Jet refrigeration and active cooling beam combined applying system

A combined application and active technology, applied in applications, air conditioning systems, household heating, etc., can solve the problems of low energy efficiency of injection refrigeration, and achieve the effect of simple structure, low energy consumption, and simplified structure of air conditioning system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

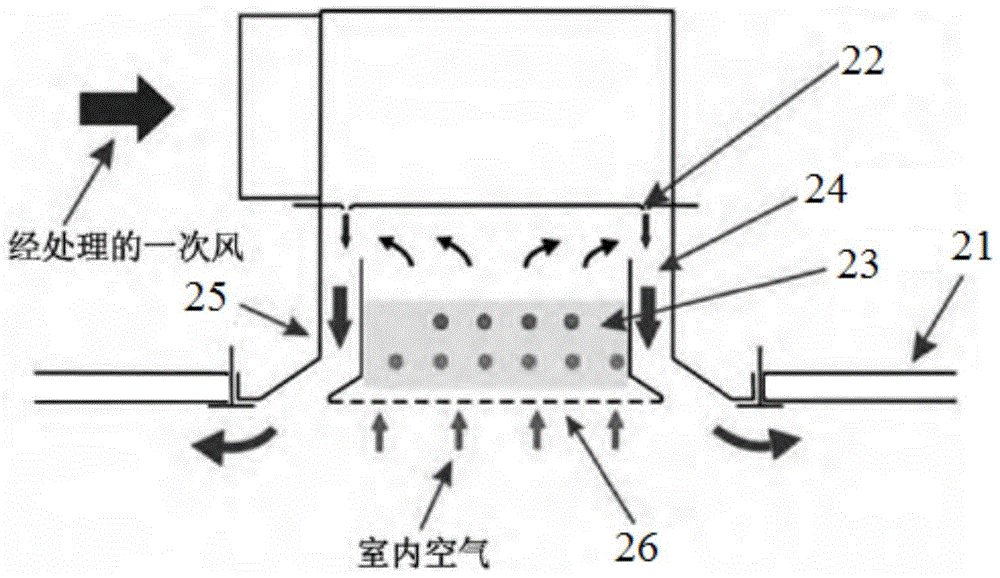

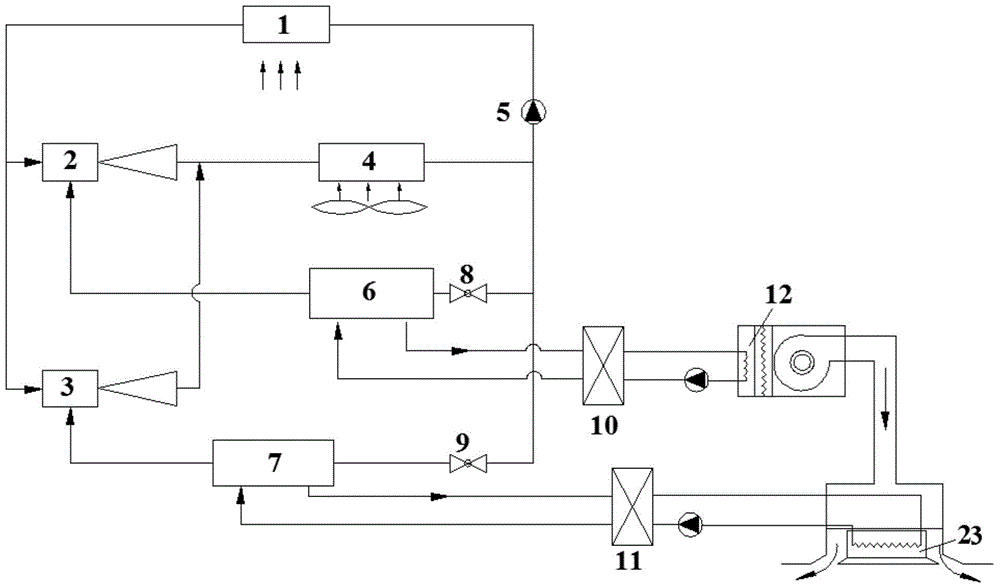

[0028] like figure 1 As shown, the end of the active chilled beam includes the end of the wind side of the chilled beam and the end of the water side of the chilled beam. After the treated primary air is sent to the active chilled beam, it is sprayed at high speed through the nozzle 22, and the high-speed airflow generates negative pressure in the mixing chamber 24, thereby inducing the indoor low-speed indoor air to pass through the orifice plate 26 and pass through the water side end of the chilled beam. The heat exchange coil 23 is cooled and mixed with the primary air belonging to the end of the wind side of the chilled beam, then forms an attached jet through two closed diversion grooves 25, and attaches and supplies air to the room along the suspended ceiling. The refrigerant temperature (16°C / 19°C) of the active chilled beam air-conditioning system is higher than that of the traditional air-conditioning system (7°C / 12°C).

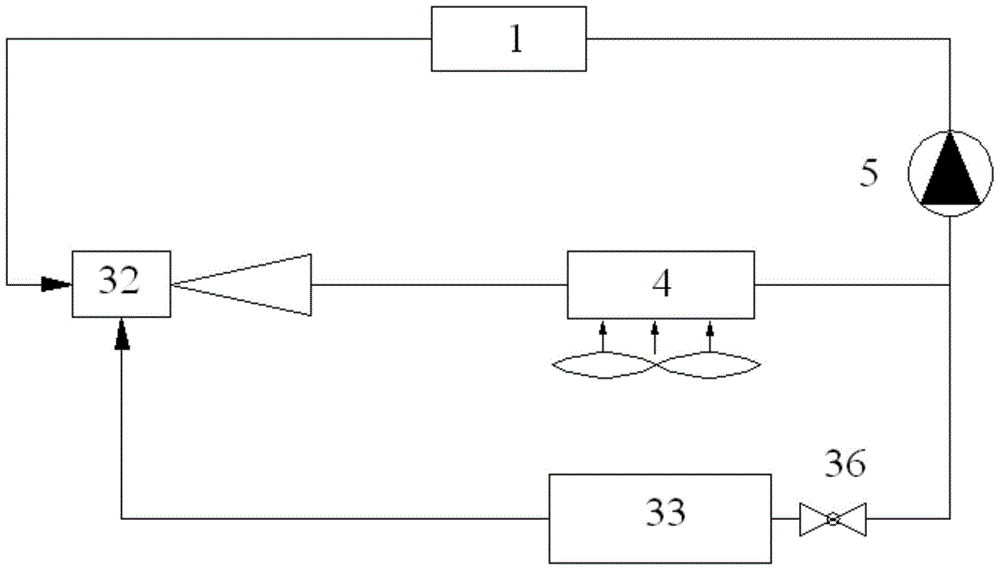

[0029] like figure 2 As shown, the traditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com