Patents

Literature

38results about How to "Simple design and installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

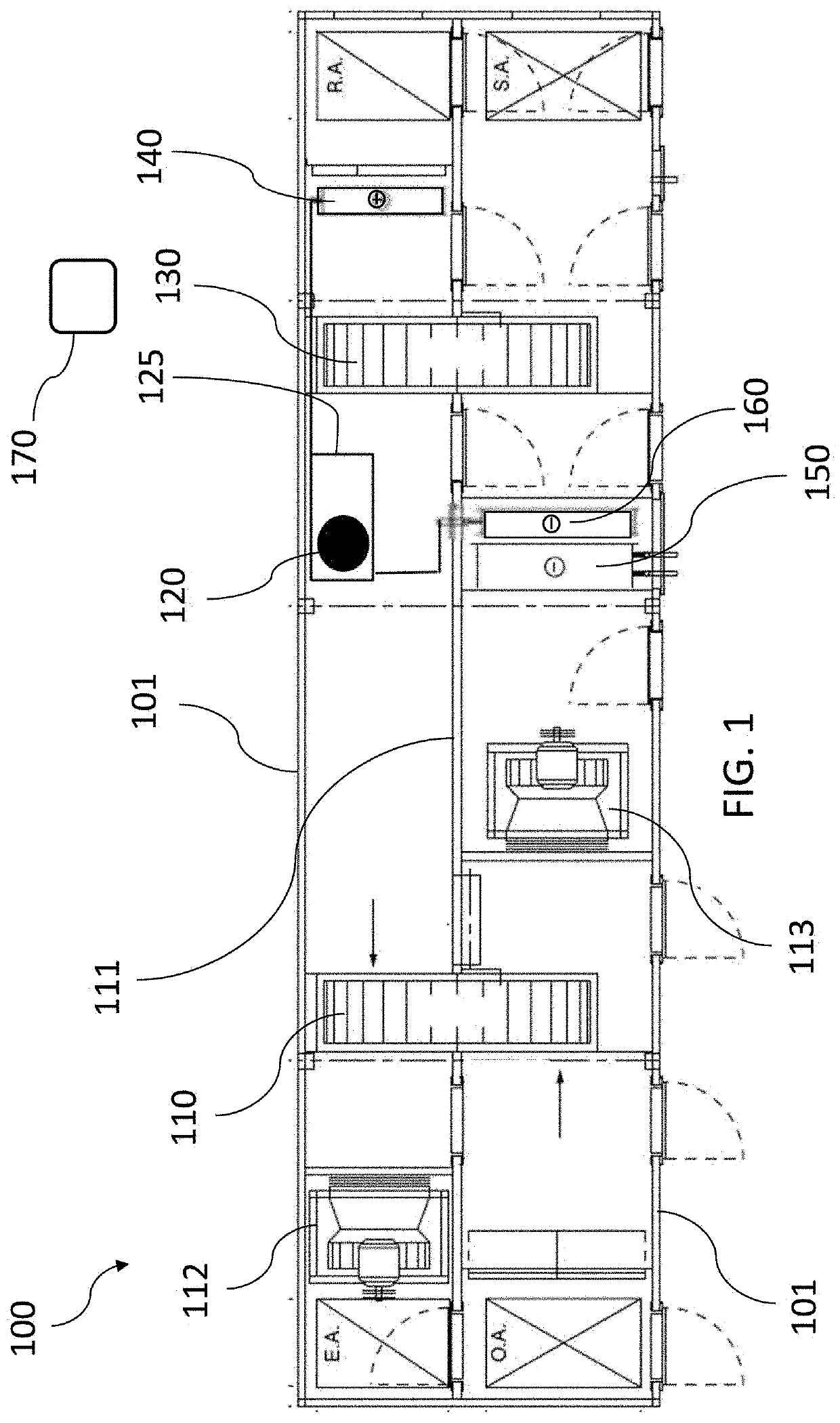

Chilled beam pump module, system, and method

ActiveUS20130199772A1Improve performanceSimple design and installationTemperatue controlHeat exchange apparatusWarm waterComputer module

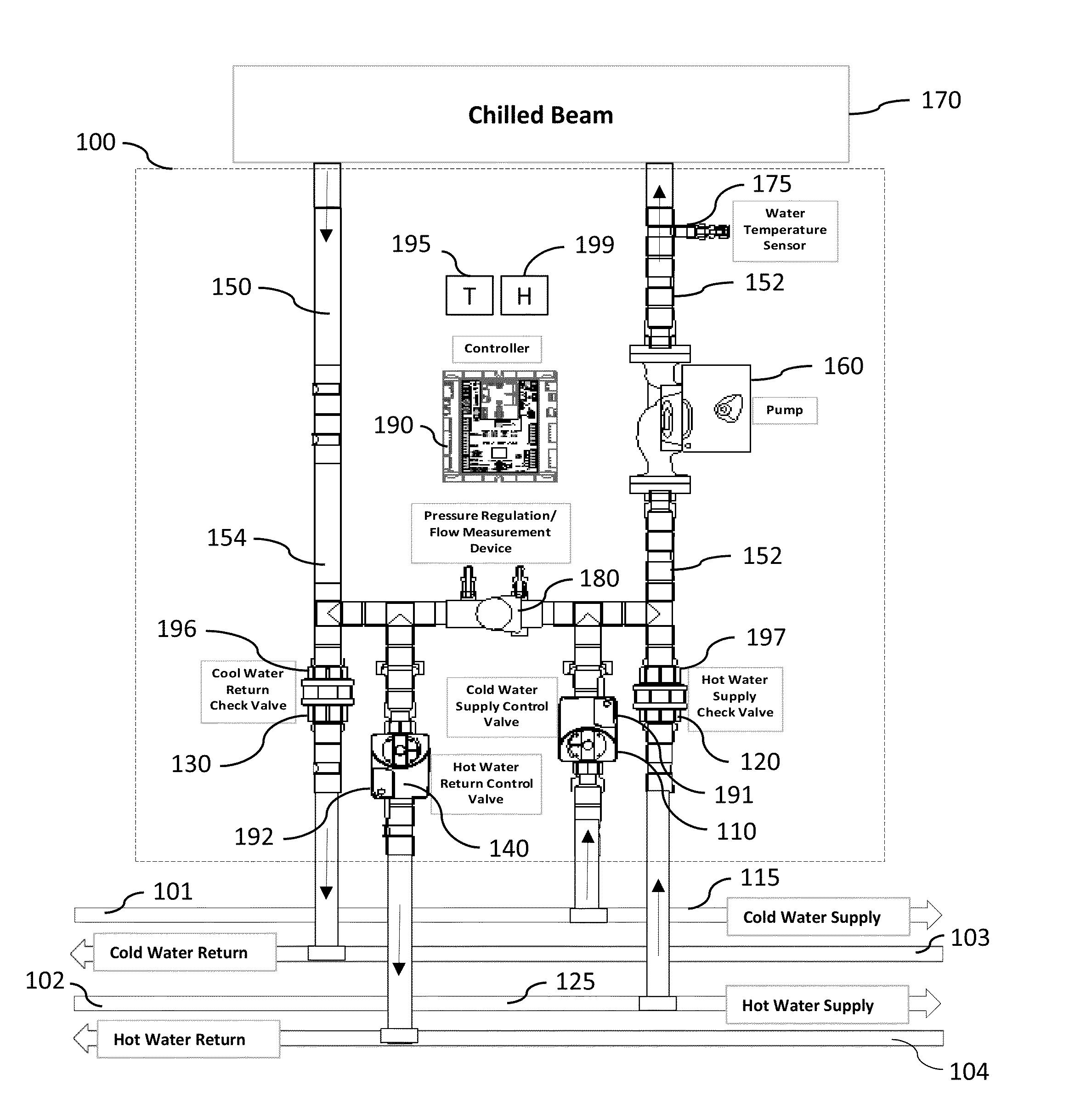

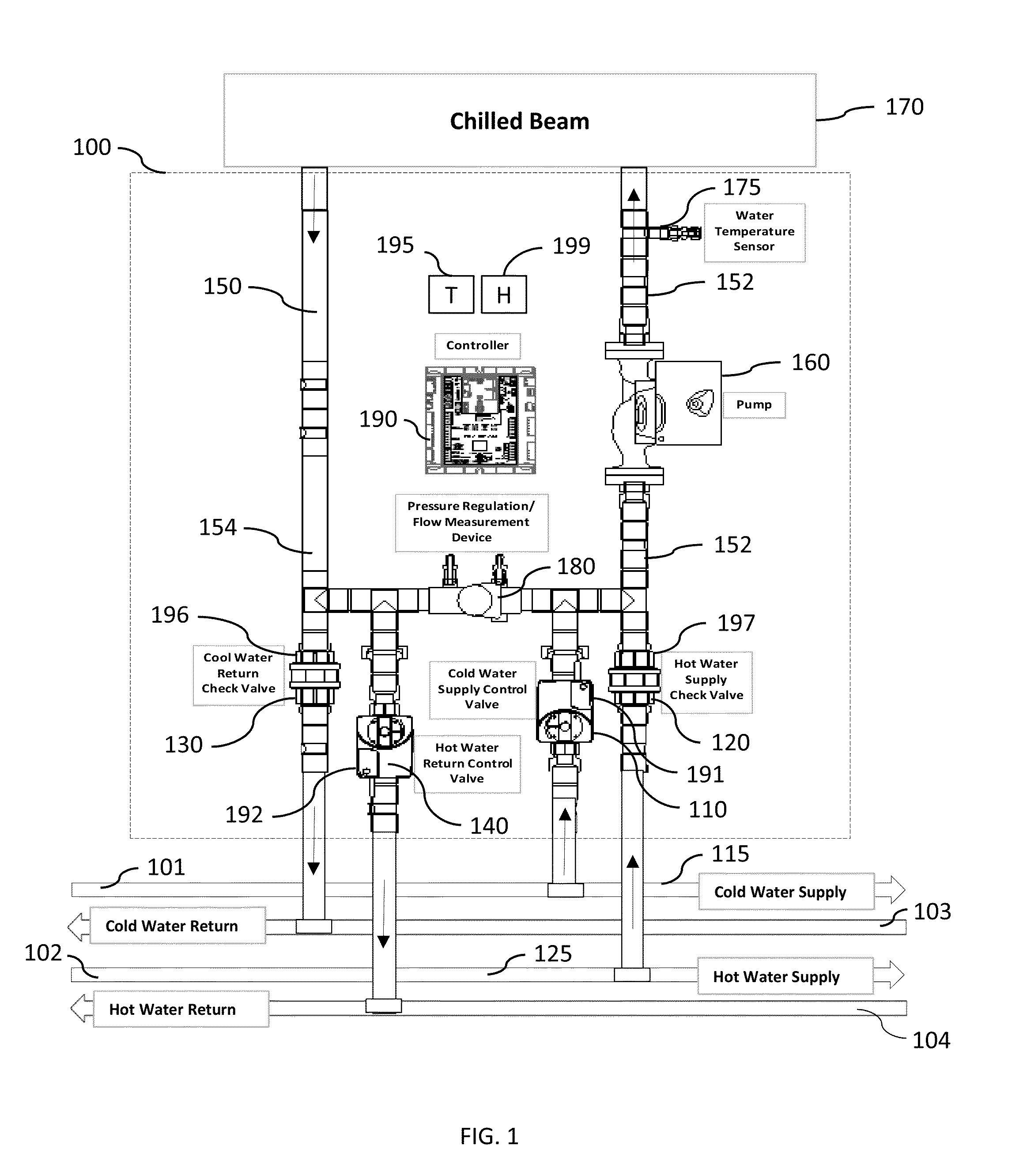

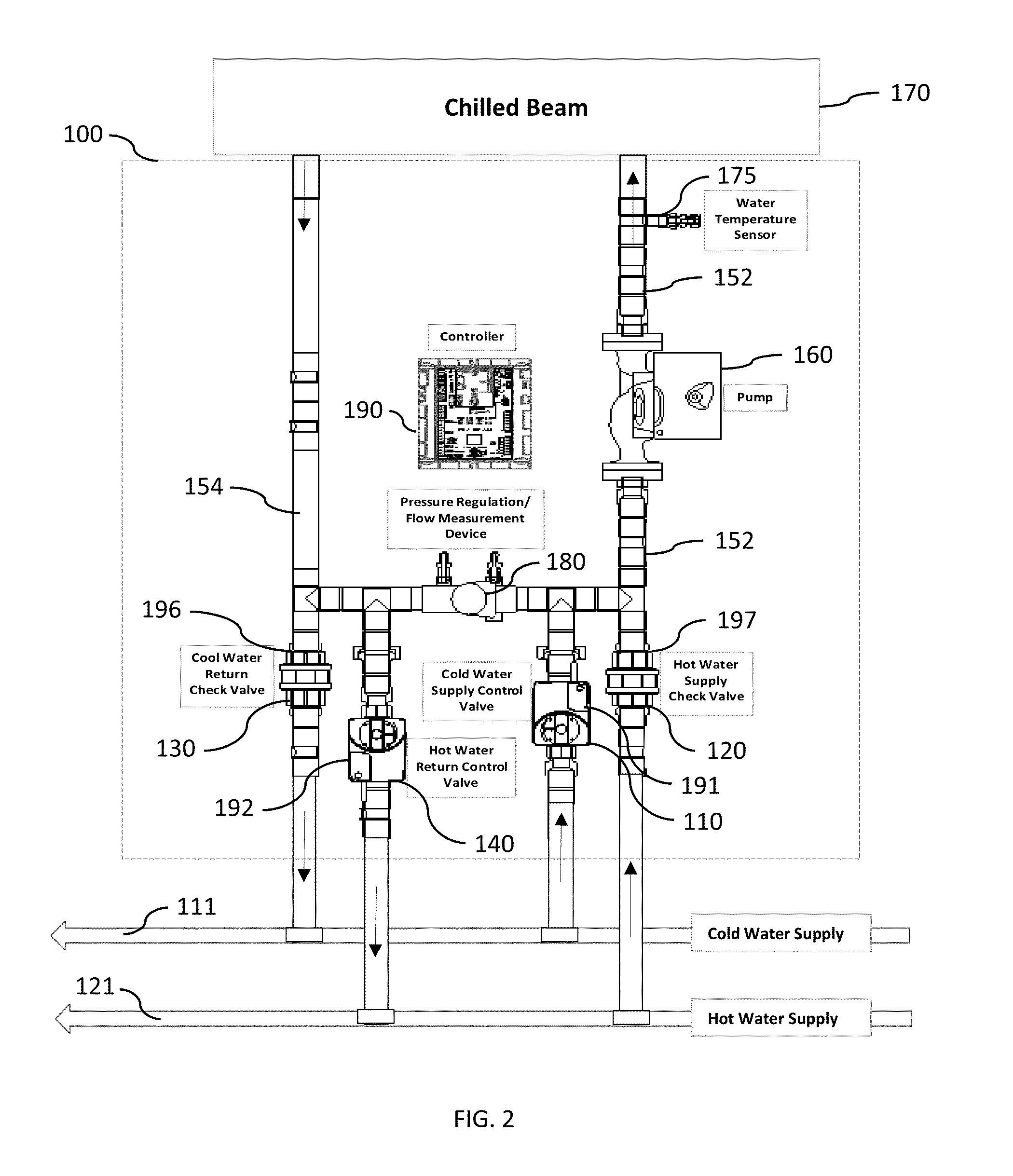

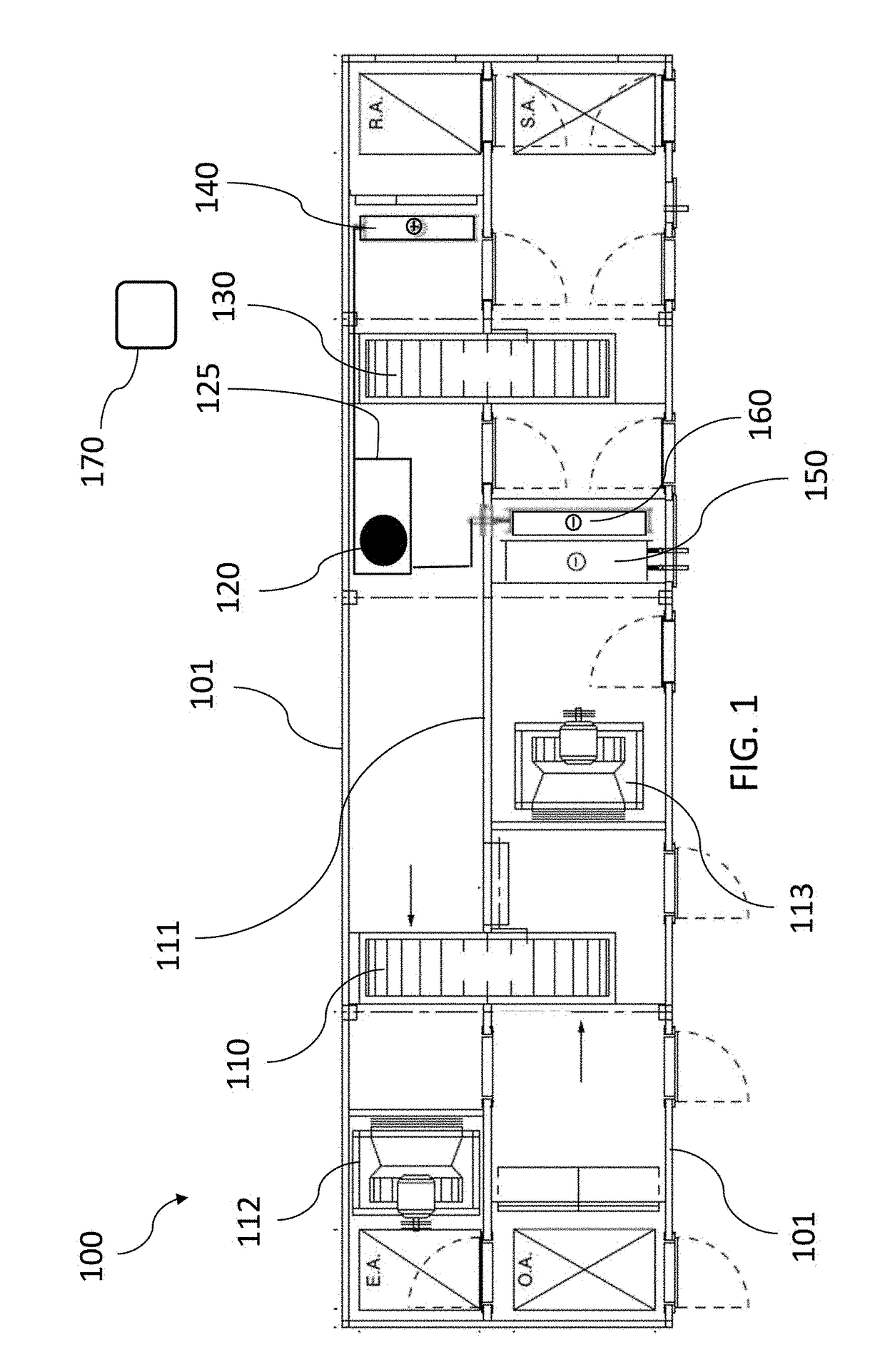

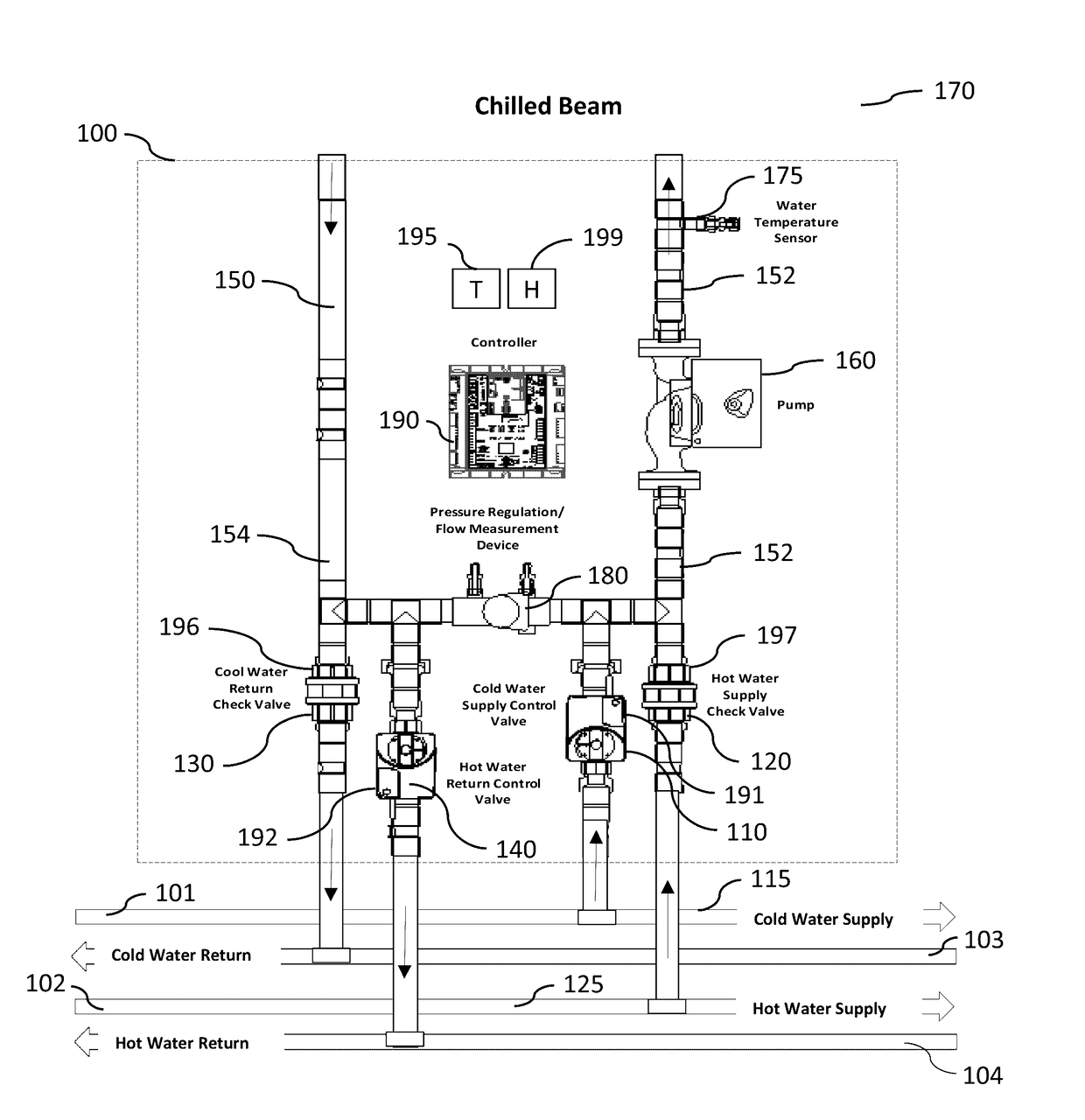

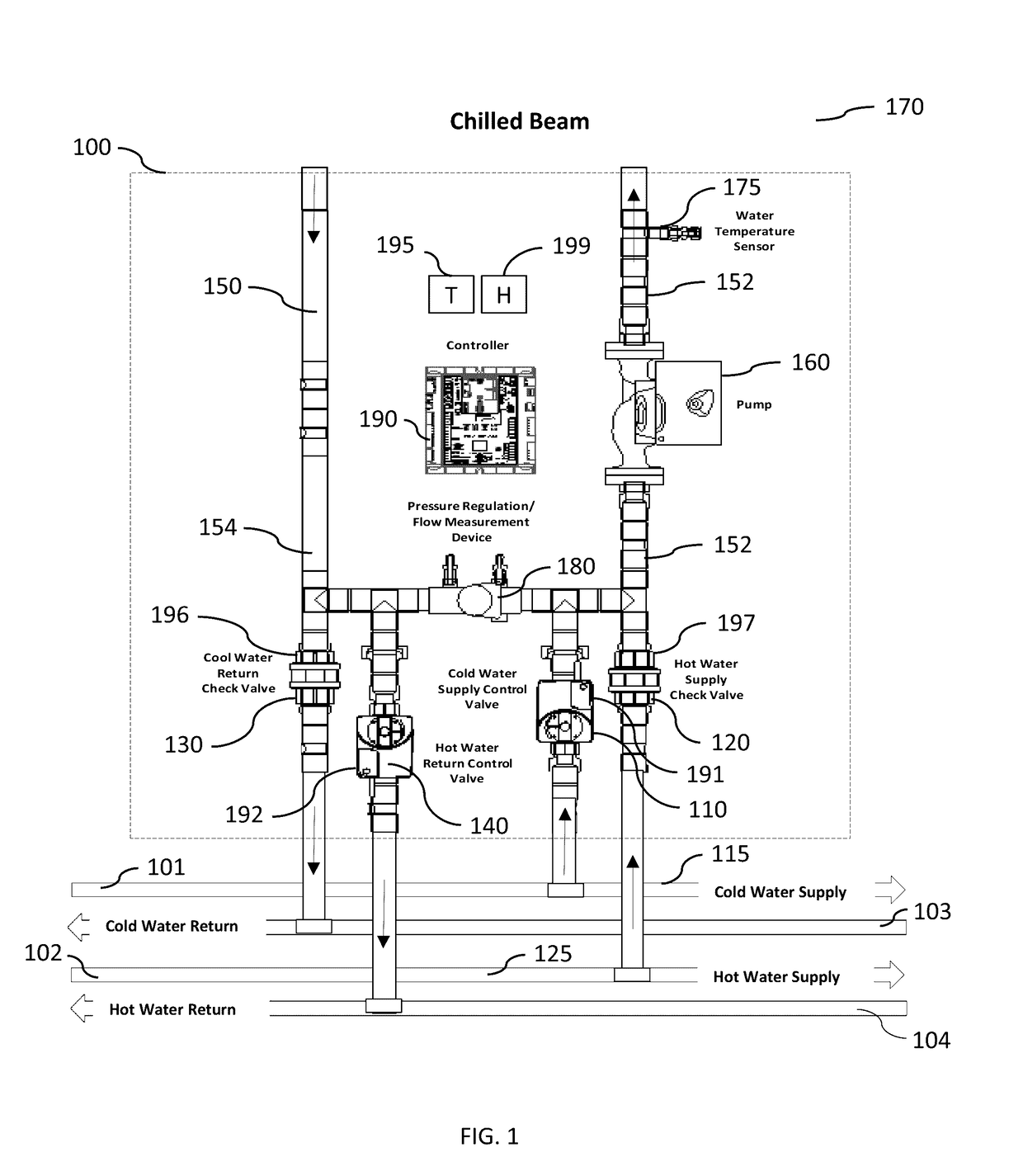

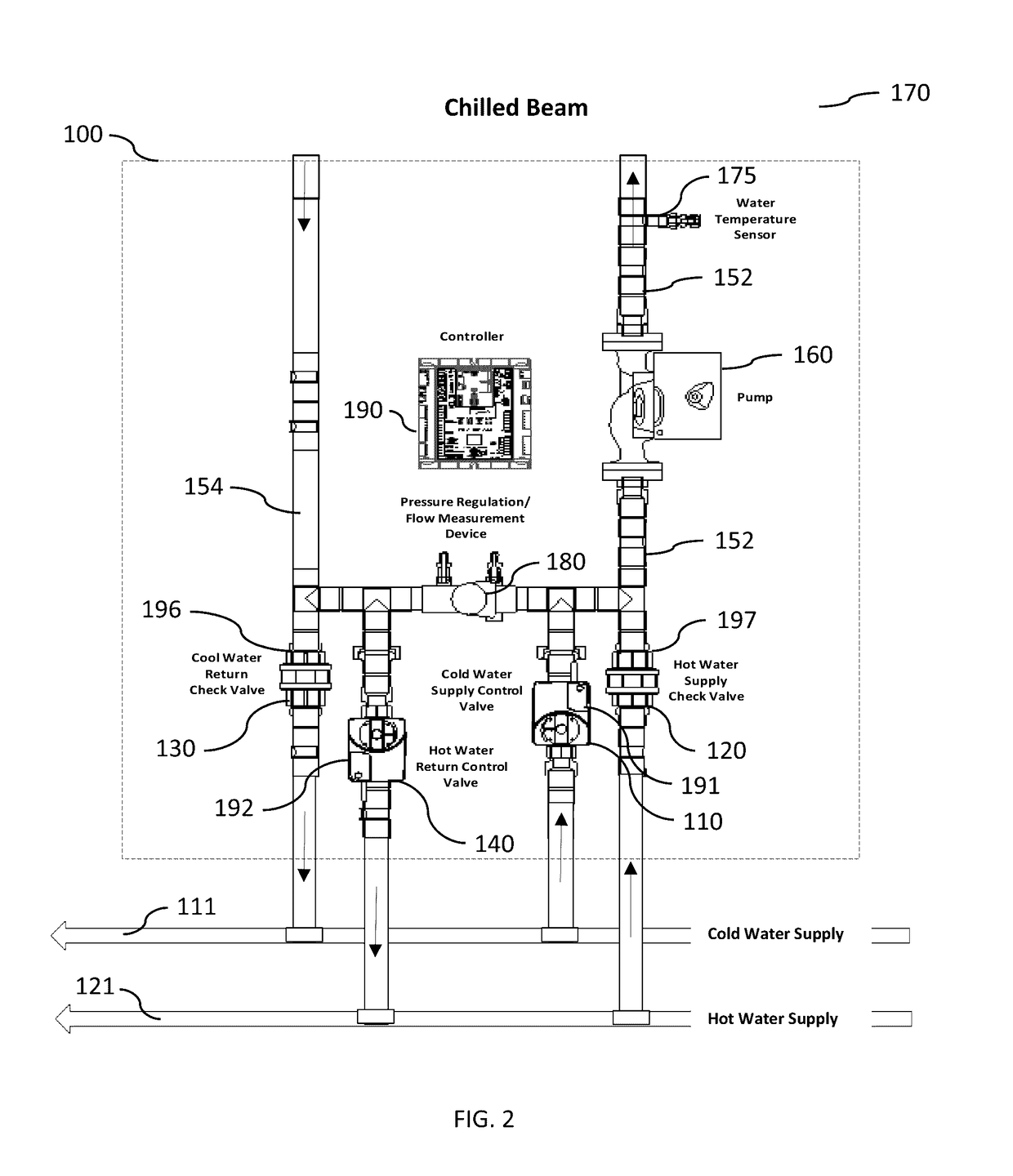

Chilled-beam zone pump modules for controlling zones of a chilled-beam heating and air conditioning system, multiple-zone chilled beam air conditioning systems for cooling multiple-zone spaces, and methods of controlling chilled beams in multi-zone air conditioning systems. Embodiments include a pump serving each zone that both recirculates water within the module and chilled beam and circulates water in and out of a chilled or warm water distribution system through valves to control temperature. Different embodiments provide heating as well as cooling, use check valves to reduce the number of control valves required, adjust the temperature of the beam to avoid condensation, change pump speed to save energy or increase capacity, can be used in two- or four-pipe systems, allow for lower installation cost, provide better performance or control, improve reliability, overcome barriers to the use of chilled beams, or a combination thereof.

