A composite joint of steel and concrete strengthened by angle steel

A technology of combining joints and reinforced concrete slabs, applied in the directions of building maintenance, construction, building construction, etc., can solve the problems of flexural bearing capacity and flexural rigidity changes, improve the tensile connection capacity, good economic benefits, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

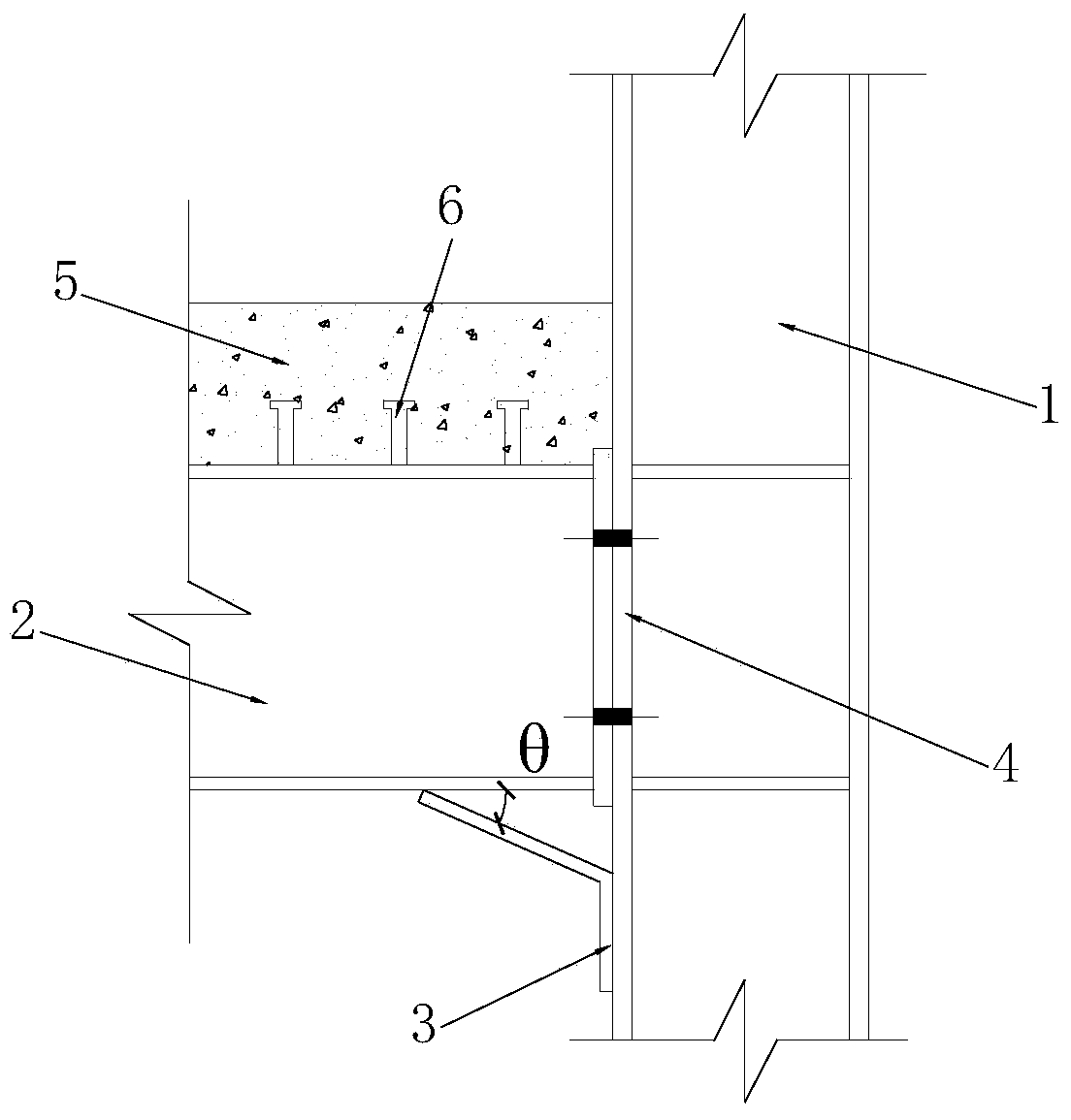

[0010] Specific implementation mode one: combine figure 1 Describe this embodiment, the device of this embodiment comprises steel column 1, steel beam 2, angle steel 3, end plate 4, reinforced concrete plate 5 and shear connection key 6, the vertical section of angle steel 3 and the flange of steel column 1 Connection, the angle steel 3 is located below the joint between the steel beam 2 and the steel column 1 and the free end of the inclined section of the angle steel 3 is against the position of the lower flange of the steel beam 2 and connected with the lower flange of the steel beam 2, the reinforced concrete slab 5 are connected through the shear connection key 6 provided on the steel beam 2, and the shear connection key 6 and the steel beam 2 are connected by welding.

