Solution spray type heat pump set

A technology of heat pump unit and solution pump, which is applied in the direction of heating and cooling combination, refrigerator, compressor, etc., which can solve the problems of freezing of circulating water, inability to realize heating, and low energy efficiency of cooling, so as to reduce metal materials and avoid removal Frost problem, the effect of large heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

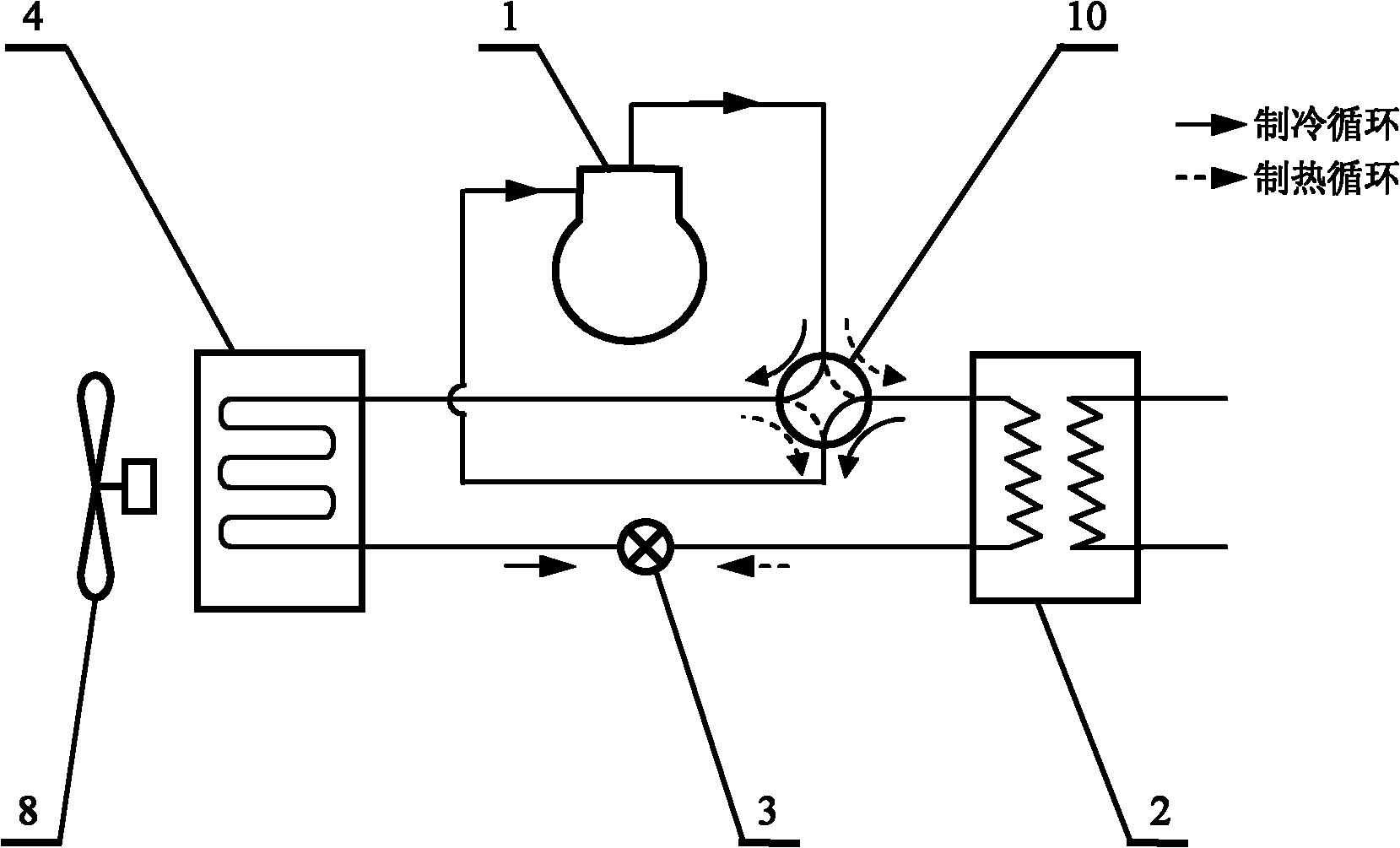

[0033] Figure 4 It is the structural principle diagram of the first embodiment of the solution spray type air conditioner heat pump unit provided by the present invention. In this embodiment, the recooling and heat of the high-pressure liquid refrigerant is used as the regeneration heat source of the solution, and it includes a compressor 1, a first heat exchanger Device 2, throttling device 3, second heat exchanger 4, solution collecting pan 5 located at the lower part of the second heat exchanger, first solution pump 6a, heat exchanger sprayer 7, fan 8 and heat exchanger shell 9. An air inlet is provided at the middle and lower part of the heat exchanger shell 9, and the outdoor air flows through the second heat exchanger 4 and flows out of the heat exchanger shell 9 under the action of the fan 8. It is characterized in that: the solution spray type heat pump unit is also It includes a four-way valve 10 and a solution-refrigerant heat exchanger 11; the solution-refrigerant ...