Owner:SEMCO INC

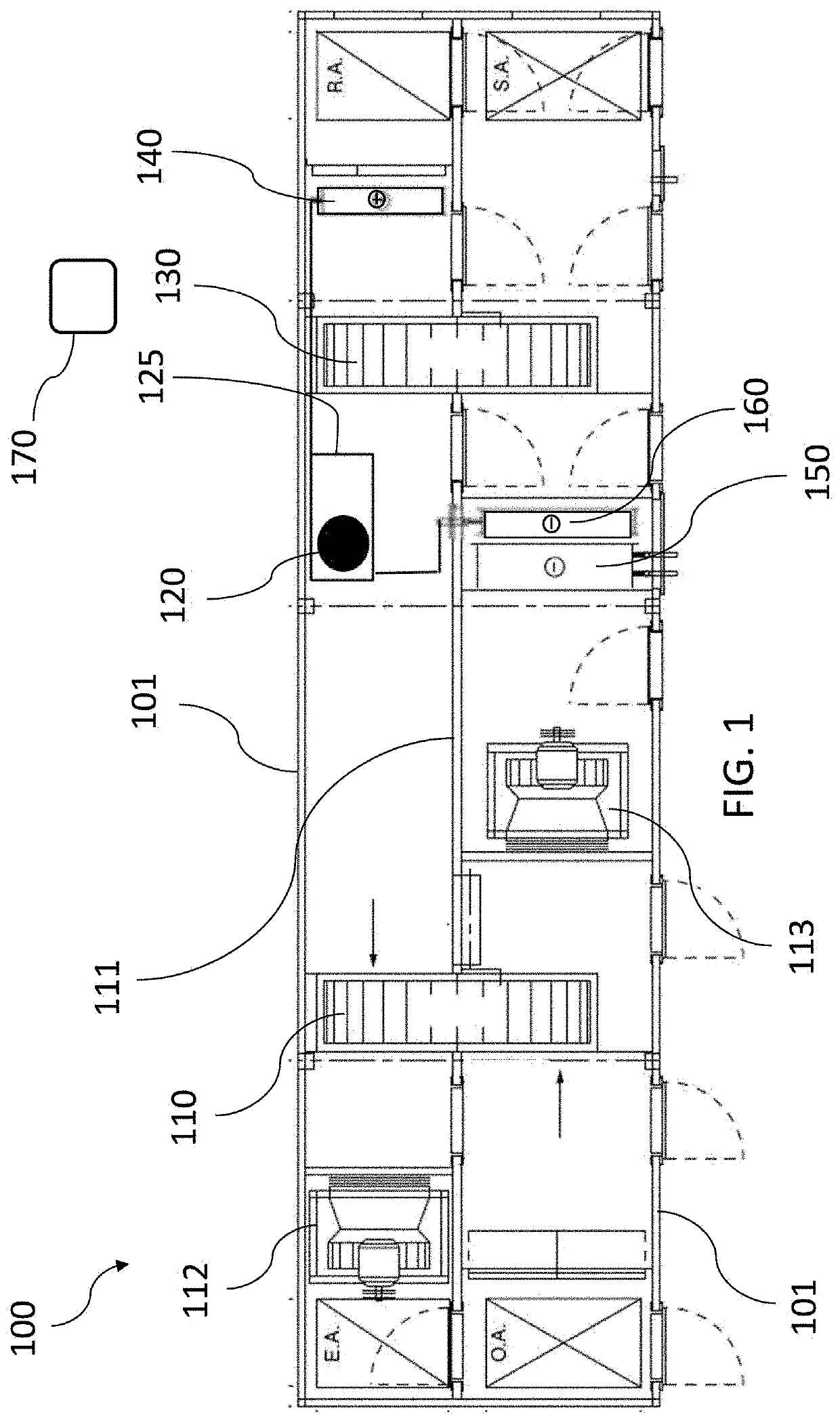

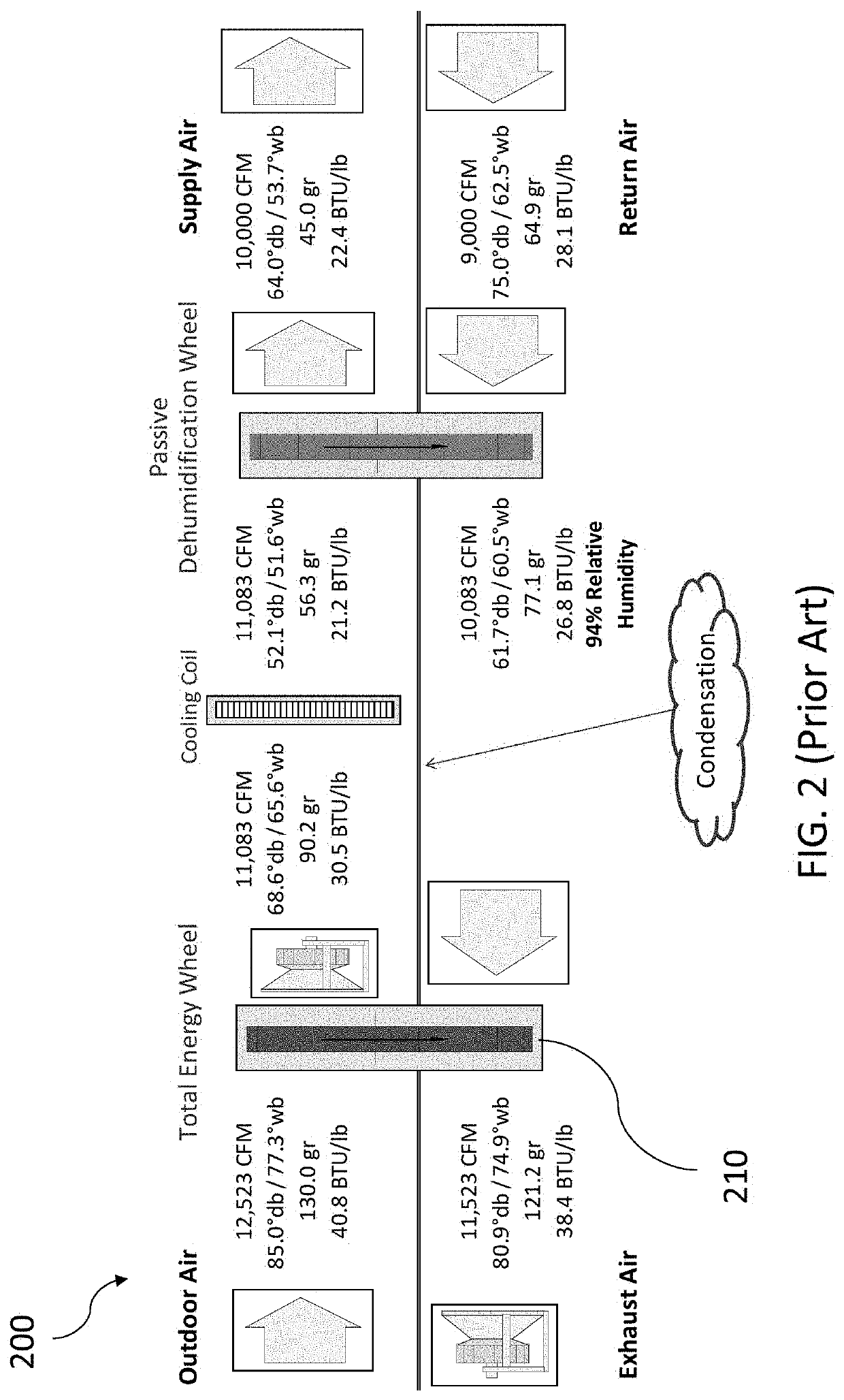

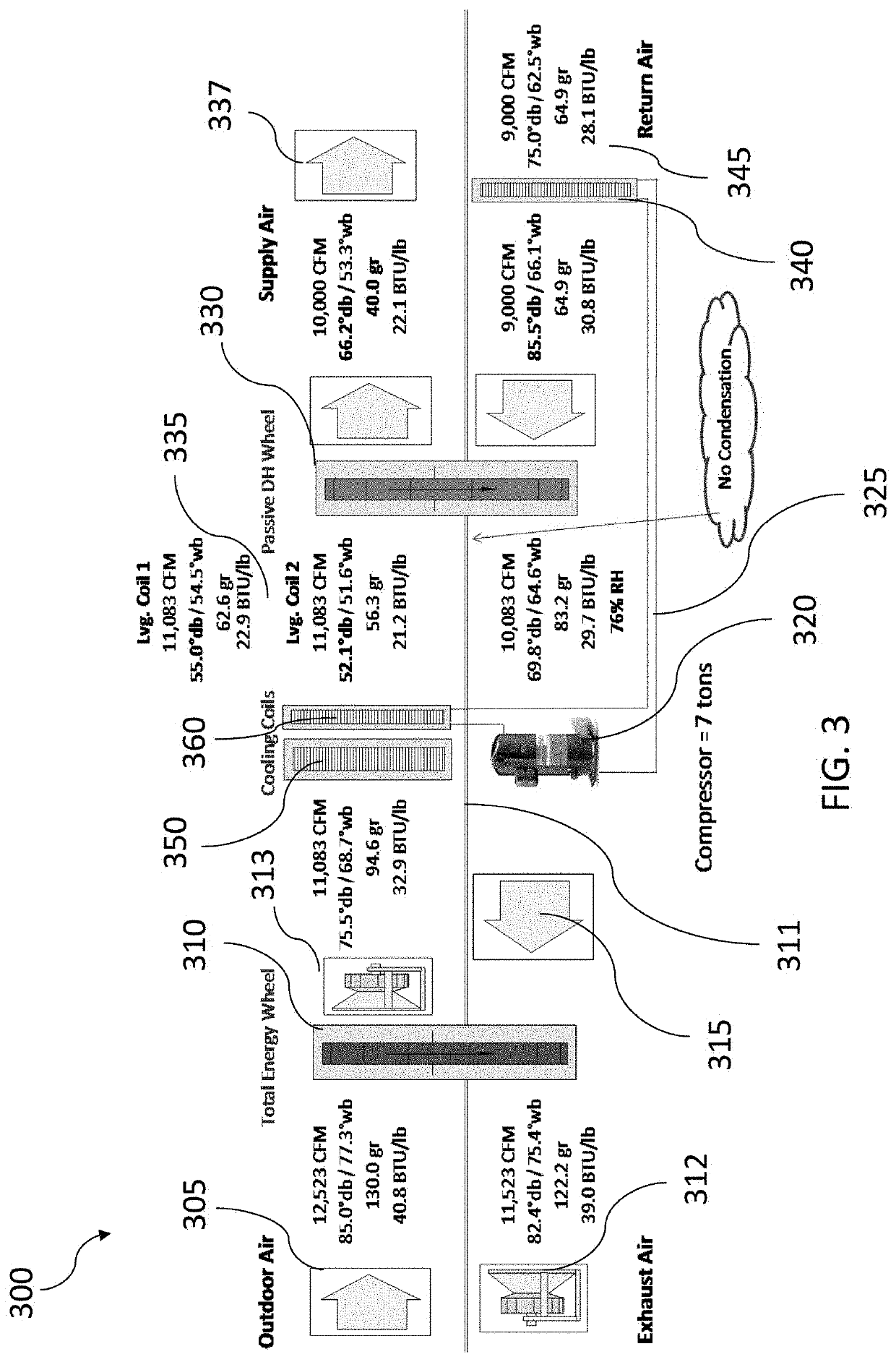

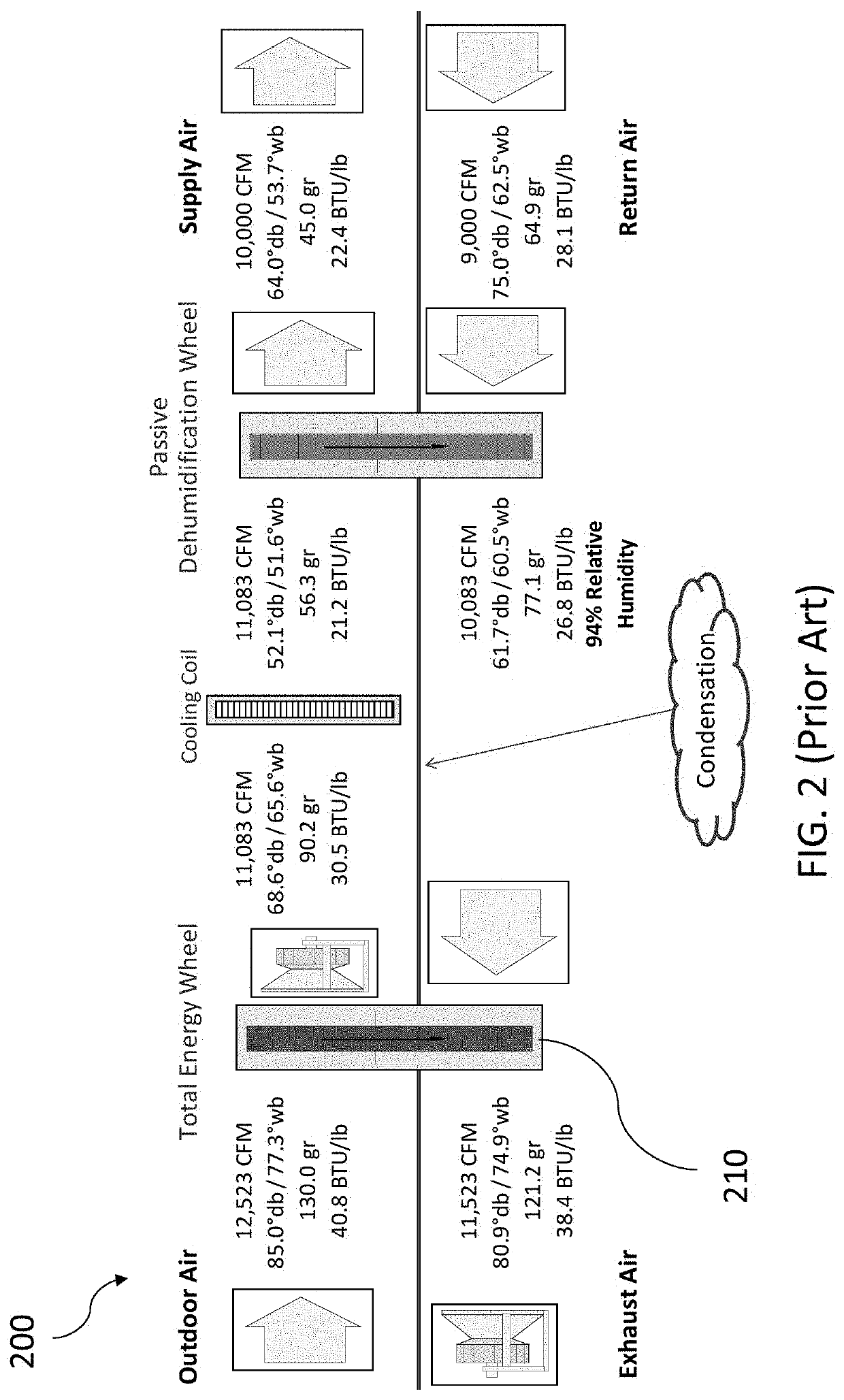

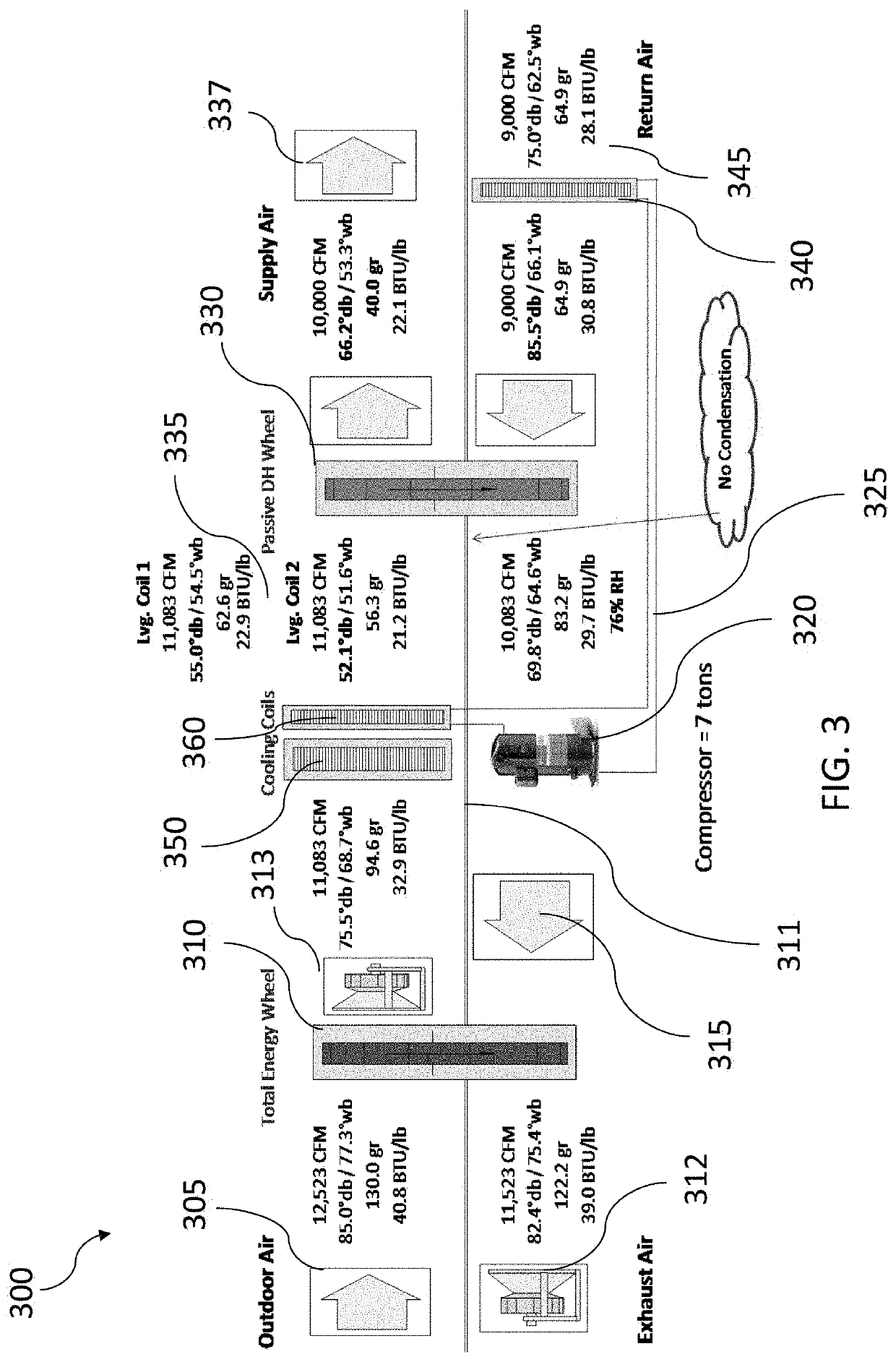

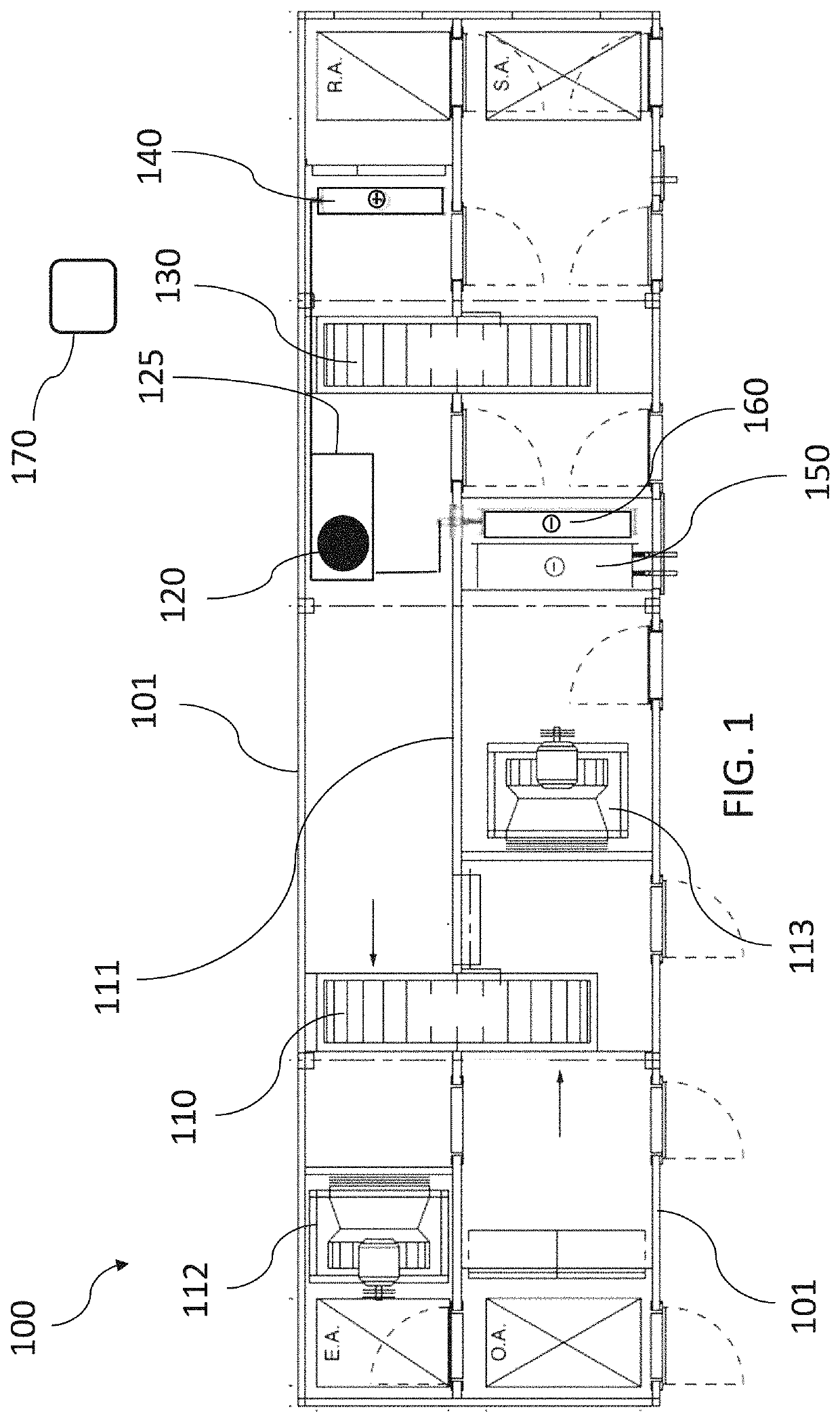

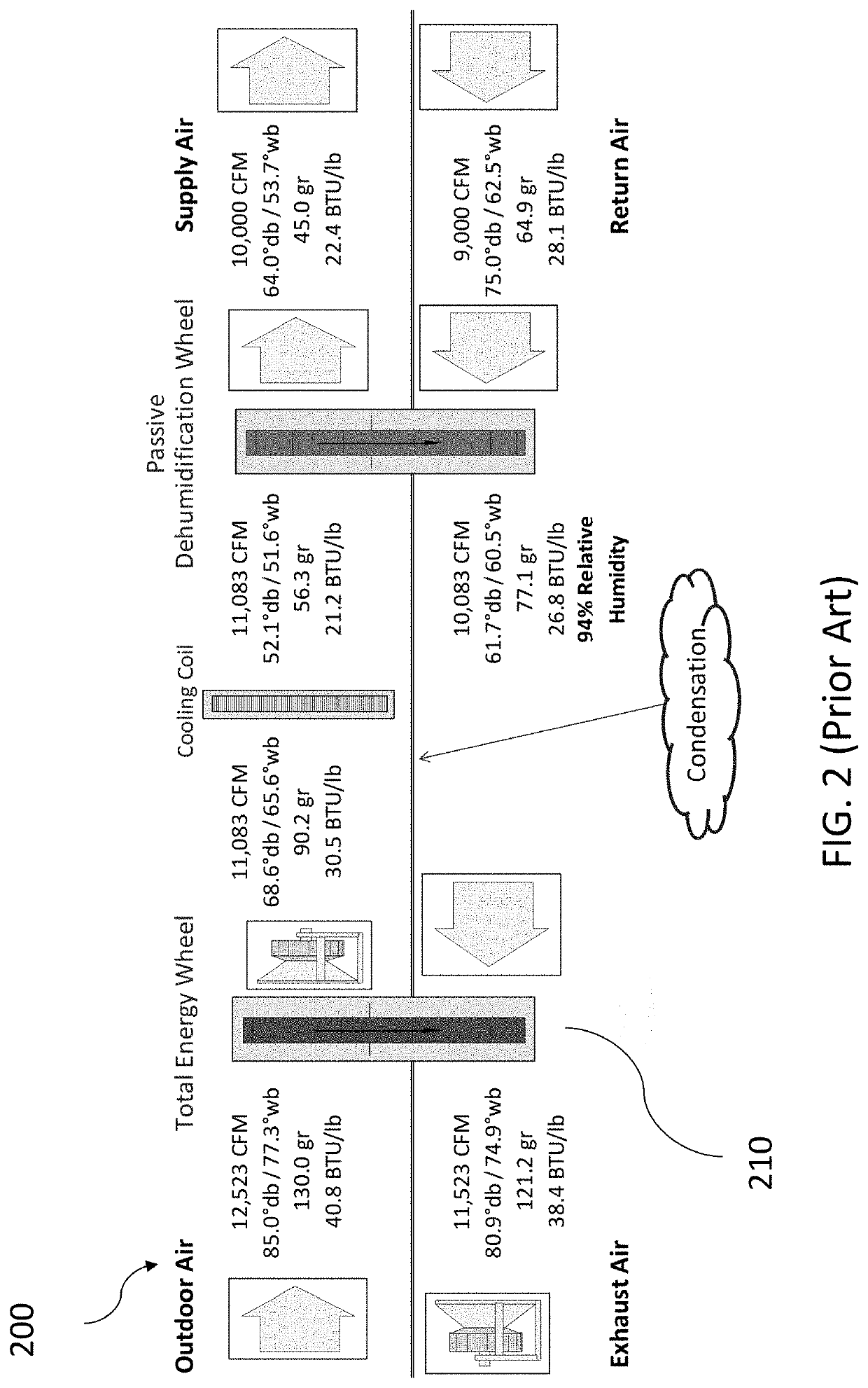

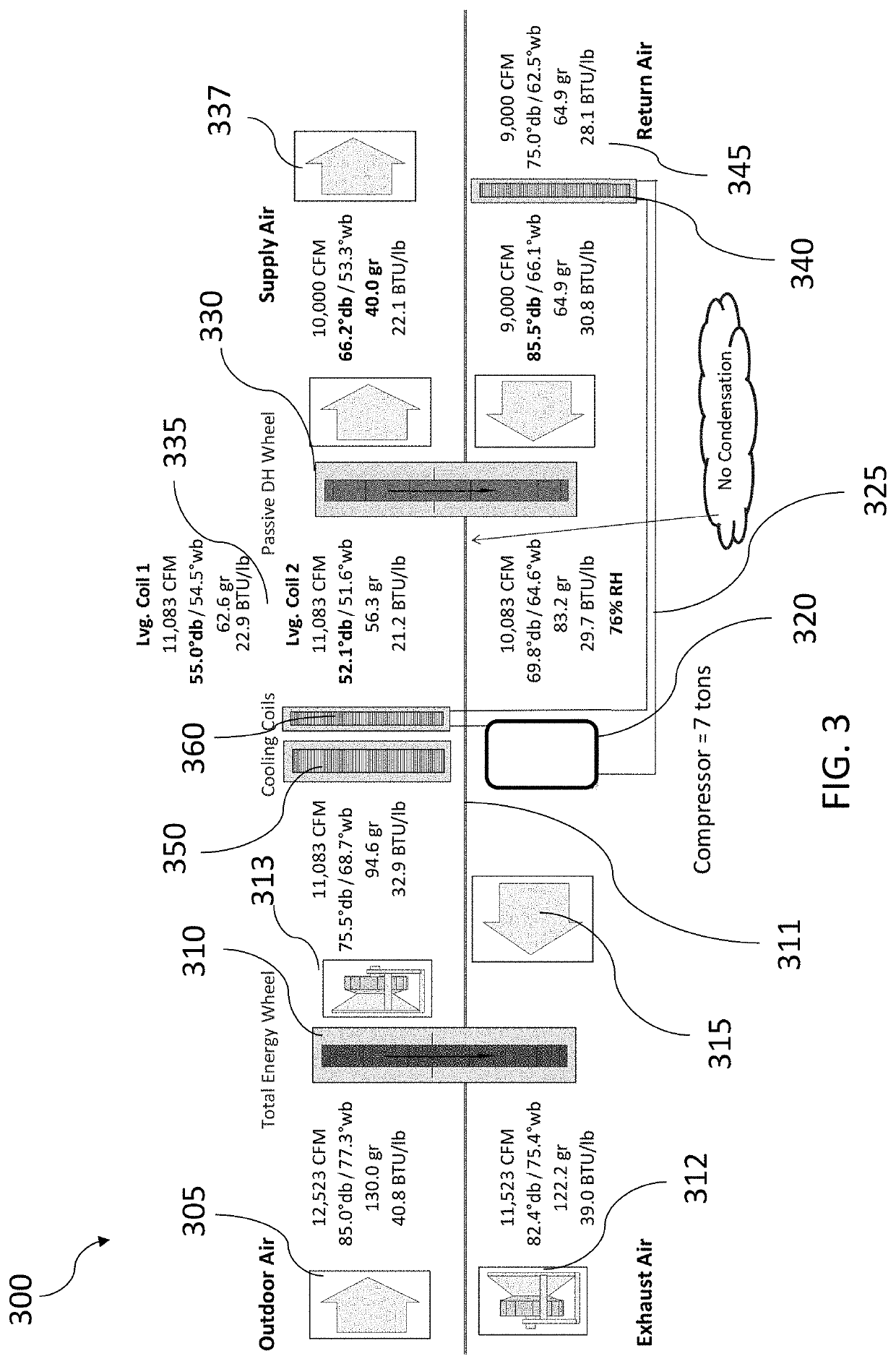

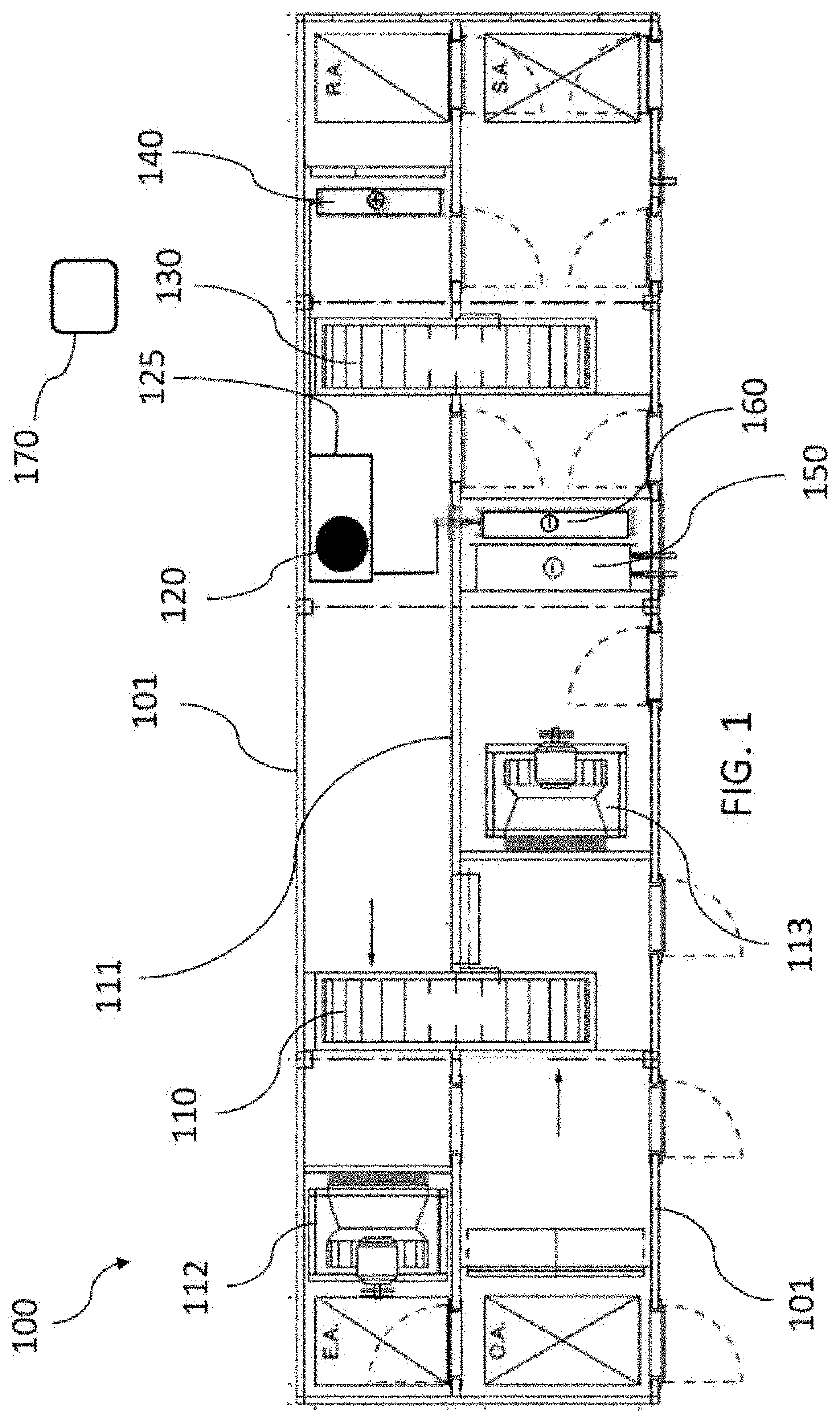

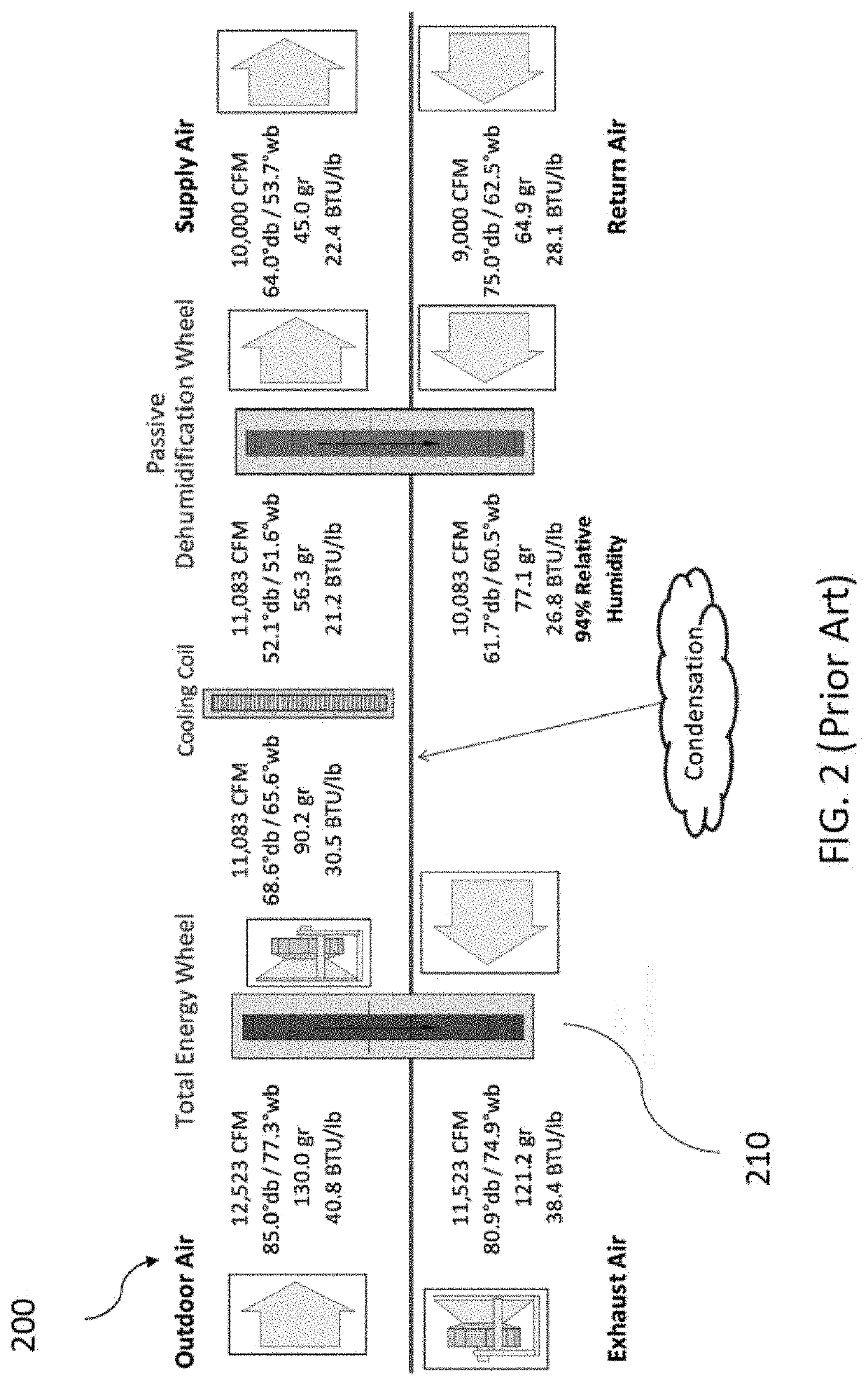

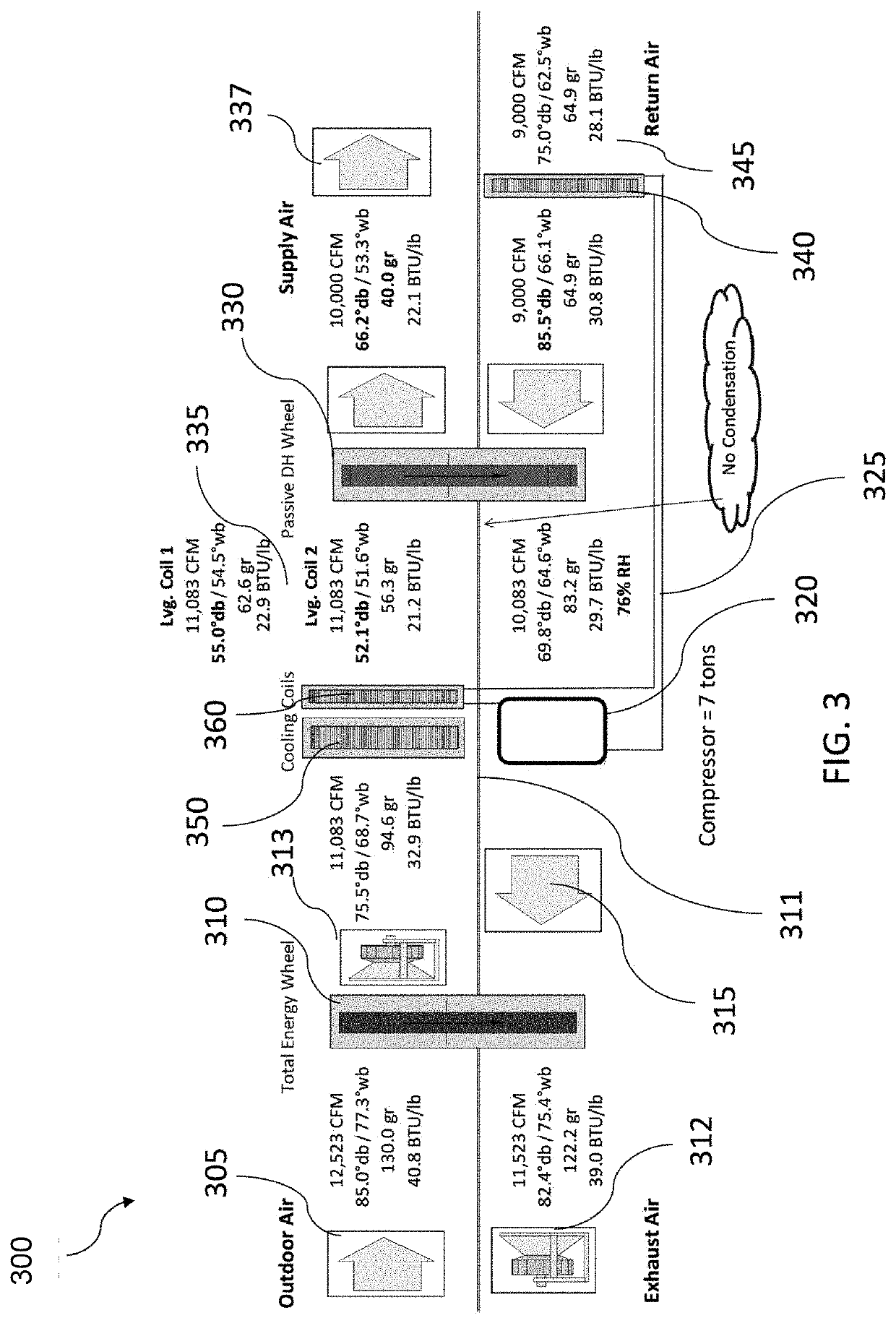

Air conditioning with recovery wheel, passive dehumidification wheel, cooling coil, and secondary direct-expansion circuit

ActiveUS20170356661A1Increase temperatureLess riskEnergy recovery in ventilation and heatingAir treatment detailsDesiccantCooling coil

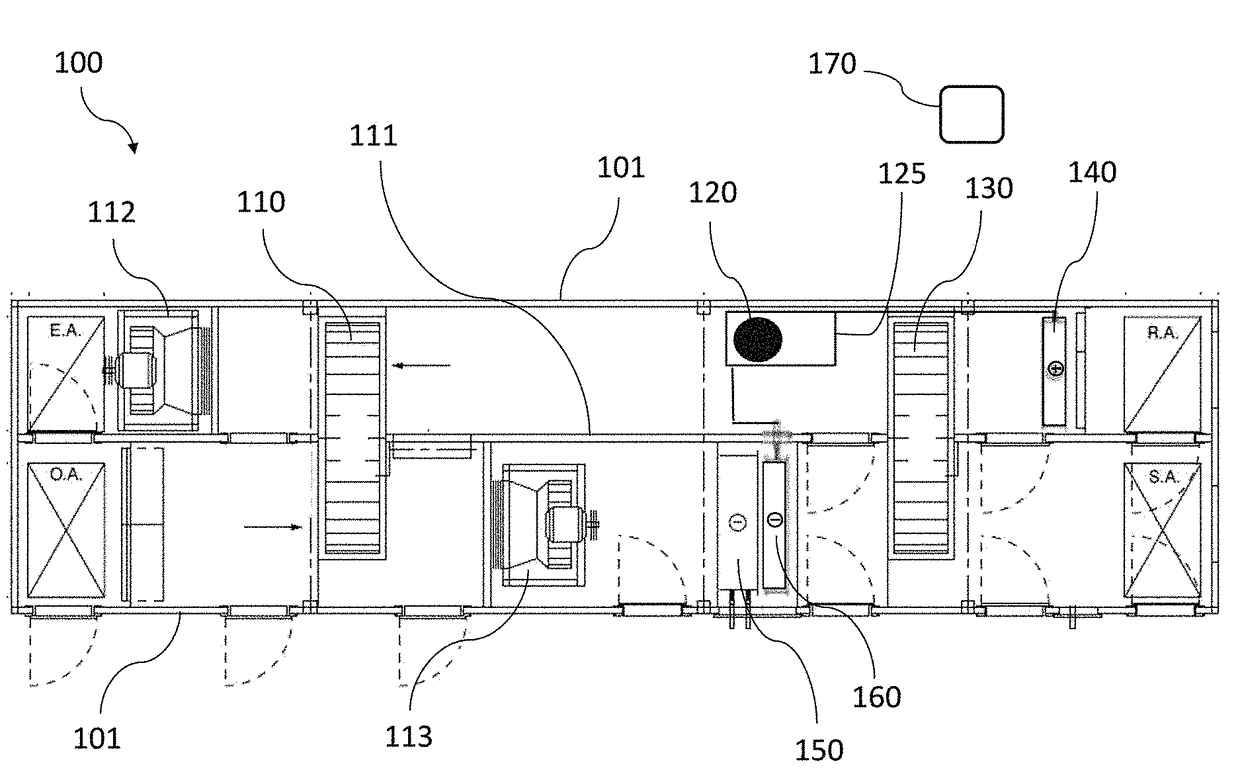

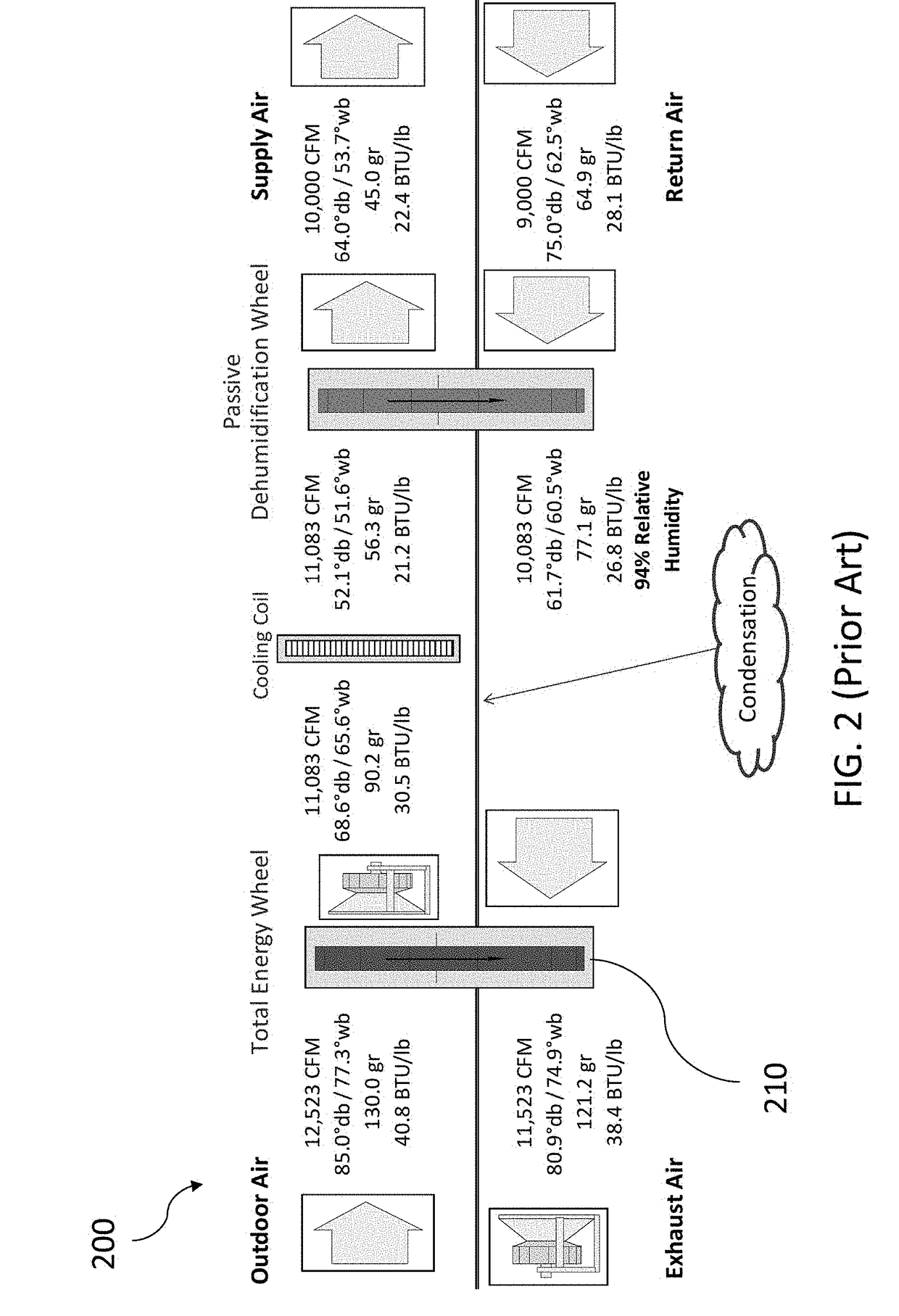

Air conditioning units, systems, and methods that control temperature and humidity within a space in a building, for example, using a recovery wheel, a desiccant-based or passive dehumidification wheel, a primary cooling coil; and a secondary direct-expansion refrigeration circuit that includes a secondary circuit compressor, a secondary circuit evaporator coil, and a secondary circuit condenser coil. In various embodiments, the system forms a supply airstream that passes outdoor air first through the recovery wheel, then through the primary cooling coil, then through the secondary circuit evaporator coil, then through the dehumidification wheel, and then to the space. Further, in many embodiments, the system forms an exhaust airstream that passes return air from the space first through the secondary circuit condenser coil, then through the dehumidification wheel, and then through the recovery wheel. In some embodiments, various quantities of heat and moisture are transferred between the two airstreams.

