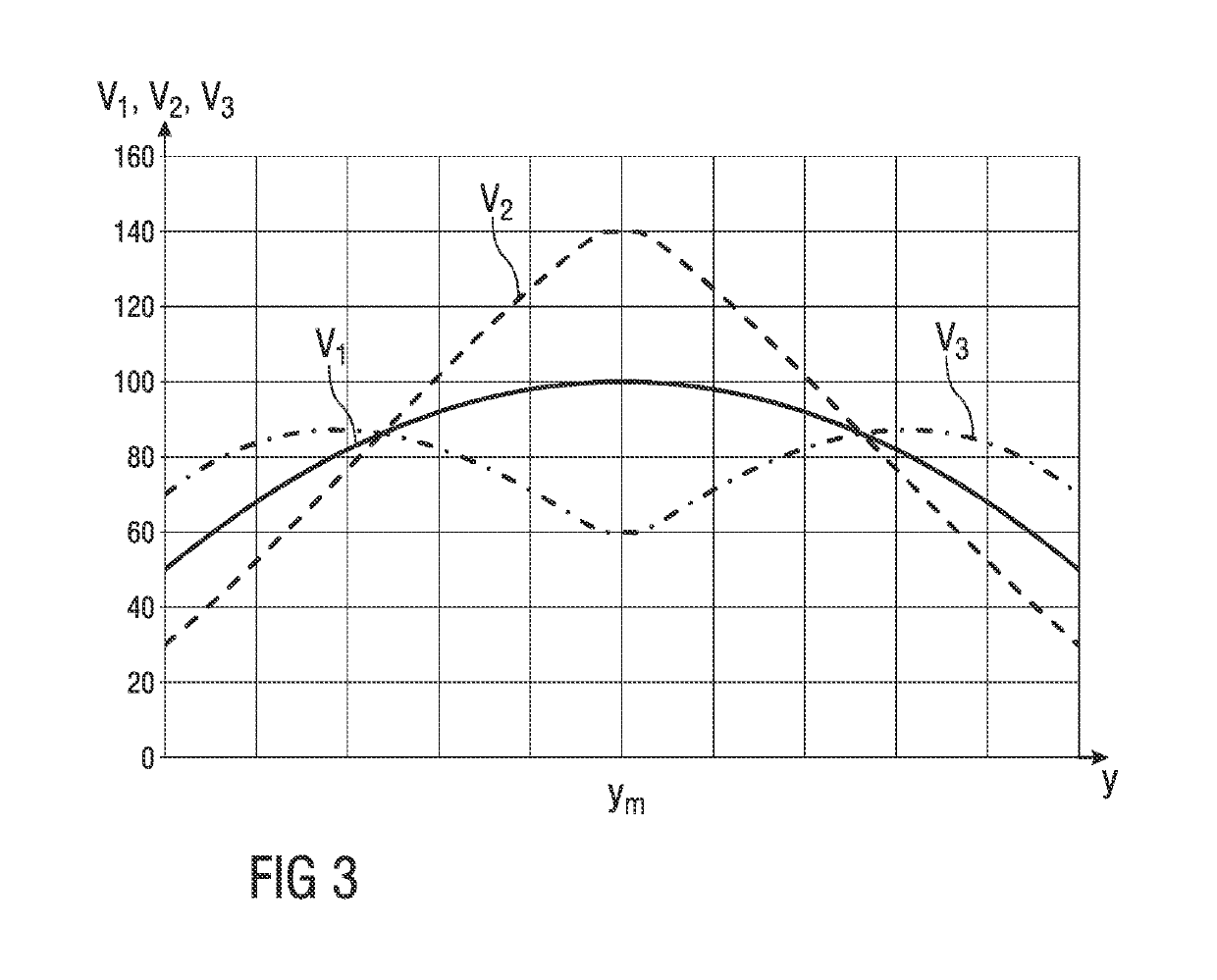

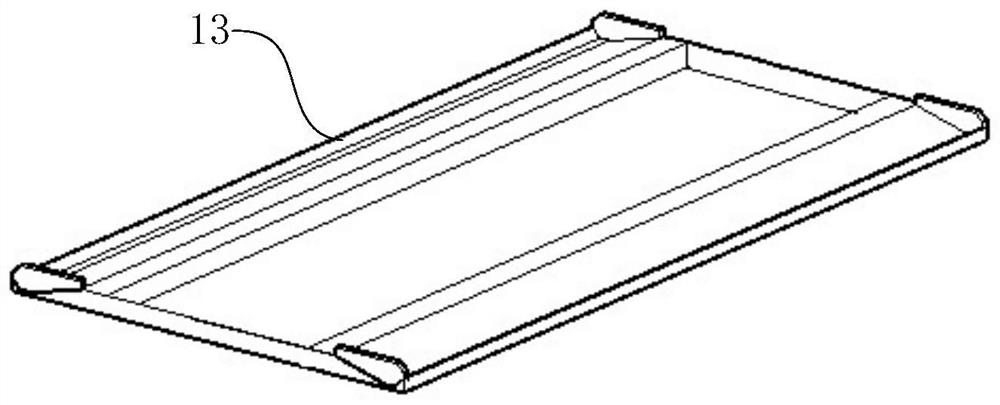

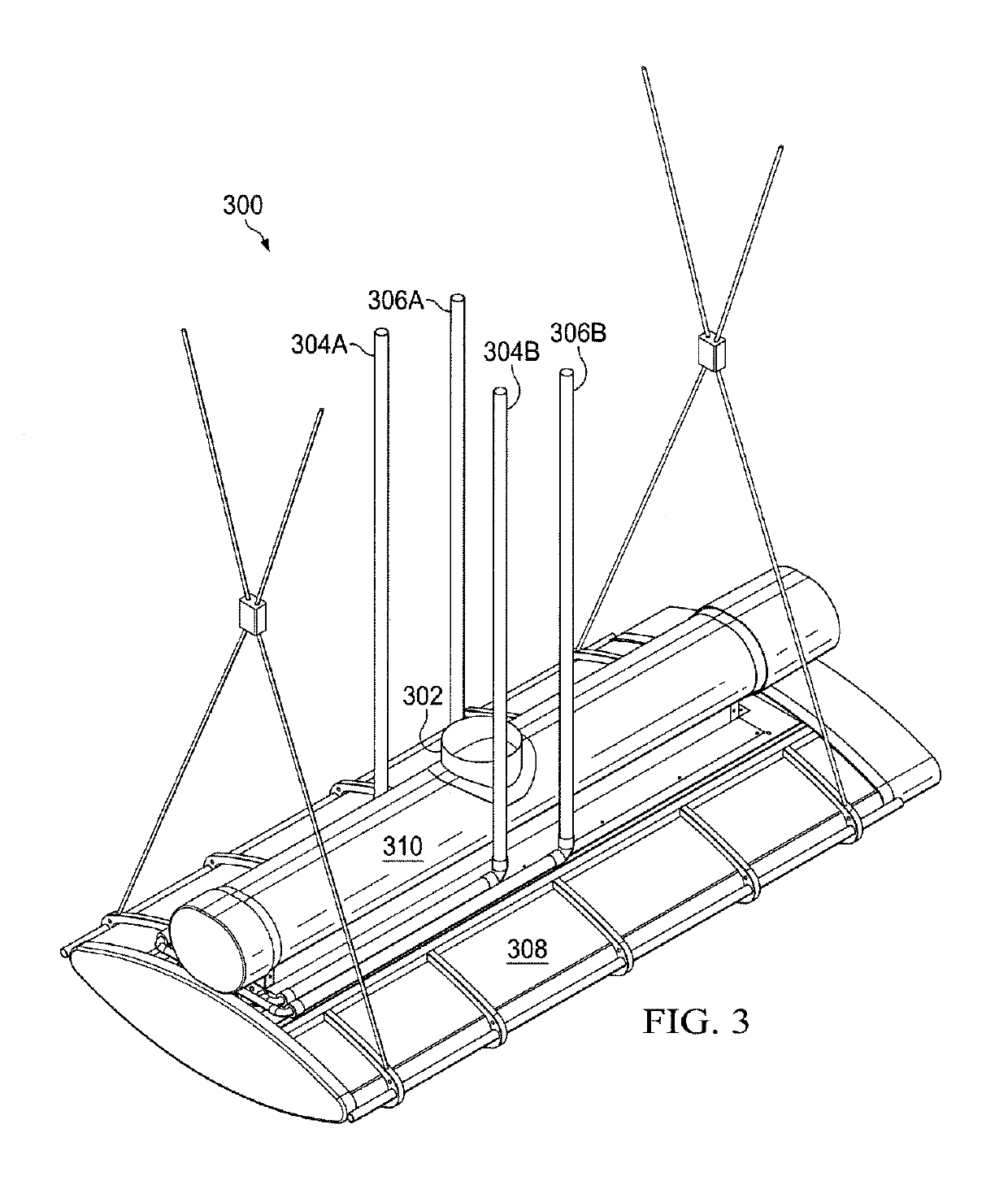

ActiveUS20190308233A1Reduce operating costs and energy consumptionIncrease impact pressureRollsMetal rolling arrangementsChilled beamCoolant

A cooling device (7) for cooling a roll (5) of a roll stand (1). The cooling device (7) includes a chilled beam (13) for receiving and discharging a coolant. The chilled beam (13) has multiple full jet nozzles (21) disposed on a discharge side (19) of the chilled beam (13), the side facing the roll (5) and extending parallel to a roll axis (17) of the roll (5). Through each of the full-jet nozzles, a jet of coolant having a nearly constant jet diameter can be sprayed from the chilled beam (13) towards the roll (5) in a discharge direction (23).