Embodiment 2

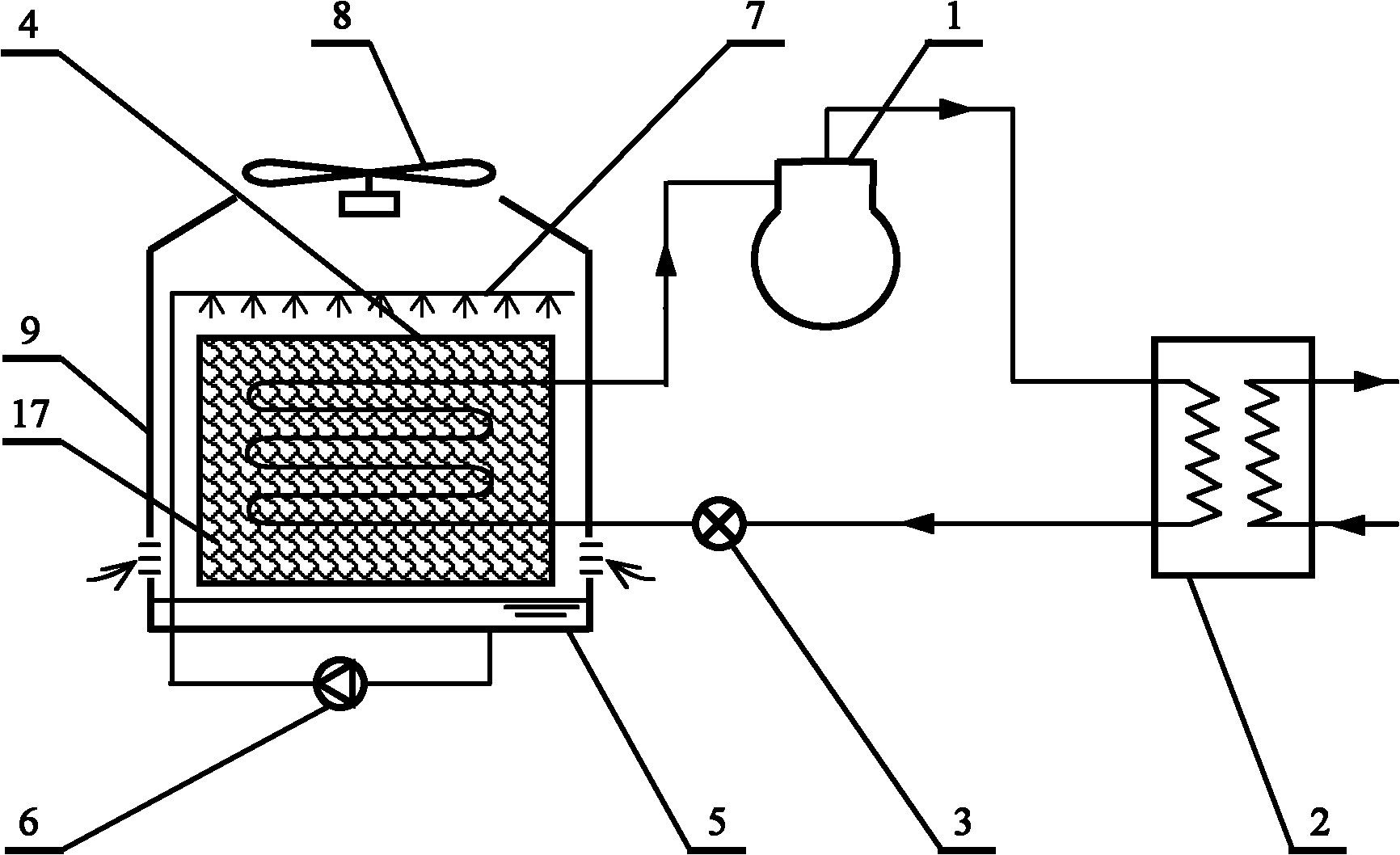

[0038] Figure 5 It is the structural principle diagram of the second embodiment of the solution spray type air-conditioning heat pump unit provided by the present invention. This embodiment uses the recooling and heat of the high-pressure liquid refrigerant as the regeneration heat source of the solution. Compared with the first embodiment, the difference lies in: On the vapor compression heat pump circuit, a communication pipe is added between the outlet of the refrigerant side of the first heat exchanger 2 and the inlet of the throttling device 3, and the first valve 12 is arranged on the communication pipe; at the same time, the solution- A second valve 13 is set on the refrigerant side inlet pipeline of the refrigerant heat exchanger 11; a solution regenerator 16 is set above the second heat exchanger 4 inside the heat exchanger shell 9, and a porous filler 17 is set in the solution regenerator 16 The heat exchanger shower 7 is made up of the first regenerator-heat exchan...

Embodiment 3

[0044] Figure 6 It is the structural principle diagram of the third embodiment of the solution spray type air conditioner heat pump unit provided by the present invention. In this embodiment, the recooling and heat of the high-pressure liquid refrigerant is used as the regeneration heat source of the solution, and it includes a compressor 1, a first heat exchanger Device 2, throttling device 3, second heat exchanger 4, solution collecting pan 5 located at the lower part of the second heat exchanger, first solution pump 6a, heat exchanger sprayer 7, fan 8 and heat exchanger shell 9. An air inlet is provided at the middle and lower part of the heat exchanger shell 9, and the outdoor air flows through the second heat exchanger 4 and flows out of the heat exchanger shell 9 under the action of the fan 8. It is characterized in that: the solution spray type heat pump unit is also Including a four-way valve 10 and a solution-refrigerant heat exchanger 11, the solution-refrigerant he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com