Owner:SEMCO INC

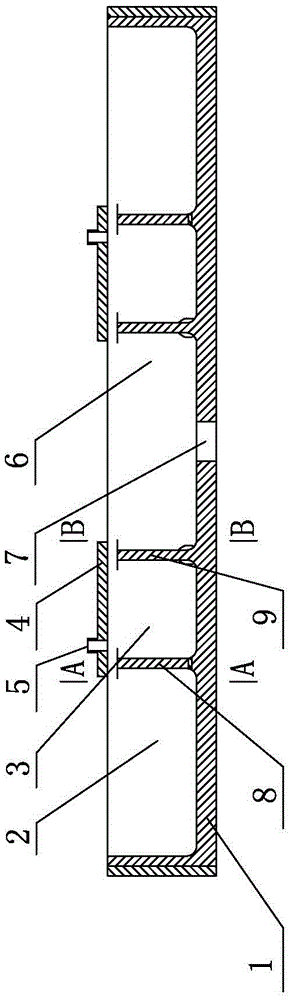

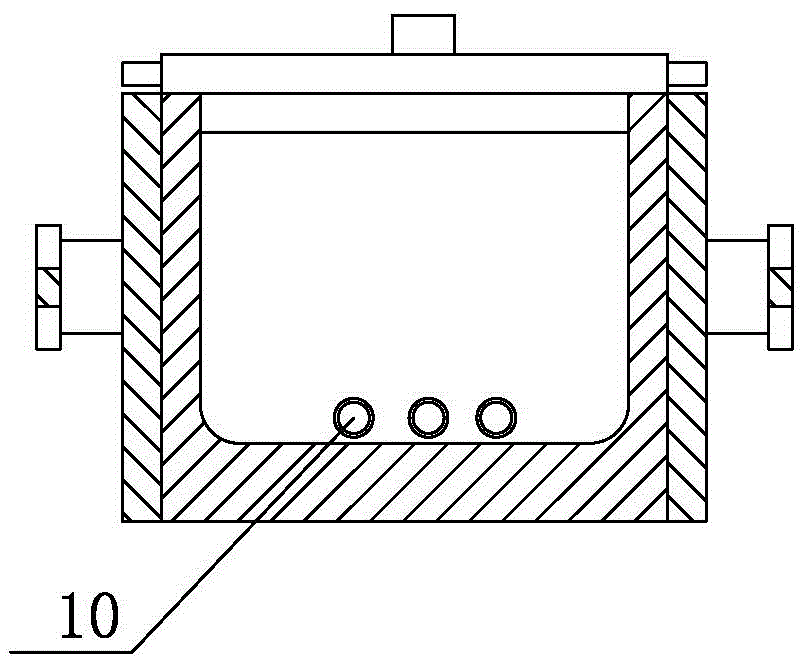

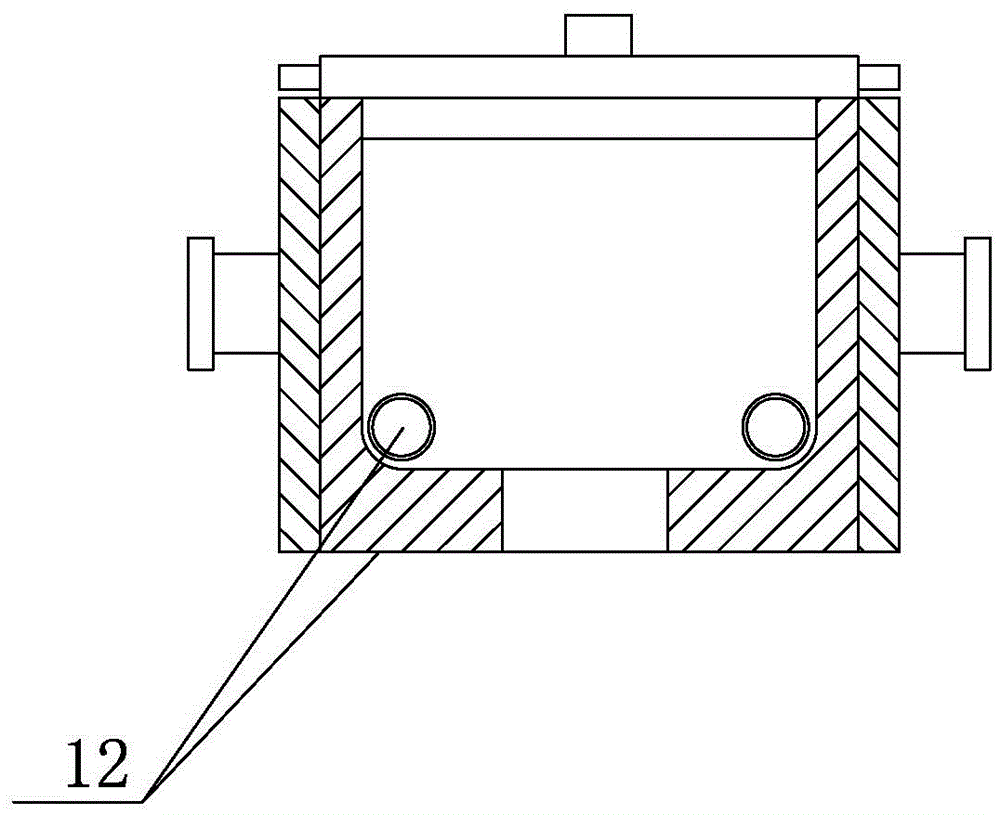

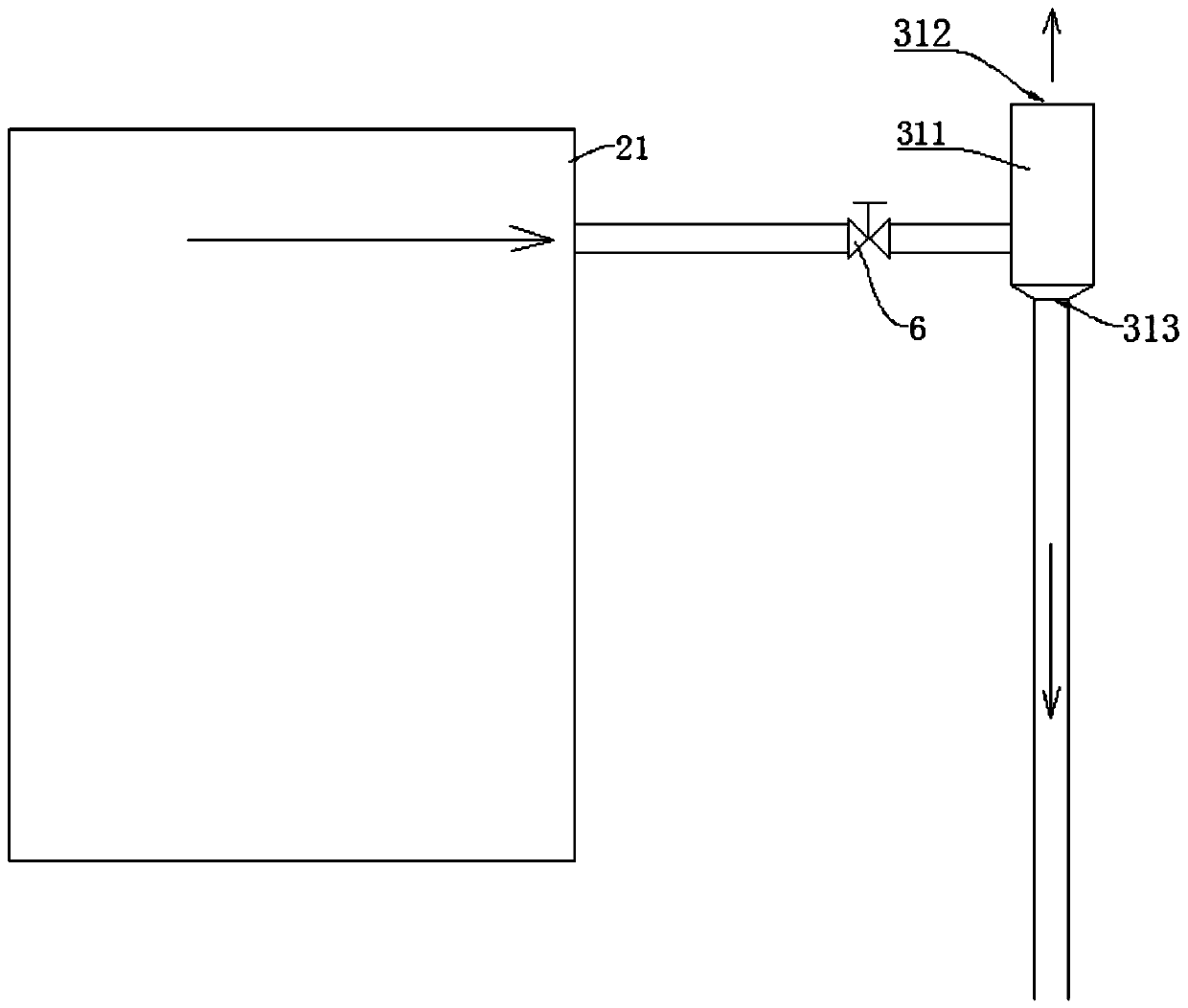

Chilled beam pump module, system, and method

ActiveUS9625222B2Improve performanceSimple design and installationTemperatue controlHeat exchange apparatusWarm waterDistribution system

Chilled-beam zone pump modules for controlling zones of a chilled-beam heating and air conditioning system, multiple-zone chilled beam air conditioning systems for cooling multiple-zone spaces, and methods of controlling chilled beams in multi-zone air conditioning systems. Embodiments include a pump serving each zone that both recirculates water within the module and chilled beam and circulates water in and out of a chilled or warm water distribution system through valves to control the temperature of the water delivered to the chilled beams. Different embodiments provide heating as well as cooling, use check valves to reduce the number of control valves required, adjust the temperature of the beam to avoid condensation, change pump speed to save energy or increase capacity, can be used in two- or four-pipe systems, or a combination thereof.

Owner:SEMCO INC

Leak detection with artificial intelligence

PendingUS20210216852A1Quick and easy implementationLess timeData processing applicationsFluid-tightness measurementAlgorithmEngineering