Owner:PRIMETALS TECH AUSTRIA GMBH

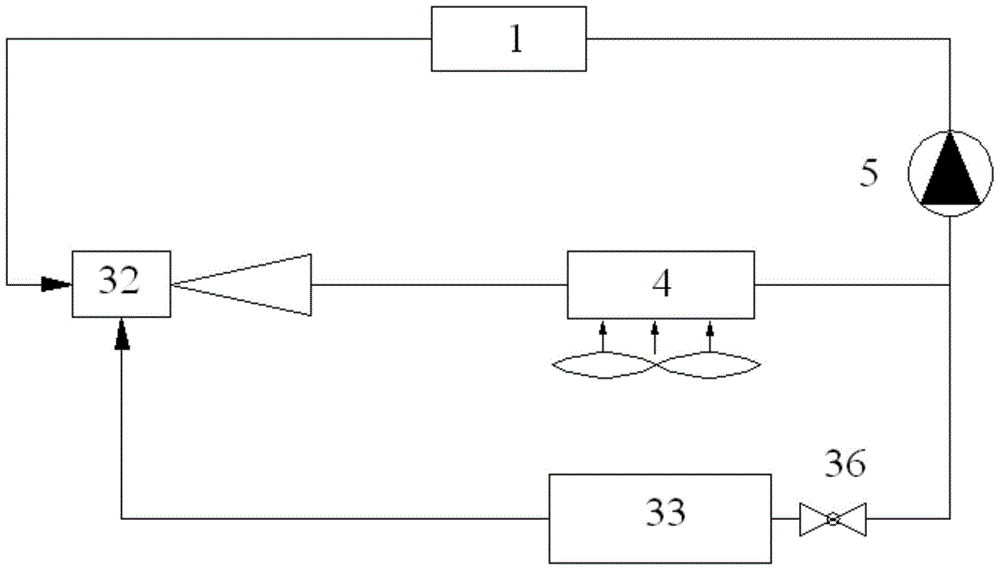

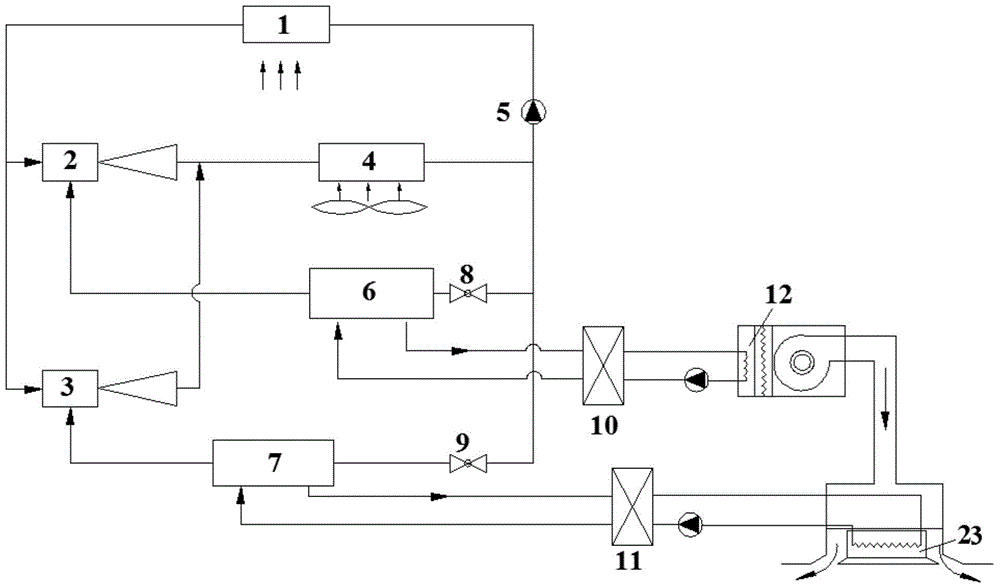

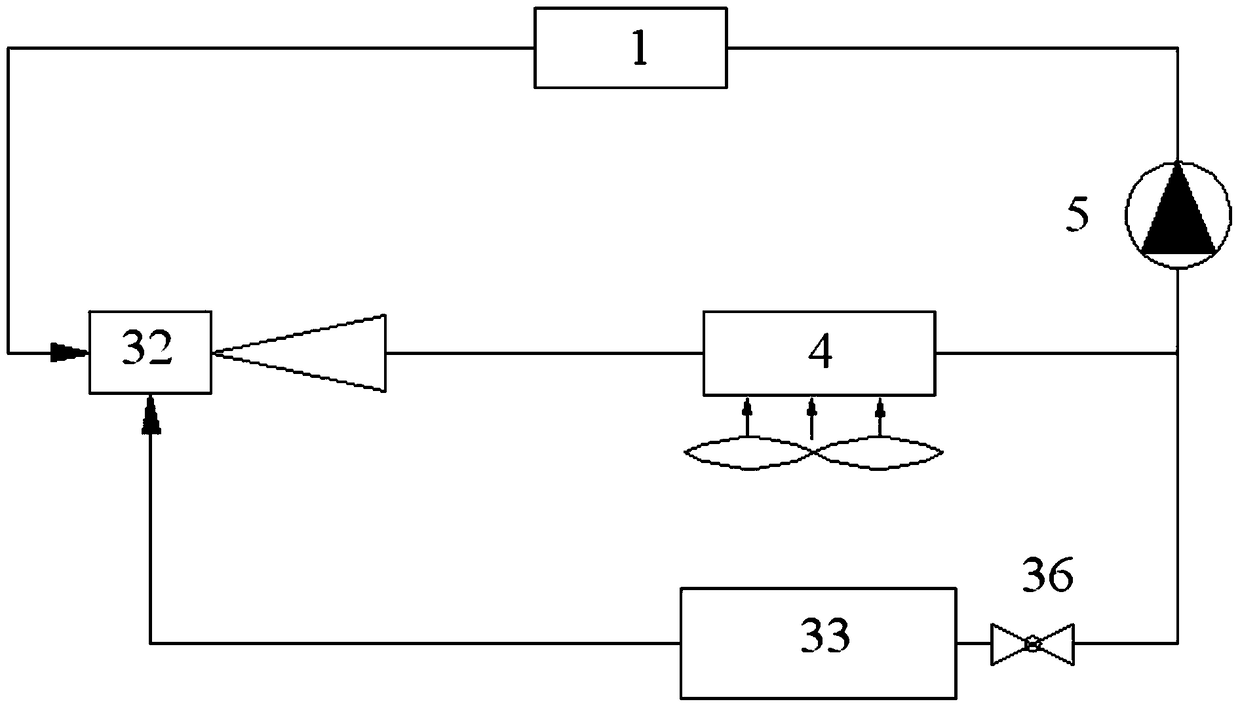

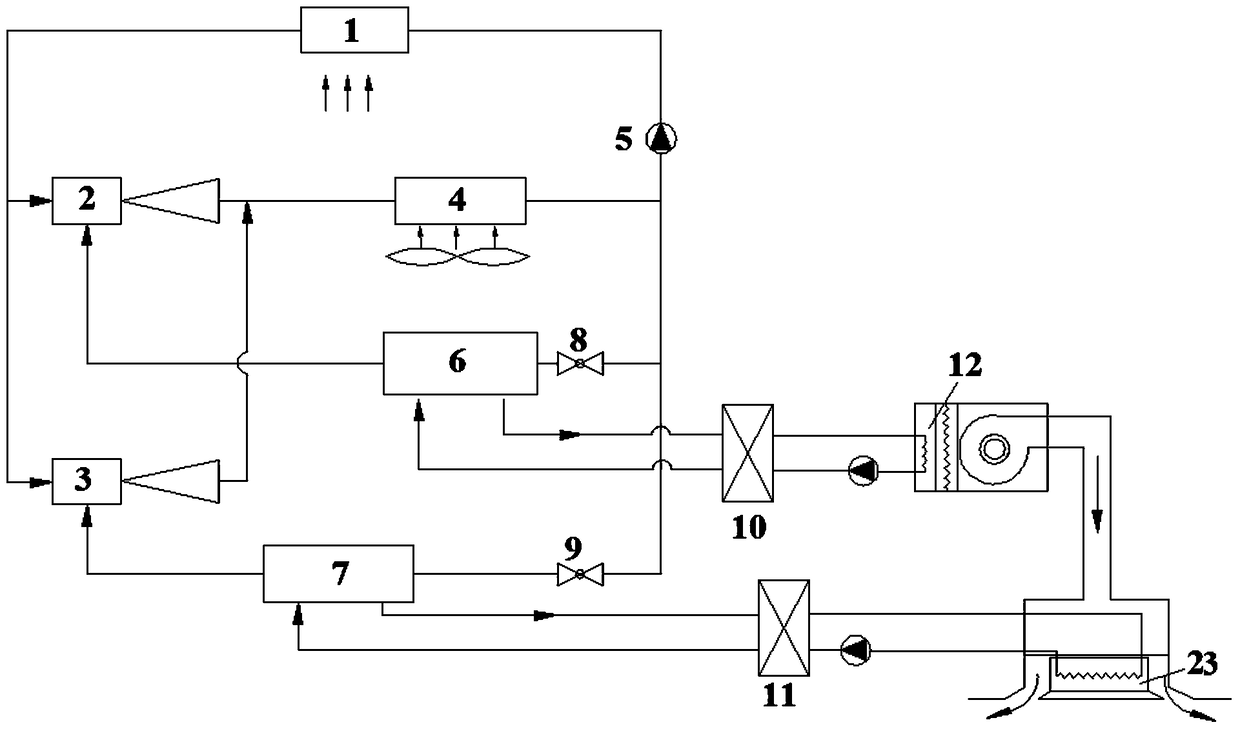

Jet refrigeration and active cooling beam combined applying system

ActiveCN105042741ARaise the evaporation temperatureImprove performanceLighting and heating apparatusAir conditioning systemsPlate heat exchangerActive cooling

The invention relates to a jet refrigeration and active cooling beam combined applying system which comprises a jet refrigeration subsystem and an active cooling beam subsystem. The jet refrigeration subsystem comprises a generator (1), a low-pressure ejector (2), a high-pressure ejector (3), a condenser (4), a water pump (5), a low-temperature side evaporator (6), a high-temperature side evaporator (7), a low-pressure throttling valve (8) and a high-pressure throttling valve (9). Outlet gas of the generator (1) is divided into two routes and enters the condenser (4). Outlet refrigerant of the condenser (4) enters the generator (1), the high-temperature side evaporator (7) and the low-temperature side evaporator (6) to complete refrigeration circulation. A cooling beam wind side tail end exchanges heat with the low-temperature side evaporator (6) through a low-temperature heat exchanger (10), and a cooling beam water side tail end exchanges heat with the high-temperature side evaporator (7) through a high-temperature heat exchanger (11). Compared with the prior art, the jet refrigeration and active cooling beam combined applying system has the advantages that the advantages of a cooling beam are brought into play, the structure is simple, the jet refrigeration evaporation temperature is increased, and the integrity of the system is high.

