Patents

Literature

40results about How to "Save insulation material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

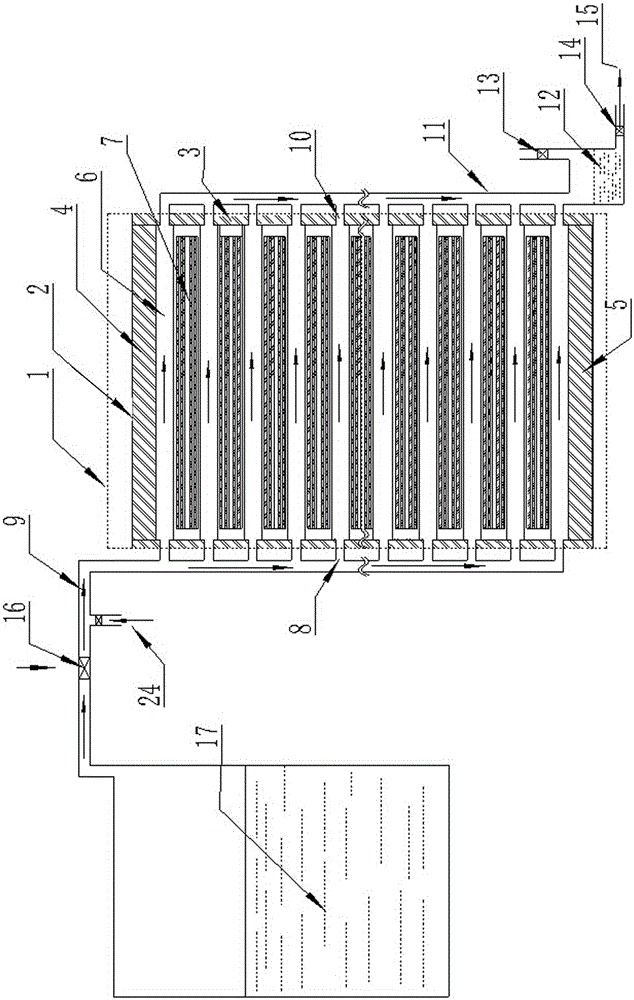

Multiple shell passes shell-and-tube helica-baffle heat exchangers

ActiveCN1821700ACompact structureExtended service lifeHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