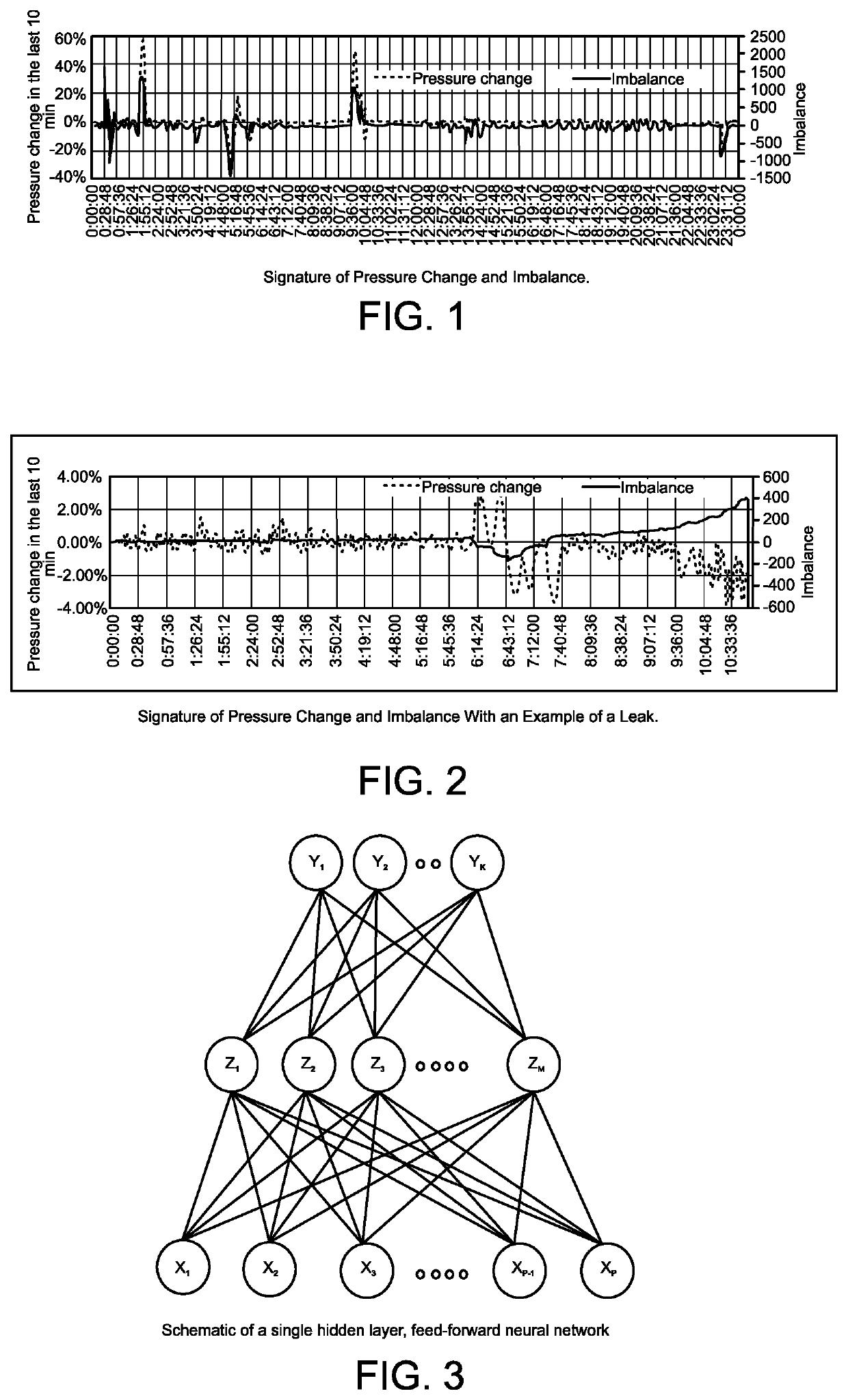

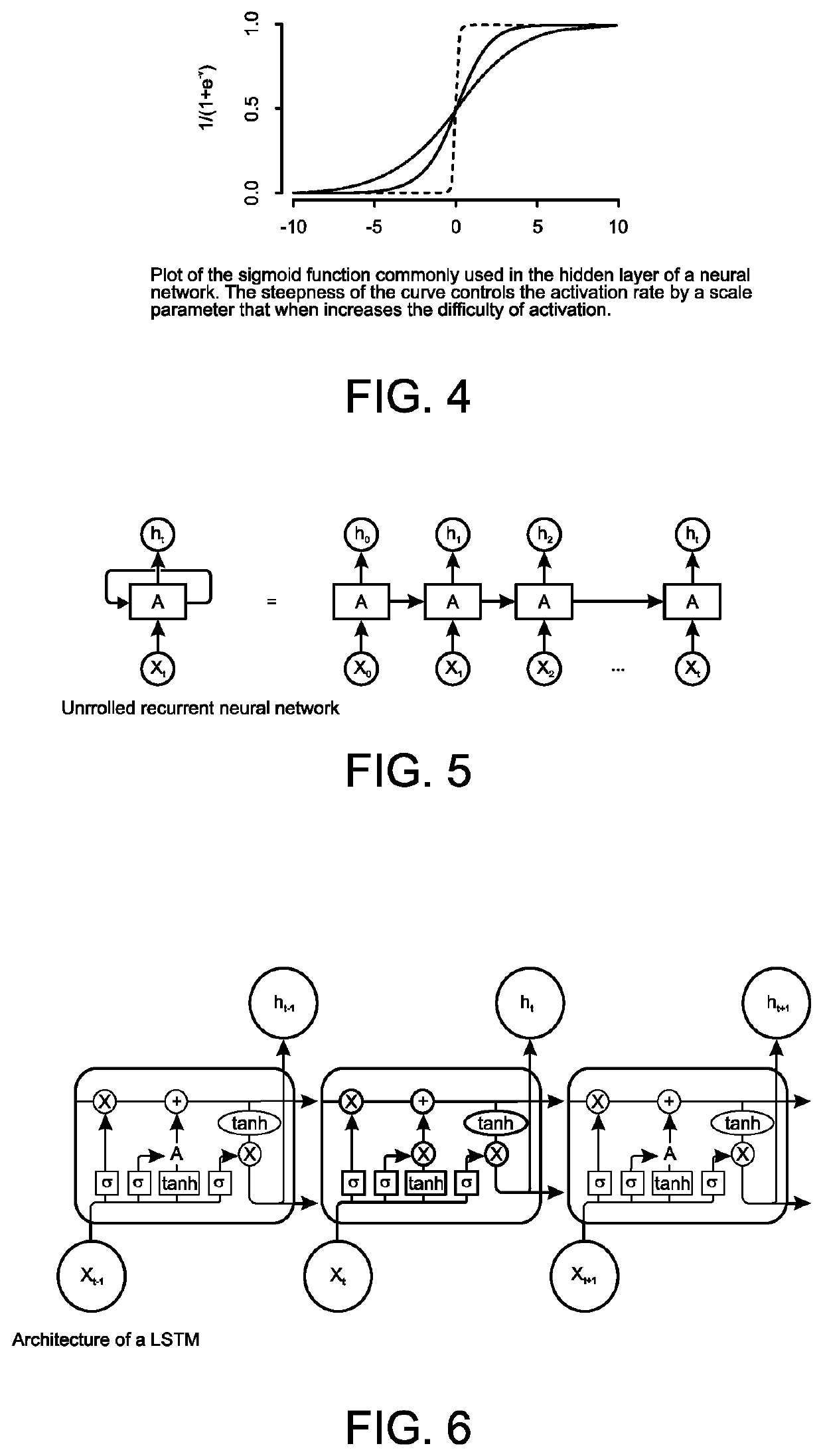

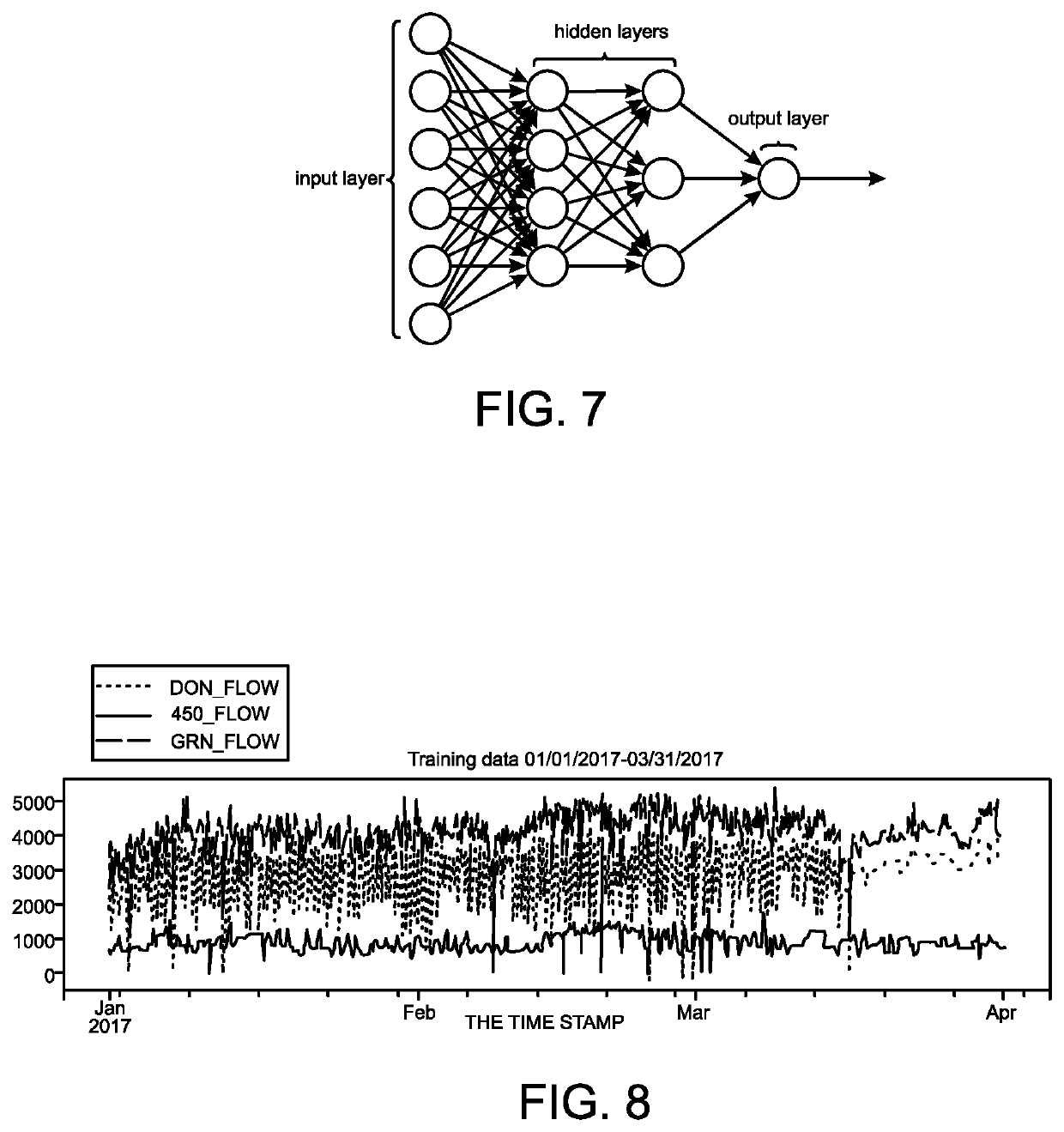

Computer-implemented methods, systems, and software of detecting leaks, for example, in a pipeline that conveys a liquid or gas. Embodiments include inputting into a computer system a first set of data acquired (e.g., from the pipeline) during (e.g., normal) operation (e.g., of the pipeline), acquiring a second set of data (e.g., from the pipeline) while simulating leaks (e.g., from the pipeline) by releasing quantities of the liquid or gas (e.g., from the pipeline) from multiple locations (e.g., along the pipeline), inputting into the computer system the second set of data, and training the computer system to detect the leaks (e.g., from the pipeline) including communicating to the computer system that no leaks existed while the first set of data was acquired and communicating to the computer system that leaks existed while the second set of data was acquired.

Owner:FLOWSTATE TECH LLC

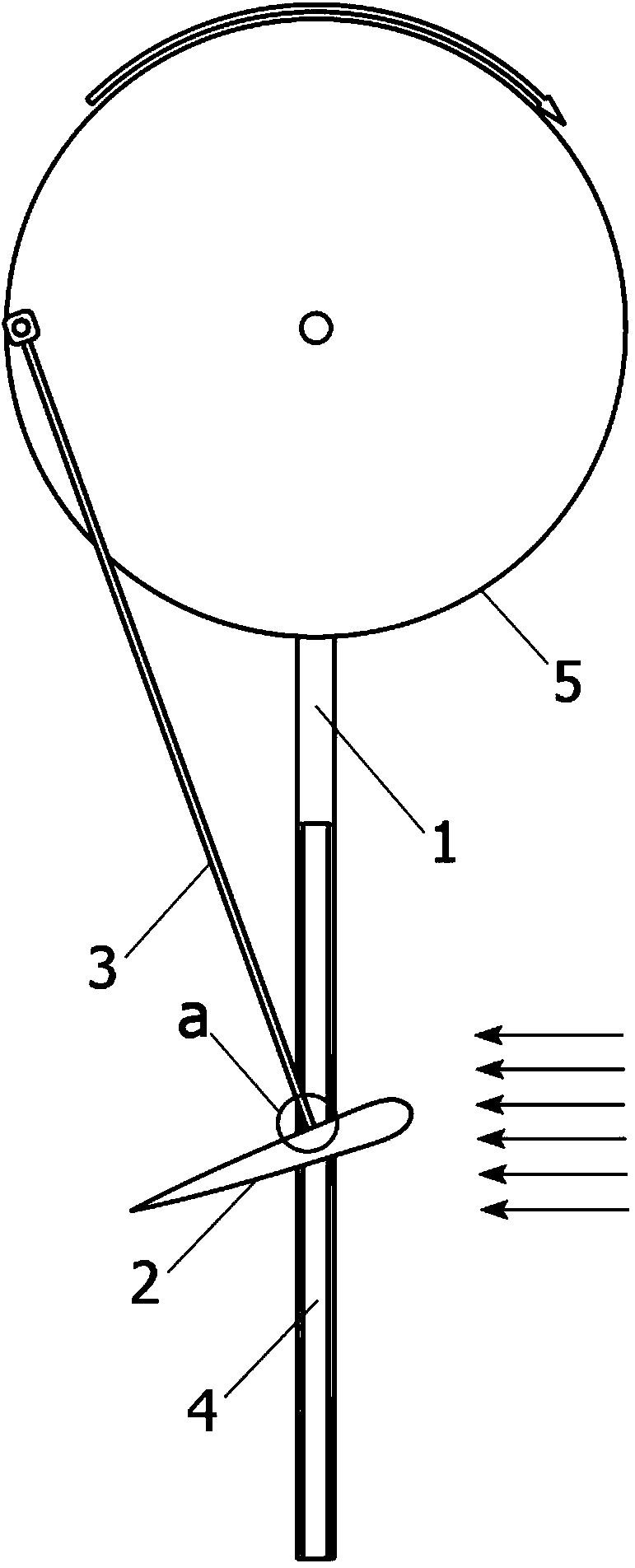

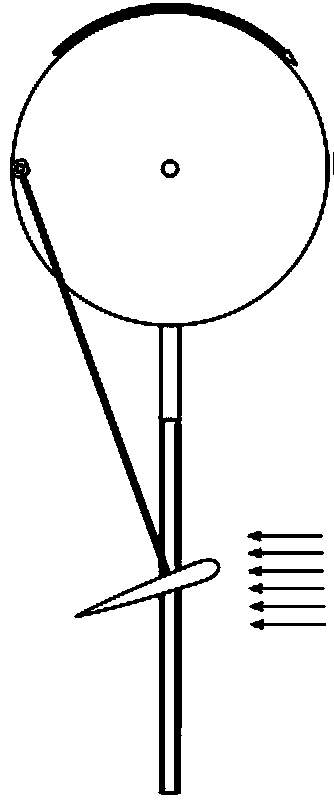

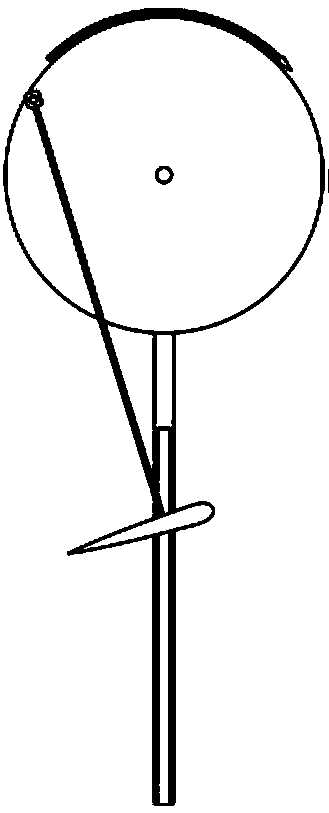

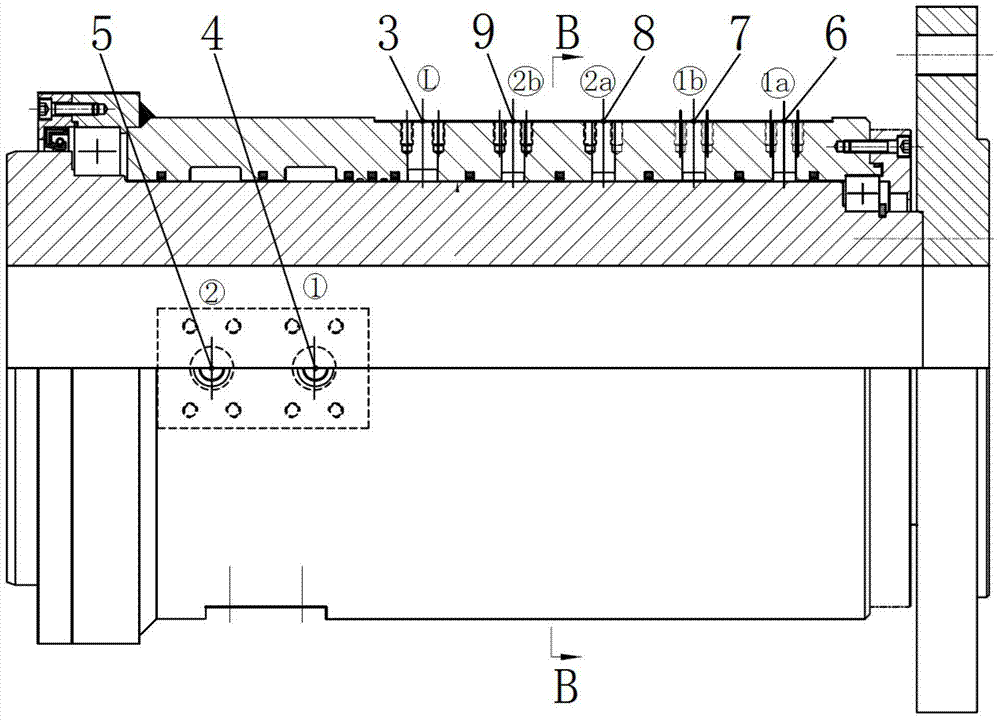

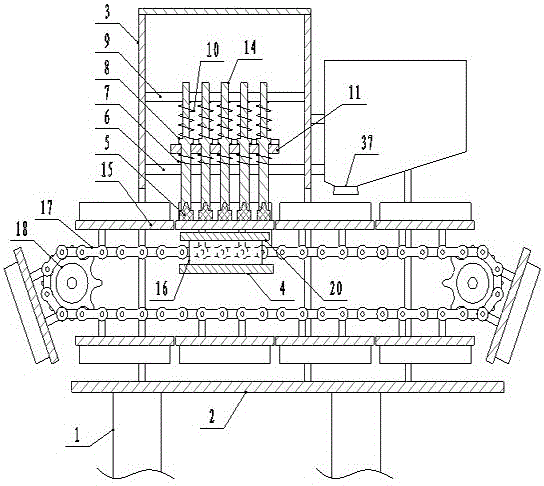

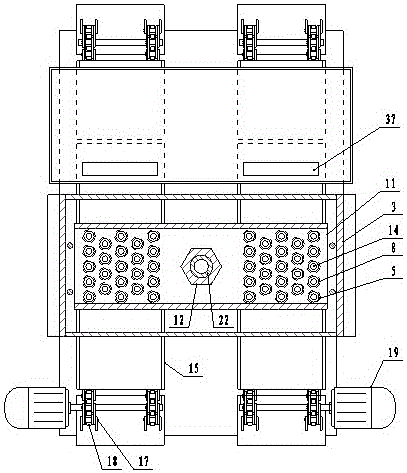

Spindle coupling reciprocating type wind energy and tide energy conversion device

InactiveCN103742356ASimple design and installationReduce maintenance costsMachines/enginesEngine componentsTidal currentEngineering

The invention provides a spindle coupling reciprocating type wind energy and tide energy conversion device which comprises supports, blades and spindles. Each spindle is mounted on the two corresponding supports through bearings, guide rails are mounted on one opposite sides of every two supports, two ends of each blade are connected with the corresponding guide rails through bearings and sliders, a transmission mechanism is arranged between each blade and the corresponding spindle and comprises connecting rods and rocking rods, one end of each rocking rod is fixedly connected with the corresponding spindle, the other end of each rocking rod is hinged to one end of the corresponding connecting rod, the other end of each connecting rod is fixedly connected with a rotation center of the corresponding blade, and a plane of chordwise center lines of the blades is perpendicular to the connecting rods. The spindle coupling reciprocating type wind energy and tide energy conversion device is a simple and effective wind energy / tide energy power generation device, and is simple to design and install, low in maintenance cost and high in power generation efficiency. Compared with a horizontal-axis power generation device, the spindle coupling reciprocating type wind energy and tide energy conversion device is small in influence due to wind direction deviation.

Owner:HARBIN ENG UNIV

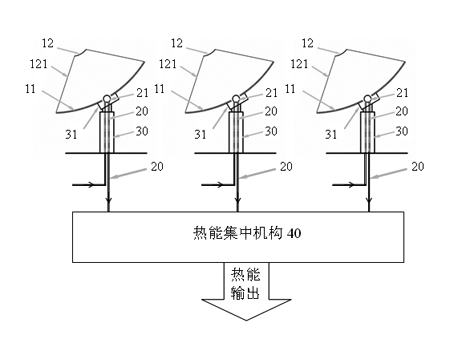

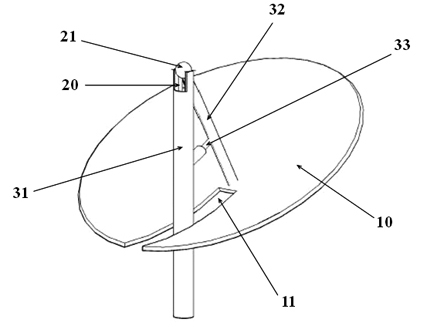

Two-mirror type solar collecting device and system

InactiveCN102072567AMaximize the effective receiving areaSimple design and installationSolar heating energySolar heat devicesThermal energySunlight

The invention discloses a two-mirror type solar collecting device and a two-mirror type solar collecting system. The device is provided with a condensing mechanism and a heated point, wherein the condensing mechanism comprises primary and secondary reflectors to track the sun so as to collect photo-thermal energy; the heated point is positioned on a secondary reflecting focus of the condensing mechanism; the position of the heated point is invariable when the condensing mechanism rotates; and the sunlight is collected by the primary reflector, reflected to the secondary reflector, is subjected to secondary reflection by the secondary reflector and focused on the heated point so as to heat a working medium conveyed in a collector tube connected with the heated point. Because the heated point is heated in a concentrated way, high temperature of the working medium can be achieved. The collecting system collects high-temperature media conveyed by a plurality of collector tubes and externally supplies heat or generates power in a unified mode. The primary and secondary reflectors can track the sun along rotation, and the sunlight is transmitted to the primary reflector vertically, so that an effective receiving area is maximized. Because the spatial position of the heated point is invariable when the primary and secondary reflectors track the sun, the design and installation of the collector tubes are simplified.

Owner:SHANGHAI NEW IND OPTOELECTRONICS TECH

Air conditioning with recovery wheel, dehumidification wheel, and cooling coil

ActiveUS20200116372A1Increase temperatureLess riskEnergy recovery in ventilation and heatingMechanical apparatusEvaporative coolerVariable refrigerant flow

Methods and systems for controlling temperature and humidity within a space in a building. Outdoor air and return air from the space are passed through particular equipment in a particular order. Equipment includes a secondary direct-expansion refrigeration circuit, a recovery wheel, a primary cooling coil or direct-expansion refrigeration circuit, secondary circuit coils, and a dehumidification wheel. Various embodiments include modulating the secondary circuit compressor to adjust reheat capacity at the secondary circuit condenser coil, a geothermal direct-expansion refrigeration circuit, a variable refrigerant flow subsystem, fan coil units, multiple zones, a dedicated outdoor air supply subsystem, an evaporative cooler, supplemental outdoor air, or a combination thereof. In some embodiments, supply air passes first through the recovery wheel, then through the primary cooling coil, then through the dehumidification wheel, and then to the space. Further, in some embodiments, exhaust air passes through the dehumidification wheel, and then through the recovery wheel.