Owner:TONGJI UNIV

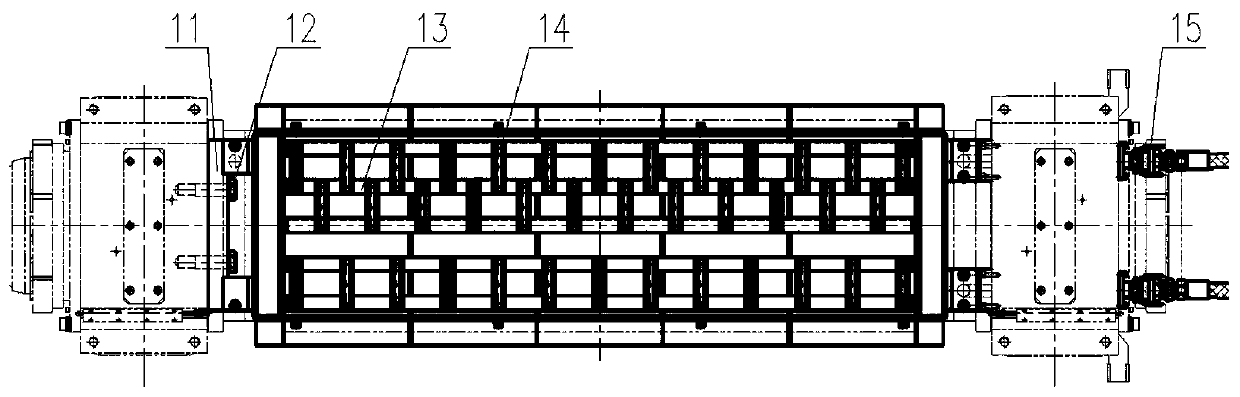

Air mist cooling device for 2+8 roller combined type thick slab big screwdown casting-rolling machine

The invention provides an air mist cooling device for a 2+8 roller combined type thick slab big screwdown casting-rolling machine and belongs to the technical field of slab continuous casting production. The air mist cooling device for the 2+8 roller combined type thick slab big screwdown casting-rolling machine comprises an upper water cooling beam, an upper protective plate, an upper water sealing plate, a water spraying ring, a lower protective plate, a lower water cooling beam and a lower water sealing plate. One end of the upper protective plate is fixed to the upper water cooling beam through bolts. The upper water sealing plate and the water spraying ring are located on bearing bases in roller diameter positions on two sides of a casting-rolling machine respectively. The upper watersealing plate and the lower water sealing plate are located between the water spraying ring and a big screwdown roller of the casting-rolling machine. One end of the lower protective plate is fixed to the lower water cooling beam through bolts, and the other end of the lower protective plate is connected with the bearing bases of the casting-rolling machine. The lower water sealing plate is installed on the bearing bases in the roller diameter positions on two sides of the casting-rolling machine. The air mist cooling device of the 2+8 roller combined type thick slab big screwdown casting-rolling machine has the advantages that an air mist cooling manner is adopted; and problems such as big screwdown roller deforming and cracking brought about by poor cooling are effectively solved.

