Prefabricated air feeding cooling beam and production method thereof

A chilled beam and air supply technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of affecting the operation effect of air conditioning systems, increasing construction complexity, increasing building energy consumption, etc., achieving simple design, shortening construction period, and maintenance low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

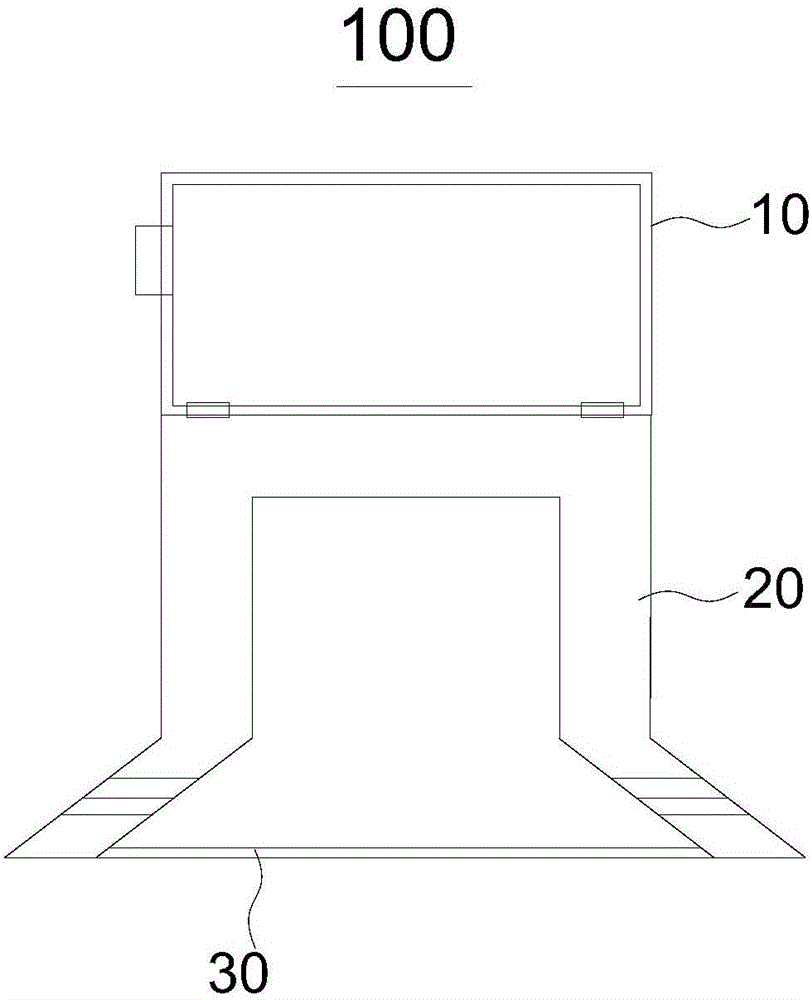

[0037] Please refer to figure 1 As shown, Embodiment 1 of the present invention provides a prefabricated air supply chilled beam 100 , including a chilled beam main body 10 , an air supply element 20 and an air return element 30 . The chilled beam main body 10 , the air supply element 20 and the air return element 30 communicate with each other to form a channel for air circulation.