Owner:SEMCO INC

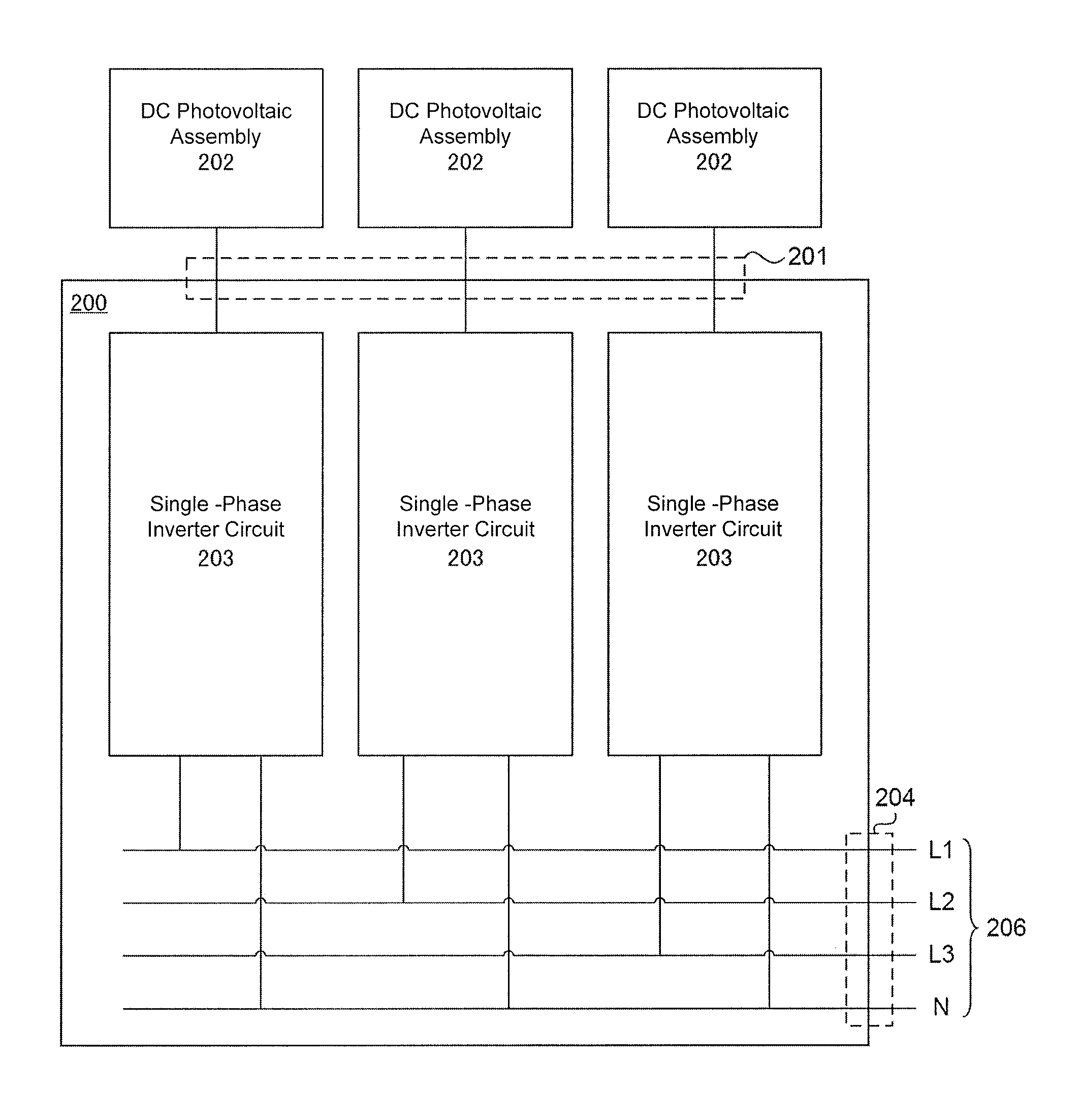

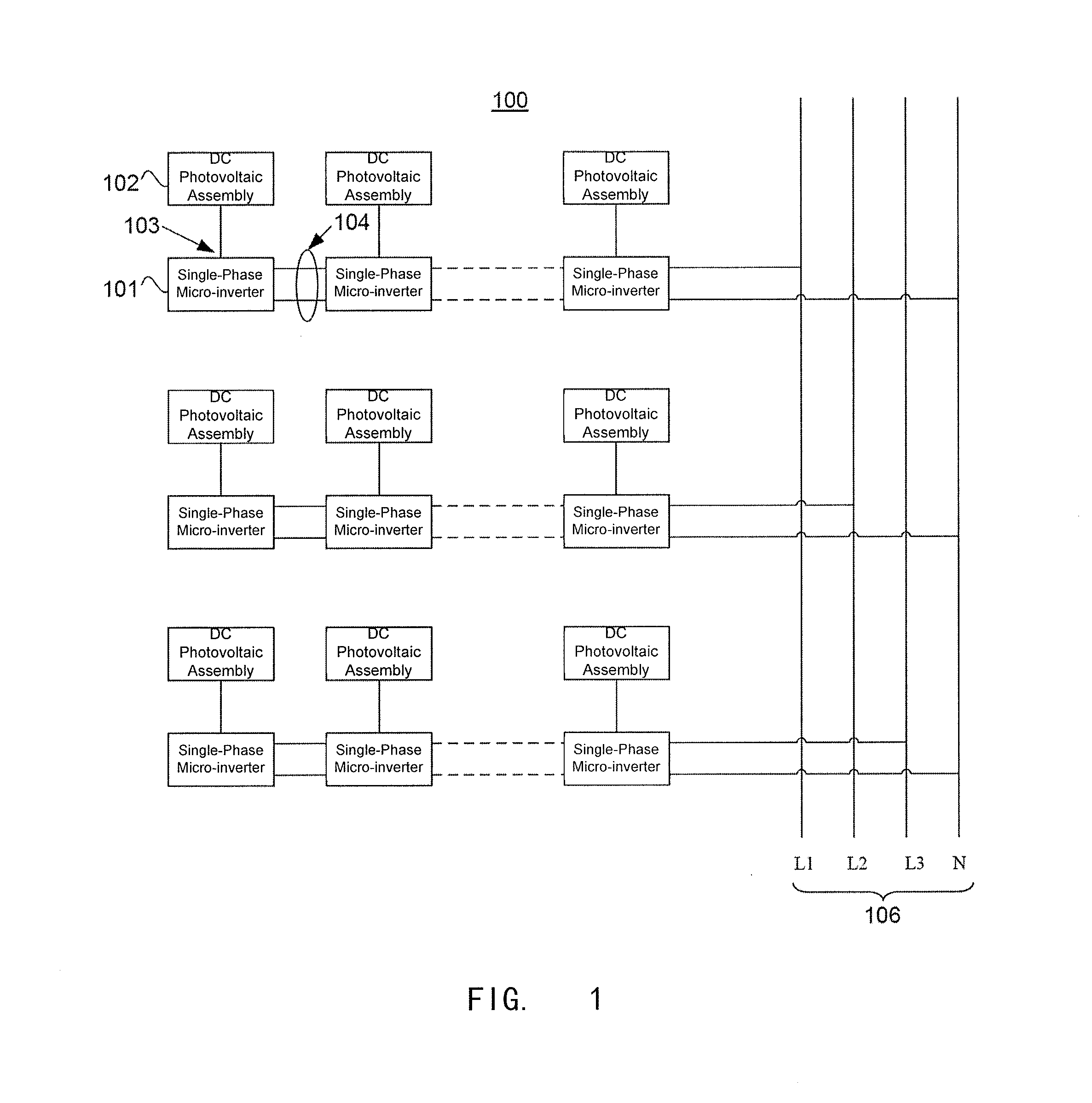

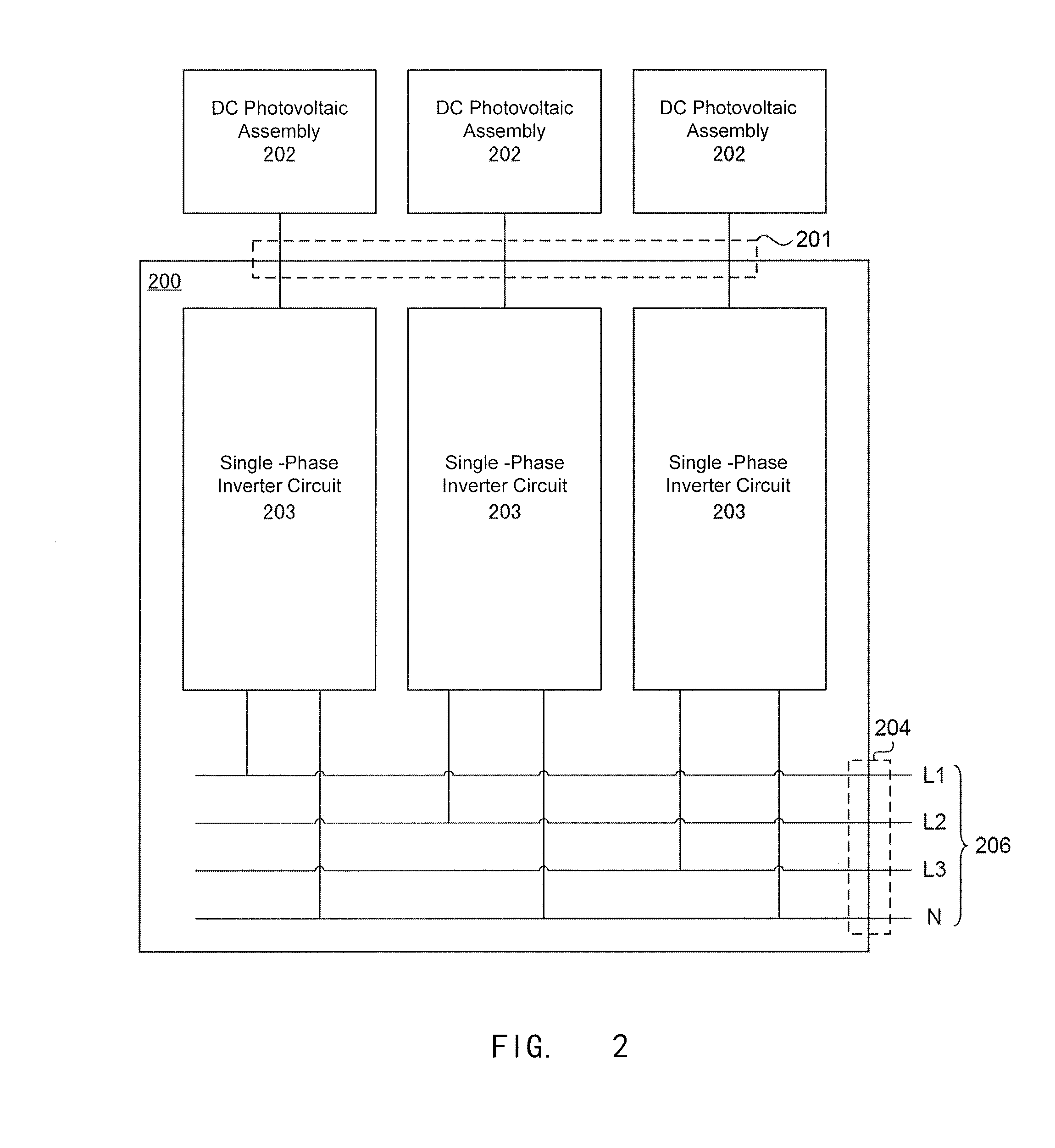

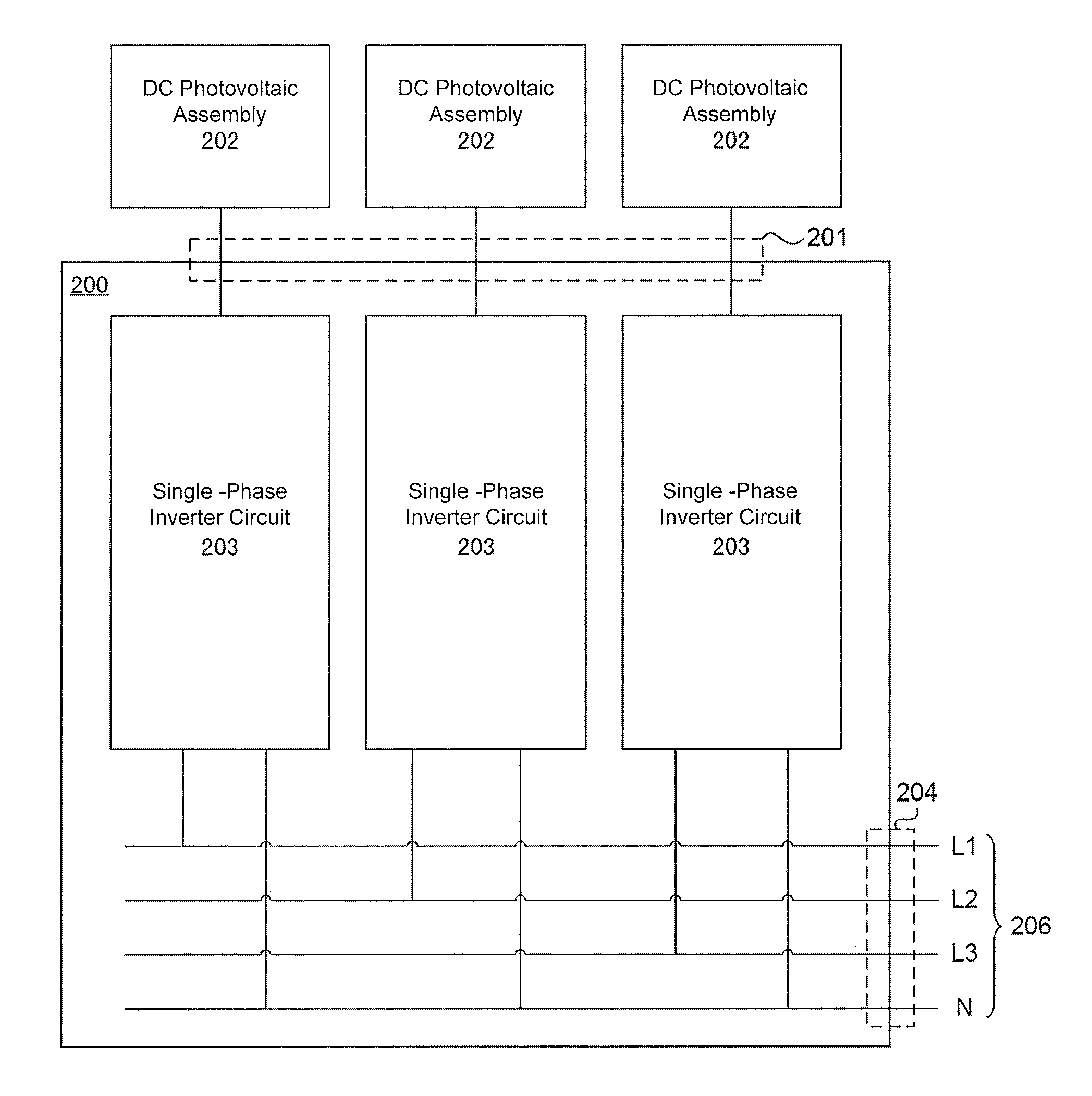

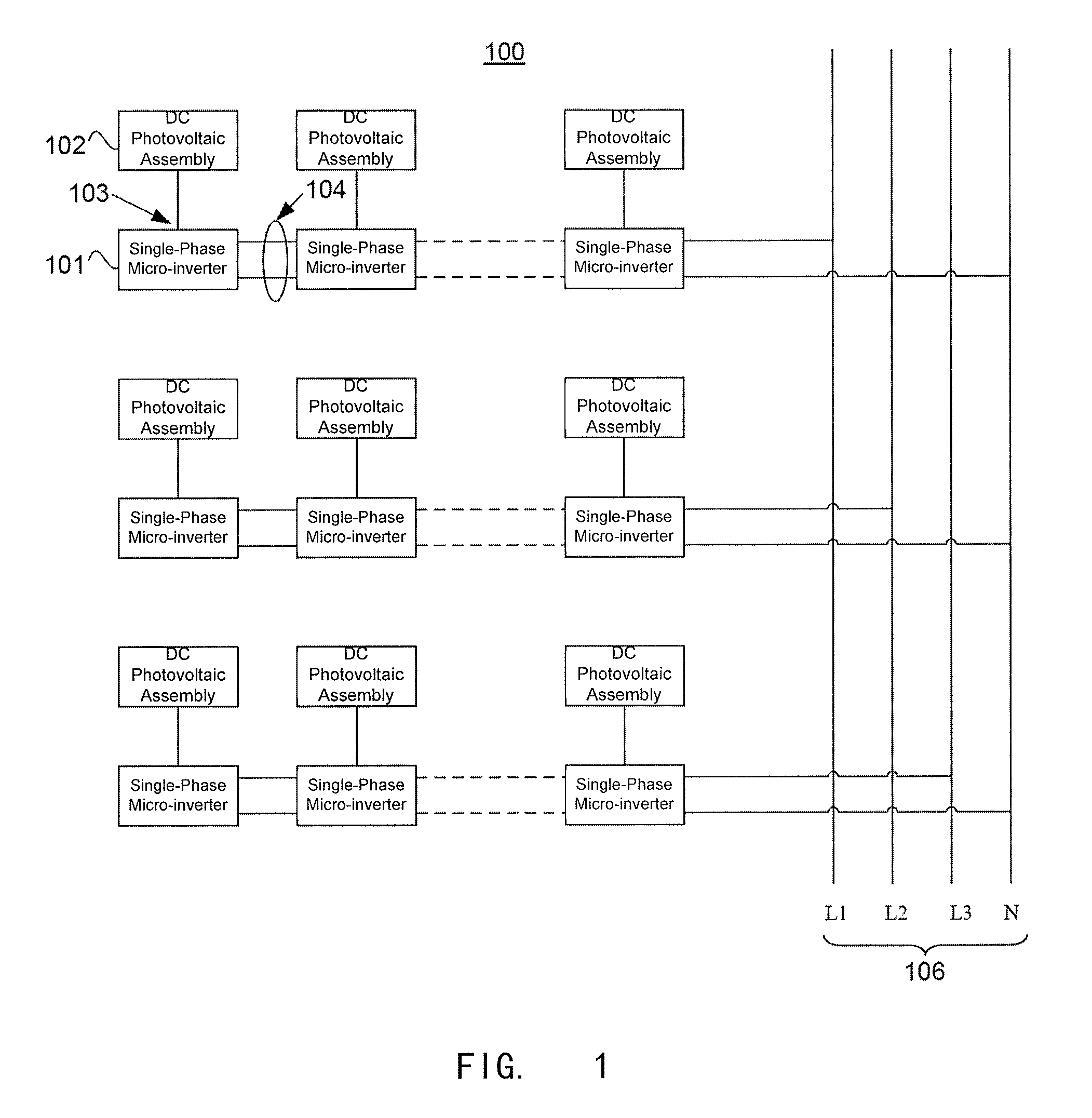

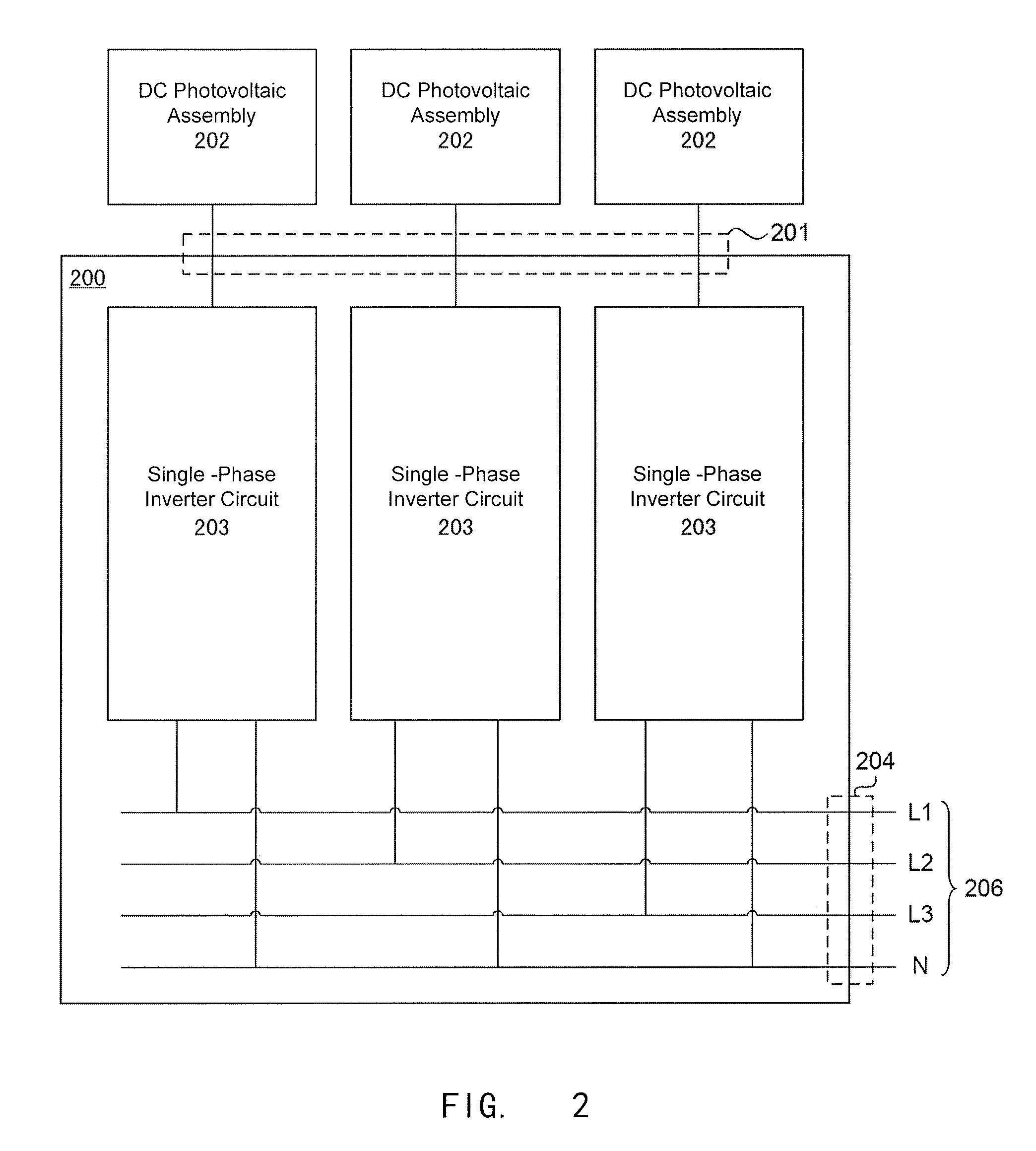

Solar photovoltaic three-phase micro-inverter and solar photovoltaic power generation system

ActiveUS20130334888A1Simple designEasy to installDc network circuit arrangementsSingle network parallel feeding arrangementsDc currentThree-phase

A solar photovoltaic three-phase micro-inverter comprises: DC terminals, coupled with three DC photovoltaic assemblies adjacent to each other; three single-phase inverter circuits having input terminals coupled respectively with the three DC photovoltaic assemblies via the DC terminals, for converting the DC currents generated by the three DC photovoltaic assemblies to AC currents, respectively; AC terminals coupled with a three-phase AC power grid; wherein output terminals of each single-phase inverter circuit are coupled respectively with a neutral wire and one of the three phases of the three-phase AC power grid. A solar photovoltaic power generation system is also provided. The three single-phase inverter circuits can be integrated as above Because the three DC photovoltaic assemblies on one three-phase micro-inverter are disposed adjacently and have similar environment conditions, such as illumination, temperature, etc., the three-phase AC current can be well balanced.

Owner:ALTENERGY POWER SYST

Air conditioning with recovery wheel, passive dehumidification wheel, cooling coil, and secondary direct-expansion circuit

ActiveUS10690358B2Less riskImprove cooling effectEnergy recovery in ventilation and heatingAir treatment detailsDesiccantCooling coil