Owner:BEIJING SHOUGANG INT ENG TECH +1

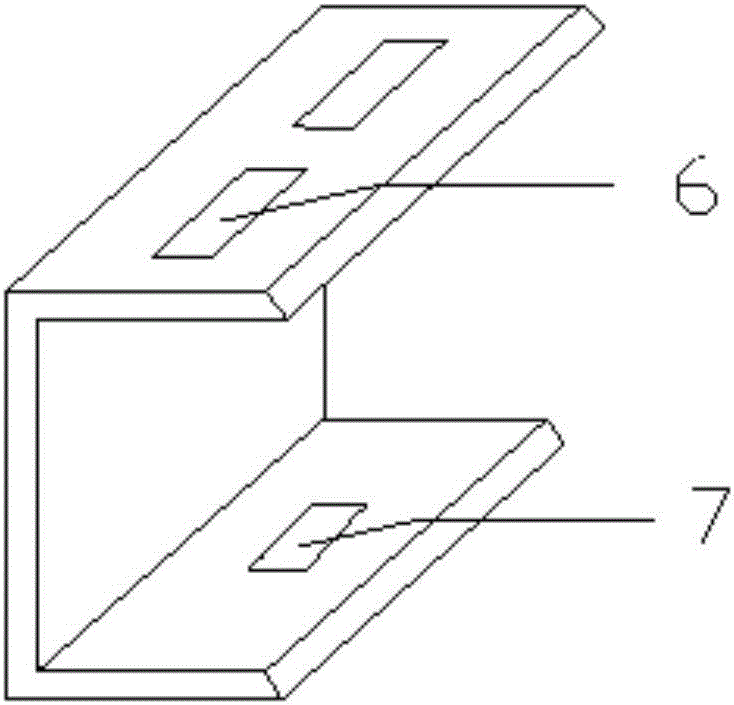

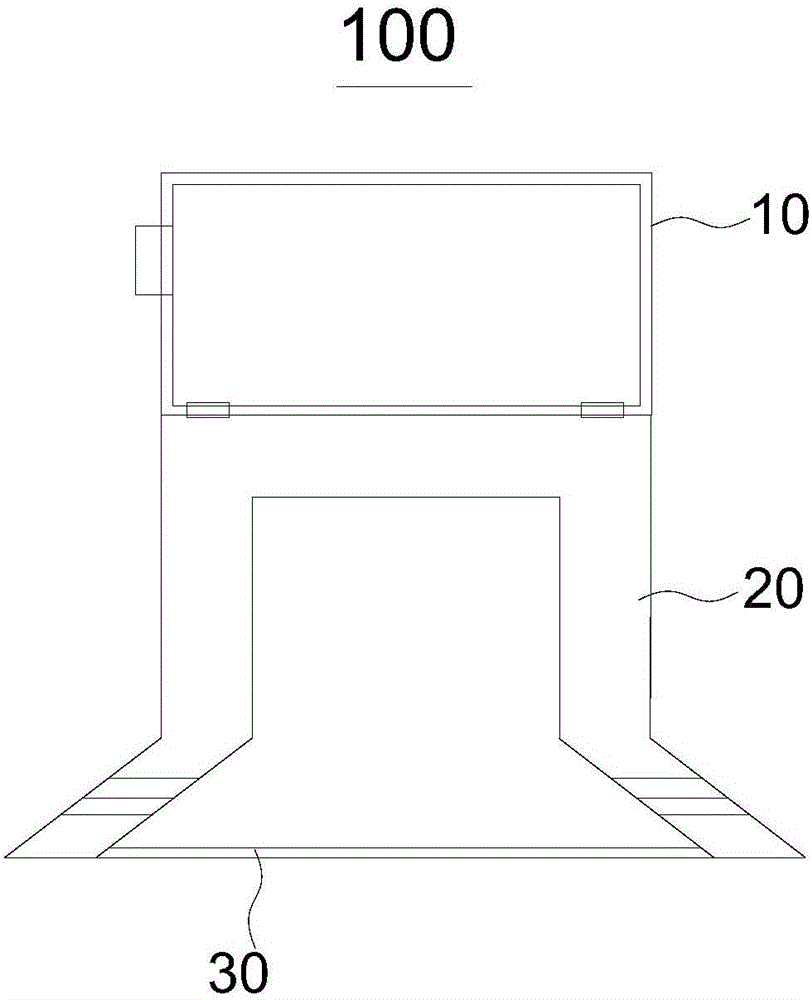

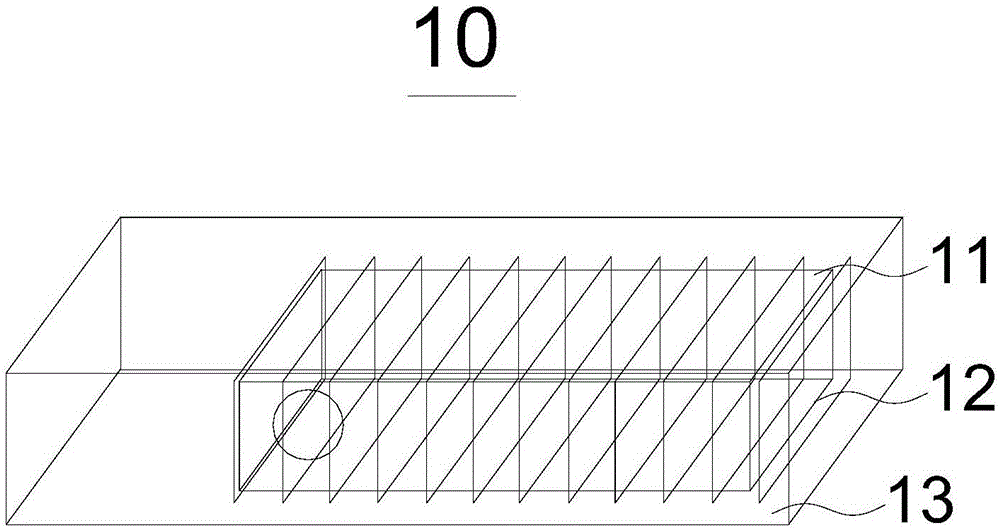

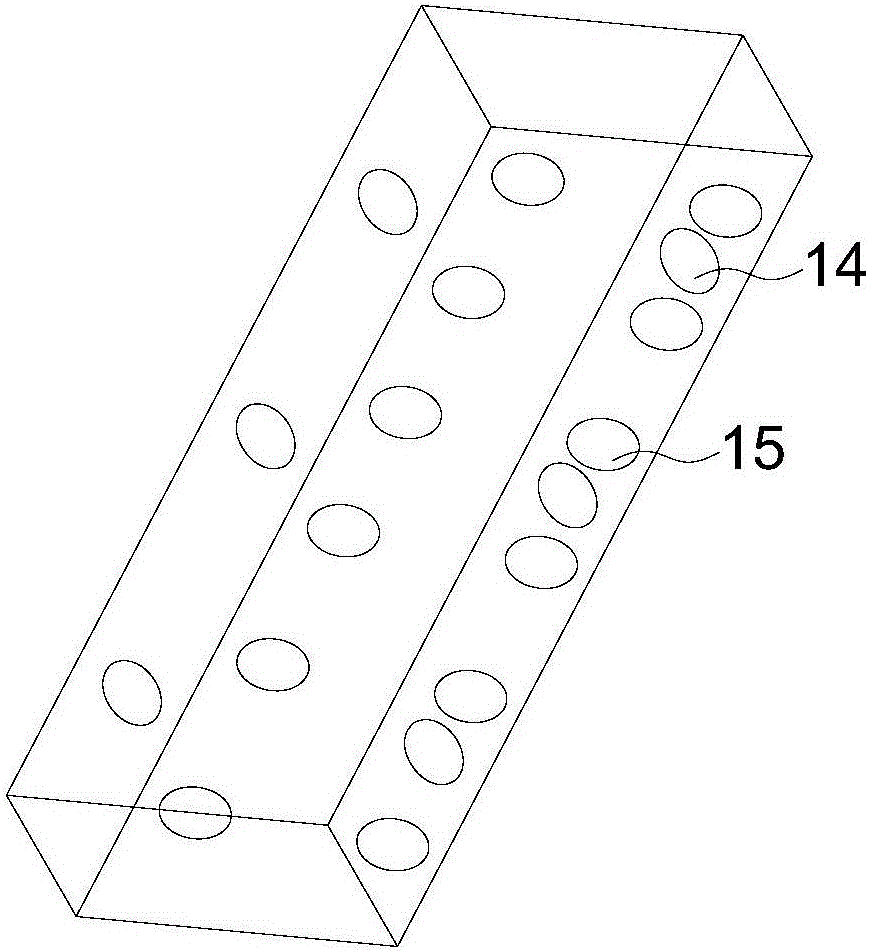

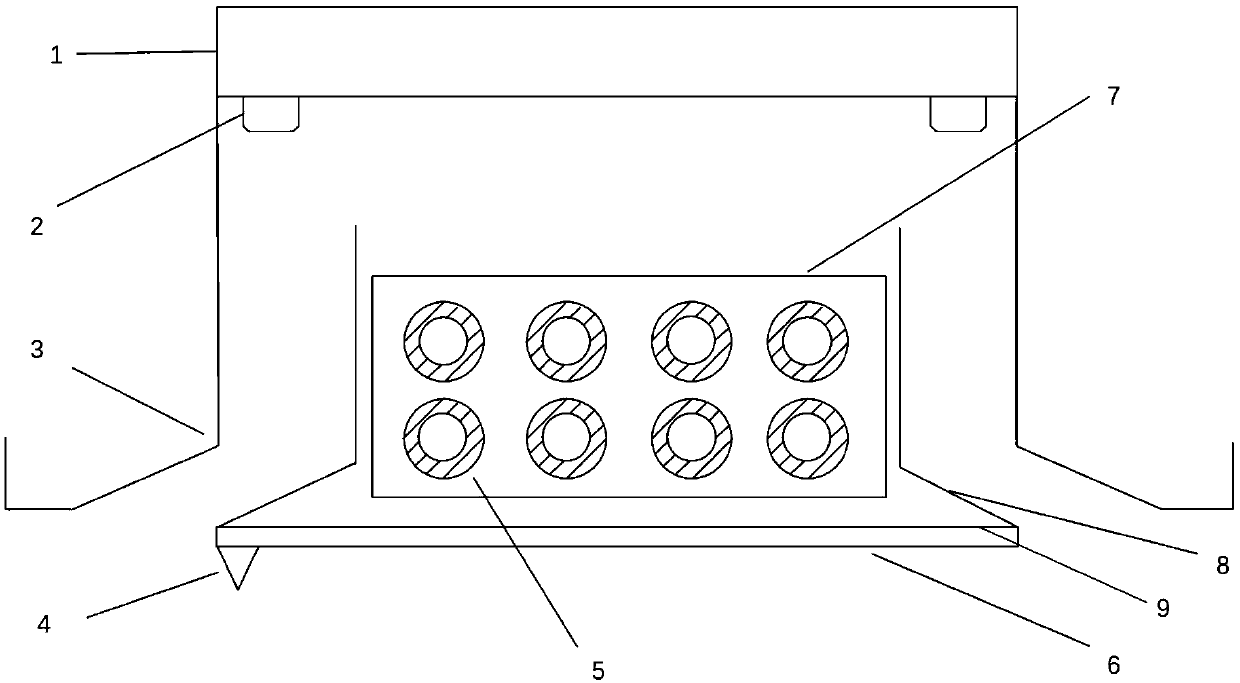

Four-pipe active chilled beam equipment and mounting method thereof

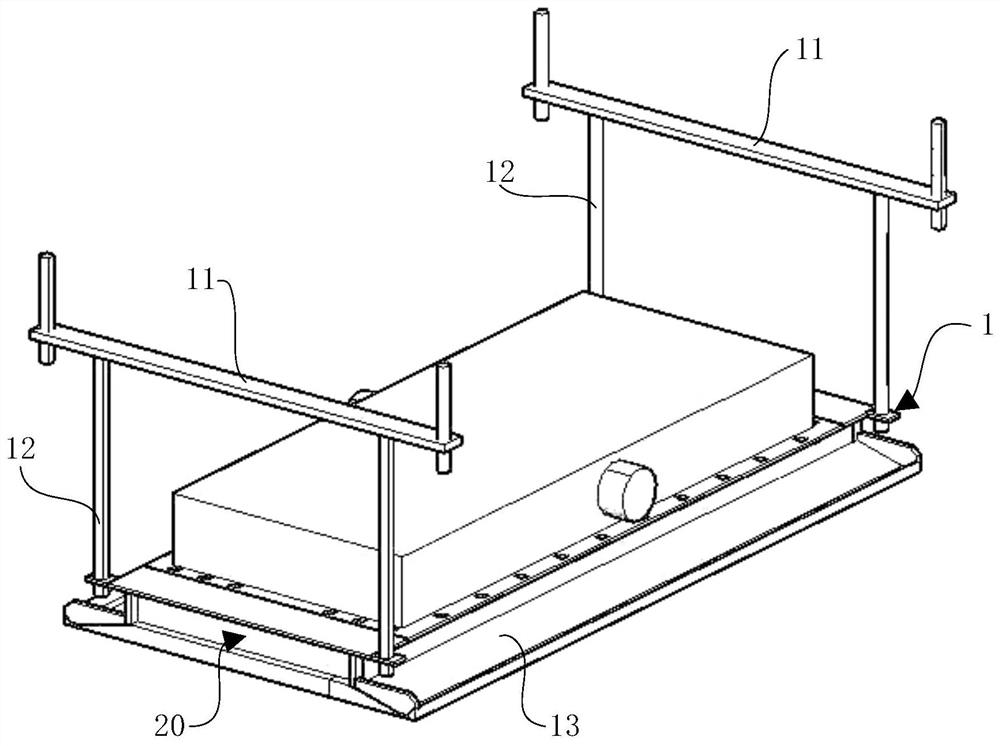

ActiveCN113483390ARealize free adjustmentSolve the problem of re-stentingDucting arrangementsMechanical apparatusEngineeringChilled beam

The invention discloses a four-pipe active chilled beam device and a mounting method thereof. The four-pipe active chilled beam device comprises a conversion support and a four-pipe active chilled beam body, wherein the conversion support comprises two horizontal guide rails arranged in the same direction, a plurality of vertically-arranged transfer rods and a positioning frame; the horizontal guide rails are arranged below a ceiling in a hung mode; guide sliding grooves are formed in the bottoms of the horizontal guide rails; suspended ceiling decoration plates located below the horizontal guide rails are mounted below the ceiling; mounting holes are formed in the suspended ceiling decoration plates; the positioning frame is embedded in the mounting holes; the bottom of the positioning frame is flush with the lower surfaces of the suspended ceiling decoration plates; the upper ends of the transfer rods are arranged in the guide sliding grooves in a sliding mode; at least two transfer rods are arranged in one guide sliding groove; the lower ends of the transfer rods are connected with the positioning frame; the four-pipe active chilled beam body is hung on the ceiling and arranged on the inner sides of the suspended ceiling decoration plates; and a heat exchange return air inlet of the chilled beam body is connected to an upper end opening of the positioning frame. According to the four-pipe active chilled beam device and the mounting method thereof, the problems that the blowing feeling is strong, the operation noise is large and the energy consumption is high because an existing building uses a combined air conditioner or a fan coil or other tail end devices are solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Lighting control for chilled beam