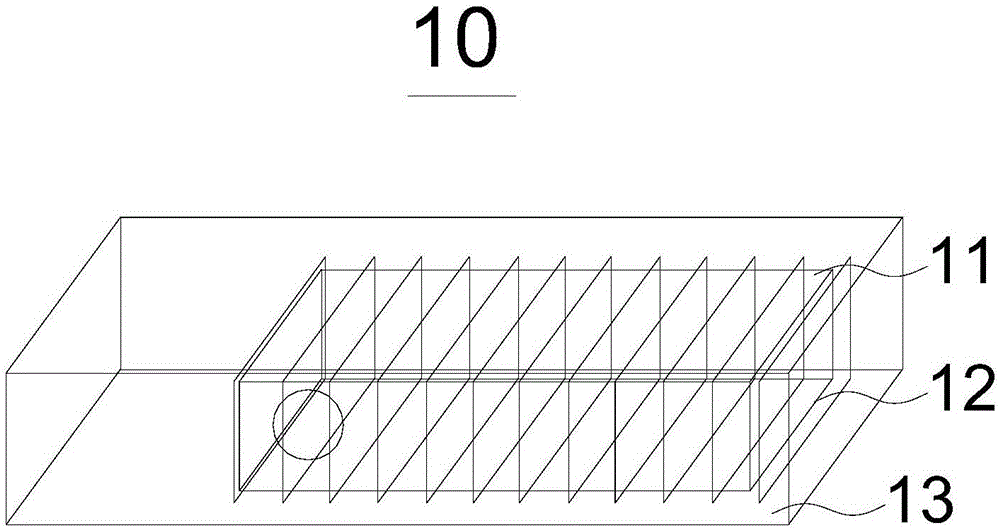

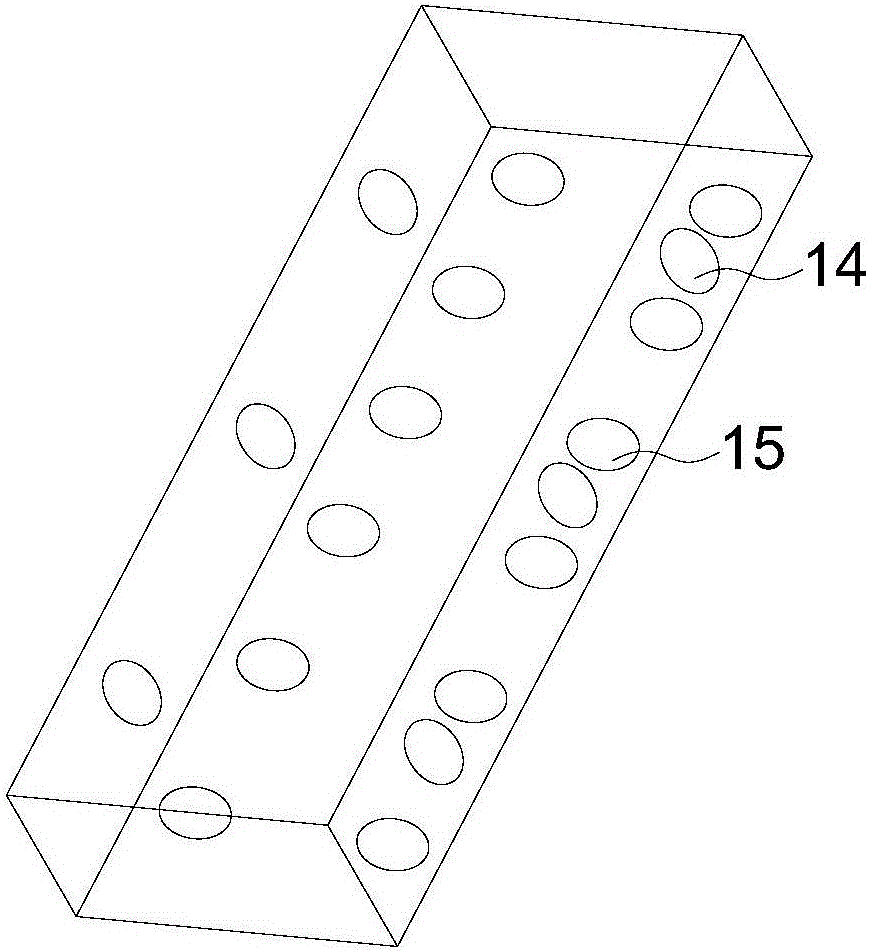

[0038] Please refer to figure 2 As shown, the chilled beam main body 10 is a hollow box girder, and its shape is rectangular, and it can also be other shapes, mainly to meet the design specification requirements of the construction industry, and the standardized rectangle is also for the convenience of production, construction and installation. .

[0039] It should be noted that when designing the prefabricated air-supply chilled beam 100, the primary consideration is the load-bearing capacity, and the design of the air duct 11 needs to be carried out on the basis of meeting the load-bearing c...

Embodiment 2

[0061] Embodiment 2 of the present invention also provides a kind of production method of prefabricated air supply chilled beam 100, comprises the following steps:

[0062] Structural design of the prefabricated air supply chilled beam 100: design the prefabricated air supply chilled beam 100 according to the characteristics of the construction site and specification requirements; usually, the design is based on the building structure, and the arrangement of the chilled beams is carried out according to actual needs The cloth has been designed for the air inlet and outlet parts.

[0063] Binding of steel bars 12: according to the design drawings, at first carry out the binding of the steel bars 12 of the prefabricated air supply chilled beam 100, and form a reinforcement cage;

[0064] Installation of air duct 11: Bundle the air duct 11 in sections in the steel cage, each segmented air duct 11 is hot-melt welded, and the binding points are evenly arranged; the solder joints be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com