Owner:SEMCO INC

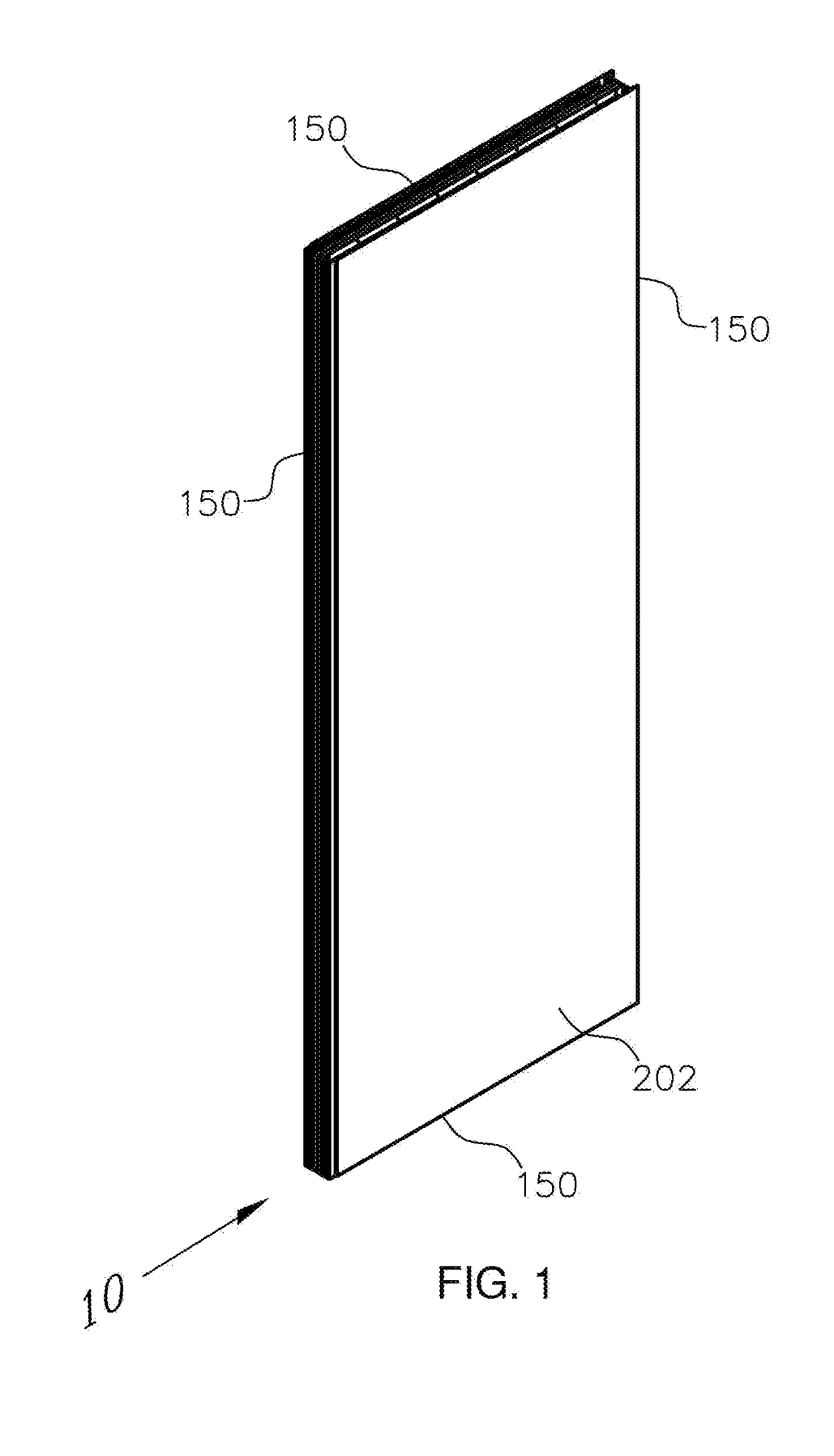

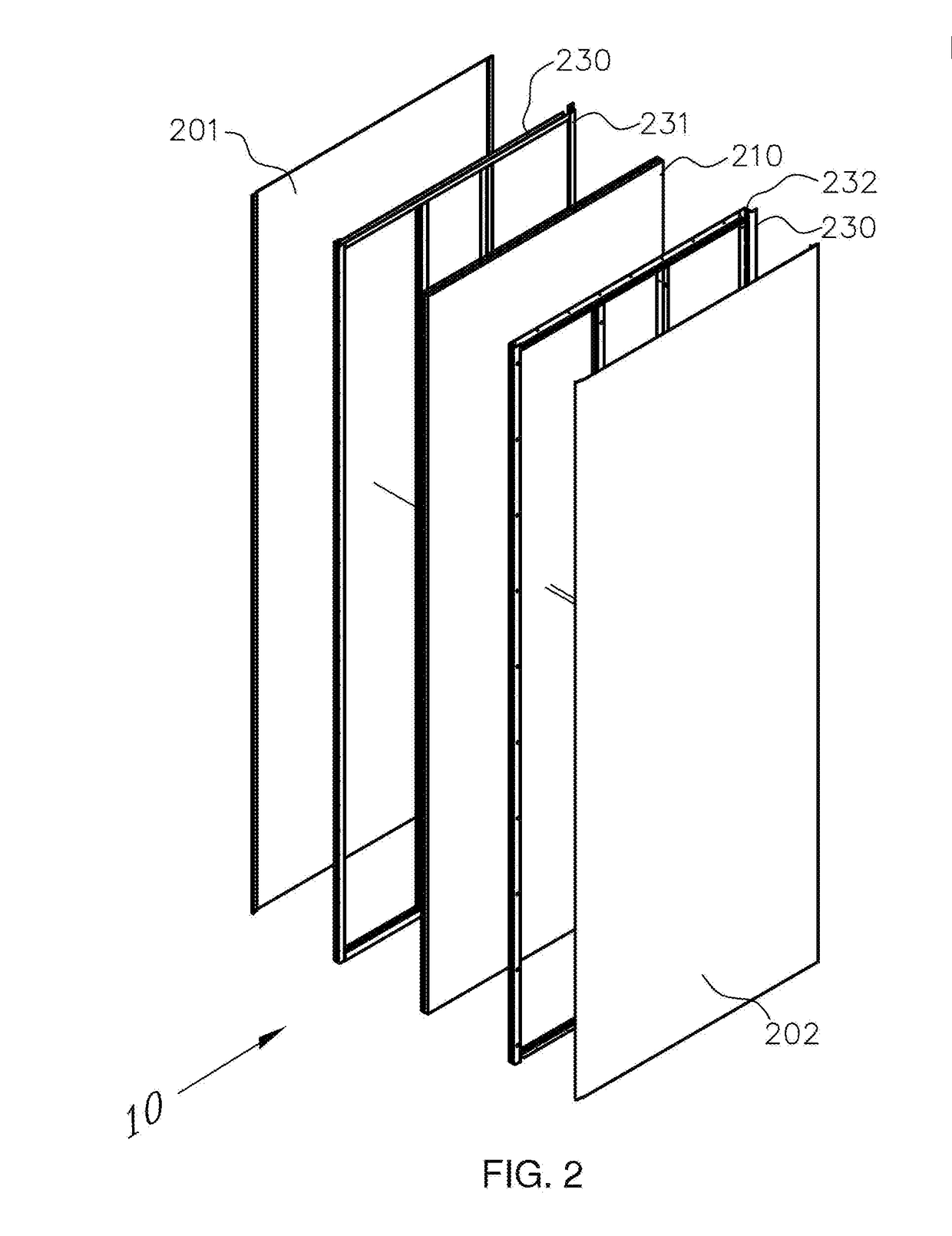

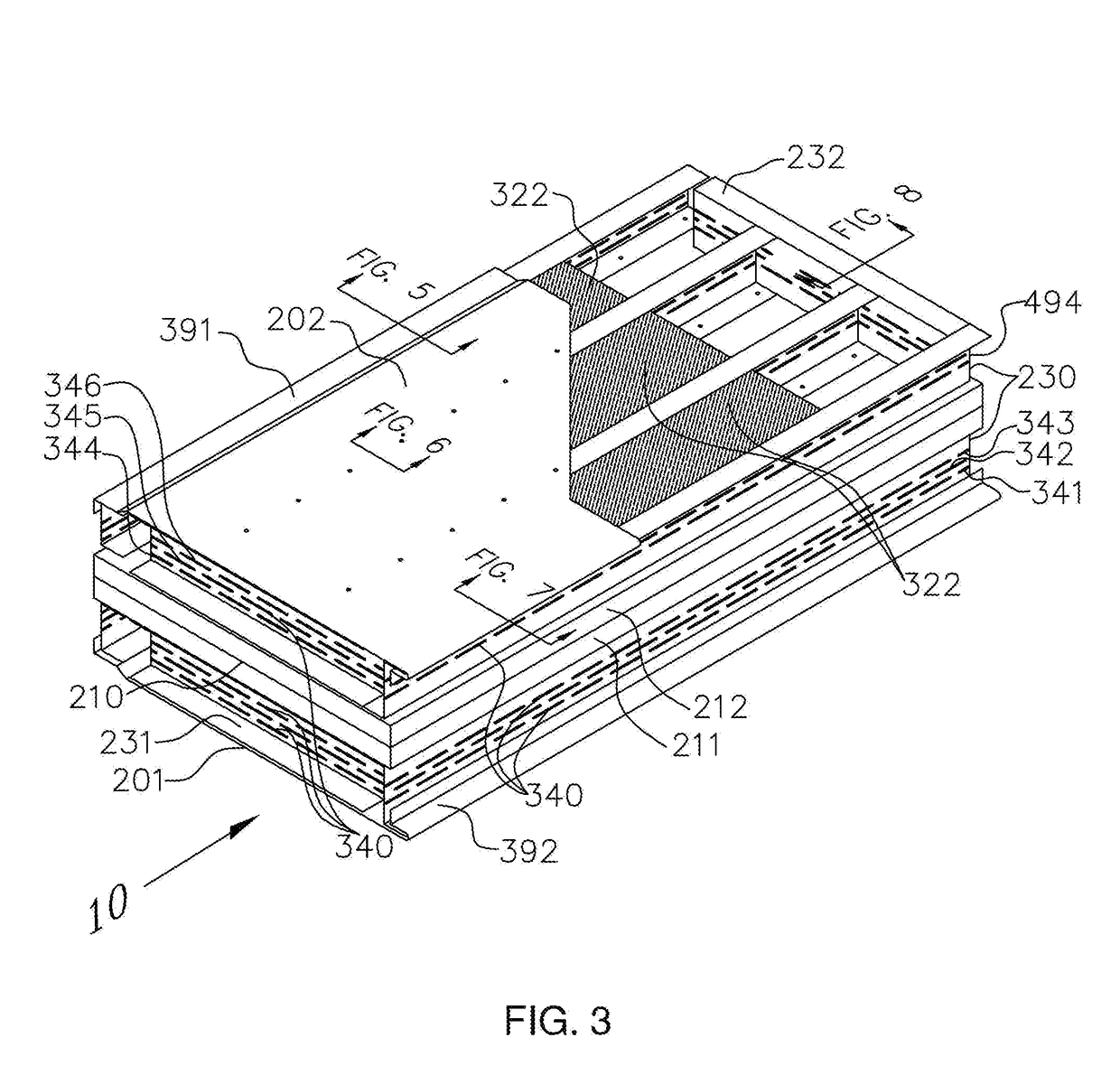

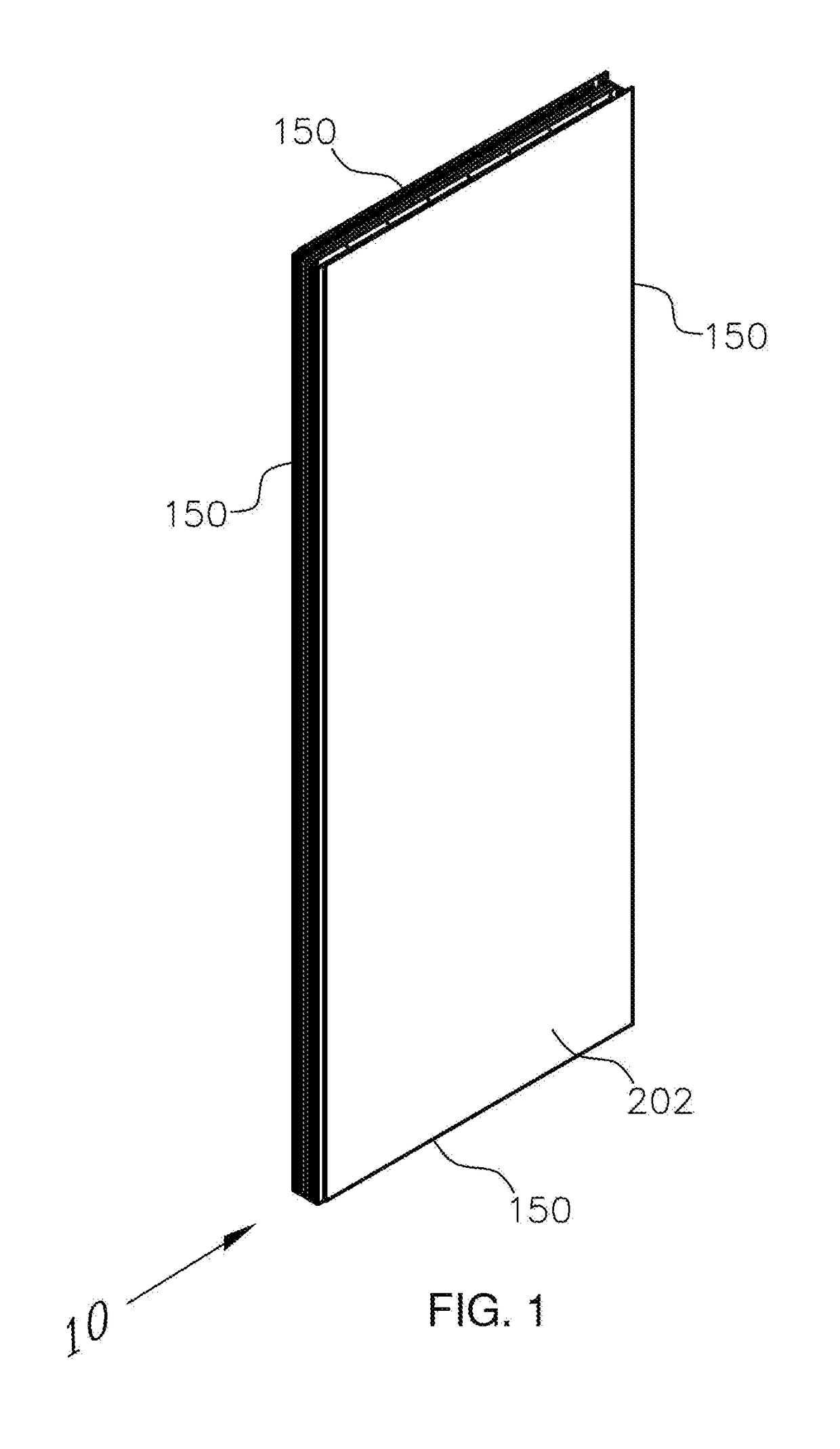

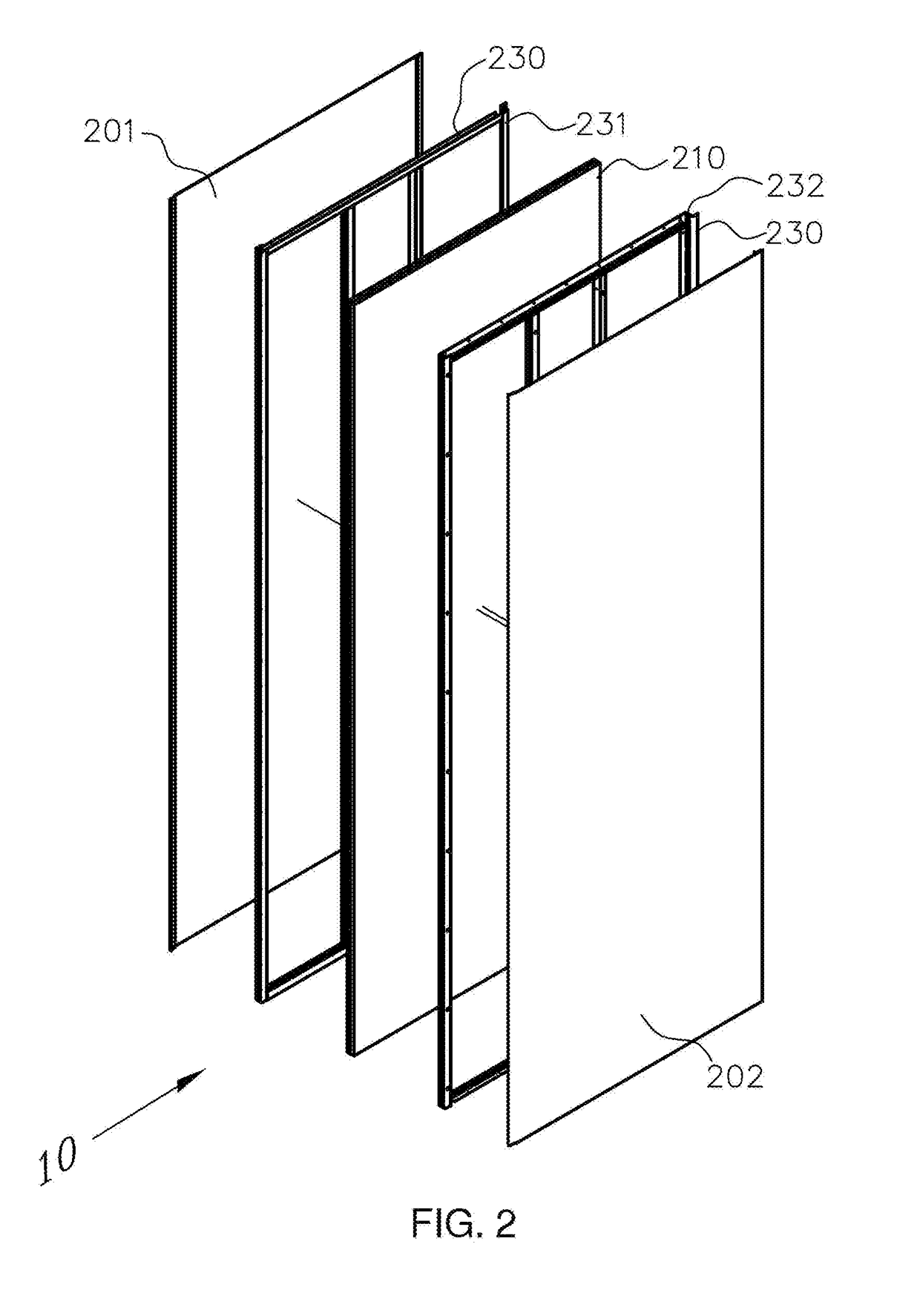

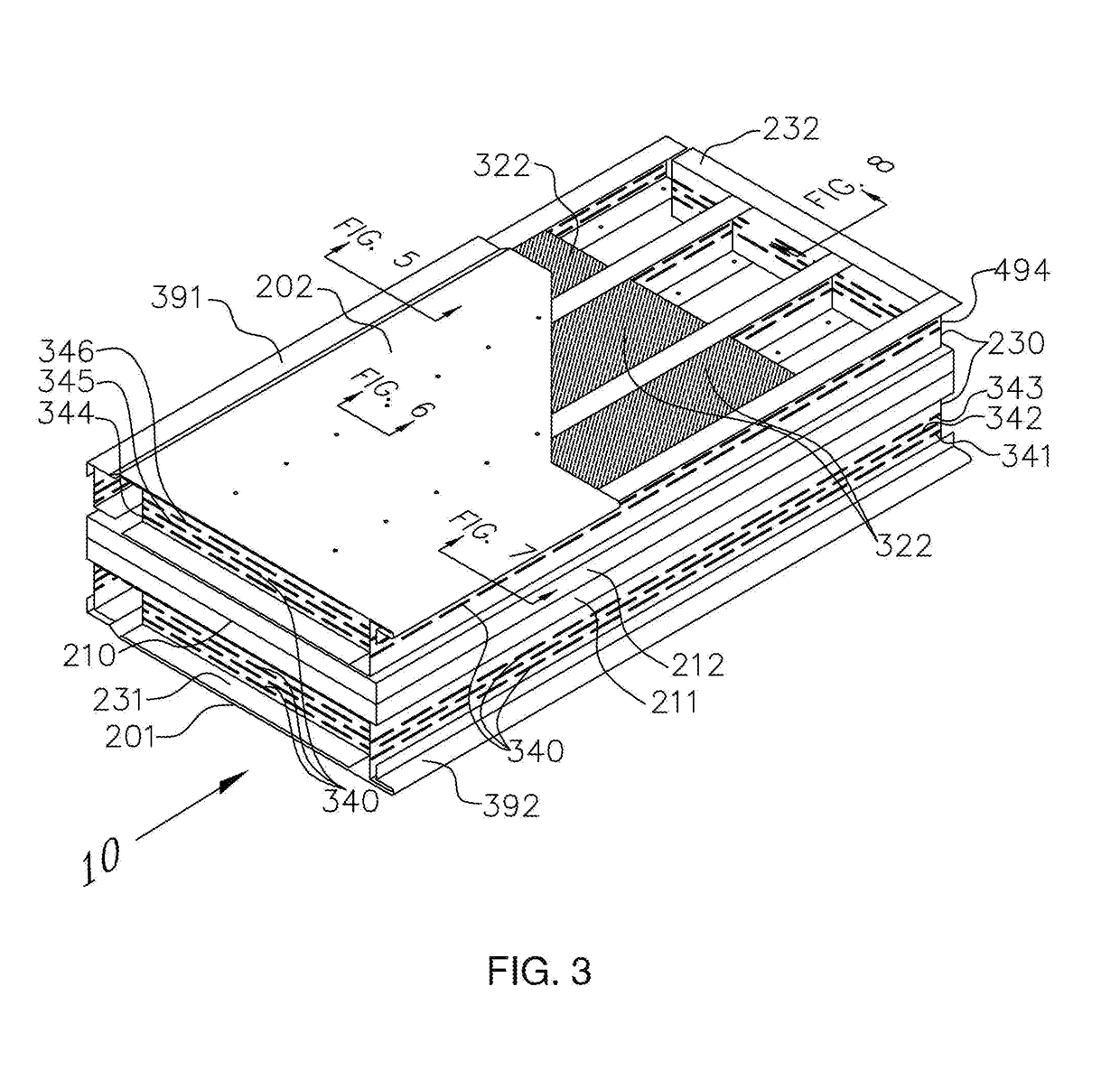

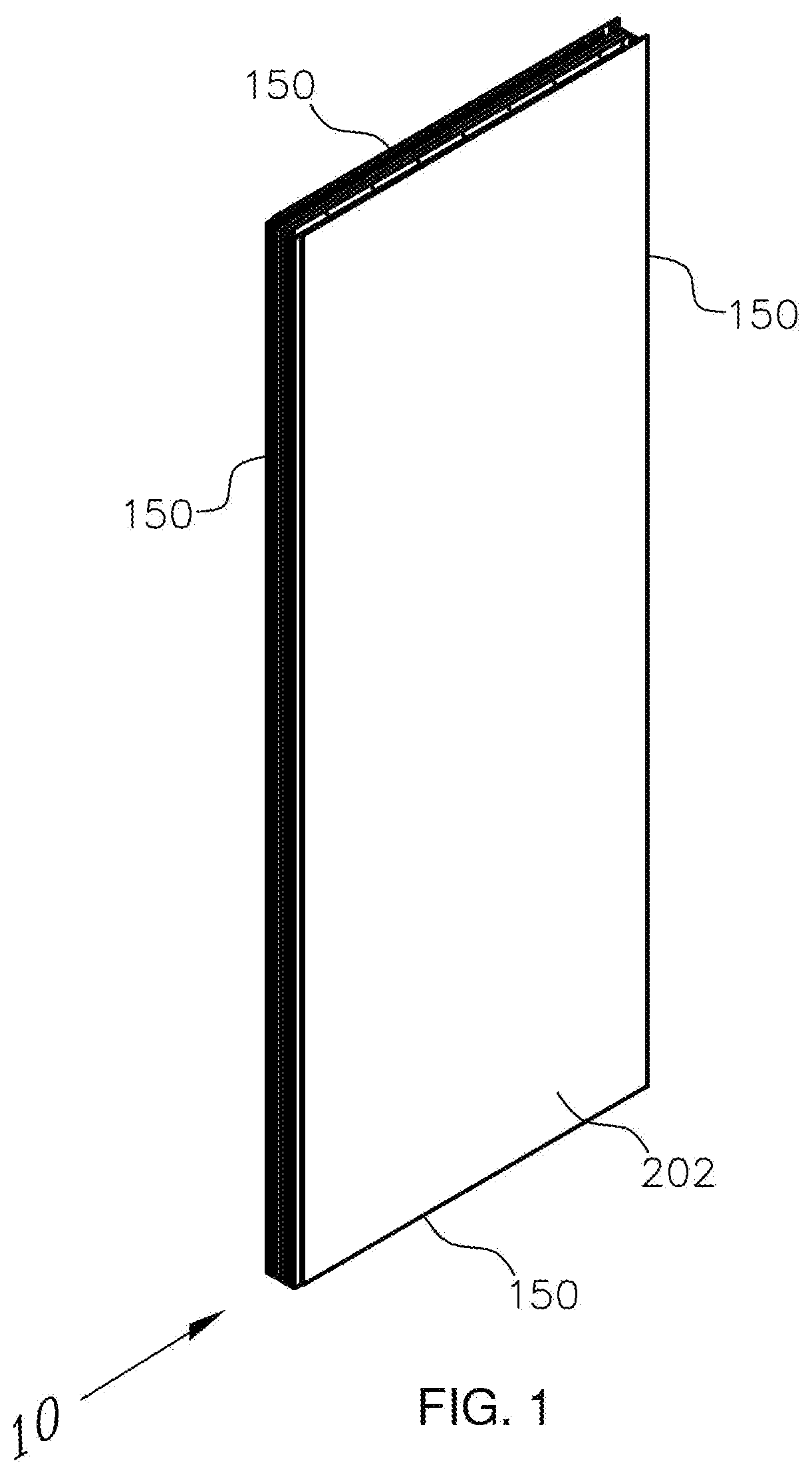

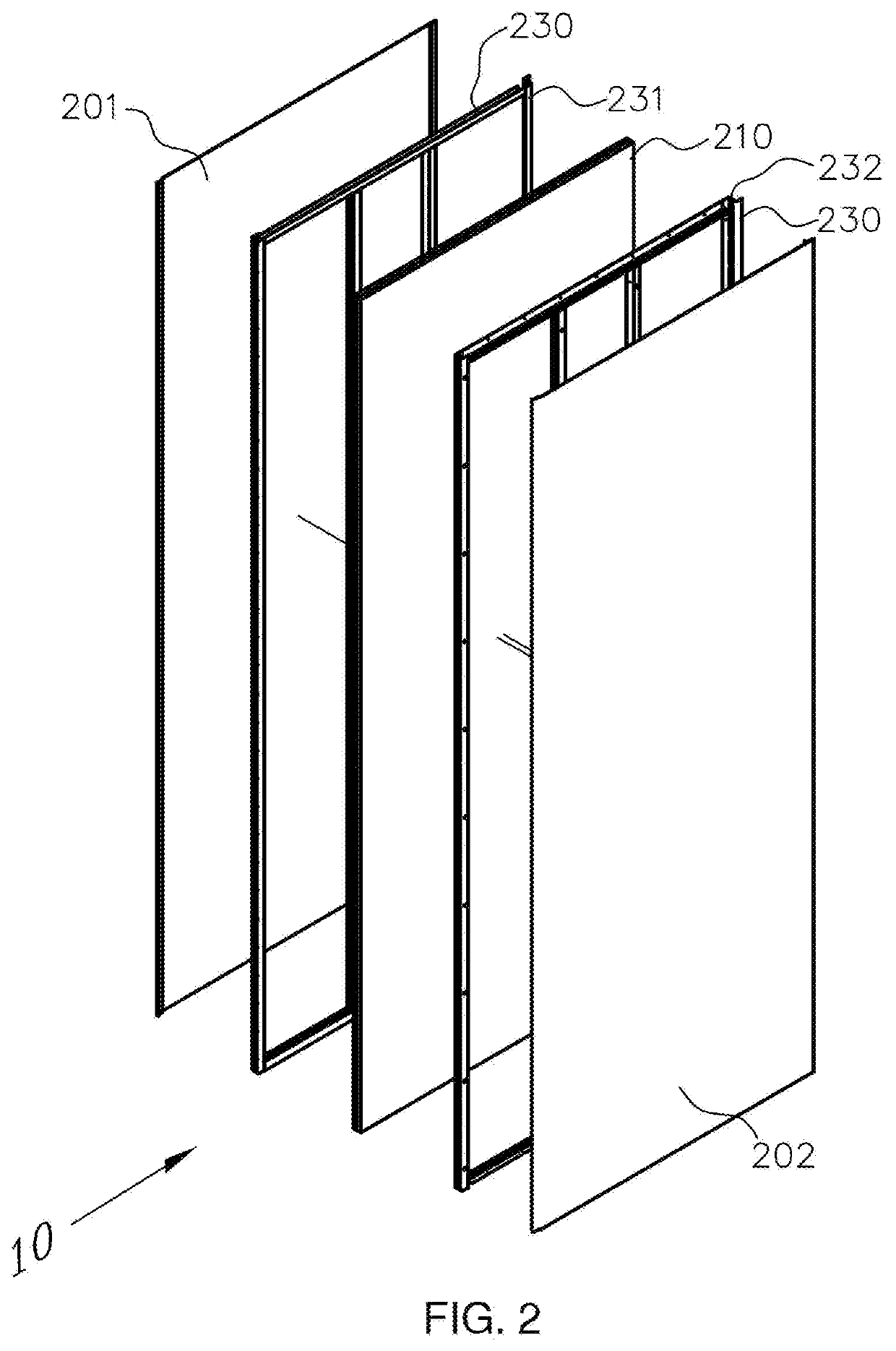

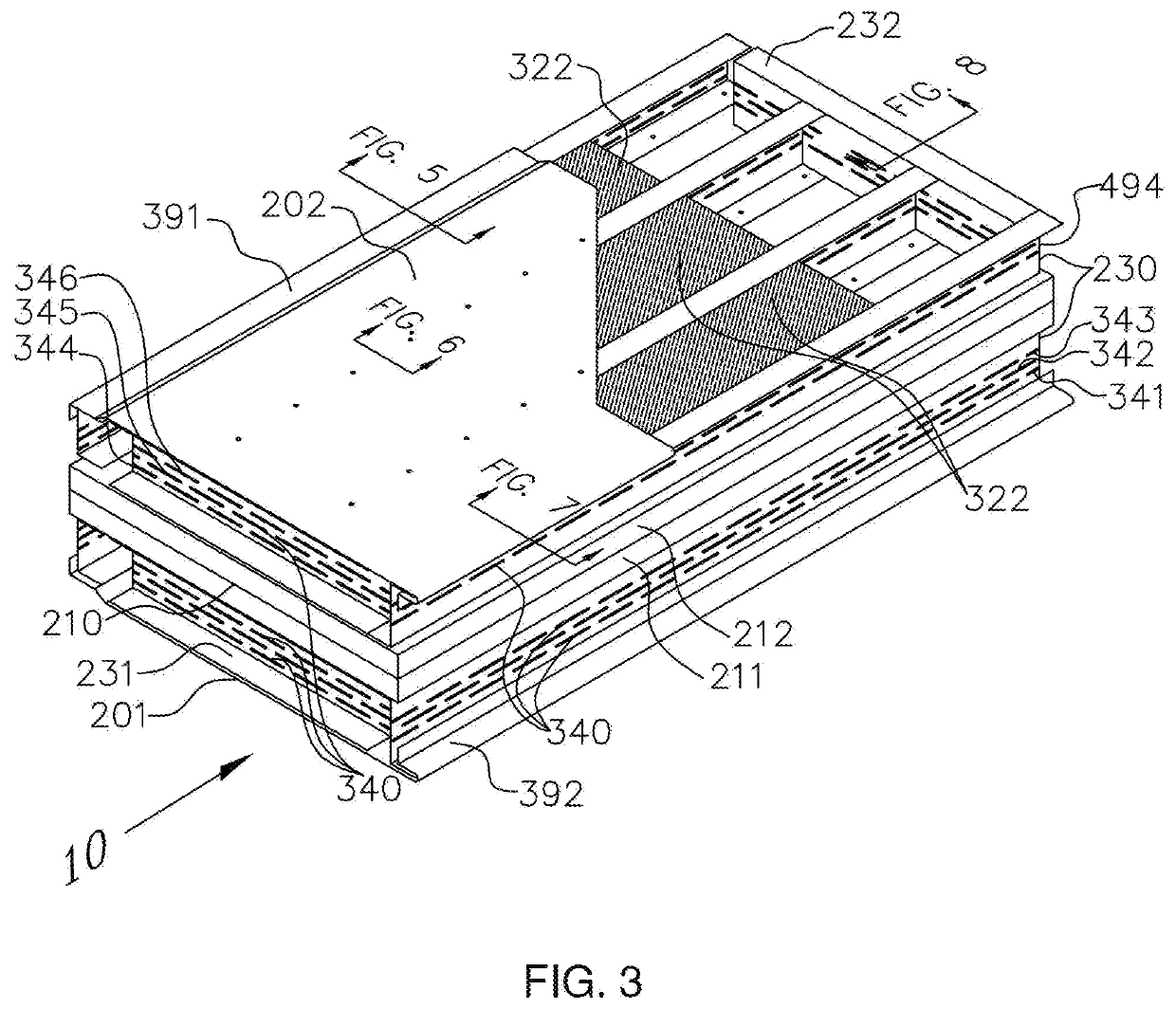

Fire-retardant panel with frame

ActiveUS20190078326A1Reduce the risk of fireEasy to installConstruction materialConstructions elementsGypsumFire retardant

Fire-retardant panels that include: a frame with multiple holes in at least two rows that reduce heat conduction through the panel; or a frame that includes two portions separated by a layer of fire-resistant material (e.g., gypsum, calcium silicate, or gypsum board). Some embodiments include layers of skin (e.g., sheet metal) or insulation (e.g., between skin and fire-resistant material). In particular embodiments, the fire-resistant material is (e.g., midway) between: two skins, two layers of insulation, two portions of the frame, or a combination thereof. The portions of the frame can be: sheet metal, attached (e.g., screwed) to the skin(s), or extend around the perimeter. The frame can include: various elongated members, one or two (e.g., parallel) bends, or holes that are: in at least three rows, staggered, elongated, or slots (e.g., parallel to each other or to the skin).

Owner:SEMCO INC

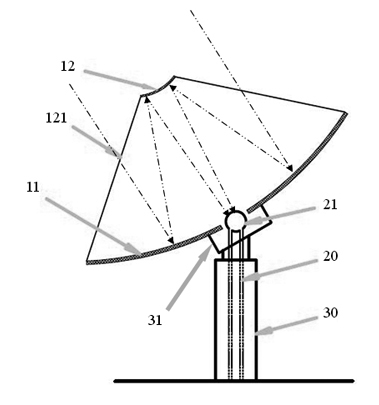

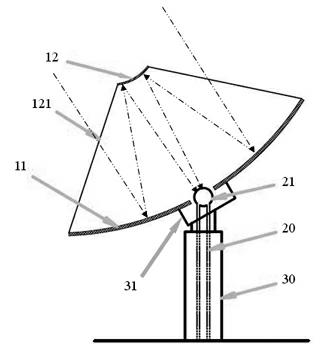

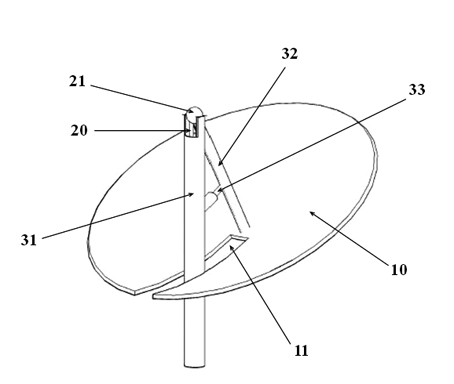

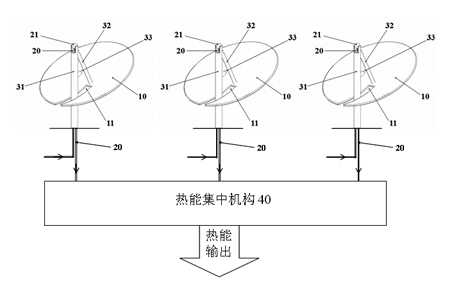

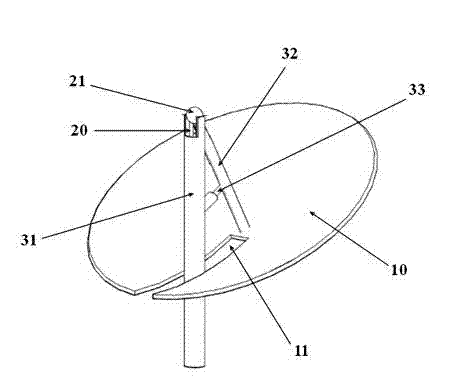

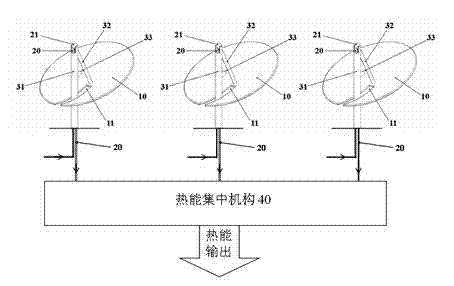

Novel disc-type solar-powered heat collecting device and system

InactiveCN102032689AEasy to installMaximize the effective receiving areaSolar heating energySolar heat collector controllersThermal energySunlight

The invention discloses a novel disc-type solar-powered heat collecting device and a novel disc-type solar-powered heat collecting system. The device comprises a reflecting mirror, a heated point and a heat collecting pipe, wherein the reflecting mirror traces sunlight by rotation, so that the sunlight irradiates vertically to gather photo-thermal energy; the heated point is positioned on the focal point of the reflecting mirror; the spatial position of the heated point is stationary when the reflecting mirror traces the sun by rotation; the heat collecting pipe is connected with the heated point; and a working medium in the pipe is heated by solar energy focused at the heated point. By the device and the method, the reflecting mirror rotates or changes an inclination angle to trace the sun by rotation, so that the sunlight irradiates vertically on the reflecting mirror and an effective receiving area is maximized. After the sunlight is collected by the reflecting mirror, the heated point at the focal point is heated in a centralized way and a higher working medium temperature can be obtained in a point focusing mode. The heat collecting system collects high-temperature media output by a plurality of heat collecting pipes and uniformly supplies heat to the outside or generates power. The spatial position of the heated point is stationary when the reflecting mirror traces the sun, so that the design and installation of the heat collecting pipe are simplified greatly.

Owner:SHANGHAI NEW IND OPTOELECTRONICS TECH

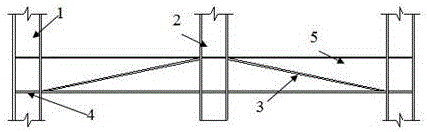

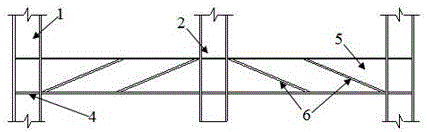

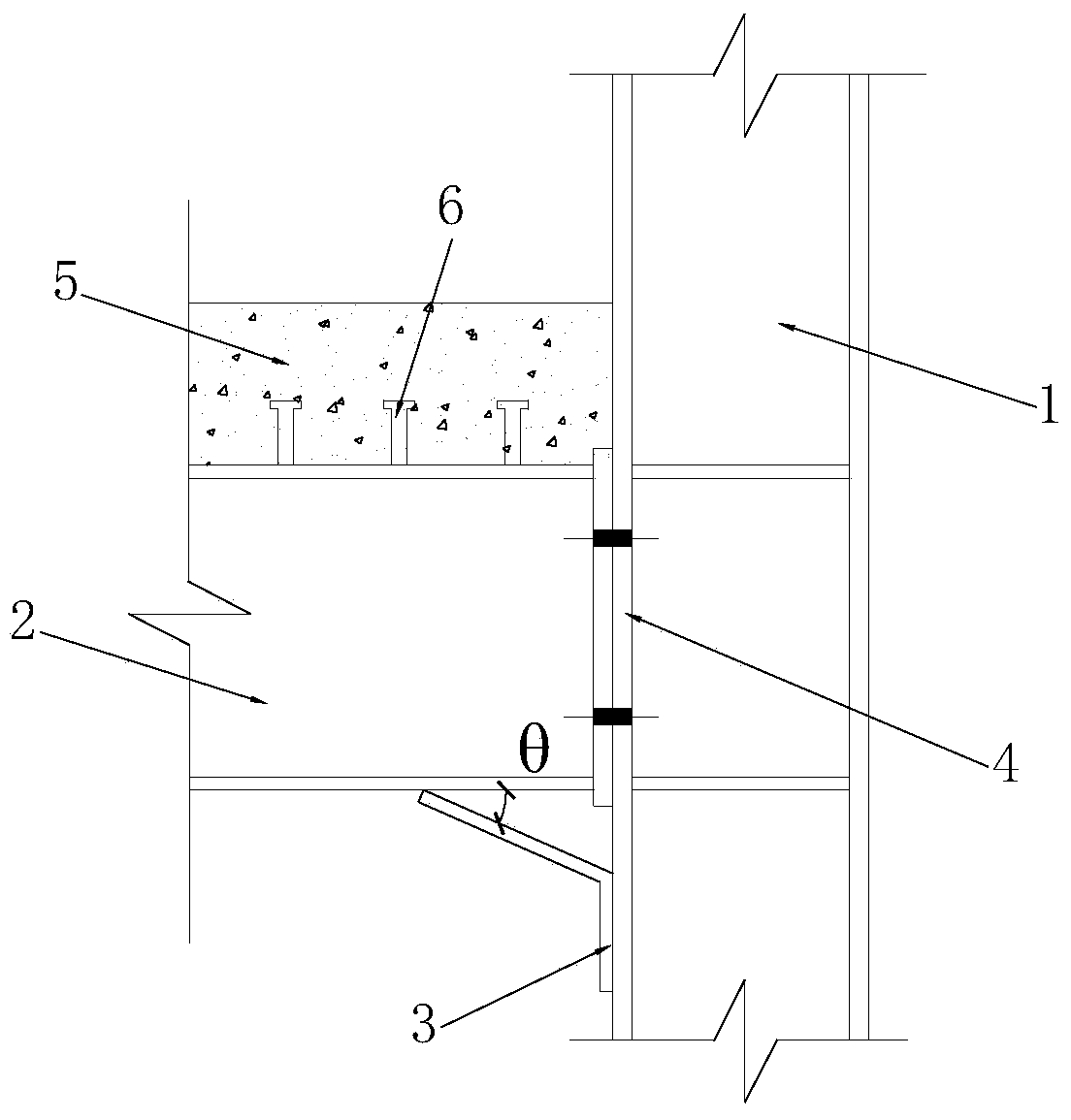

Strengthening method for resisting progressive collapse through steel frame structure

ActiveCN106593006ASimple design and installationLow costBuilding repairsSteel columnsProgressive collapse

The invention provides a strengthening method for resisting progressive collapse through a steel frame structure. Through the design method for resisting progressive collapse in the standard, the position of a key pillar is determined. After the key pillar is chosen and determined, the key pillar is assumed as a destroyed steel pillar, and single oblique ribs or double oblique ribs are additionally arranged on joist steel of the two sides of the destroyed steel pillar. The pressure arching effect of the key pillar position is reinforced, and the redundancy degree and the progressive collapse resistance property of a newly-built building are improved. Or after a weak pillar or a destroyed pillar is known through exploration and observation, the weak pillar or the destroyed pillar is assumed as the destroyed steel pillar. According to the arrangement conditions of building components and site conditions of construction, the single oblique ribs or the double oblique ribs are chosen for strengthening, and strengthening for progressive collapse resistance is achieved. The strengthening method for resisting progressive collapse through the steel frame structure is simple in design and mounting and good in economic benefits. Oblique ribs and regular stress components are not superimposed, so that the strengthening method for resisting progressive collapse through the steel frame structure is applied to a newly-built structure, strengthening reconstruction of an existing structure, a full welding beam pillar joint point, and an end plate connecting beam pillar joint point.

Owner:XIJING UNIV

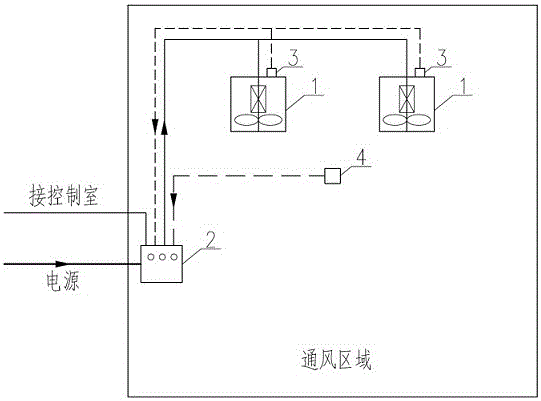

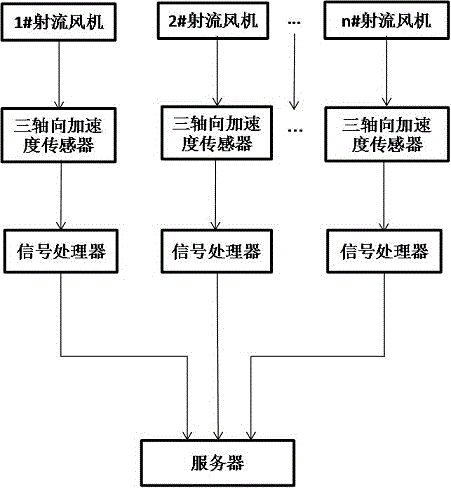

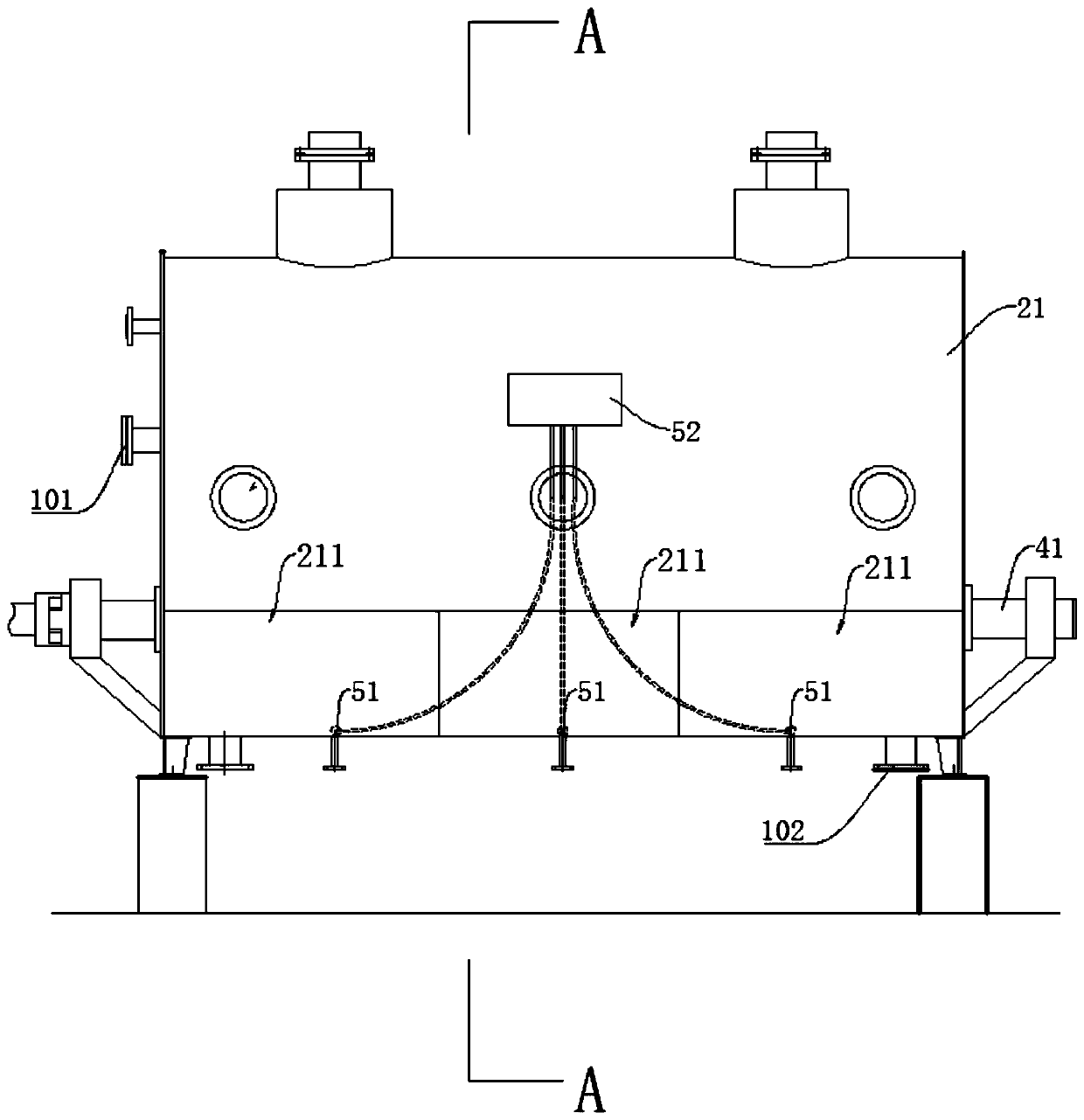

Anti-vibration anti-loosening ventilating system and ventilating method

InactiveCN106322686ARealize start-stop monitoringAchieve securityMechanical apparatusSpace heating and ventilation safety systemsData controlEngineering

The invention provides an anti-vibration anti-loosening ventilating system and a ventilating method. The anti-vibration anti-loosening ventilating system comprises a gas sensor, a fan, a tri-axial acceleration sensor and a control box; the gas sensor is used for monitoring a gas state of a ventilating area in real time; the tri-axial acceleration sensor is mounted on the fan and is used for acquiring vibration information of the fan, and is also set with identifying information of the fan; the fan, the gas sensor and the tri-axial acceleration sensor are connected with the control box; and the control box can be used for controlling on or off of the fan according to gas condition data monitored by the gas sensor, and also can be used for identifying the corresponding fan according to the identifying information transmitted from the tri-axial acceleration sensor and judging a working state of the fan according to vibration information. According to the anti-vibration anti-loosening ventilating system provided by the invention, the fan, the gas sensor, the tri-axial acceleration sensor and the control box are integrated as one piece of equipment, so that design and mounting are relatively simple.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

Air conditioning with recovery wheel, dehumidification wheel, and cooling coil

ActiveUS11320161B2Less riskImprove cooling effectEnergy recovery in ventilation and heatingMechanical apparatusEvaporative coolerVariable refrigerant flow

Owner:SEMCO INC

Moulding basin for moulding two ladles at same time

ActiveCN106001431ASimple design and installationImprove cleanlinessFoundry mouldsFoundry coresSlagPhysics

The invention relates to a moulding basin for moulding two ladles at the same time in the technical field of casting. The moulding basin comprises a moulding basin body of which the length size is larger than the width size and the upper part is opened; inlet cavities are respectively and symmetrically formed in two sides of the moulding basin body along the length direction; an outlet cavity is formed in the middle part of the moulding basin body; a sprue connector is formed in the bottom wall of the outlet cavity; the inlet cavities in the two sides and the outlet cavity in the middle part are respectively separated through filter cavities; each inlet cavity and the adjacent filter cavity are separated through a separating wall I; the outlet cavity and the filter cavities in the two sides are respectively separated by separating walls II; a plurality of filter holes I which are communicated with the inlet cavities and the filter cavities are formed in the bottom parts of the separating walls I; a plurality of filter holes II which are communicated with the filter cavities and the outlet cavity are formed in the bottom parts of the separating walls II. According to the moulding basin for moulding the two ladles at the same time, disclosed by the invention, the two inlet cavities and the filter cavities are formed in one moulding basin, the structure is simple, the cost is low, the slag blocking effect is good, the mould filling is stable, and the moulding basin is beneficial for increasing the moulding quality of castings.