A device comprising a fin structure, a vent disposed in the fin structure, a cooling coil disposed in the vent, a light disposed in the fin structure and wherein the fin structure is configured to create a Coanda effect for air exiting the vent.

Owner:AIR DISTRIBUTION TECH IP LLC

Cold beam with two coiled tubes

PendingCN110500658AEasy to handleIncrease coil areaLighting and heating apparatusSpace heating and ventilation detailsSpray nozzleFresh air

The invention discloses a cold beam with coiled tubes. The cold beam comprises a housing, wherein the cross section of the housing is in the shape of a trapezoid; an air return hole is formed in the bottom of the housing; two inner side walls of the housing are equipped with air outlet pipelines parallel to the side surface of the housing in a length direction of the housing; the bottom surfaces of the air outlet pipelines are equipped with air outlets in a length direction of the air outlet pipelines; the inner side walls of the air outlet pipelines are symmetrically equipped with one heat exchange coiled tube which communicates with the air outlet pipelines separately; and top surfaces, close to fresh air inlets, of the air outlet pipelines are equipped with spray nozzles for guiding fresh air into the air outlet pipelines. According to the technical scheme adopted by the invention, the key point is that the two heat exchange coiled tubes can be adopted to increase coiled tube area,and improves processing ability of circulating air; and fresh air is sprayed in from the spray nozzle after entering the housing to cause low-pressure of the air outlet pipelines, so that indoor circulating air is sucked in from the air return hole, and is mixed with fresh air for being fed into the room after being treated through the heat exchange coiled tubes, and mixed air is blown out from the two sides below the housing, and therefore, better refrigerating effect and air circulating ability are achieved.