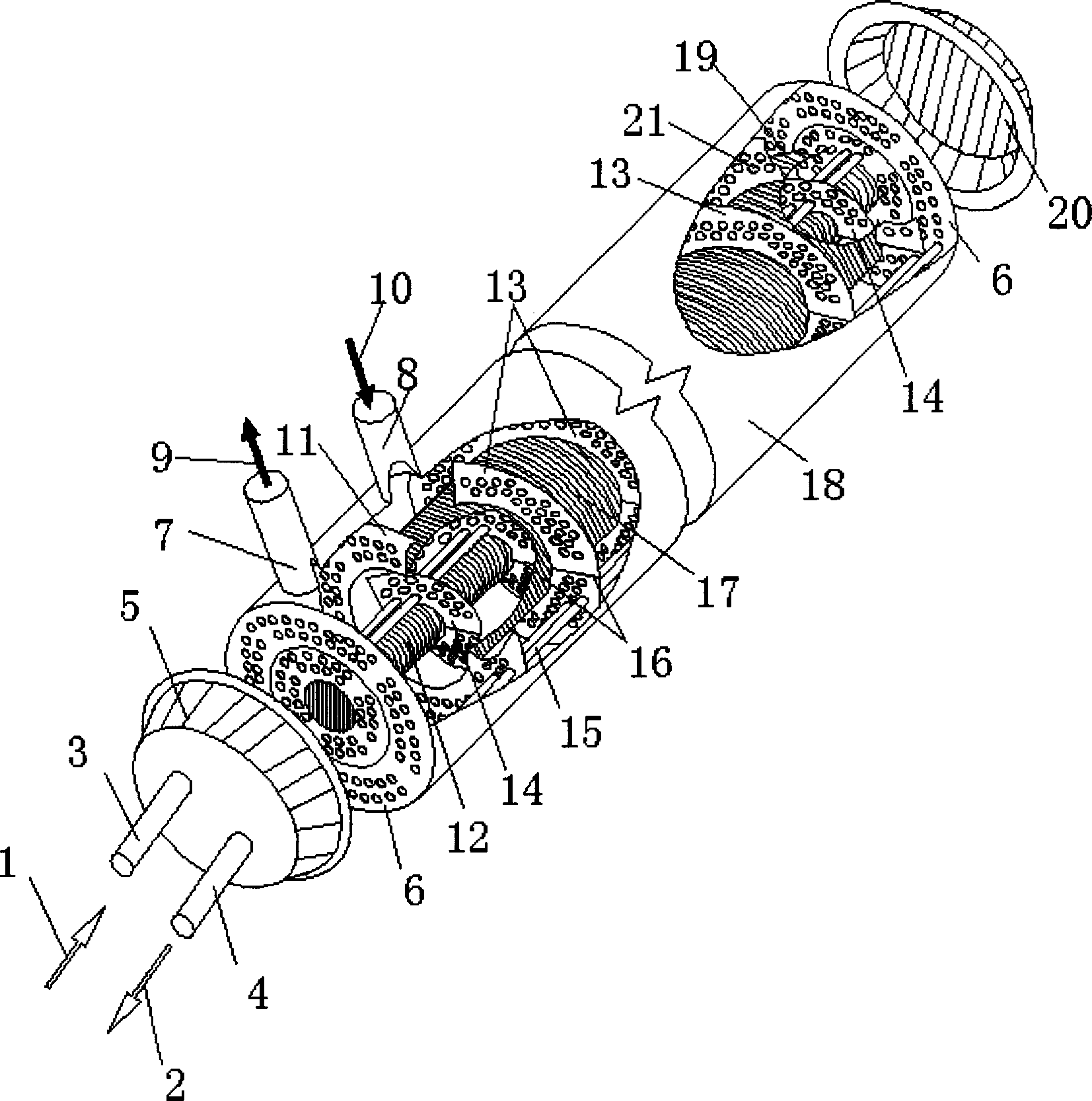

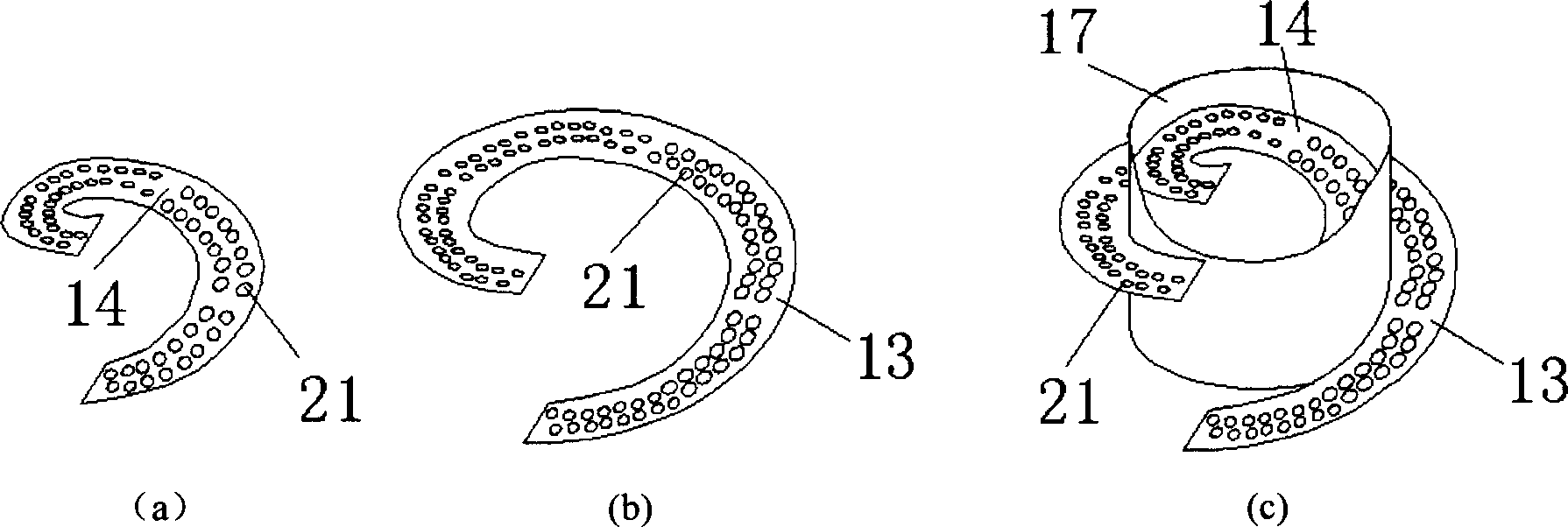

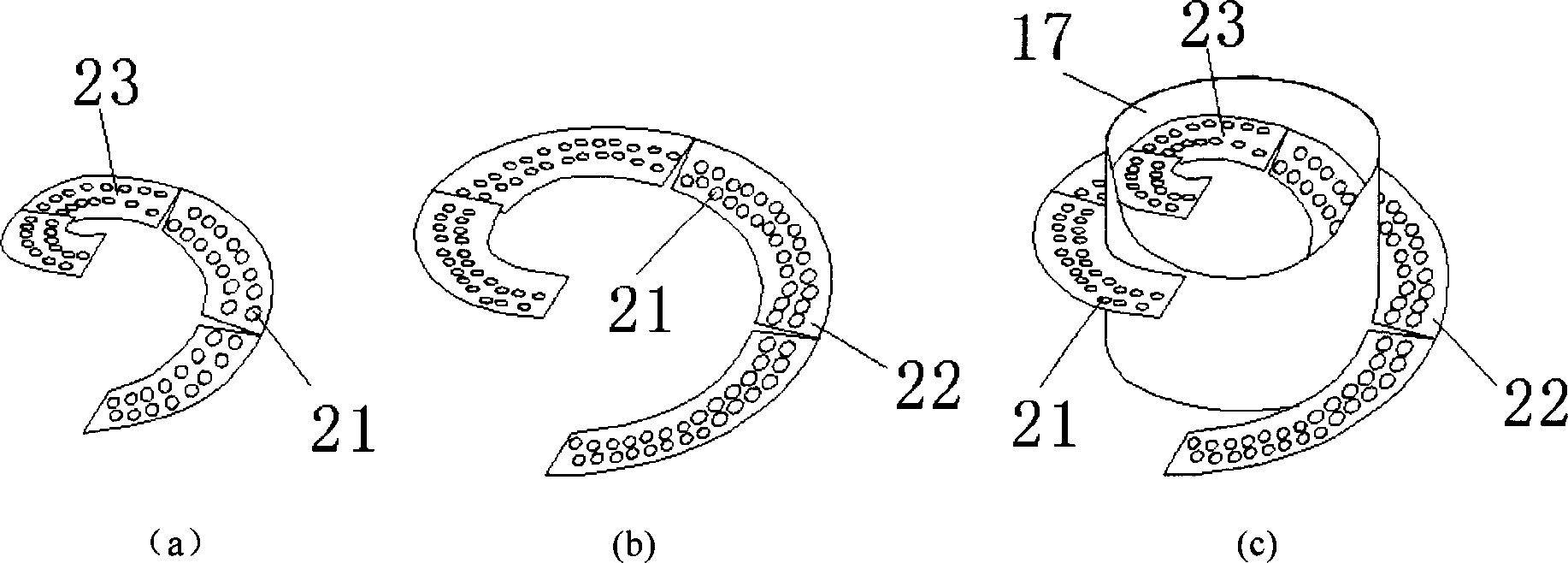

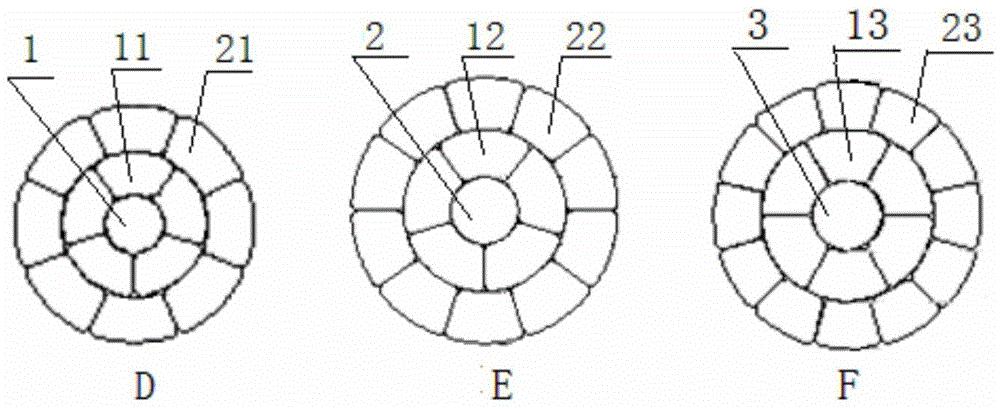

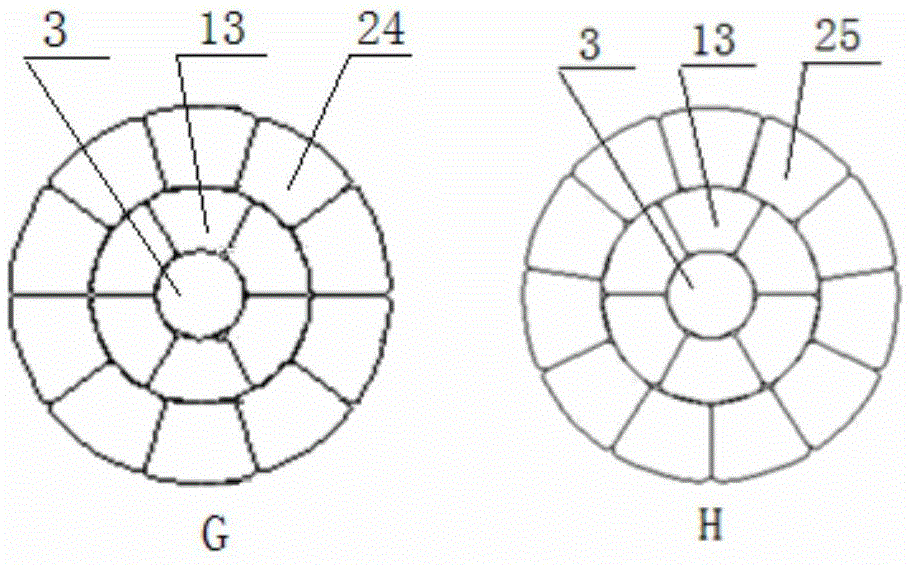

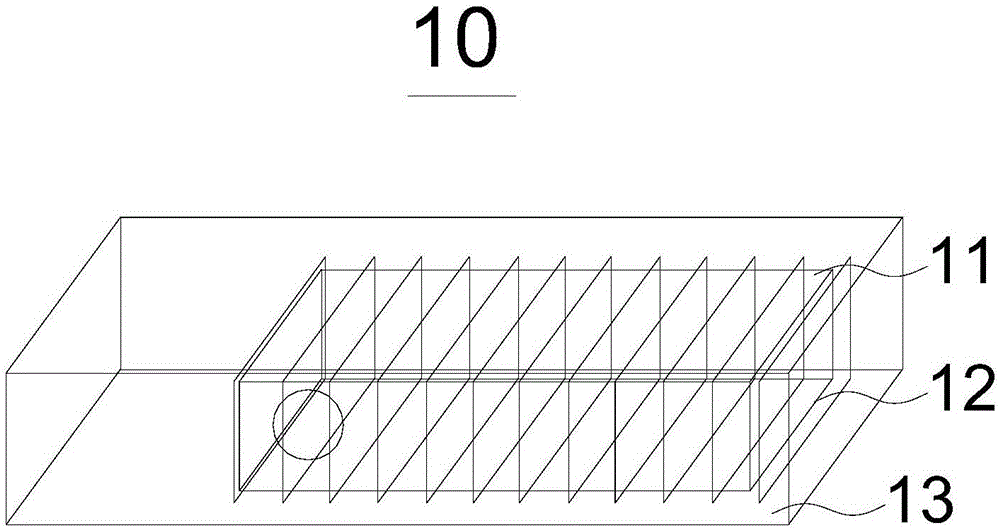

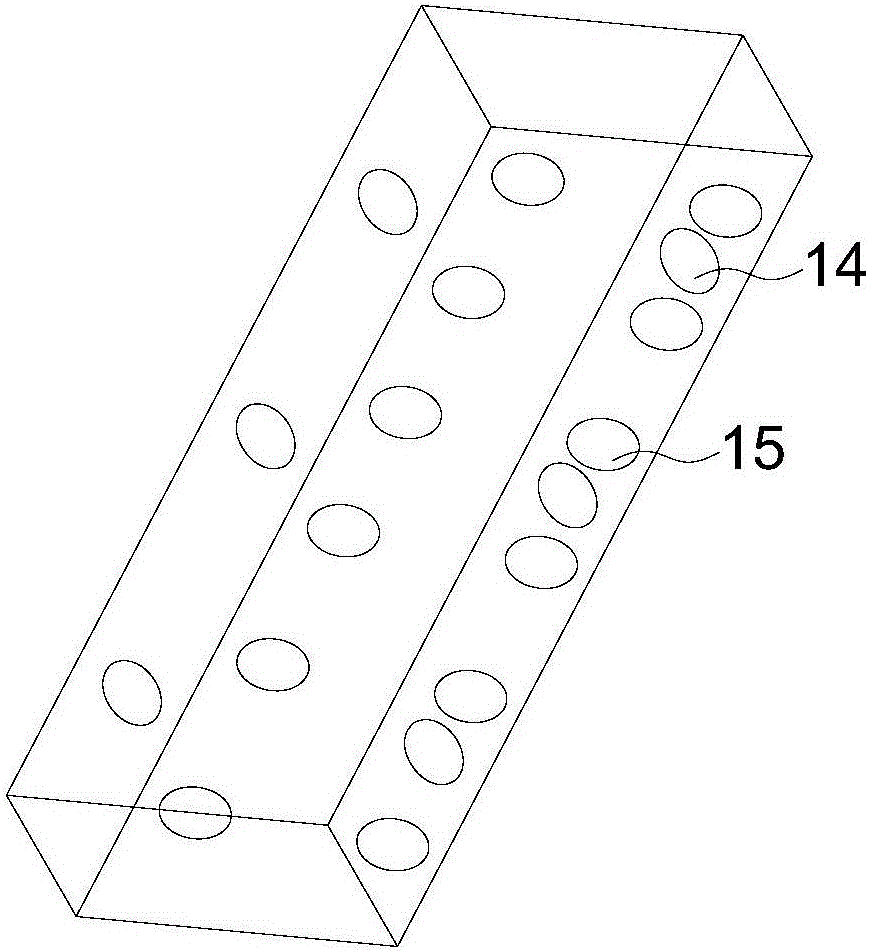

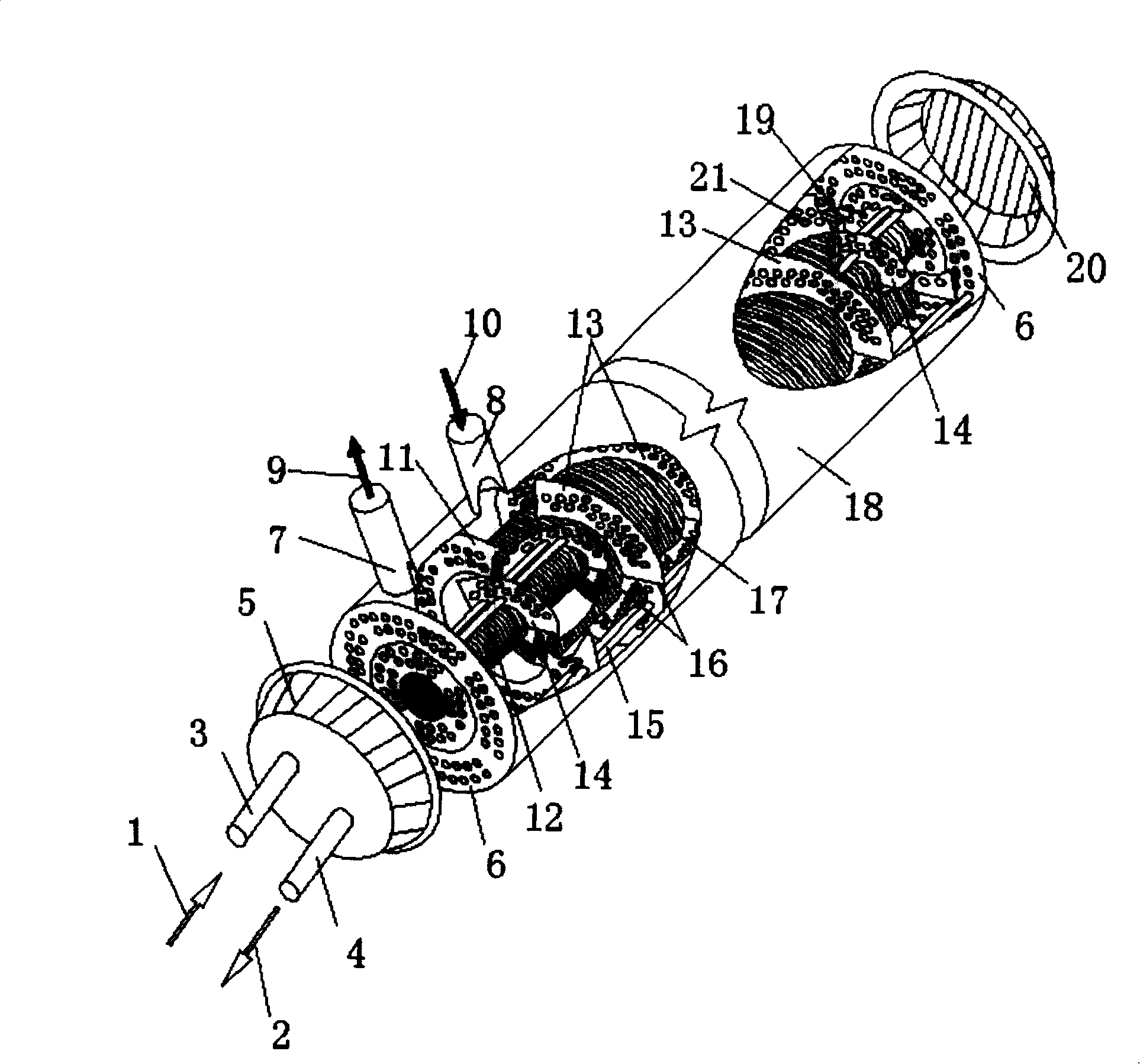

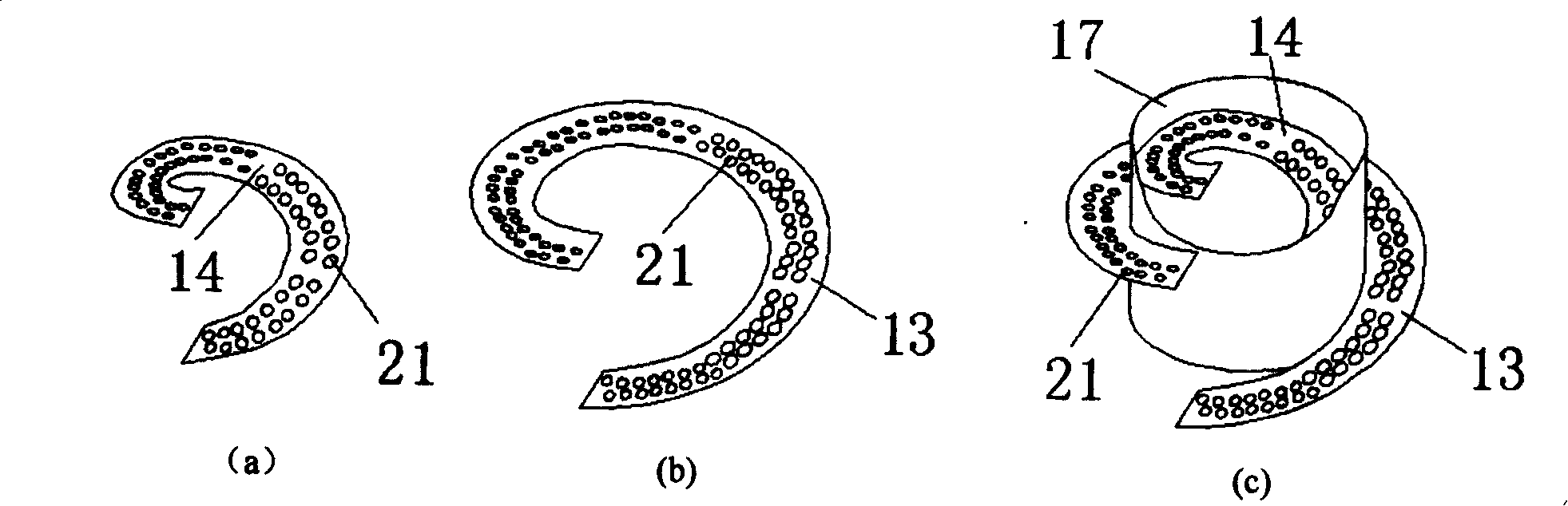

The multiple shell spiral baffle shell-and-tube heat exchanger includes one shell, one central tube in the center oft shell, two tube plates on ends of the shell and with separate end covers, one inlet pipe and one outlet pipe beside the tube, one heat exchange tube bundle, one inlet pipe and one outlet pipe beside the shell, one external spiral baffle plate and one internal spiral baffle plate, and one internal casing between the external spiral baffle plate and the internal spiral baffle plate. The shell, the external spiral baffle plate and the internal casing enclose one external spiral shell pass; and the internal casing, the internal spiral baffle plate and the central tube enclose one internal spiral shell pass, so that one two-shell pass spiral baffle plate shell-and-tube heat exchanger is formed. Adopting two or more internal casings can form multiple spiral shell pass. The present invention has raised heat exchange efficiency, compact heat exchanger structure, less vibration, high safety, less scaling and long service life.

