Draining system for brown-sugar continuous boiling tank

A sugar-boiling, water-repellent technology, applied in the boiling/evaporation of sugar solution, sucrose production, sugar production, etc., can solve the problems of low utilization rate of hot water, waste of hot water, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

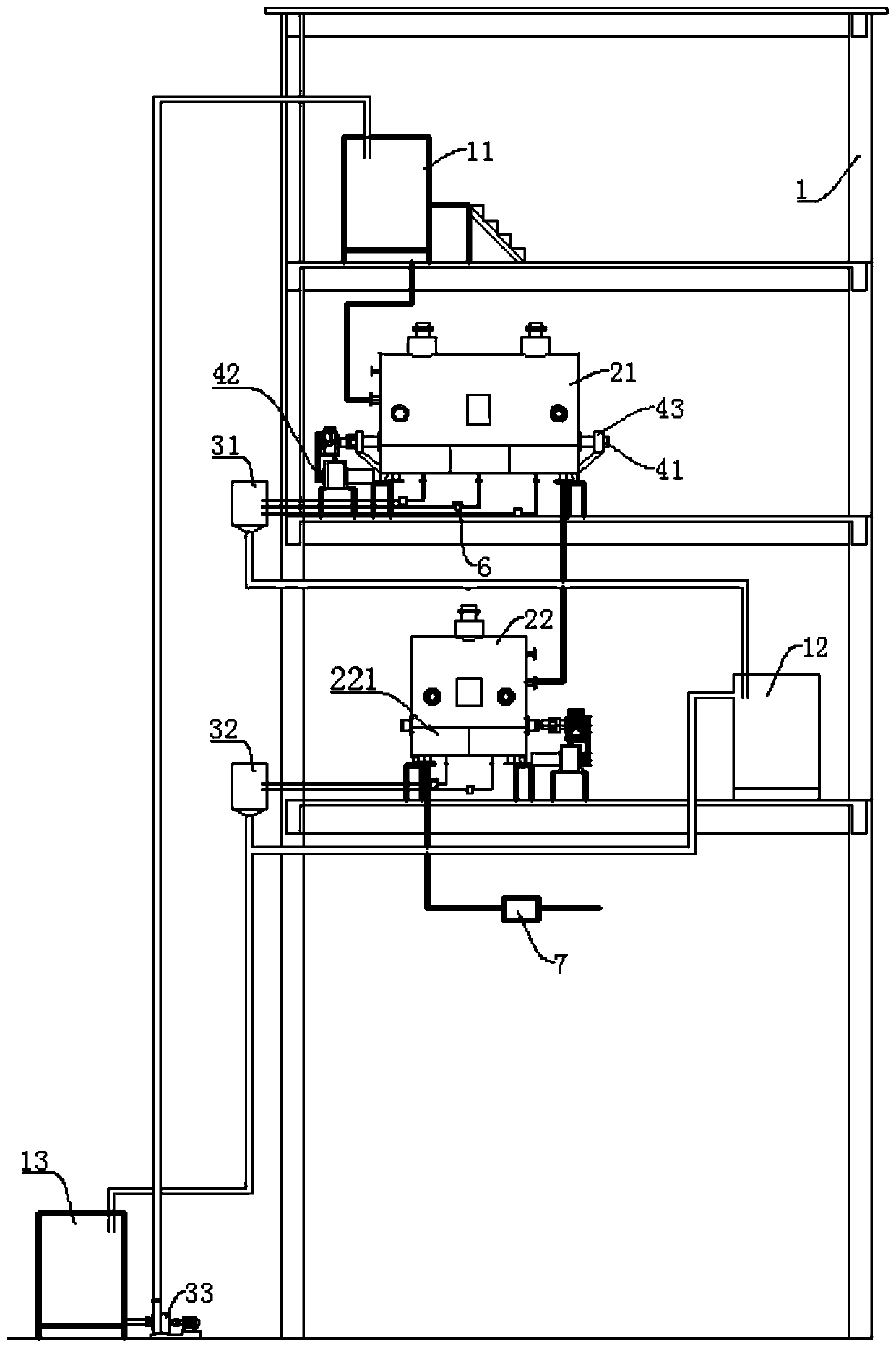

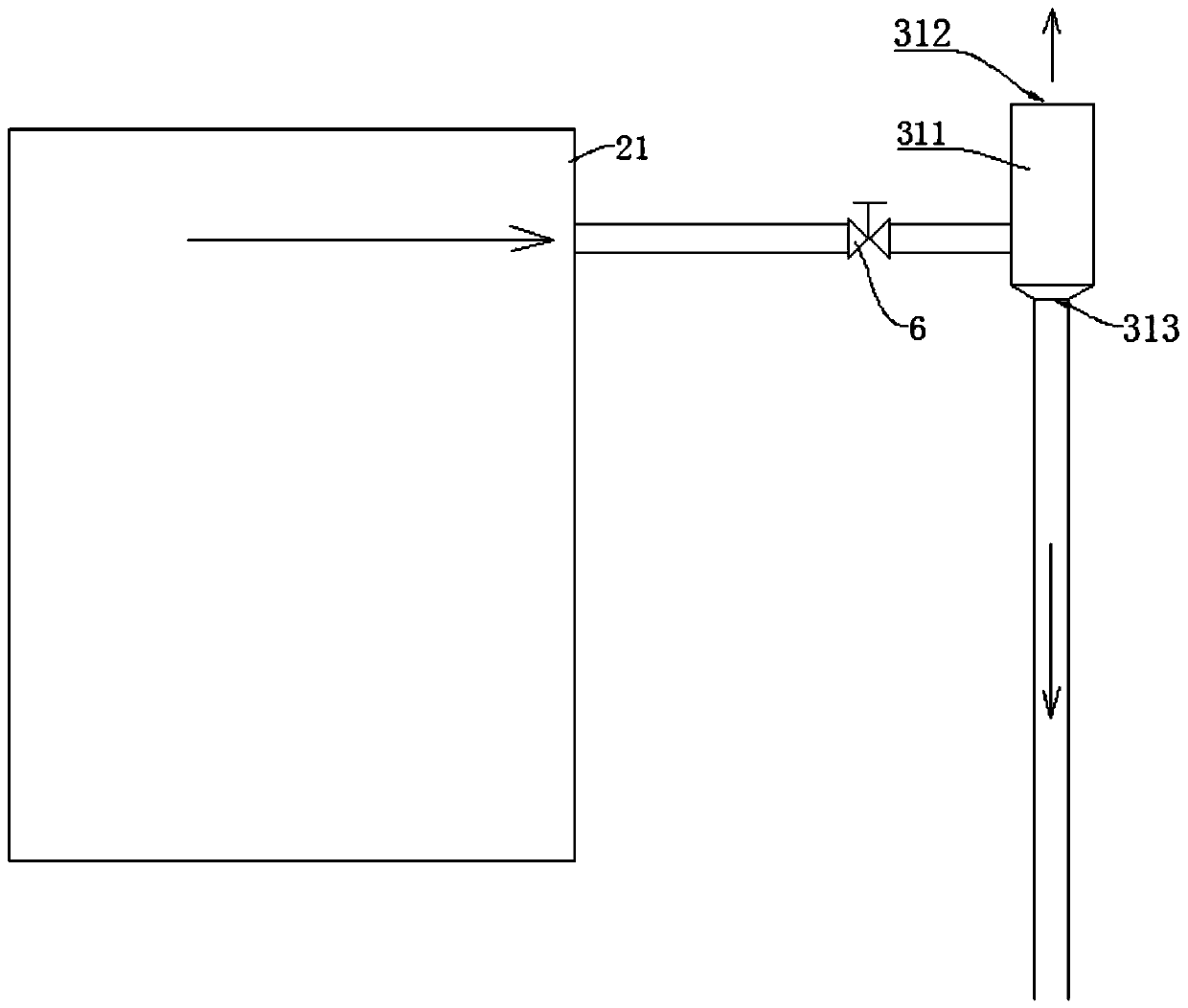

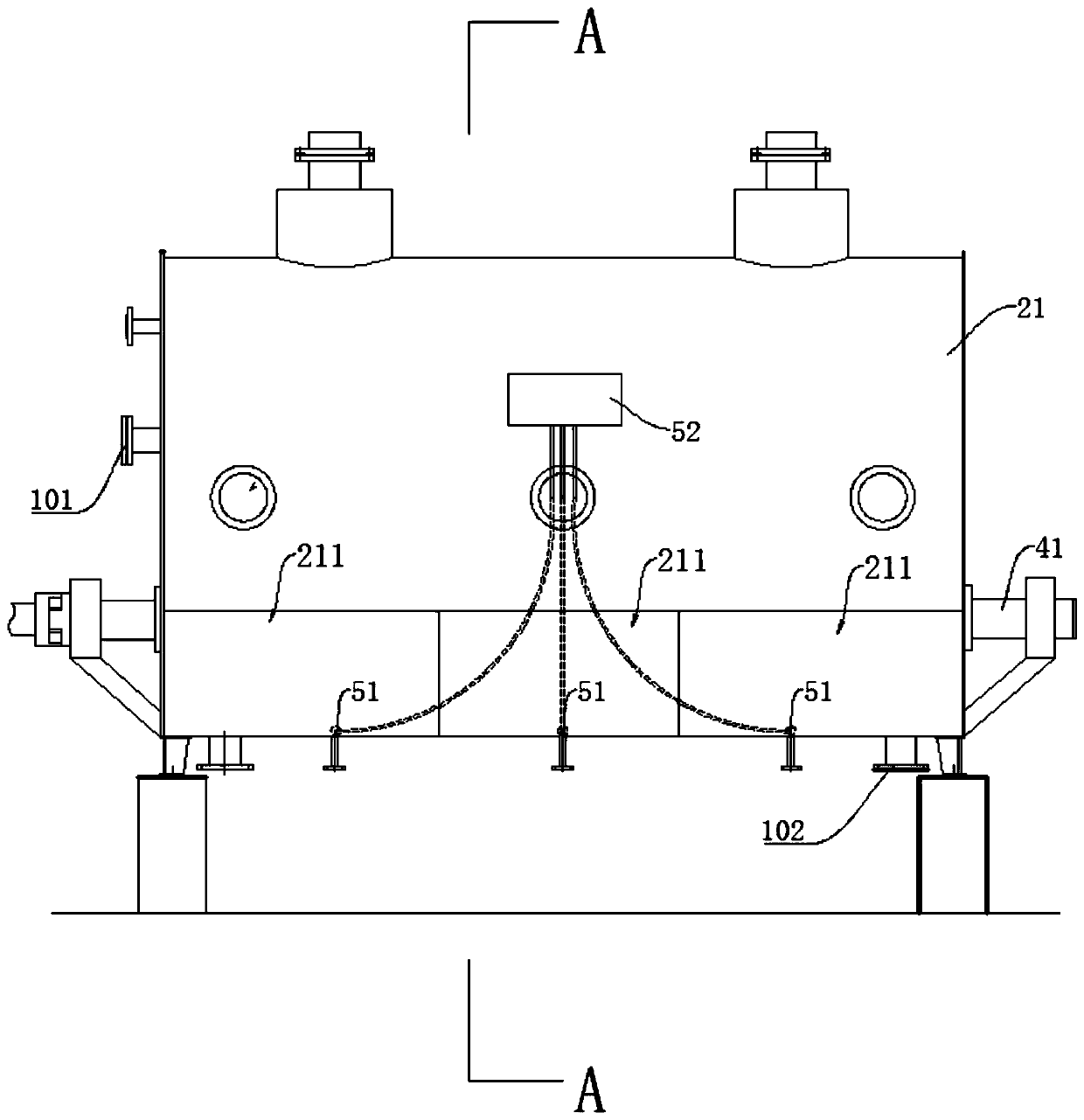

[0024] Such as figure 1 and figure 2As shown, a brown sugar continuous boiling sugar tank drainage system includes a base frame 1, an upper water tank 11, a sugar boiling tank, a heating device and a water circulation device, and the upper water tank 11 is fixedly installed on the top of the base frame 1 . The sugar cooking tank includes a first-effect sugar cooking tank 21 and a second-effect sugar cooking tank 22. The first-effect sugar cooking tank 21 is installed on the base frame 1 and is located below the upper water tank 11. The bottom of the first-effect sugar cooking tank 21 is provided with a first steam chamber. 211. The first steam chamber 211 is provided with a first steam inlet and a first steam outlet. The two-effect sugar cooking tank 22 is installed on the base frame 1 and is located below the first-effect sugar cooking tank 21. The bottom of the second-effect sugar cooking tank 22 is provided with a second steam chamber 221, and the second steam chamber 221...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com