Owner:KUNSHAN KLIMASYSTTECHN

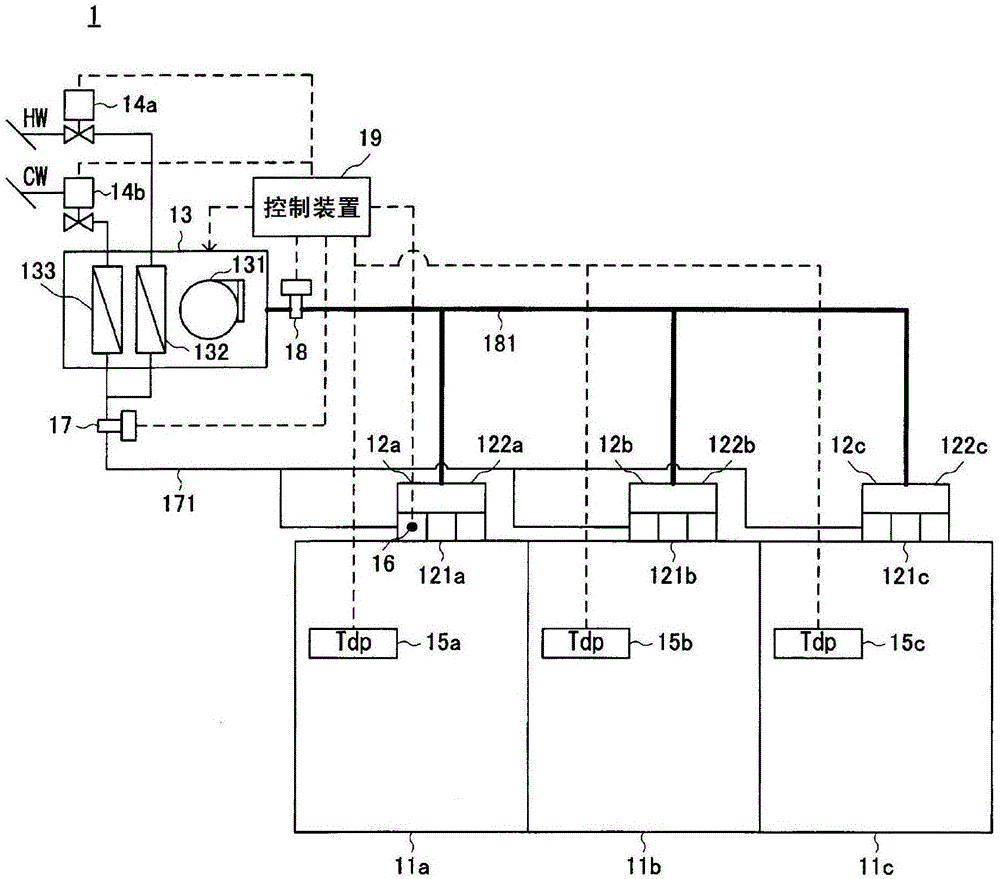

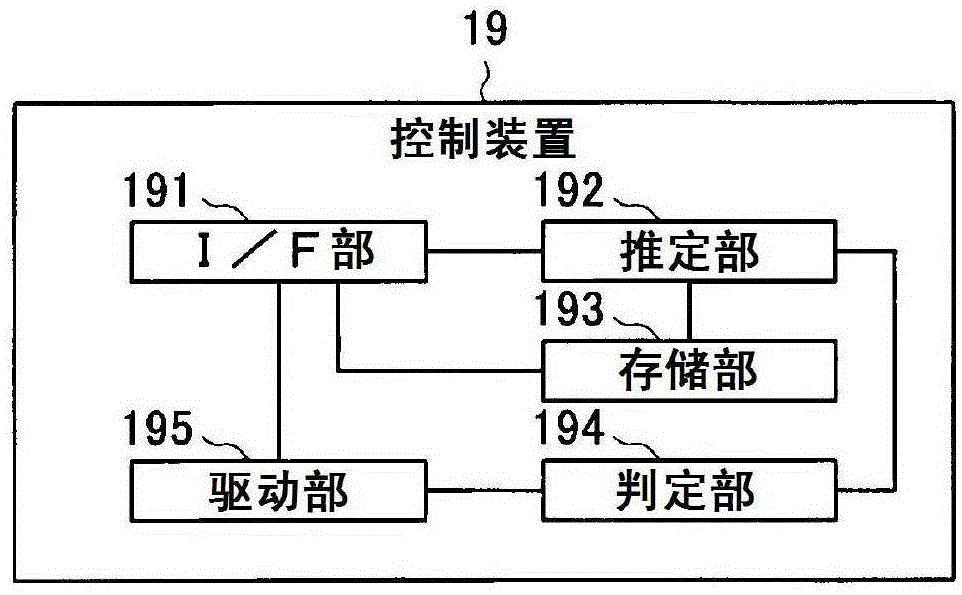

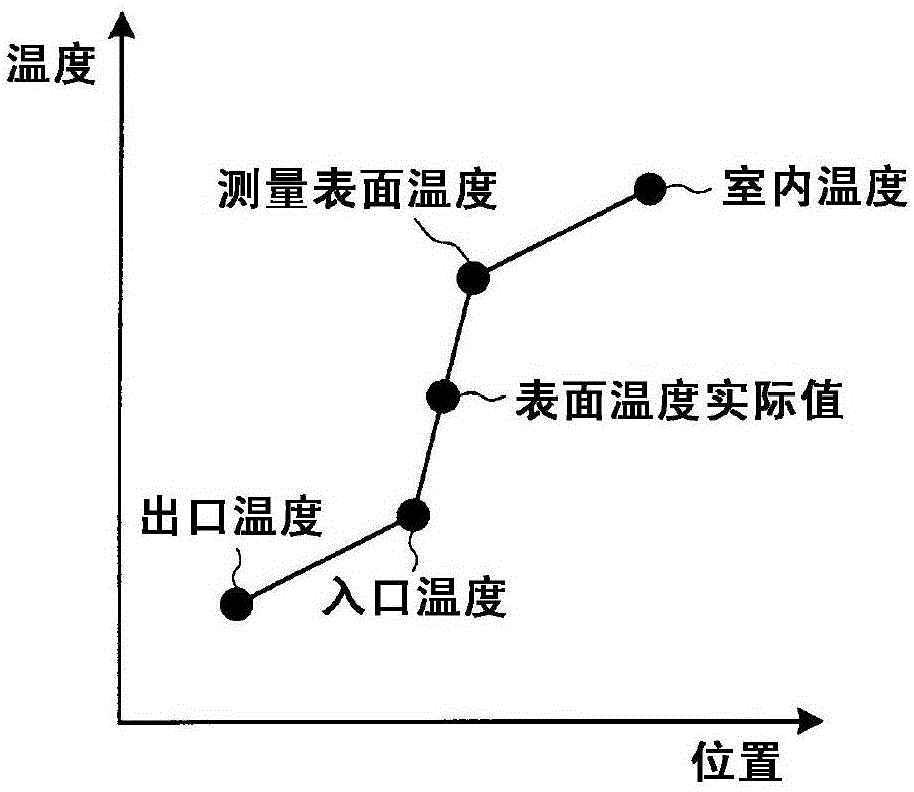

Surface temperature estimating device, surface temperature estimating method, and dew condensation judging device

InactiveCN103075784BSpace heating and ventilation safety systemsLighting and heating apparatusEstimation methodsEngineering

The present invention provides a surface temperature estimation device which is suitable for estimating the surface temperature of a heat exchanger with condensate generation, a surface temperature estimation method and a condensate determination device. A control device (19) estimates surface temperature of a heat exchanger (121a) according to the temperature of refrigerant which is supplied by an outer unit (13) and is measured by an outlet temperature sensor (17) and the temperature that is measured by a surface temperature sensor configured on the surface of the heat exchanger (121a). Therefore, the surface temperature of the heat exchanger which is suitable for forecasting condensate generation can be obtained. Furthermore, the obtained value is compared with an indoor dew point temperature which is measured by indoor sensors (15a-15c) for determining whether condensate occurs on the heat exchangers (121a-121c) of cold beams (12a-12c). Therefore, the result of the surface temperature estimation device can forecast condensate more accurately.

Owner:YAMATAKE HONEYWELL CO LTD

Cooling a roll of a roll stand

ActiveUS11338339B2Reduce operating costs and energy consumptionIncrease impact pressureRollsMetal rolling arrangementsJet flowEngineering

A cooling device (7) for cooling a roll (5) of a roll stand (1). The cooling device (7) includes a chilled beam (13) for receiving and discharging a coolant. The chilled beam (13) has multiple full jet nozzles (21) disposed on a discharge side (19) of the chilled beam (13), the side facing the roll (5) and extending parallel to a roll axis (17) of the roll (5). Through each of the full-jet nozzles, a jet of coolant having a nearly constant jet diameter can be sprayed from the chilled beam (13) towards the roll (5) in a discharge direction (23).