Owner:上海益焓能源科技有限公司

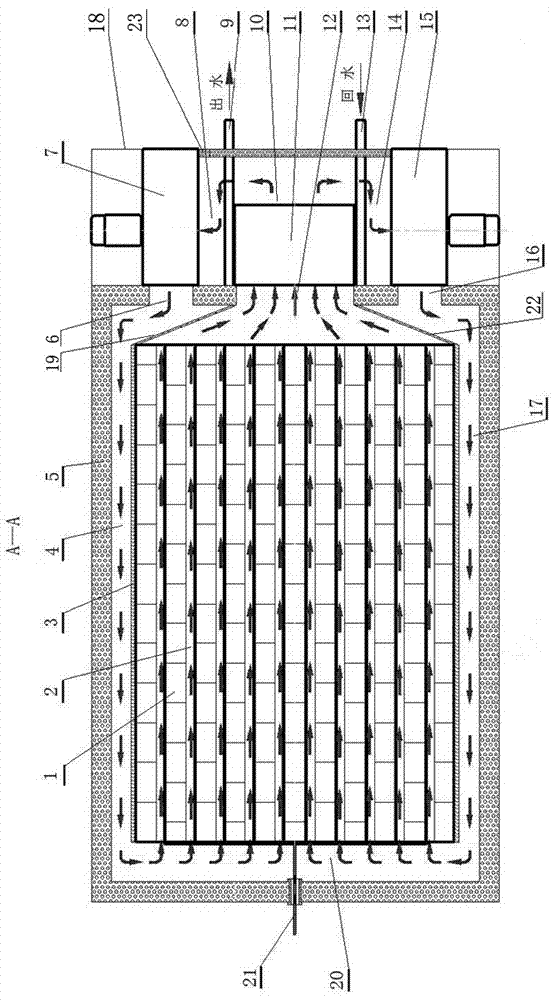

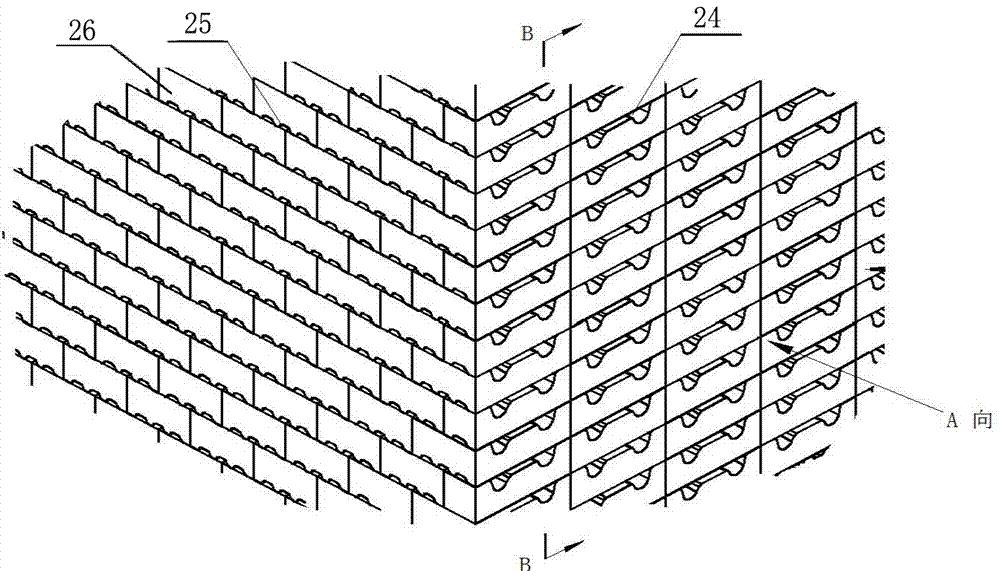

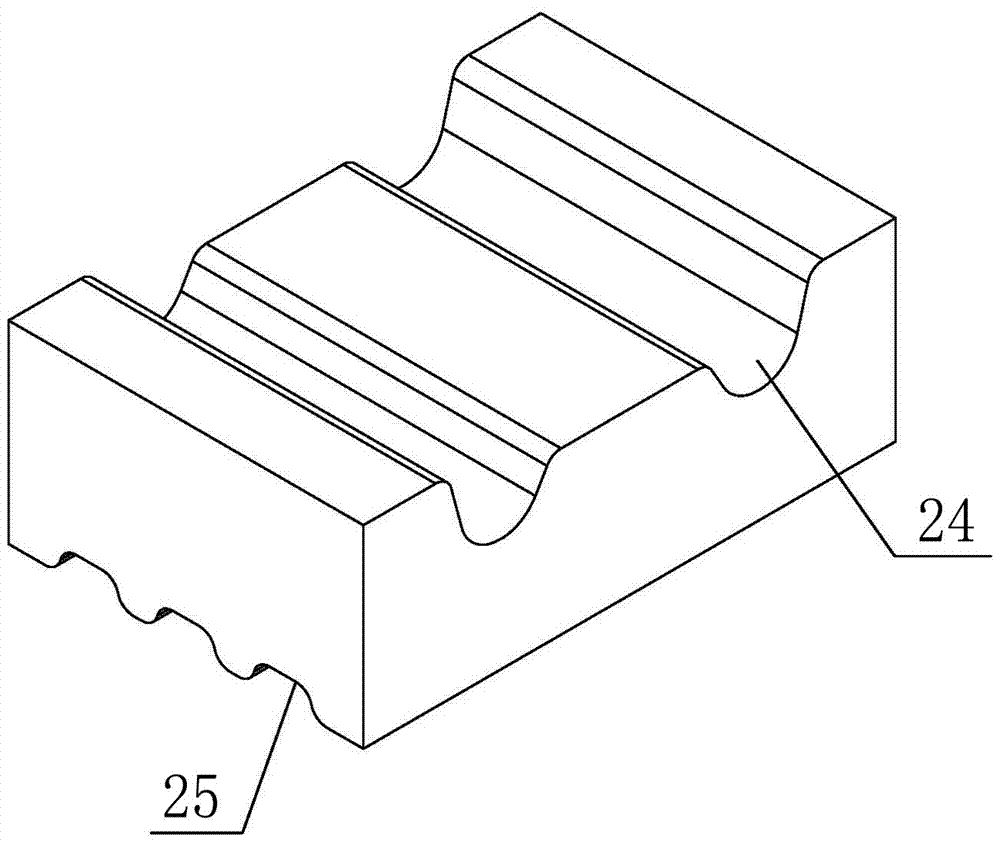

