Strengthening method for resisting progressive collapse through steel frame structure

A technology of steel frame and design method, applied in the direction of building construction, building maintenance, construction, etc., can solve the problems such as the failure of the steel frame structure to form the "compression arch effect, the structural deformation control of the initial damage of the structural column damage, etc., to achieve simple installation, Cost reduction and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with accompanying drawing.

[0022] A method for reinforcing a steel frame structure against progressive collapse, characterized in that it comprises the following steps:

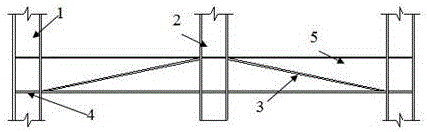

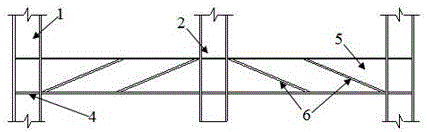

[0023] For new buildings, first determine the position of the key column through the anti-progressive collapse design method in the code. After the key column is selected, it is assumed to be a damaged steel column, and a single diagonal rib or rib is added to the beam steel on both sides of the damaged steel column Double diagonal ribs enhance the compression arch effect at the key column position and improve the redundancy and progressive collapse resistance of new buildings;

[0024] For existing buildings, after knowing the weak column or the column with failure phenomenon through investigation and observation, it is assumed to be a damaged steel column, and depending on the layout of the building components and the construction site...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com