Owner:PRIMETALS TECH AUSTRIA GMBH

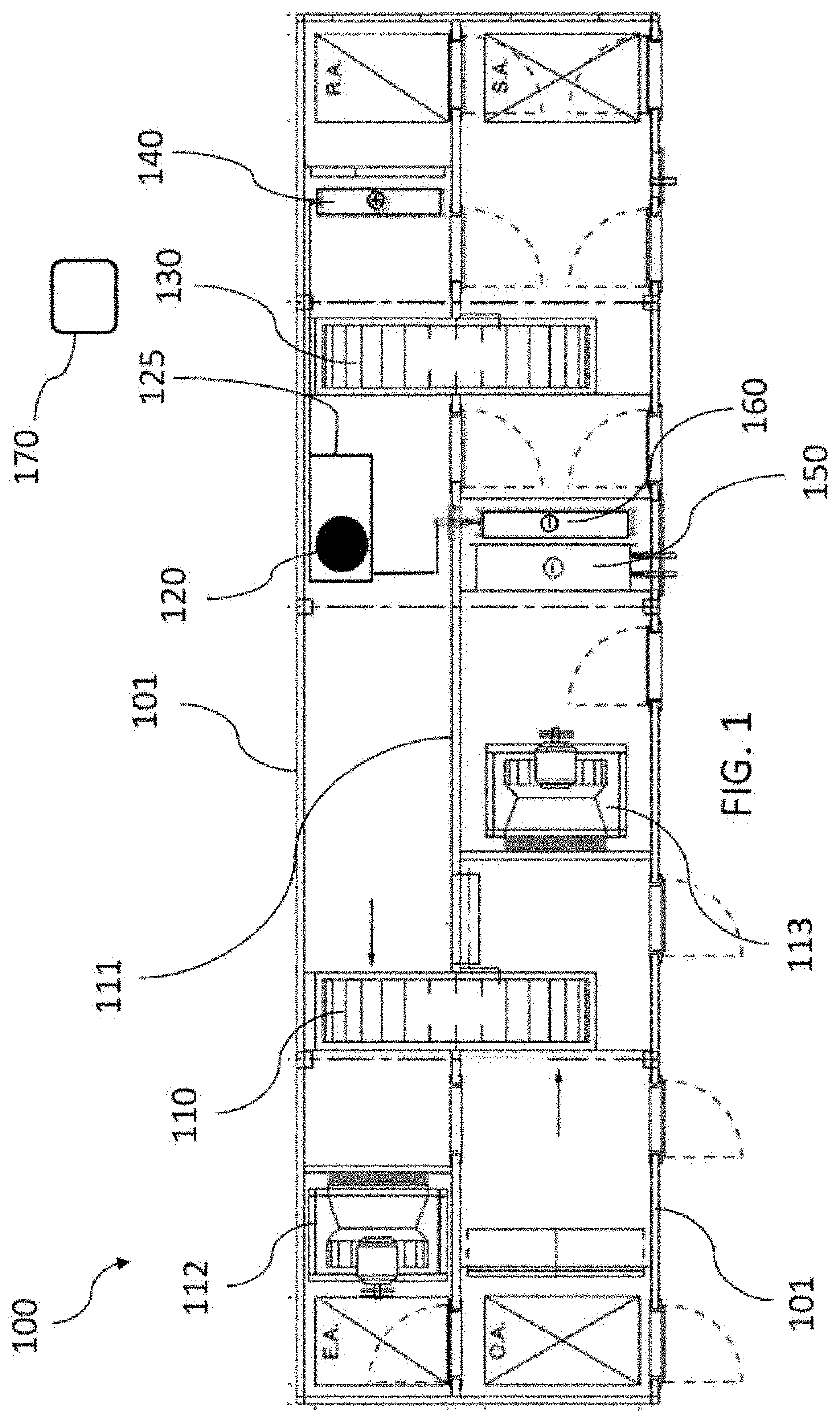

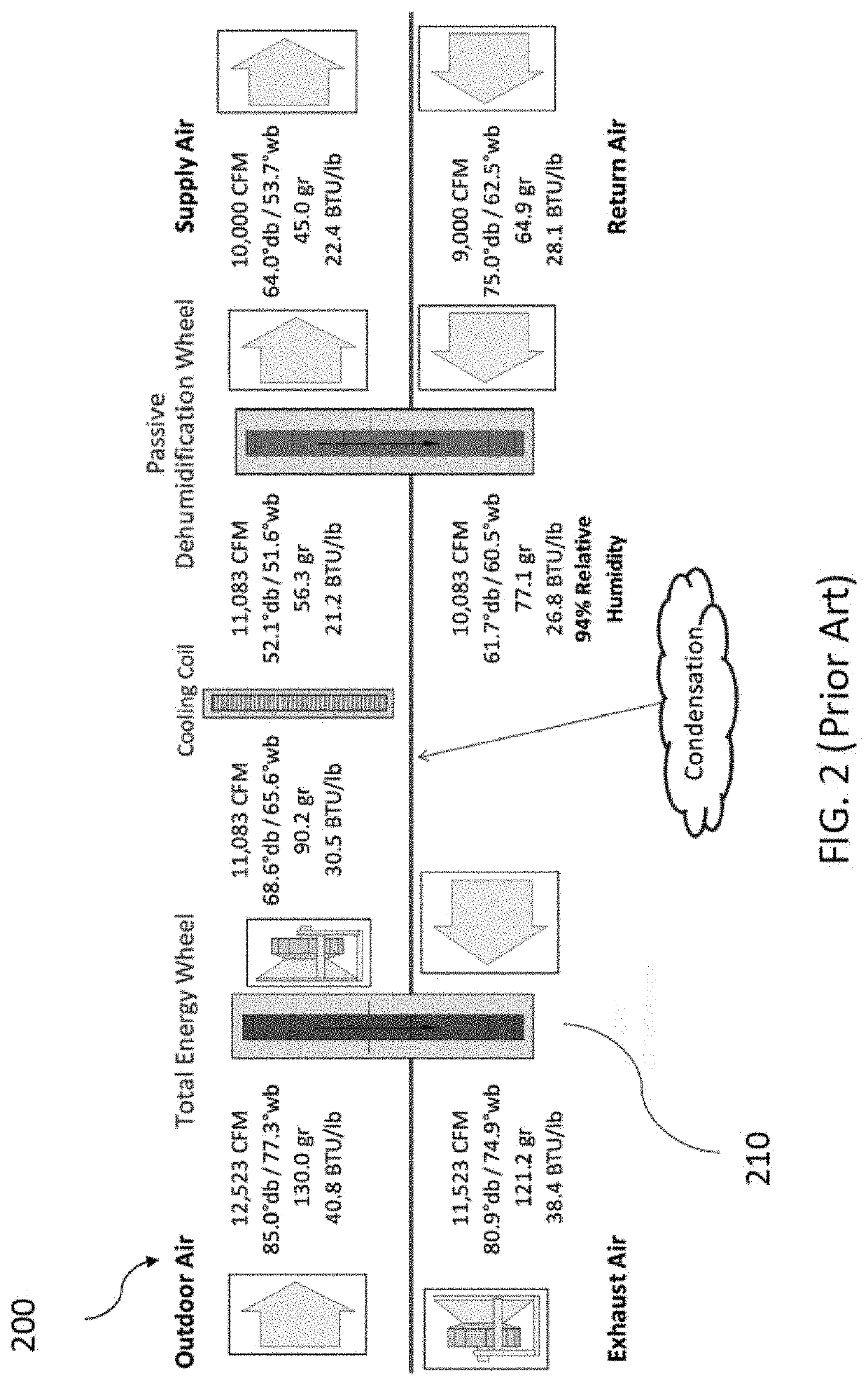

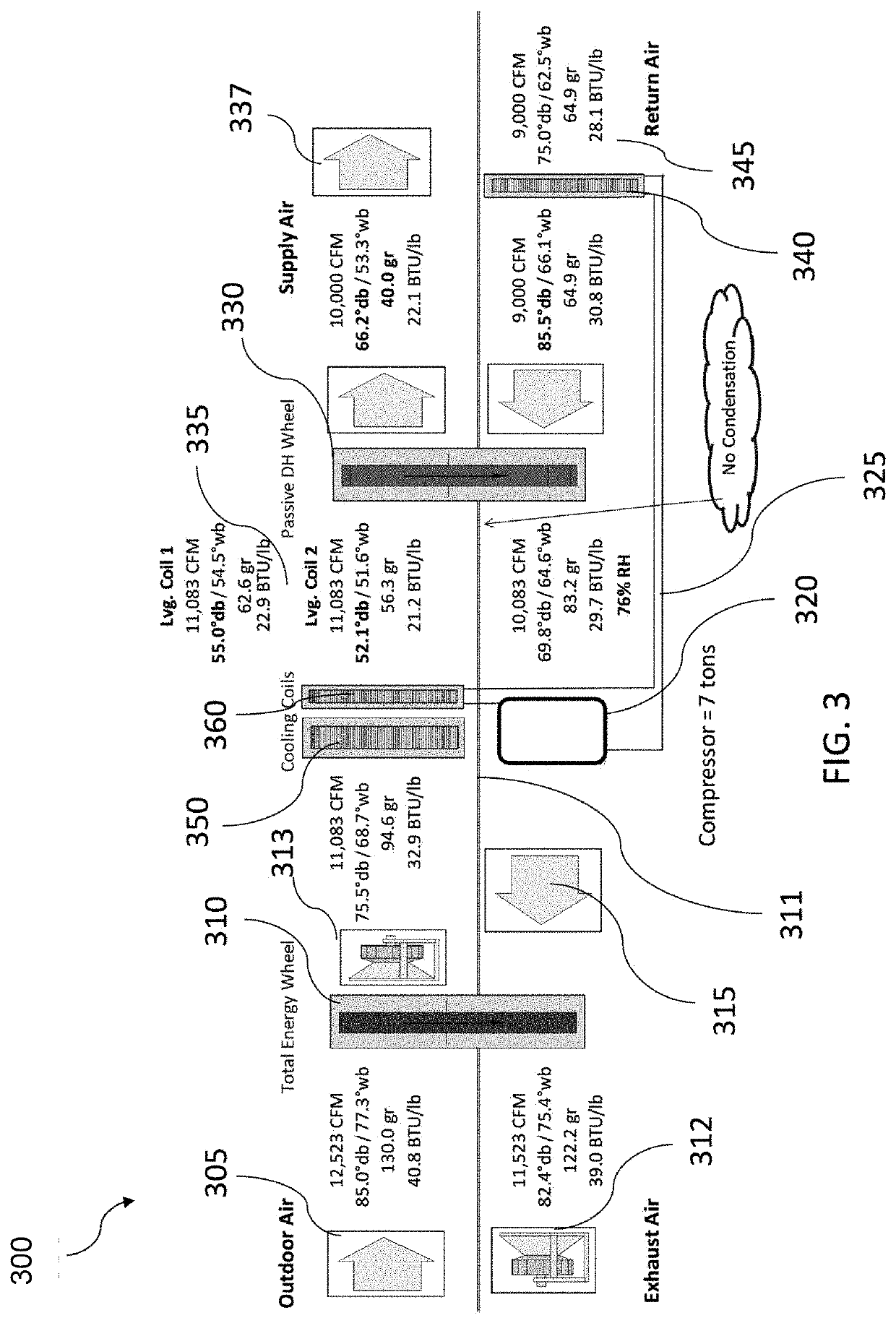

Air conditioning with recovery wheel, dehumidification wheel, cooling coil, and secondary direct-expansion circuit

PendingUS20220228763A1Inhibition formationLess riskMechanical apparatusEfficient regulation technologiesCooling coilExhaust fumes

Systems and methods for controlling temperature and humidity within a space in a building. Outdoor air and return air from the space are passed through particular equipment in a particular order. Equipment includes a secondary direct-expansion refrigeration circuit, a recovery wheel, a primary cooling coil, secondary circuit evaporator and condenser coils, and a dehumidification wheel. Various embodiments include multiple zones, chilled beams, and a dedicated outdoor air supply (DOAS) subsystem delivering dehumidified air to active chilled beams. In various embodiments, supply air passes first through the recovery wheel, then through the primary cooling coil, then through the dehumidification wheel, and then to the space. Further, in some embodiments, exhaust air passes through the dehumidification wheel and then through the recovery wheel. Pump modules may supply chilled beams and control their temperature to avoid condensation. A chiller may supply cooling water to both the primary cooling coil and the pump modules.