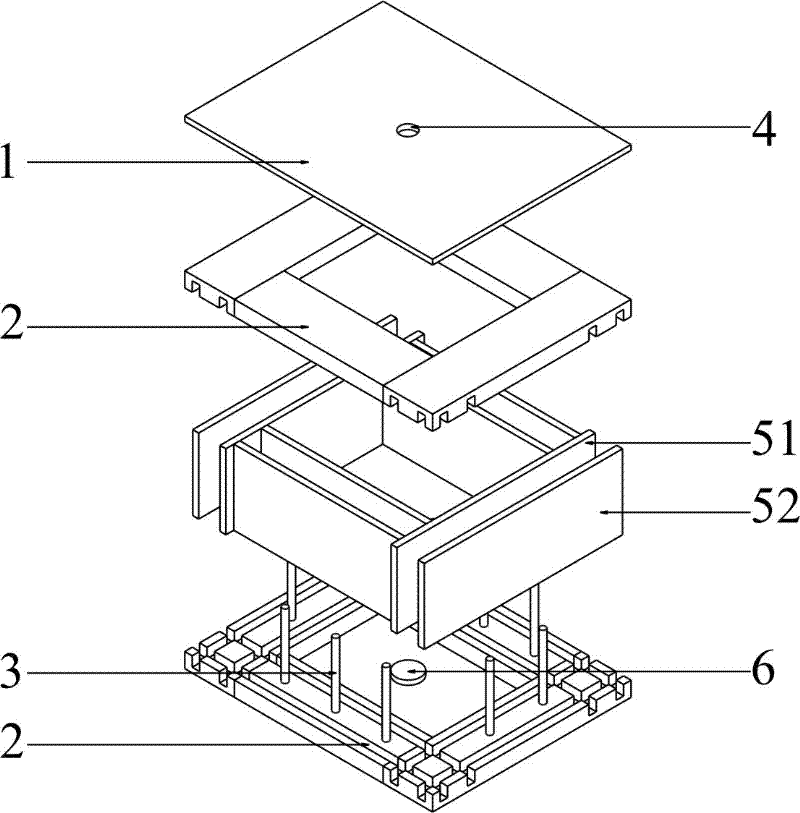

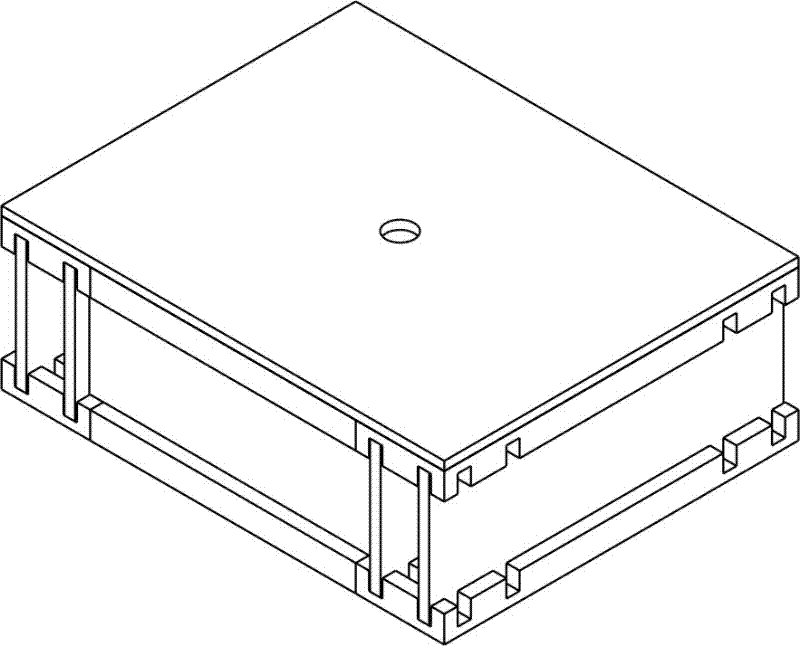

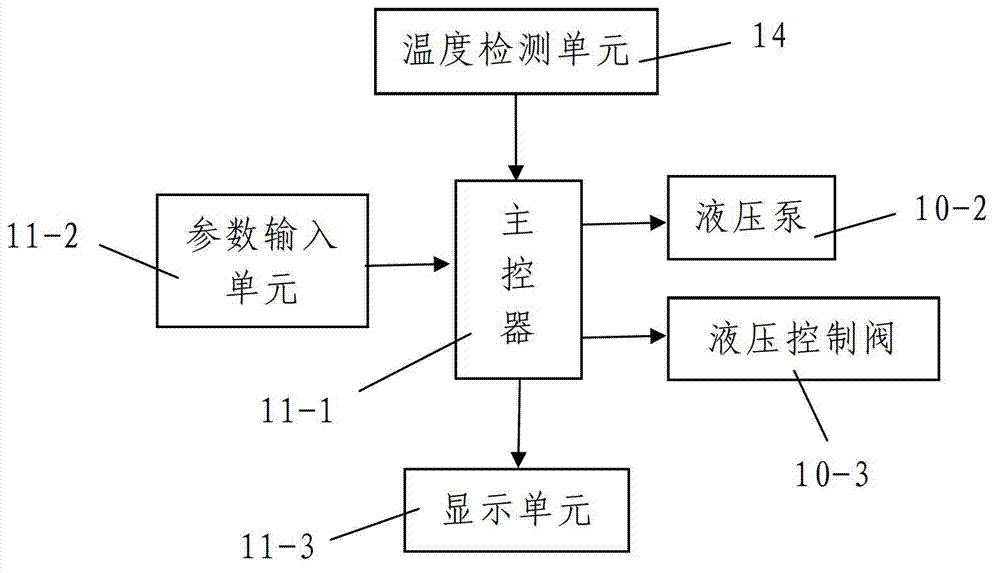