Owner:KOCEL EQUIP

Layered fire-retardant panel

InactiveUS20190078325A1Reduce the risk of fireEasy to installConstruction materialConstructions elementsCalcium silicateRefractory

Fire-retardant panels that include: two skins (e.g., sheet metal) and a layer of gypsum or calcium silicate fire-resistant material therebetween; two layers of insulation with fire-resistant material therebetween; a skin (e.g., sheet metal), a layer of gypsum or calcium silicate fire-resistant material, and insulation therebetween; or a combination thereof. Some embodiments include: two contiguous layers of the fire-resistant material, gypsum board, tongue and groove connections; or a frame that extends around the perimeter or has two portions that are attached to the skins or are separated by the fire-resistant material. In some embodiments, the fire-retardant panel is fabricated in a factory before being installed at a jobsite.

Owner:SEMCO INC

Novel disc-type solar-powered heat collecting device and system

InactiveCN102032689BMaximize the effective receiving areaSimple design and installationSolar heating energySolar heat collector controllersThermal energyHot Temperature

The invention discloses a novel disc-type solar-powered heat collecting device and a novel disc-type solar-powered heat collecting system. The device comprises a reflecting mirror, a heated point and a heat collecting pipe, wherein the reflecting mirror traces sunlight by rotation, so that the sunlight irradiates vertically to gather photo-thermal energy; the heated point is positioned on the focal point of the reflecting mirror; the spatial position of the heated point is stationary when the reflecting mirror traces the sun by rotation; the heat collecting pipe is connected with the heated point; and a working medium in the pipe is heated by solar energy focused at the heated point. By the device and the method, the reflecting mirror rotates or changes an inclination angle to trace the sun by rotation, so that the sunlight irradiates vertically on the reflecting mirror and an effective receiving area is maximized. After the sunlight is collected by the reflecting mirror, the heated point at the focal point is heated in a centralized way and a higher working medium temperature can be obtained in a point focusing mode. The heat collecting system collects high-temperature media output by a plurality of heat collecting pipes and uniformly supplies heat to the outside or generates power. The spatial position of the heated point is stationary when the reflecting mirror traces the sun, so that the design and installation of the heat collecting pipe are simplified greatly.

Owner:SHANGHAI NEW IND OPTOELECTRONICS TECH

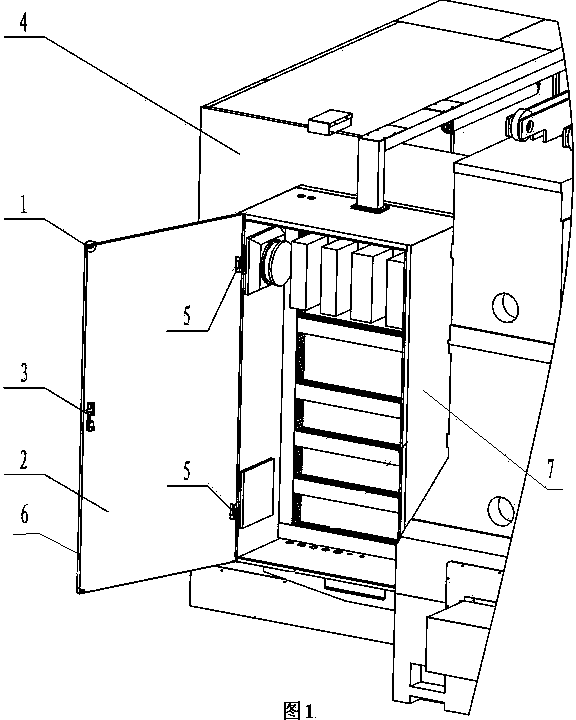

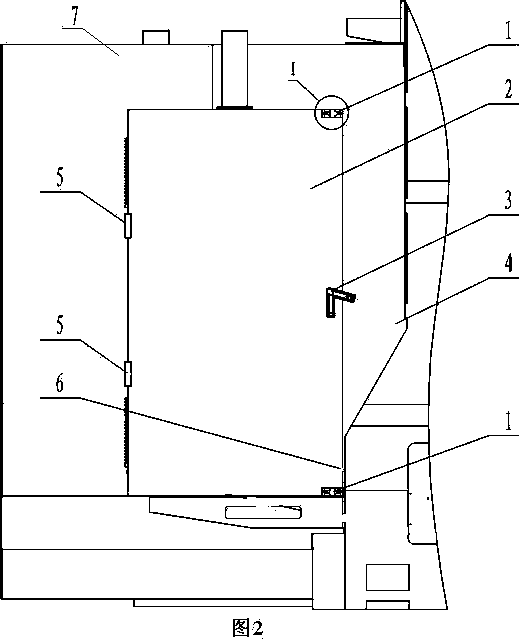

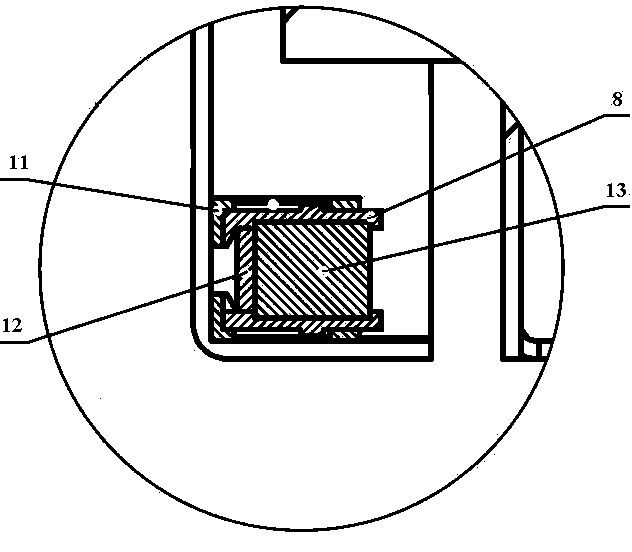

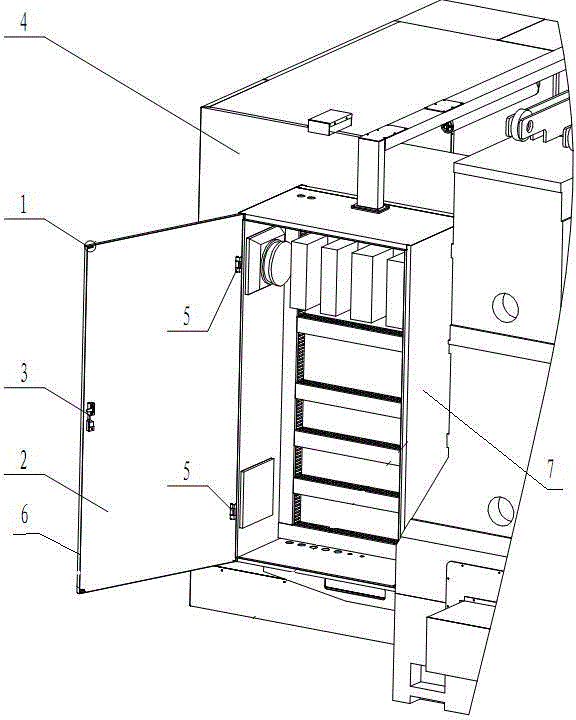

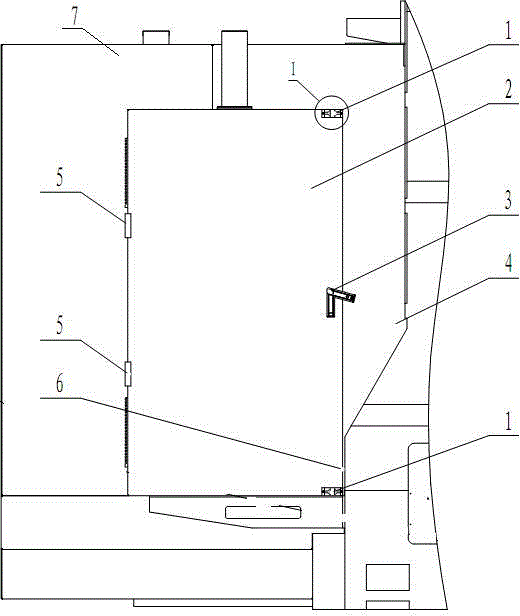

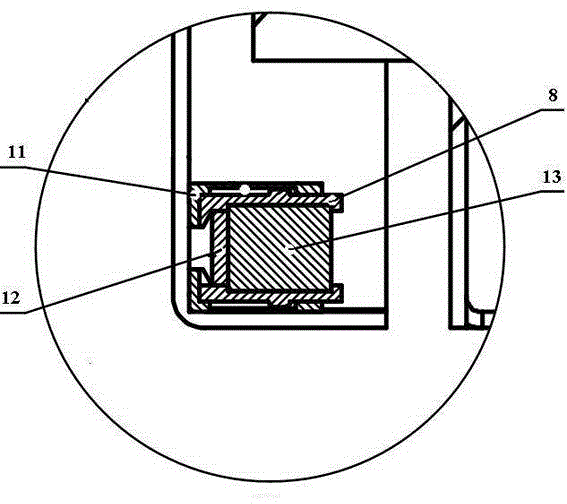

Machining center power distribution cabinet permanent magnet door lock matching device

InactiveCN104242101AMitigate mechanical shock effectsSimple design and installationAnti-seismic devicesMagnet

The invention relates to a machining center power distribution cabinet permanent magnet door lock matching device which comprises a power distribution cabinet body, a power distribution cabinet door, a safety protection lock and a machining center outer protection part. The power distribution cabinet door comprises a power distribution cabinet right door edge and a power distribution cabinet left door edge, two hinges are arranged on the power distribution cabinet left door edge and are fixed on the power distribution cabinet body, the safety protection lock is arranged in the middle of the power distribution cabinet right door edge, and permanent magnet shock-resisting devices are arranged at the upper end and the lower end of the power distribution cabinet right door edge respectively. On the aspect of structure design, spring tongues are arranged for shock reduction, pressure and vibration generated immediately when permanent magnets are attracted and separated are effectively relieved, and circuits and components in the power distribution cabinet are greatly protected.

Owner:QINGDAO KANGWEILONG COMMODITY COMPANY

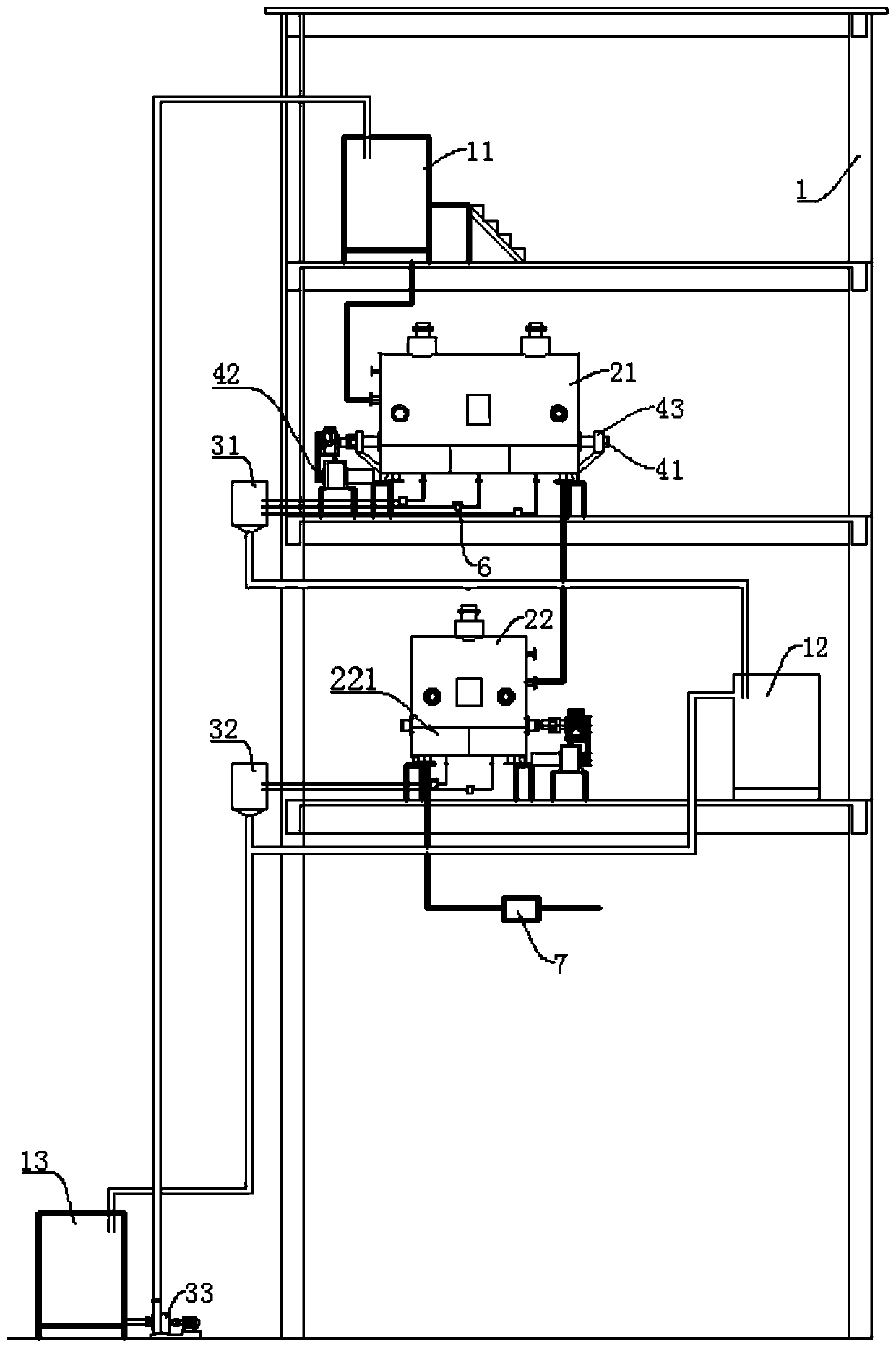

Draining system for brown-sugar continuous boiling tank

PendingCN110106292AAchieve self-sufficiencyReduce wasteSugar juice boiling/evaporationFood processingWater circulationWater pipe

The invention provides a draining system for a brown-sugar continuous boiling tank. The system includes a base frame, an upper water tank, a middle water tank, a lower water tank, a water pump, a first steam-water separator, a second steam-water separator, the sugar boiling tank, a heat supply device and a water circulation device. The middle water tank is at the same height as a second-effect sugar boiling tank body, a first steam outlet is connected with a steam inlet of the first steam-water separator through a pipeline, a water outlet of the first steam-water separator is connected with awater inlet of the middle water tank through a pipeline, a water outlet of the middle water tank is connected with a water inlet of the lower water tank through a pipeline, a water pipe is arranged between the middle water tank and the heat supply device, the water pump is used for pumping water from the lower water tank into the upper water tank, a second steam outlet is connected with a steam inlet of the second steam-water separator through a pipeline, and a water outlet of the second steam-water separator is connected with the water inlet of the lower water tank through a pipeline. The technical problem is solved that the utilization rate of hot water is low during brown-sugar boiling and thus waste of the hot water is serious.

Owner:广西糖业集团星星制糖有限公司

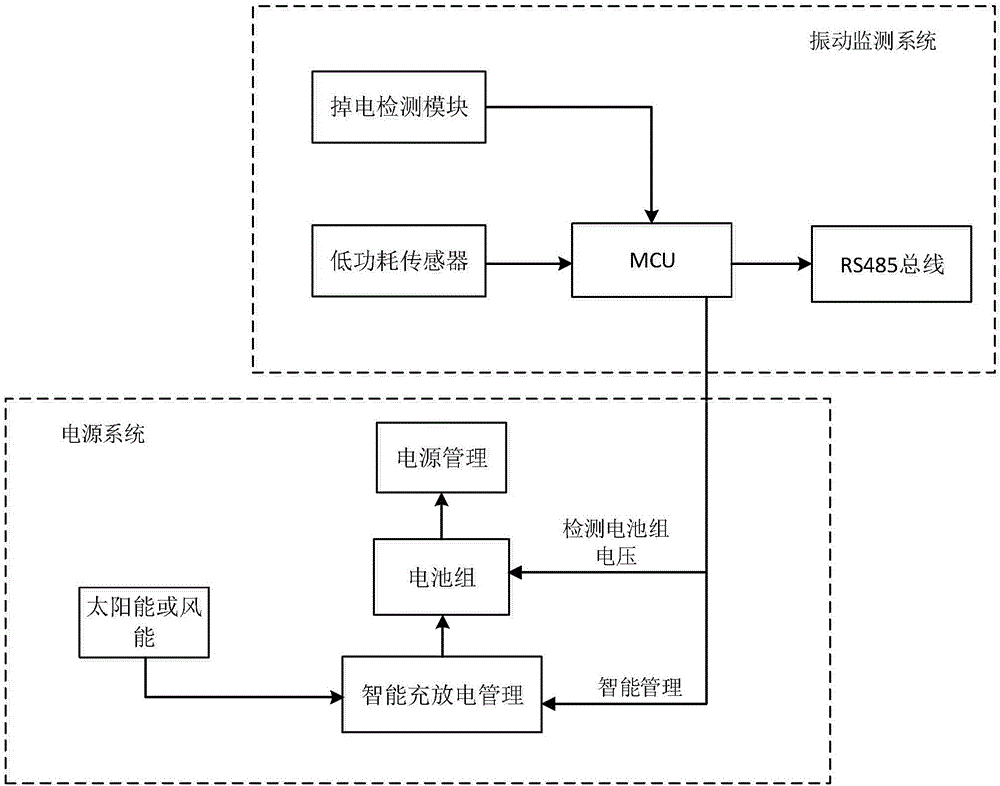

Monitoring alarm system

InactiveCN105790438AReduce power consumptionWith power-down protection functionCircuit arrangementsPV power plantsElectricityMonitoring system

The present invention discloses a monitoring alarm system. The monitoring alarm system comprises a vibration monitoring system and a power supply system. The vibration monitoring system includes a MCU, the MCU is connected with a sensor and a power failure detection module, and the MCU is provided with a RS485 for outputting; and the power failure detection module is configured to monitor the power supply state of the vibration monitoring system, when the power supply state is abnormal, alarm signals are emitted to the MCU, and the power supply system supplies power to allow the MCU to connect the sensor and the power failure detection module, so that when the power supply is abnormal and the sensor generates signals, the alarm signals and the sensor signals are emitted to the MCU. The monitoring alarm system is low in power consumption, has a power failure protection function, is very applied to the monitoring work of historical relics at field, and is reliable in performance, high in function, simple in design and installation and durable.

Owner:BEIJING TIANYIYUAN RELIC PRESERVATION TECH CO LTD

Fire-retardant panel with frame

ActiveUS20210040729A1Easy to installReduce the risk of fireConstruction materialConstructions elementsCalcium silicateClassical mechanics

Fire-retardant panels that include: a frame with multiple holes that reduce heat conduction through the panel; or a frame that includes two portions separated by a layer of fire-resistant material (e.g., gypsum, calcium silicate, or gypsum board). Some embodiments include skins (e.g., sheet metal) or insulation (e.g., between skin and fire-resistant material, for instance, within the frame). In particular embodiments, the fire-resistant material is (e.g., midway) between: two skins, two layers of insulation, two portions of the frame, or a combination thereof. The portions of the frame can be: sheet metal, attached (e.g., screwed) to the skin(s) or to each other, or extend around the perimeter. The frame can include: various elongated members, (e.g., parallel) bends, or holes that are: in at least one row, elongated, or slots (e.g., parallel to each other or to the skin).

Owner:SEMCO INC

Solar photovoltaic three-phase micro-inverter and solar photovoltaic power generation system

ActiveUS9520721B2Simple design and installationDc network circuit arrangementsElectric signal transmission systemsDc currentThree-phase

Owner:ALTENERGY POWER SYST

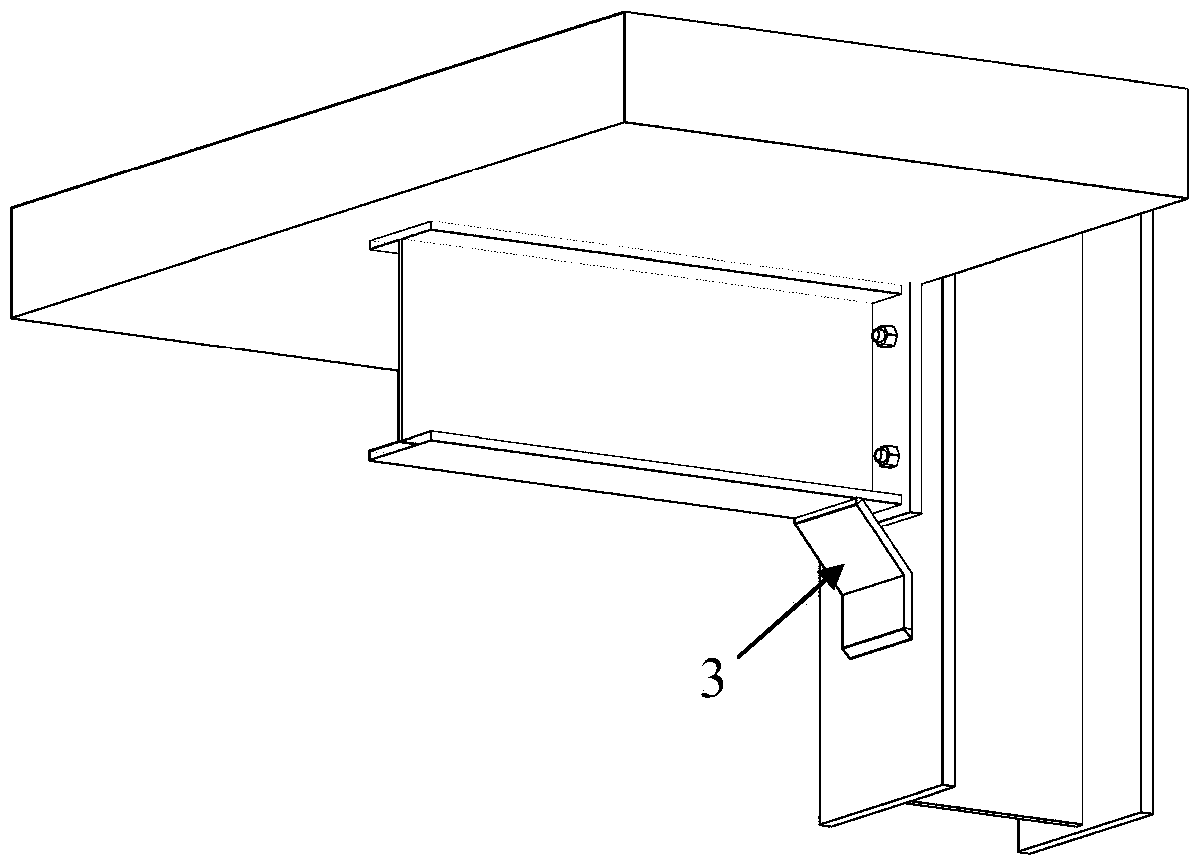

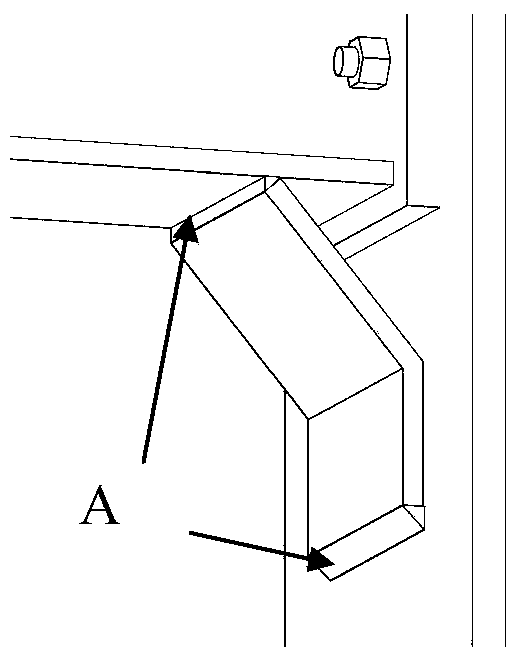

A composite joint of steel and concrete strengthened by angle steel

ActiveCN104929252BEnhanced pull abilityImprove progressive collapse resistanceBuilding repairsSteel columnsMaterials science

The invention discloses an angle steel reinforced steel and concrete combination joint and relates to the technical field of building structures. The joint solves the problem that when an existing traditional steel and concrete combination joint carries out anti-collapsing reinforcing, flexural capacity and flexural rigidity are obviously changed. According to the scheme, the joint comprises a steel column, a steel beam, angle steel, an end plate, a reinforced concrete plate and an anti-shearing connecting key. The vertical section of the angle steel is connected with the flange of a steel column. The angle steel is placed below the steel beam and the joint of the steel column, and the free end of the oblique section of the angle steel abuts against the position of the lower flange of the steel beam and is connected with the steel beam. The bottom end face of the reinforced concrete plate is connected with the lower flange of the steel beam through the anti-shearing key. The joint is used for anti-collapsing reinforcing of steel-concrete combination joints in built and newly-built structures.