Owner:SEMCO INC

An active chilled beam air conditioner terminal

ActiveCN112283799BWell mixedIncrease the areaLighting and heating apparatusAir conditioning systemsAir volumeFresh air

Owner:WUHAN UNIV OF TECH

Ejector, chilled beam tail end and chilled beam system

PendingCN110940084ASimple structureImprove reliabilityLighting and heating apparatusSpace heating and ventilation detailsEngineeringAir change

The invention provides an ejector, a chilled beam tail end and a chilled beam system. The ejector comprise a nozzle shell, the nozzle shell comprises an airflow leading-in section used for leading inprimary air, a nozzle throat part used for conducting throttling acceleration on the led-in primary air, and an airflow output section used for spraying out the throttled and accelerated primary air;the nozzle throat part is located between the airflow leading-in section and the airflow output section; and when the air pressure of the primary air changes, the nozzle shell can elastically deform so as to change the through-flow area of the nozzle throat part. According to the ejector, the chilled beam tail end and the chilled beam system, the nozzle shell can make elastic deformation when theprimary air pressure changes, then the through-flow area of the throat of the nozzle is changed, the structure is simple, the reliability is high, maintenance is convenient, and the cost is low.

Owner:GREE ELECTRIC APPLIANCES INC

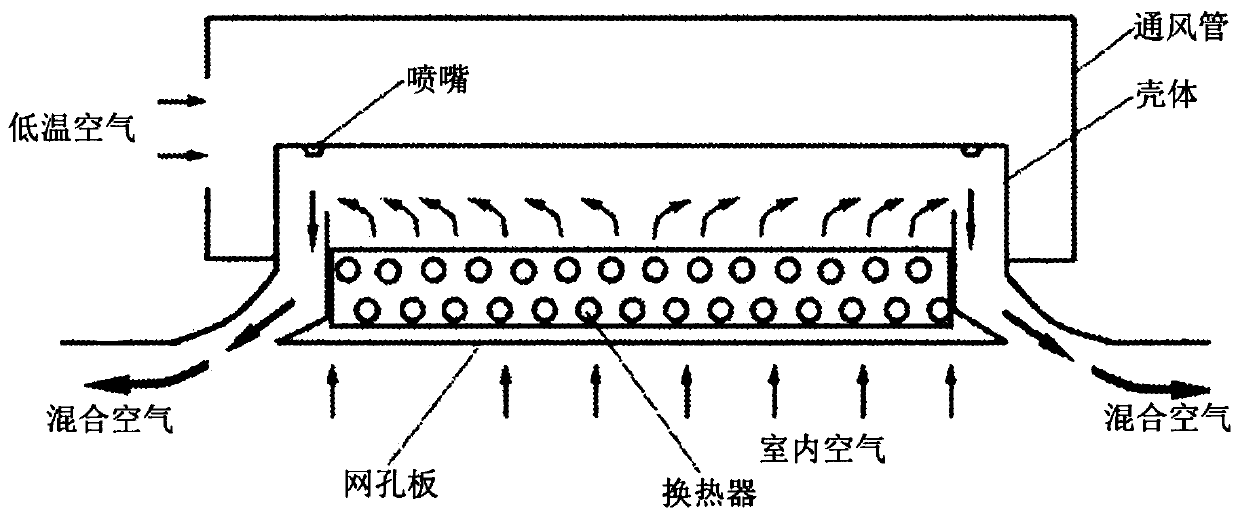

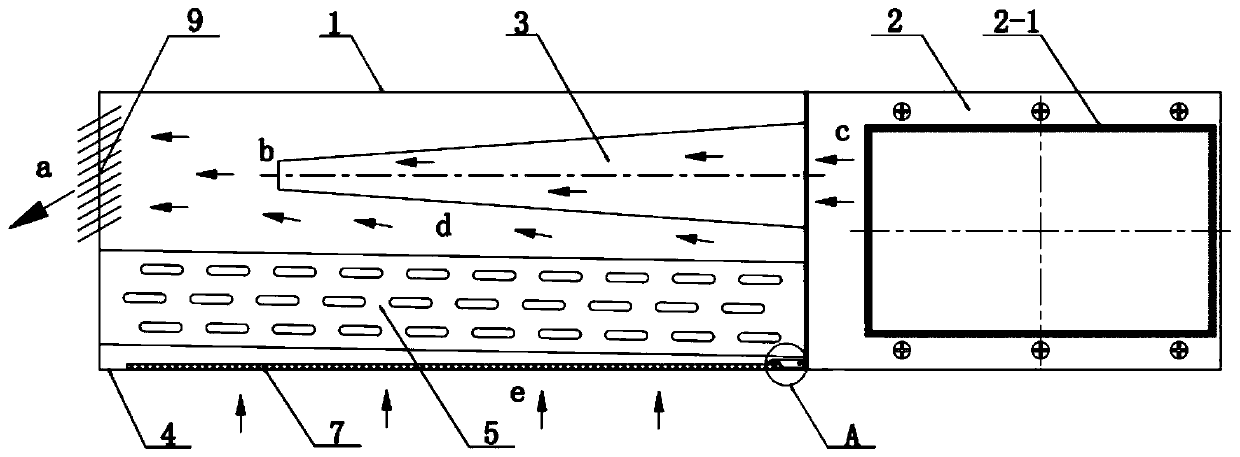

Active chilled beam tail end device and active chilled beam air conditioning system

PendingCN110887113AReduce the temperatureMake full use of cooling capacityDucting arrangementsCondensate preventionEngineeringChilled beam

The invention discloses an active chilled beam tail end device and an active chilled beam air conditioning system. The tail end device comprises a shell, a vent pipe, a nozzle, a mesh plate, a heat exchanger, a water pan and a filter, wherein one end with an air inlet hole of the shell is connected with the side wall of the vent pipe; the lower end face of the shell is provided with a mesh plate mounting hole for mounting the mesh plate; the nozzle which is in communication with the inner cavity of the vent pipe is arranged at the air inlet of the shell; one end, close to the vent pipe, of theheat exchanger is lower than one end, far away from the vent pipe, of the heat exchanger; both the water pan and the filter are arranged on the upper end face of the mesh plate; and the water pan isconnected with the filter through a siphon device. The active chilled beam air conditioning system comprises an active chilled beam tail end device, wherein the active chilled beam tail end device isthe active chilled beam tail end device disclosed by the invention. Through the adoption of the active chilled beam tail end device, the ground or a user can be protected from getting wet by falling condensed water gathered on the surface of the heat exchanger and the surface of the nozzle; the cooling capacity of the condensed water is fully utilized; the refrigerating efficiency is improved; andthe user experience is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Combined Application System of Ejection Refrigeration and Active Chilled Beam

ActiveCN105042741BRaise the evaporation temperatureImprove performanceLighting and heating apparatusAir conditioning systemsActive coolingEngineering

The invention relates to a jet refrigeration and active cooling beam combined applying system which comprises a jet refrigeration subsystem and an active cooling beam subsystem. The jet refrigeration subsystem comprises a generator (1), a low-pressure ejector (2), a high-pressure ejector (3), a condenser (4), a water pump (5), a low-temperature side evaporator (6), a high-temperature side evaporator (7), a low-pressure throttling valve (8) and a high-pressure throttling valve (9). Outlet gas of the generator (1) is divided into two routes and enters the condenser (4). Outlet refrigerant of the condenser (4) enters the generator (1), the high-temperature side evaporator (7) and the low-temperature side evaporator (6) to complete refrigeration circulation. A cooling beam wind side tail end exchanges heat with the low-temperature side evaporator (6) through a low-temperature heat exchanger (10), and a cooling beam water side tail end exchanges heat with the high-temperature side evaporator (7) through a high-temperature heat exchanger (11). Compared with the prior art, the jet refrigeration and active cooling beam combined applying system has the advantages that the advantages of a cooling beam are brought into play, the structure is simple, the jet refrigeration evaporation temperature is increased, and the integrity of the system is high.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com