Smoke pipe lengthening section preventing cold wind from flowing backward and containing air filtration for wall hanging stove

An air filtration and anti-cold wind technology, which is applied in the direction of dispersed particle filtration, fluid heaters, exhaust gas devices, etc., can solve the problems of many impurities, increased after-sales maintenance costs, poor air quality, etc., and achieve simple and easy replacement of the internal filter device Cold air backflow, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution will be described in detail below in conjunction with specific embodiments.

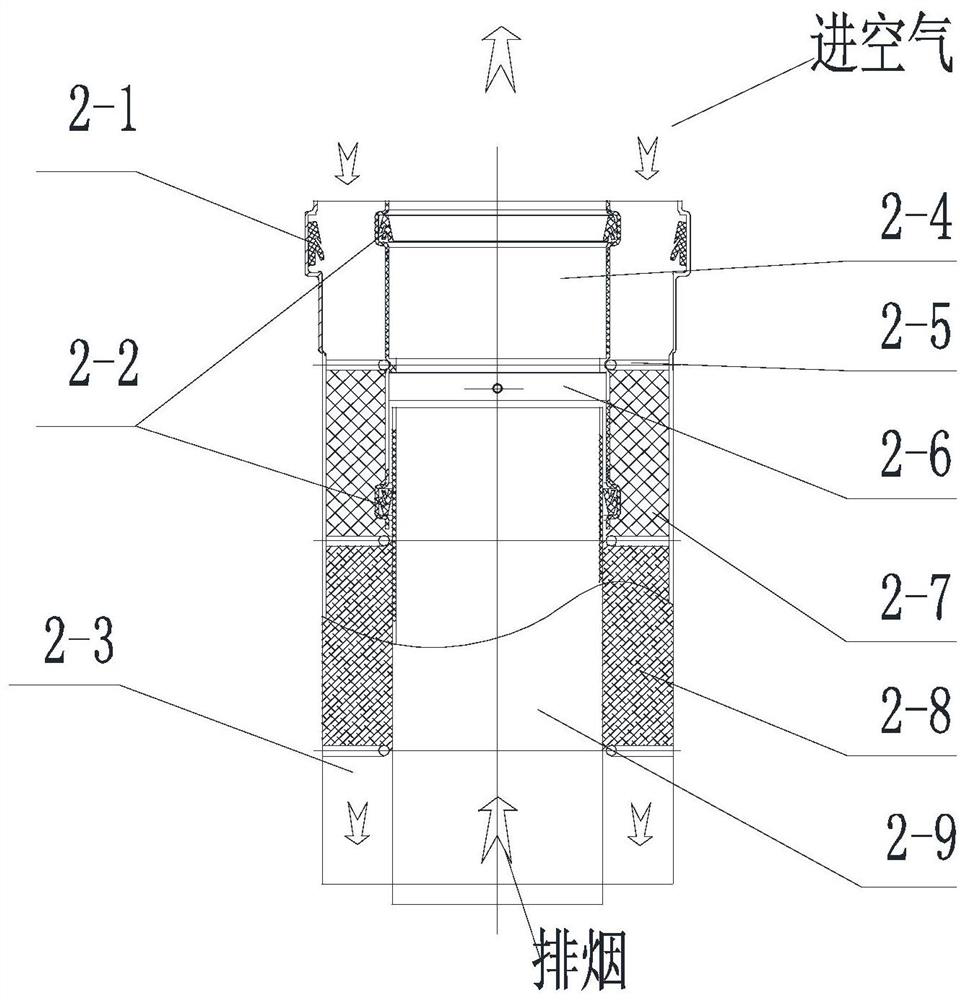

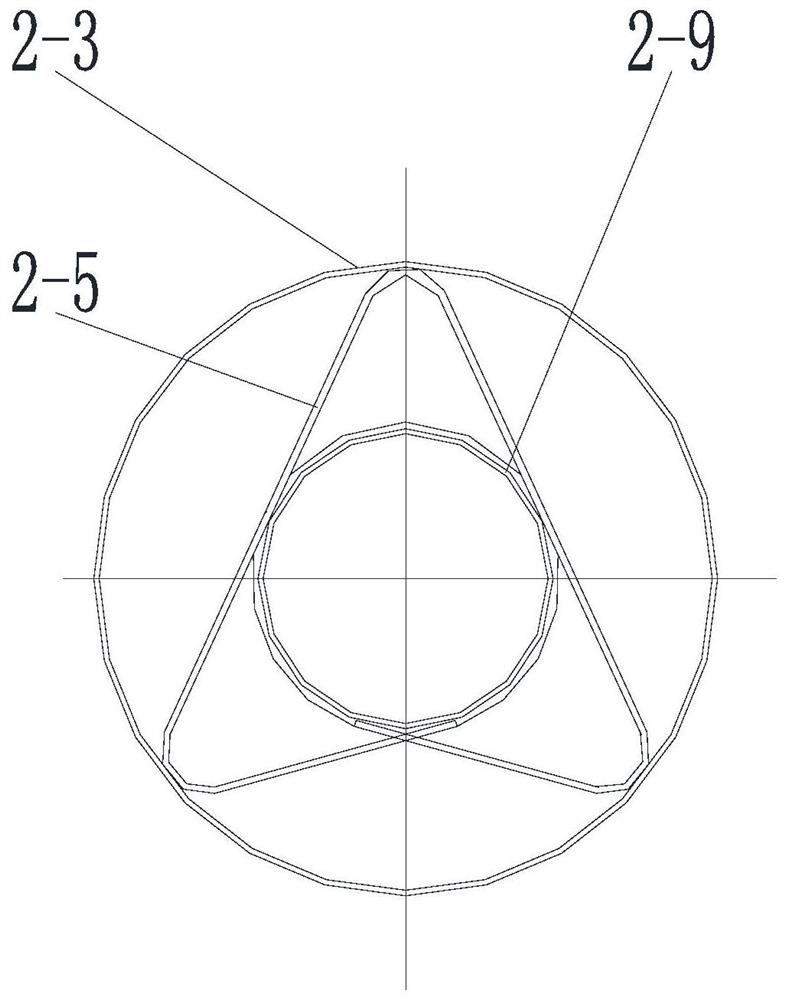

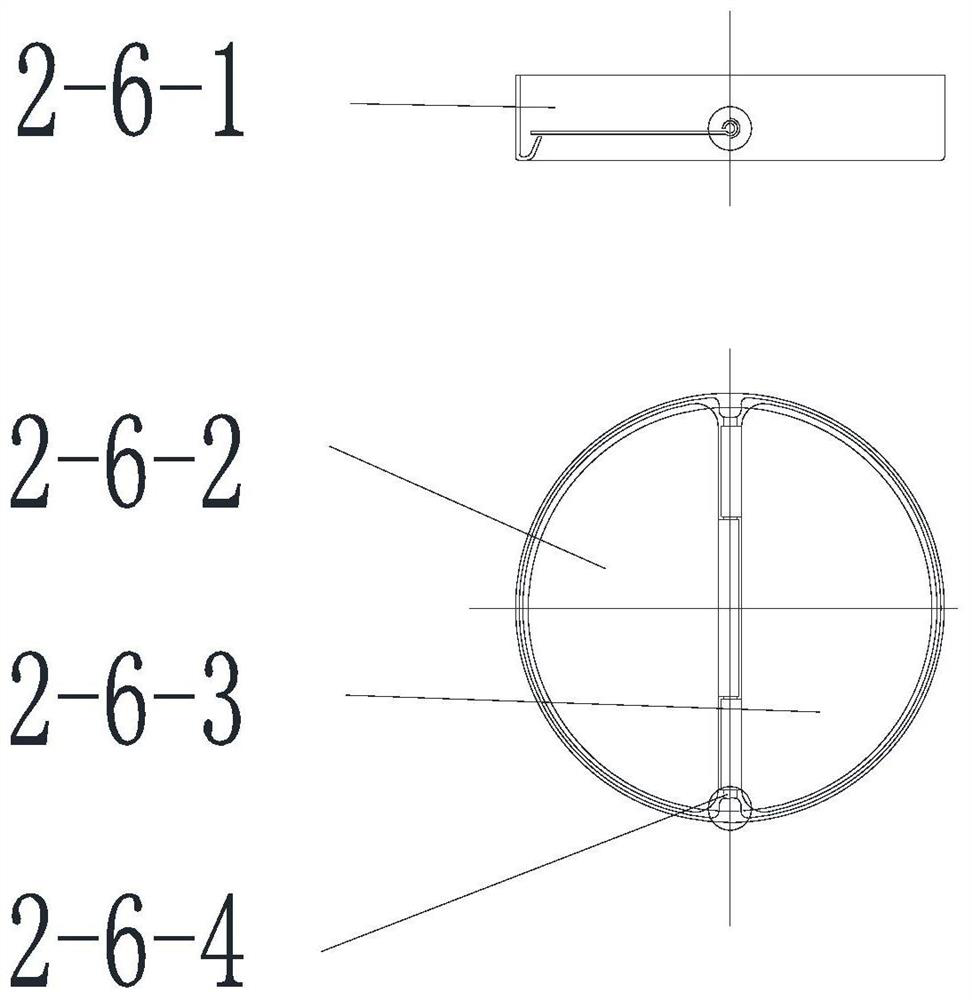

[0020] Such as Figure 1-Figure 4 As shown, the present invention is a chimney extension joint for a wall-hung furnace with anti-cold wind backflow and air filtration, which includes straight pipes 2-3 outside the chimney pipe, straight pipe assemblies inside the chimney pipe, and a windproof pipe assembly inside the straight pipe assembly. Ring 2-6, a support frame 2-5 for supporting the inner straight pipe of the smoke pipe is arranged between the outer straight pipe of the smoke pipe and the inner straight pipe assembly of the smoke pipe, and a filter device is installed between the outer straight pipe of the smoke pipe and the inner straight pipe assembly of the smoke pipe. The inner straight pipe assembly of the smoke pipe includes the inner straight pipe 2-9 and the inner pipe direct head 2-4. For the airtightness of the installation of the smoke pipe, correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com