Owner:HARBIN INST OF TECH

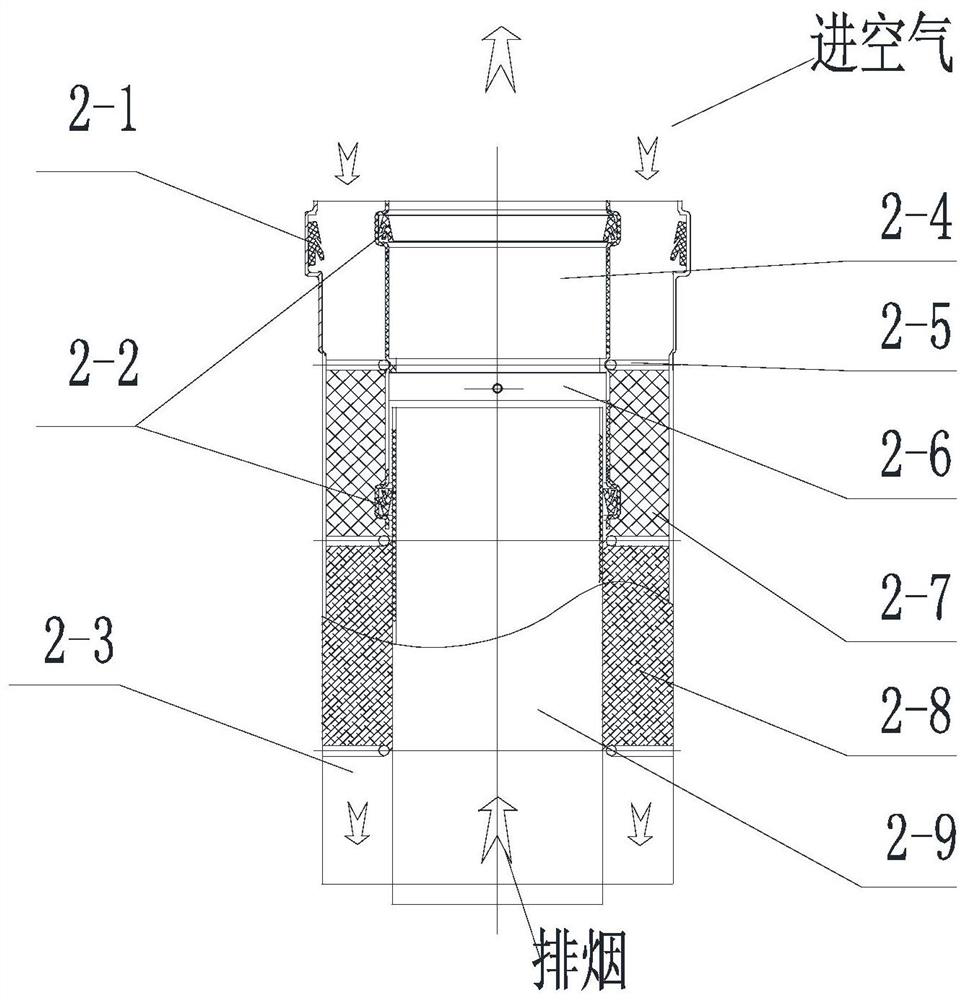

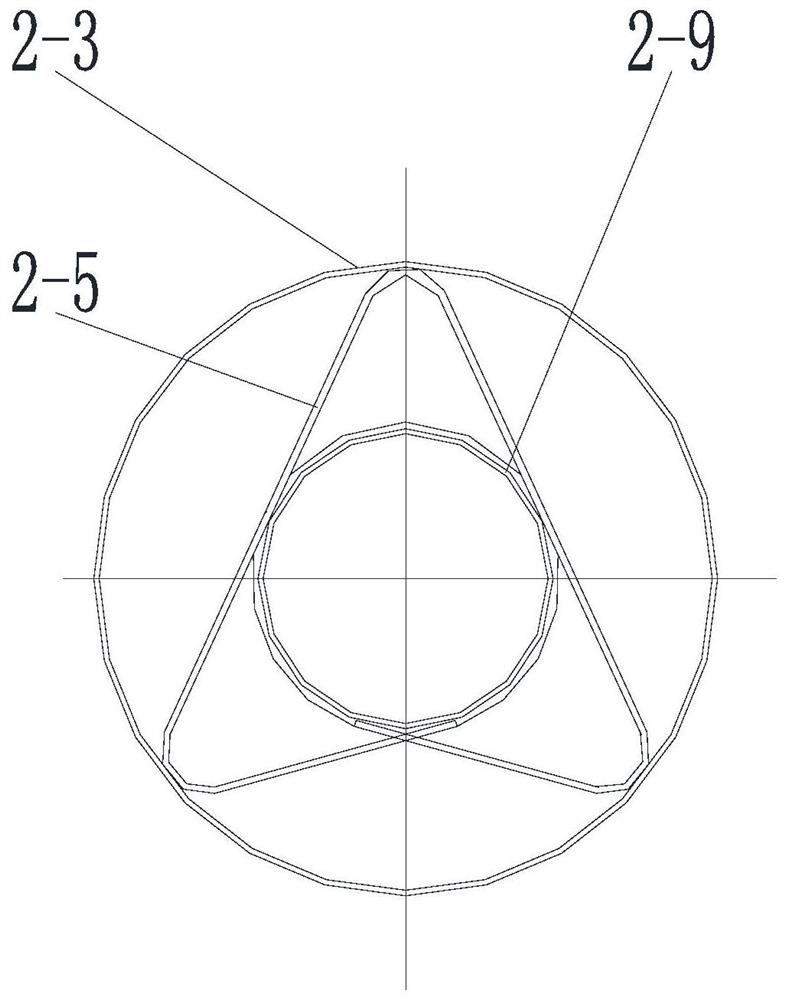

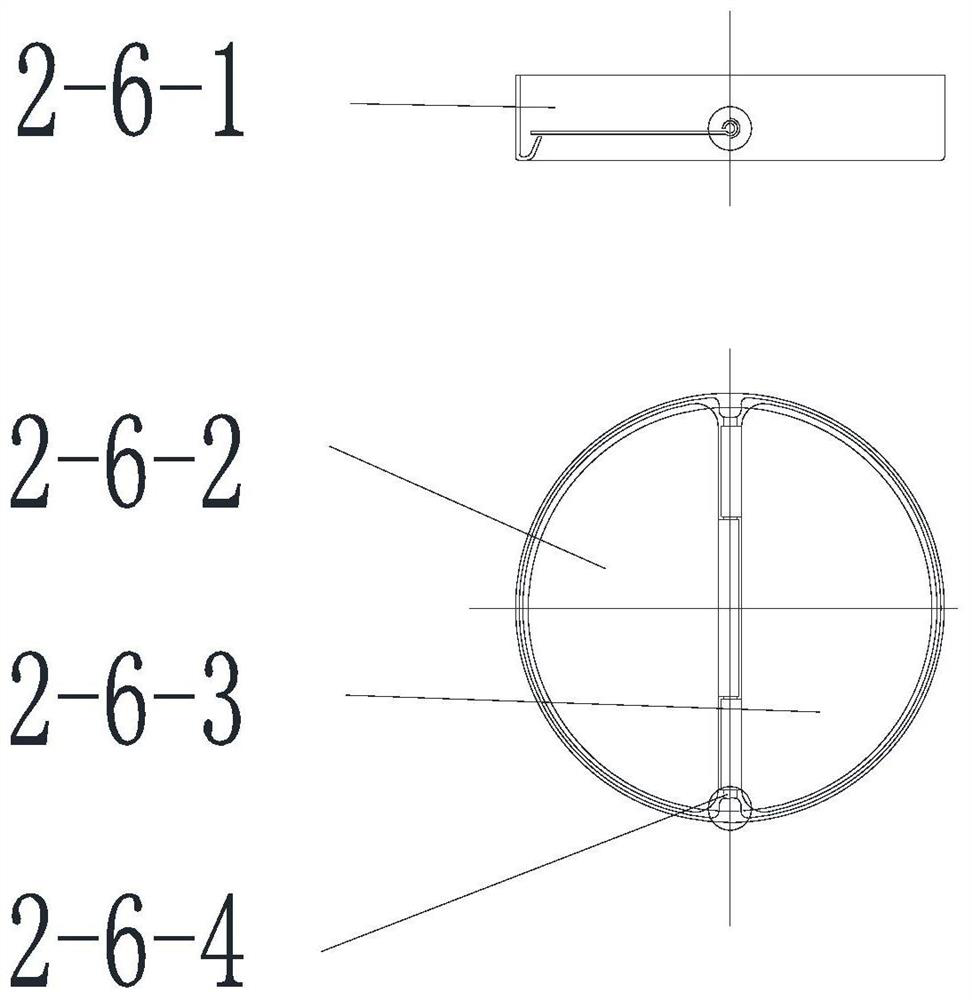

Smoke pipe lengthening section preventing cold wind from flowing backward and containing air filtration for wall hanging stove

PendingCN111854166AEffective filteringPrevent frostbiteFluid heatersDispersed particle filtrationAir filtrationThermodynamics

The invention discloses a smoke pipe lengthening section preventing cold wind from flowing backward and containing air filtration for a wall hanging stove. The lengthening section is characterized byincluding a smoke pipe outer straight pipe, and a smoke pipe inner straight pipe assembly, a wind proof ring is arranged in the smoke pipe inner straight pipe assembly, a support frame used to supporta smoke pipe inner straight pipe is arranged between the smoke pipe outer straight pipe and the smoke pipe inner straight pipe assembly, and a filtration device is mounted between the smoke pipe outer straight pipe and the smoke pipe inner straight pipe assembly. According to the lengthening section, apertures of smoke discharging and air feeding are not changed, the discharging of the content ofCO after the combustion of the wall hanging stove is not affected, and mounting is simple, convenient, and easy to operate.

Owner:MACRO THERMAL ENERGY TECH

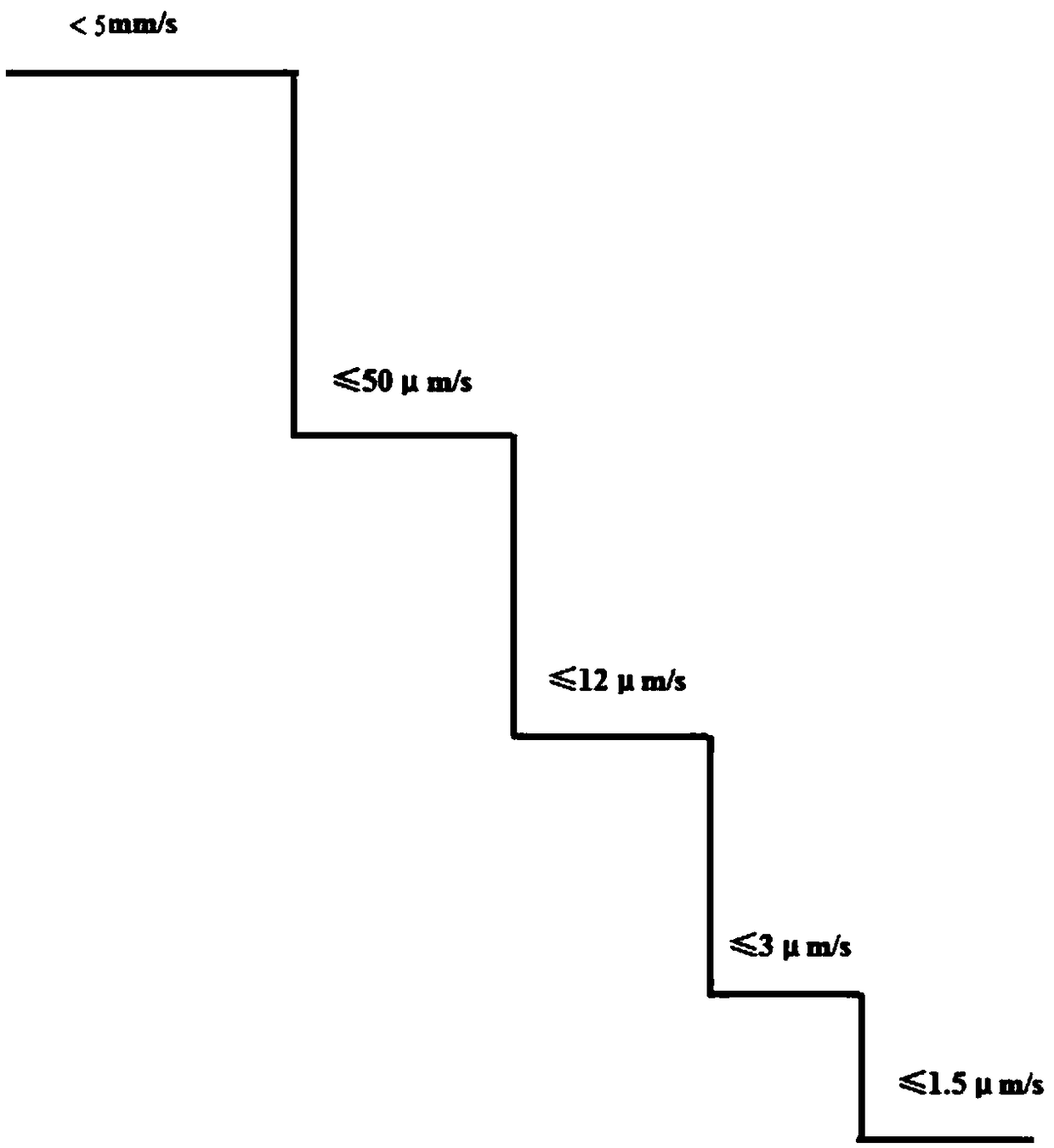

A Vibration Control Method for Buildings and Equipment Based on Hierarchical Energy Consumption

ActiveCN106593057BLow costReduce consumptionProtective buildings/sheltersShock proofingVibration controlEngineering

The invention discloses a building and equipment vibration control method based on layered energy consumption, and the method comprises the steps: 1), determining a vibration speed V of a vibration control object; 2), dividing the vibration speeds of the vibration control object into five levels which represents the vibration energy distribution of five regions according to the determined vibration speed V: 50microns / s<V<5m / s, 12microns / s<V<=50microns / s, 3microns / s<V<=12microns / s, 1.5microns / s<V<=3microns / s, and 0<V<=1.5microns / s; 3), respectively taking vibration control measures for the above five vibration energy sections, enabling the vibration control efficiencies delta D1 - delta 5, wherein the vibration control frequencies meet a formula (shown in the description). The method employs vibration isolation, reduction and control device with different performances for horizontal vibration objects with different levels based on the proposed five vibration levels from the rough to the fine through the layered energy consumption method, and finally achieves the segmentation and gradual consumption of the vibration energy of the whole building structure. Compared with a method of carrying out the vibration control through a single energy consumption target, the method reduces the consumption, and is simple in design and installation.

Owner:国机集团科学技术研究院有限公司

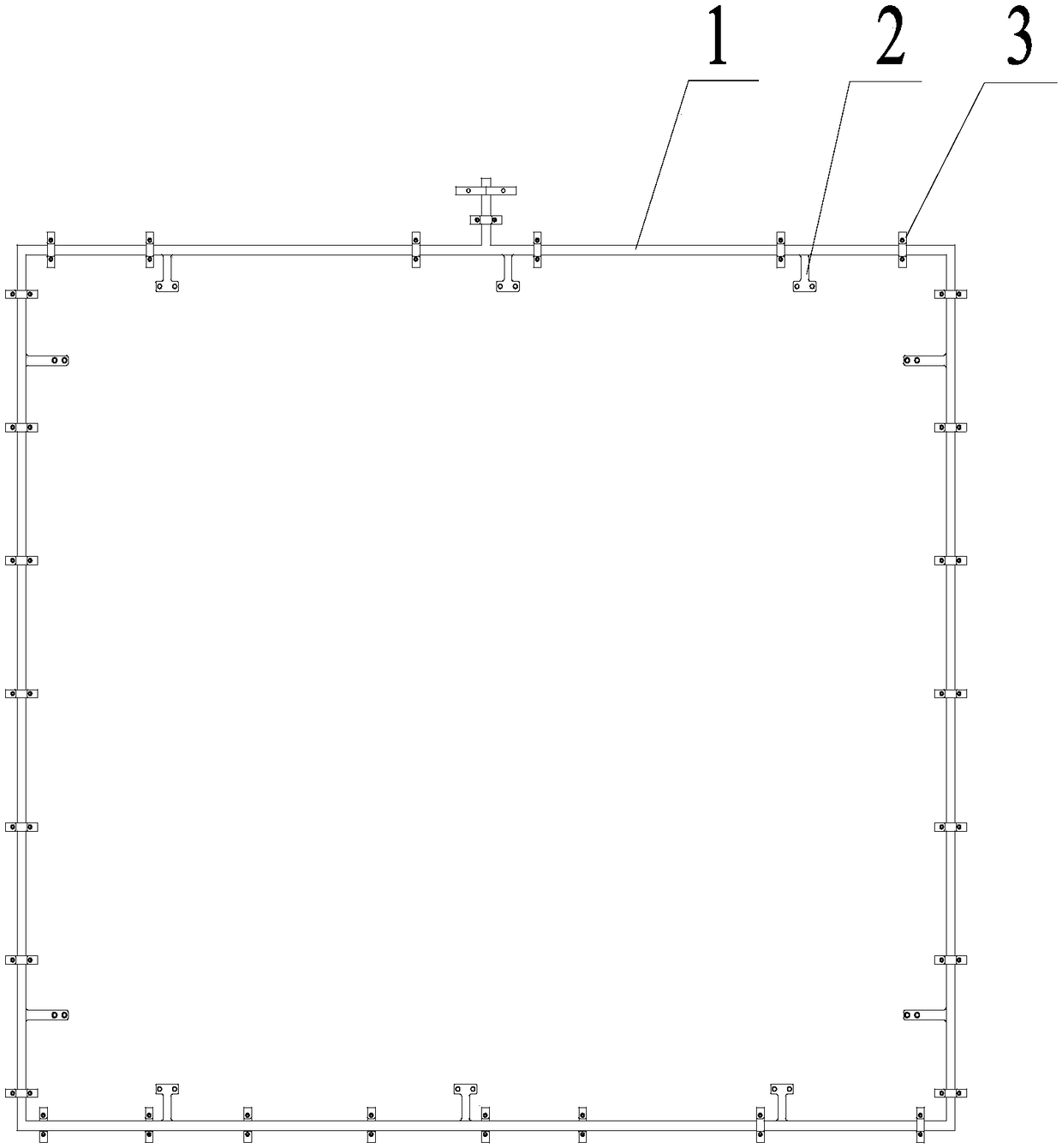

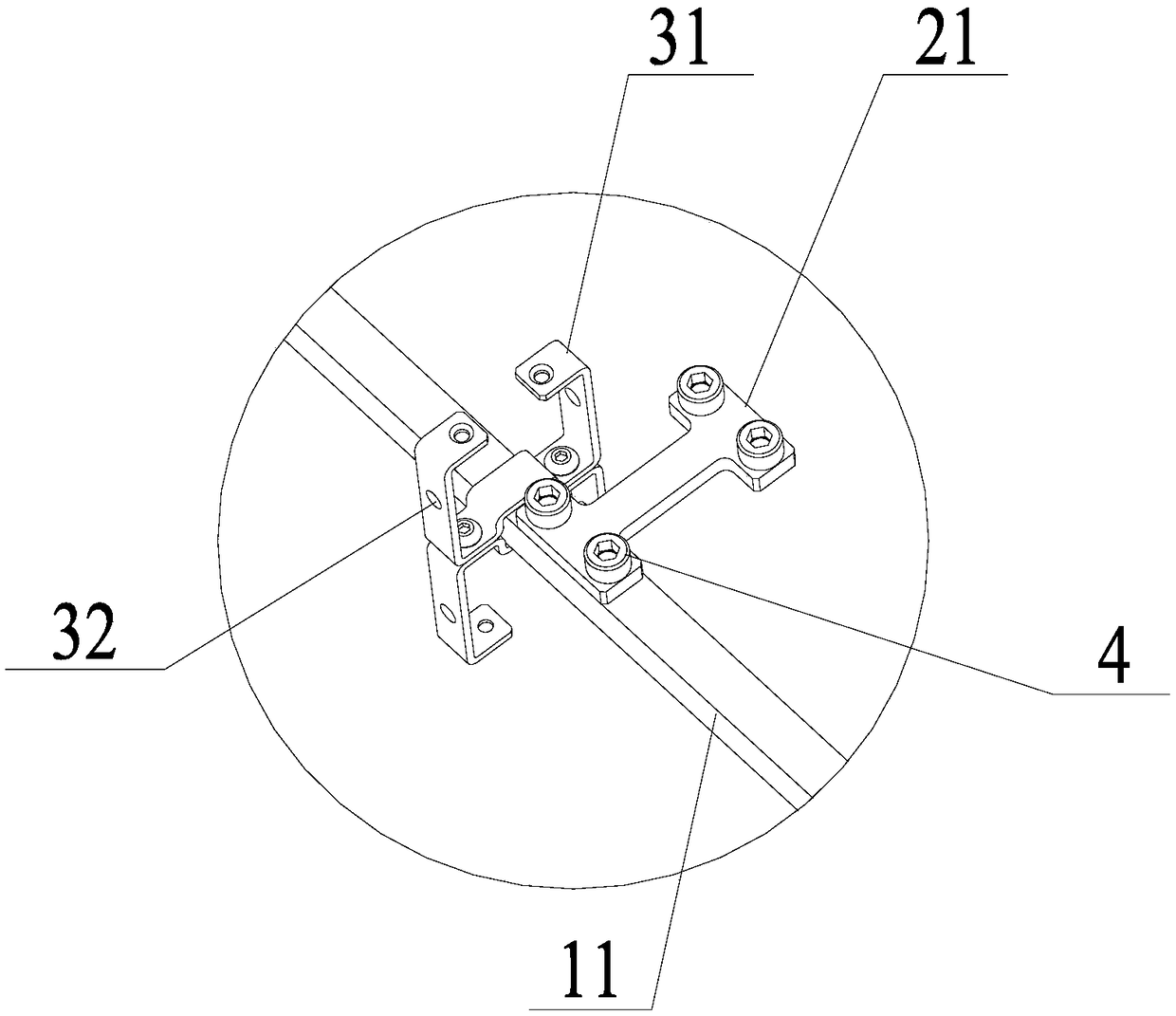

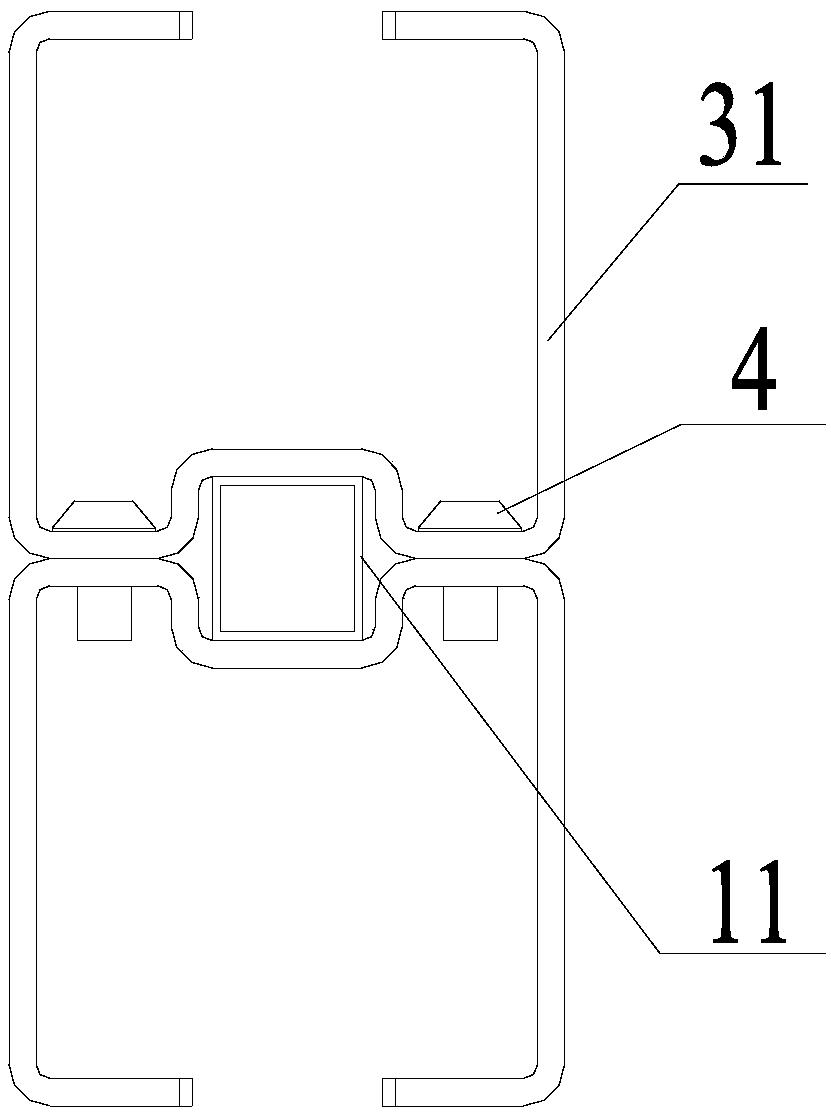

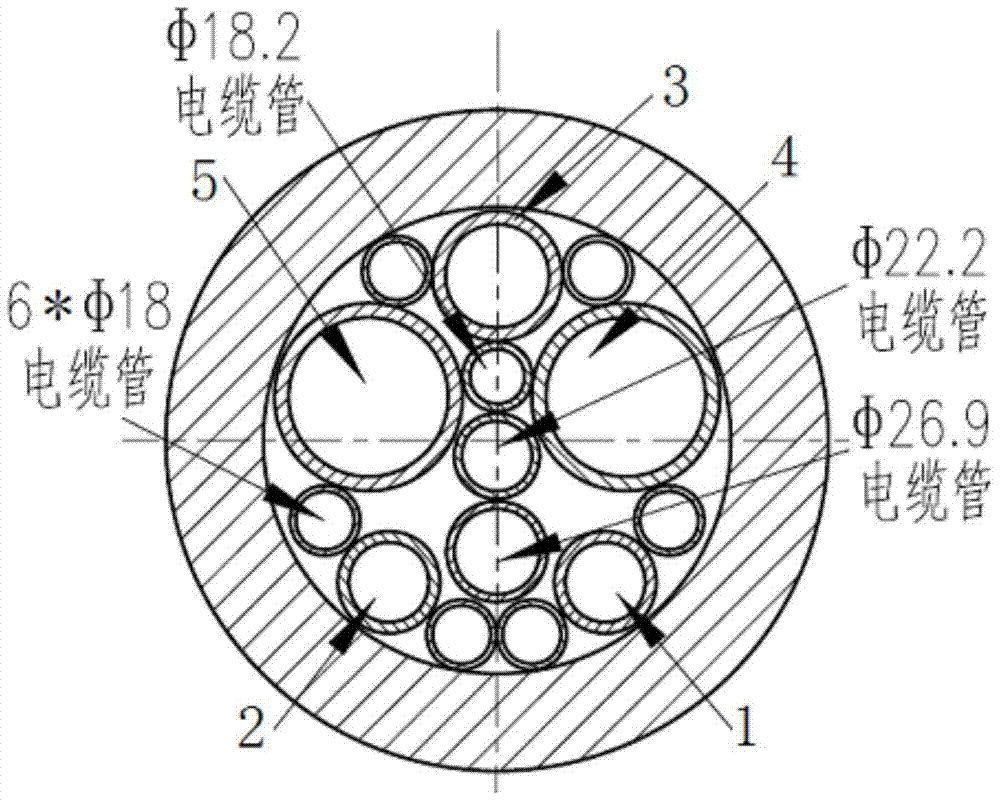

A keel type wire frame

ActiveCN106247014BWith load-bearing capacityAvoid mutual interferencePipe supportsHot runnerFixed frame

The invention relates to the technical field of a hoisting system, and particularly relates to a keel type thread rack for a whole hot runner hoisting system. The keel type thread rack comprises a rack body, wherein a connecting piece and a thread jamming clamp are arranged on the thread rack body, and the thread rack body comprises a plurality of rod-like main beams; the connecting piece comprises a connecting plate; the thread jamming clamp comprises a thread clamp body which consists of a fixed frame, a mounting plate is arranged at the bottom of the fixed frame, a clamping slot is formed in the mounting plate, and fixed holes are formed in two sides of the clamping slot. According to the keel type thread rack, the main beam plays a certain role in supporting lines and pipelines and has certain bearing capability, and a power line, a temperature sensing line, an oil gas pipeline and a cooling pipeline provided by the whole hot runner system can be separately arranged so as to avoid mutual interference and play safety and protection roles; in addition, the thread jamming clamp is connected with the main beam by adopting a manner of butt-joining the two thread clamp bodies, the installation and regulation are convenient and fast, the rapid installation can be realized, and the design and installation and the follow-up maintenance cost can be reduced.

Owner:马斯特模具有限公司

Air conditioning with recovery wheel, dehumidification wheel, cooling coil, and secondary direct-expansion circuit

PendingUS20220228763A1Inhibition formationLess riskMechanical apparatusEfficient regulation technologiesCooling coilExhaust fumes

Systems and methods for controlling temperature and humidity within a space in a building. Outdoor air and return air from the space are passed through particular equipment in a particular order. Equipment includes a secondary direct-expansion refrigeration circuit, a recovery wheel, a primary cooling coil, secondary circuit evaporator and condenser coils, and a dehumidification wheel. Various embodiments include multiple zones, chilled beams, and a dedicated outdoor air supply (DOAS) subsystem delivering dehumidified air to active chilled beams. In various embodiments, supply air passes first through the recovery wheel, then through the primary cooling coil, then through the dehumidification wheel, and then to the space. Further, in some embodiments, exhaust air passes through the dehumidification wheel and then through the recovery wheel. Pump modules may supply chilled beams and control their temperature to avoid condensation. A chiller may supply cooling water to both the primary cooling coil and the pump modules.

Owner:SEMCO INC

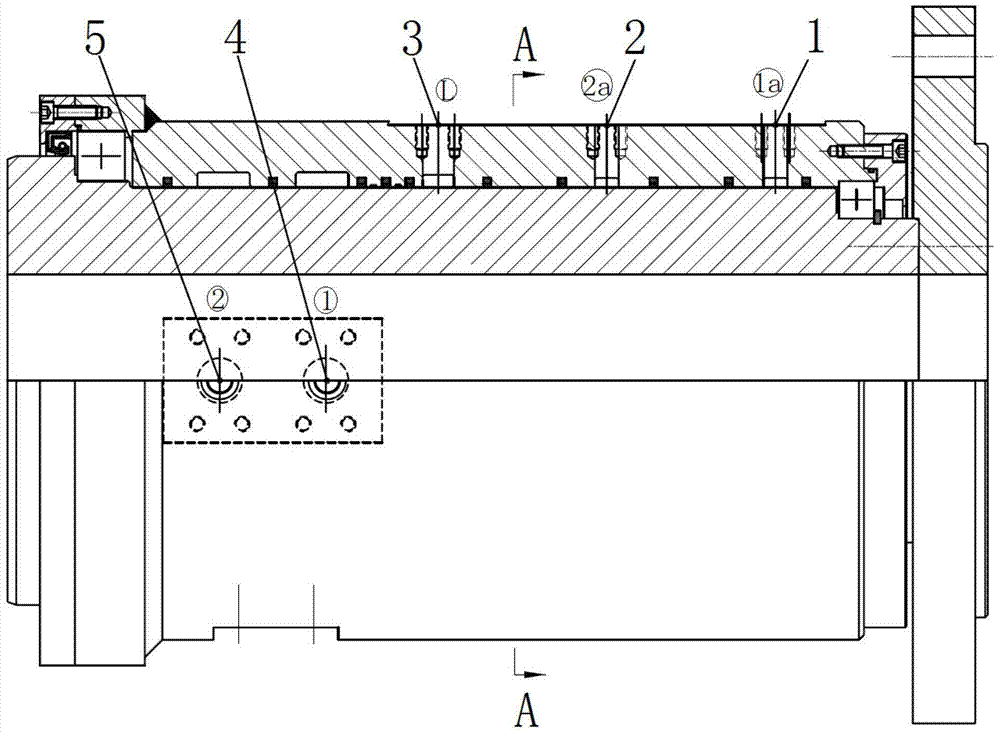

Seven-channel rotary joint device

ActiveCN105299356BSimple design and installationImprove use reliabilityAdjustable jointsWinding machineConductor Coil

The invention discloses a seven-channel rotating joint device. The seven-channel rotating joint device is installed on a main rotary table of a double-drum winding machine, the pipe wall of a rotating joint of the main rotary table is provided with an oil drain oil tube, a first winding drum lubricating oil pipe, a second winding drum lubricating oil pipe, a first winding drum expanding-collapsing oil inlet, a first winding drum expanding-collapsing oil outlet, a second winding drum expanding-collapsing oil inlet and a second winding drum expanding-collapsing oil outlet; an oil drain oil tube, a first winding drum lubricating oil pipe, a second winding drum lubricating oil pipe, a first winding drum expanding-collapsing oil inlet, a first winding drum expanding-collapsing oil outlet, a second winding drum expanding-collapsing oil inlet and a second winding drum expanding-collapsing oil outlet are correspondingly arranged in an inner cavity of a tube collecting shaft. The seven-channel rotating joint device is simple in structure, convenient to install and maintain and reliable in work.

Owner:MCC SFRE HEAVY IND EQUIP

Permanent magnet door lock cooperation device for power distribution cabinet of machining center

InactiveCN104466705AMitigate mechanical shock effectsSimple design and installationSubstation/switching arrangement casingsAnti-seismic devicesMagnetEngineering

The invention relates to a permanent magnet door lock cooperation device for a power distribution cabinet of a machining center. The device comprises a power distribution cabinet body, a power distribution cabinet door, a safety protection lock, and a machining center outer protection. The power distribution cabinet door comprises a power distribution cabinet right door frame and a power distribution cabinet left door frame. The power distribution cabinet left door frame is provided with two hinges. The hinges are fixed with the power distribution cabinet body. The middle position of the power distribution cabinet right door frame is provided with the safety protection lock. The upper end and the lower end of the power distribution cabinet right door frame are respectively provided with permanent magnetic shockproof devices. The device is provided with a spring tongue piece, designed for damping on structure. The pressure and vibration at the moment the permanent magnets adhere and disconnect are effectively buffered, so the device greatly protects internal circuits and components of the power distribution cabinet.

Owner:QINGDAO HOSEN HEAVY IND

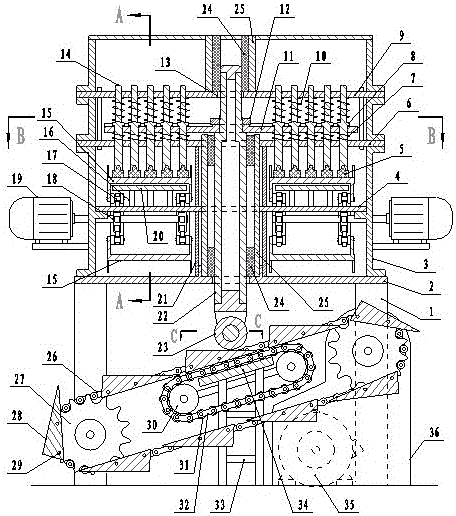

ore crusher

An ore pulverizer is composed of a frame, a hammering mechanism, feeding mechanisms, an up-lifting mechanism, and a hopper. The hammering mechanism is composed of a middle shaft, a hammer, an upper fixing plate, a lifting disc, a lifting disc fixing nut, and a lower fixing plate. Two feeding mechanisms are symmetrically arranged on the two sides of the middle shaft. Each feeding mechanism is composed of a feeding motor, a chain wheel, a feeding plate chain, a feeding plate, a cushion plate, a vertically-supporting plate, and a horizontally-supporting plate. The up-lifting mechanism is composed of a transmission device and a lifting device, the transmission device is composed of a main motor and a gearbox, and the lifting device is arranged on the middle part of the lower support of the bottom plate and is composed of a big chain wheel, a support plate chain, a support plate, a supporting plate, a support rack, a fixed chain wheel, a roller, and a roller chain. The ore pulverizer has the advantages of high efficiency, prominent electric energy saving effect, high ore pulverizing efficiency, large ore output, and convenience for installation and maintenance.

Owner:周建祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com