Seven-channel rotary joint device

A technology of rotary joints and passages, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc. It can solve the problems of short working life of the device, inconvenient maintenance, and many additional equipment, so as to save electricity. Brush slip ring device, easy installation and maintenance, and simplified design and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

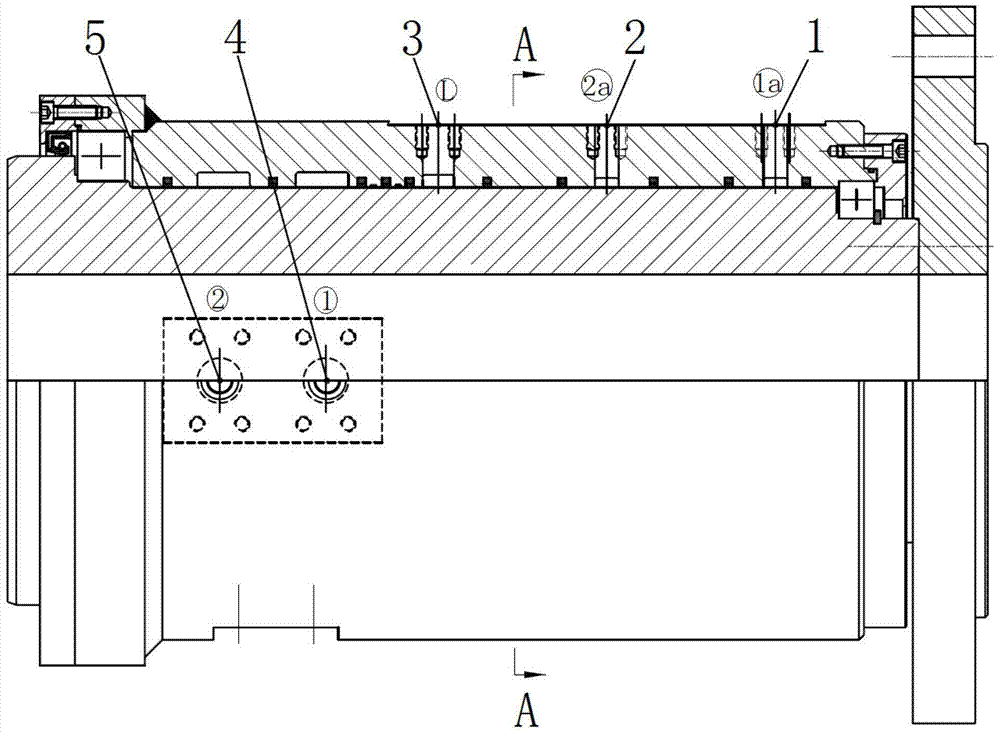

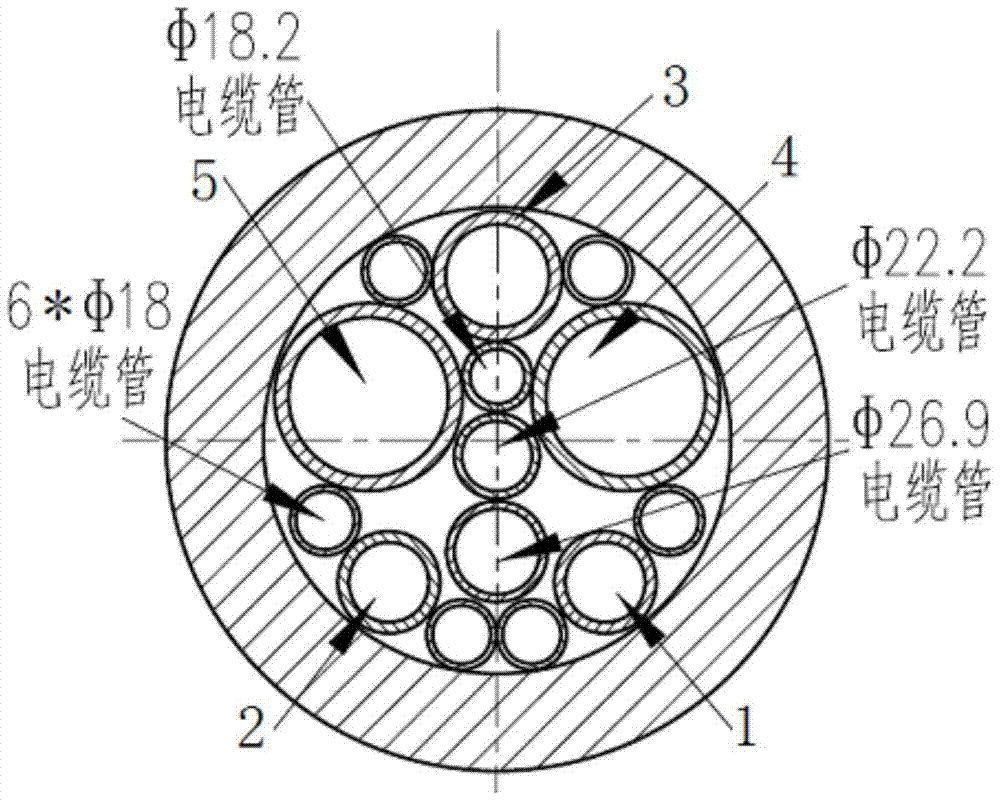

[0018] refer to figure 1 , figure 2 , the structure of the existing main turntable rotary joint device is: on the pipe wall of the main turntable rotary joint, there are respectively provided with No. 1 reel expansion