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the angle θ between the vertical section and the inclined section of the angle steel 3 is 30°-60°, which has good deformation ability and avoids the angle steel participating in the stress during the use stage. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

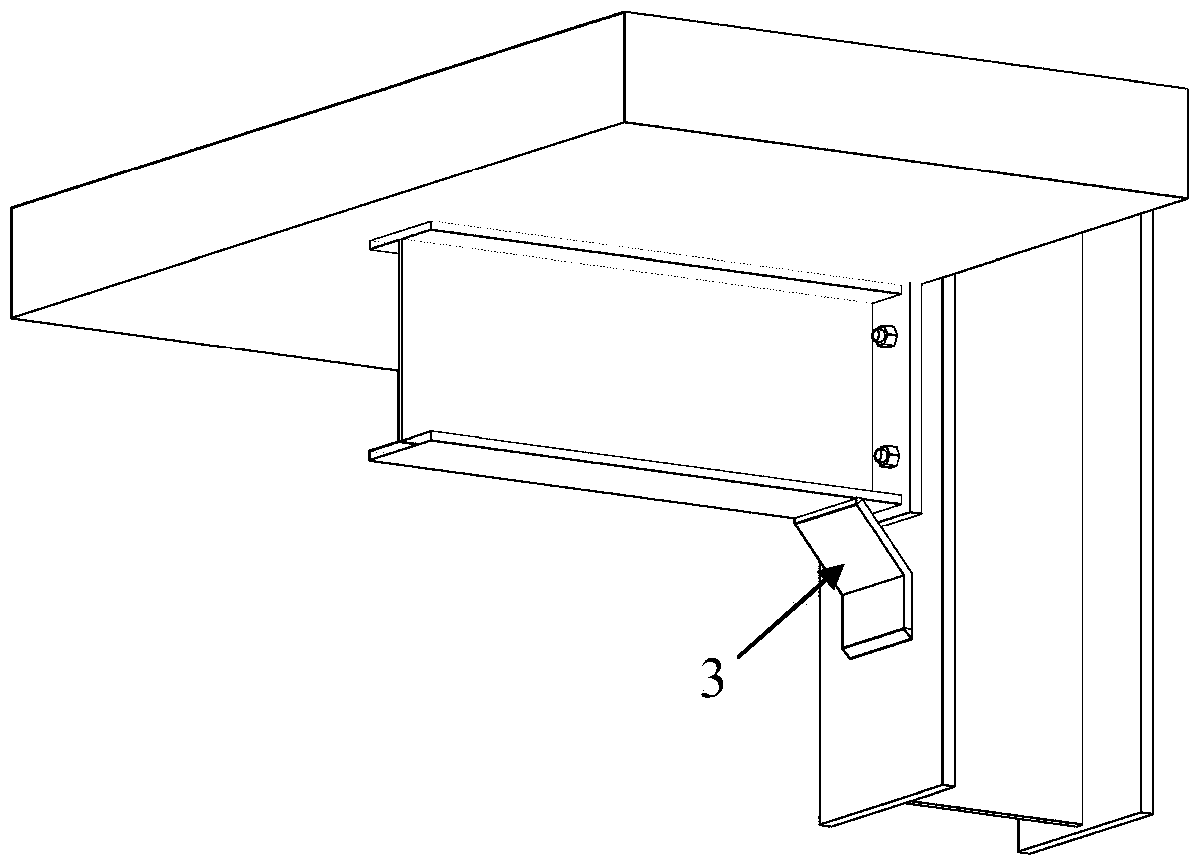

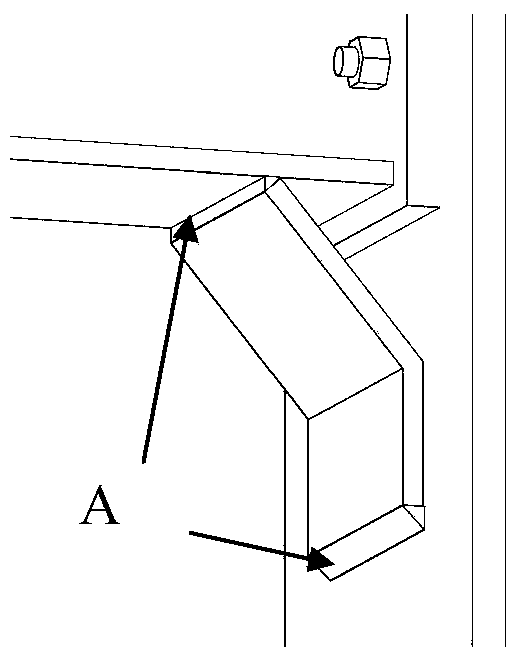

[0012] Specific implementation mode three: combination figure 2 and image 3 Describe this embodiment, the lower end of the vertical section of the angle steel 3 in this embodiment is welded to the flange of the steel column 1, the inclined section of the angle steel 3 is welded to the contact part of the lower flange of the steel beam 2, and the weld seam is at image 3 is displayed as A. The welding connection method is simple and convenient, easy to operate on site, and is suitable for the reinforcement of existing buildings. Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com