and contraction oil inlet and outlet 1, No. Lubricating oil pipe 4 for No. 2 reel, lubricating oil pipe 5 for No. 2 reel; No. Reel lubricating oil pipe 4, No. 2 reel lubricating oil pipe 5, six Φ18 cable pipes, one Φ18.2 cable pipe, one Φ22.2 cable pipe and one Φ26.9 cable pipe. The hydraulic oil enters the main turntable through the expansion and contraction oil port 1 of the No. In the electromagnetic reversing valve 13 corresponding to No. 2 reel, respectively control No. 1 and No. 2 reel expansion and contraction cylinders 12 .

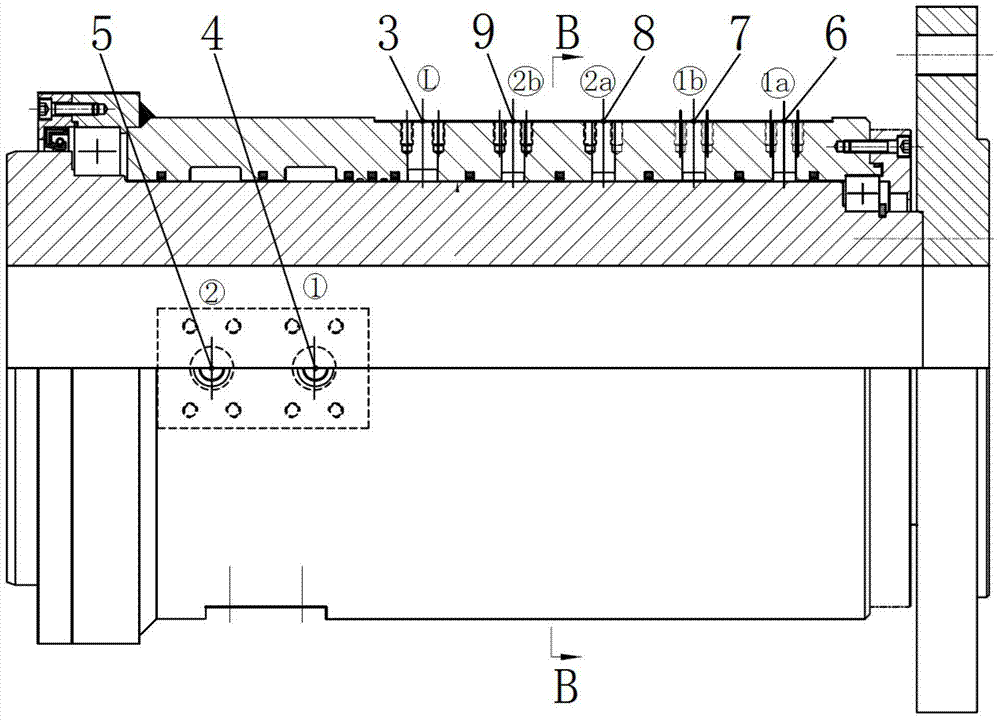

[0019] Such as Figure 5 , Figure 6 , Figure 5 The upper right corner of the center is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com