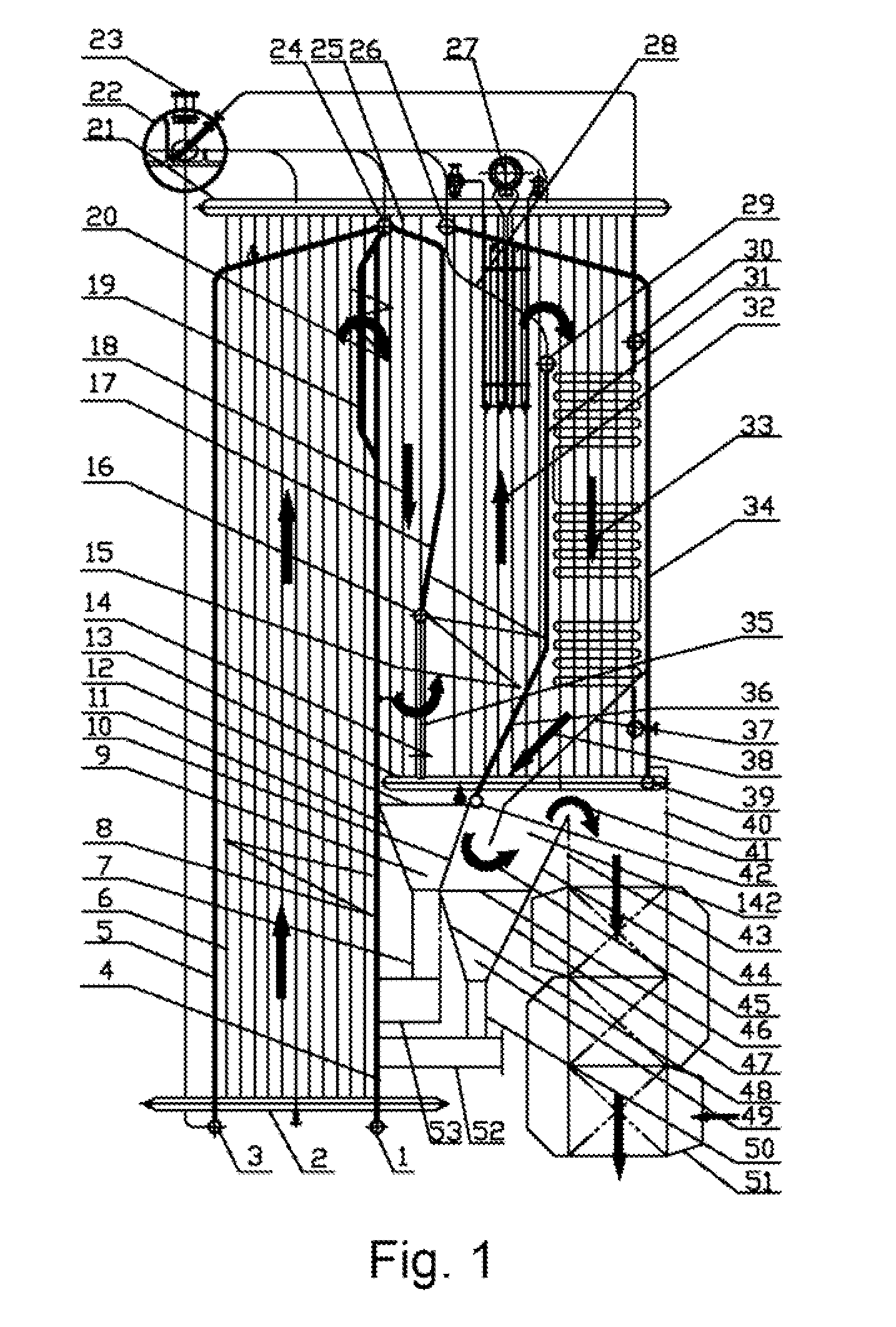

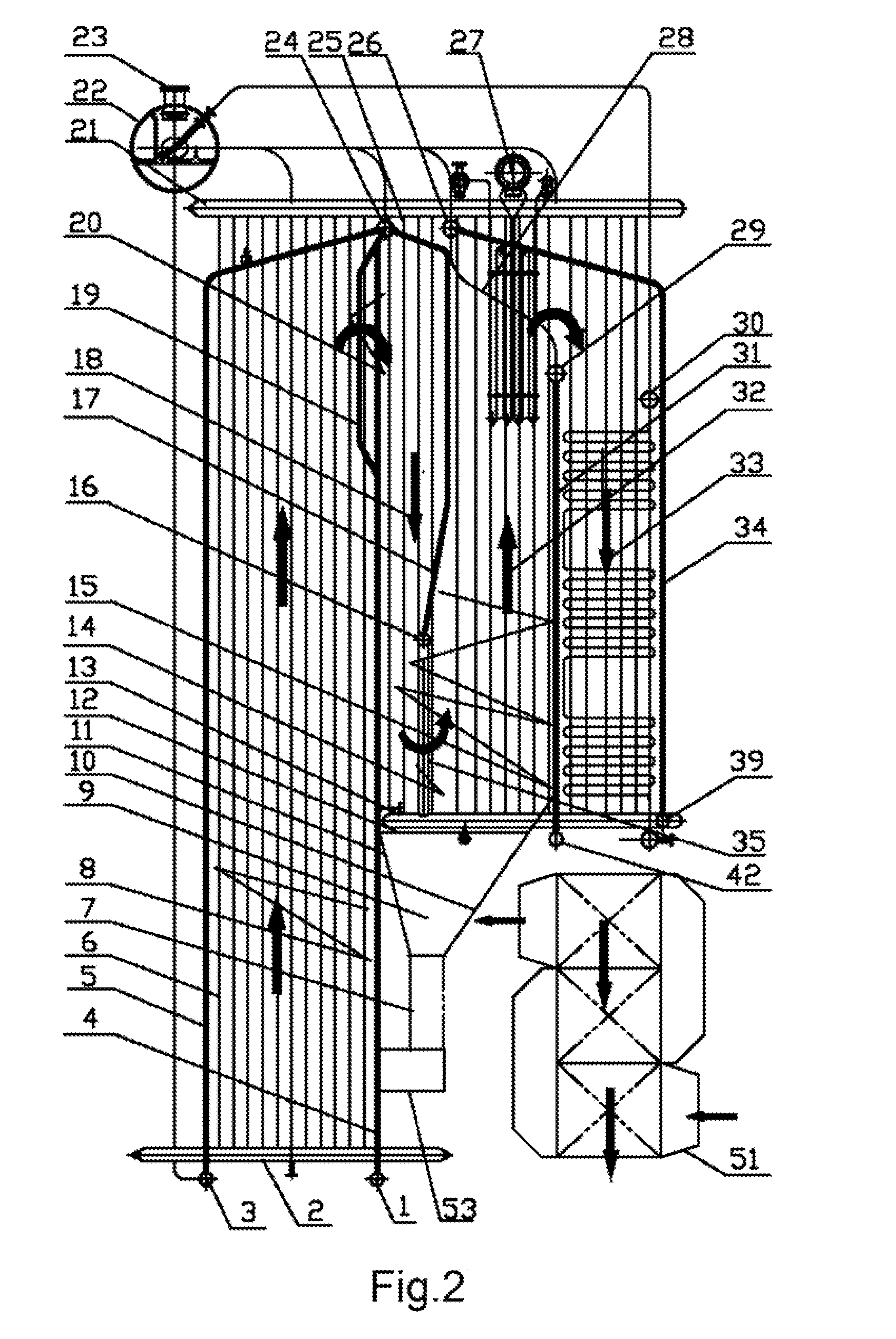

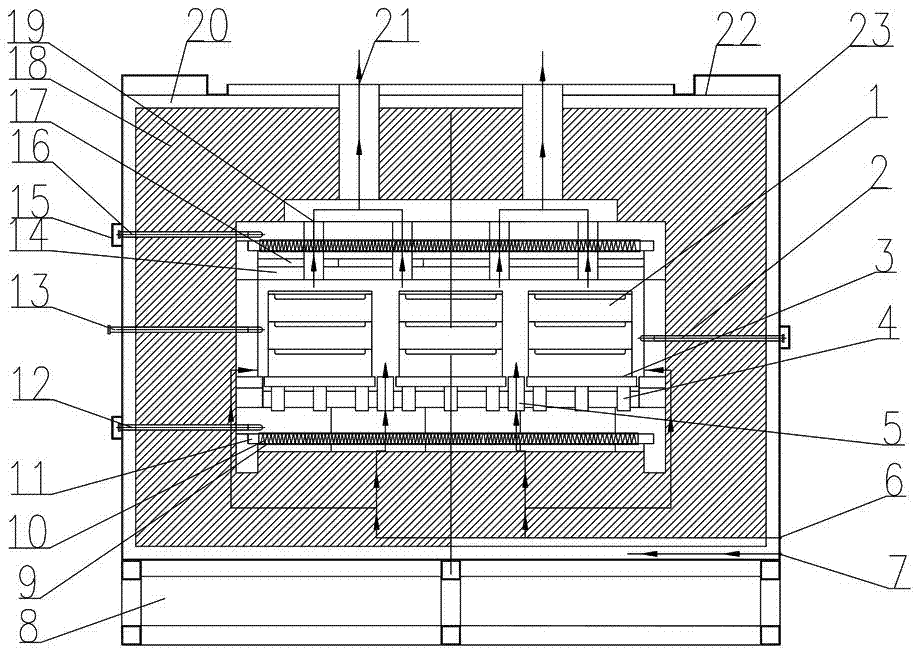

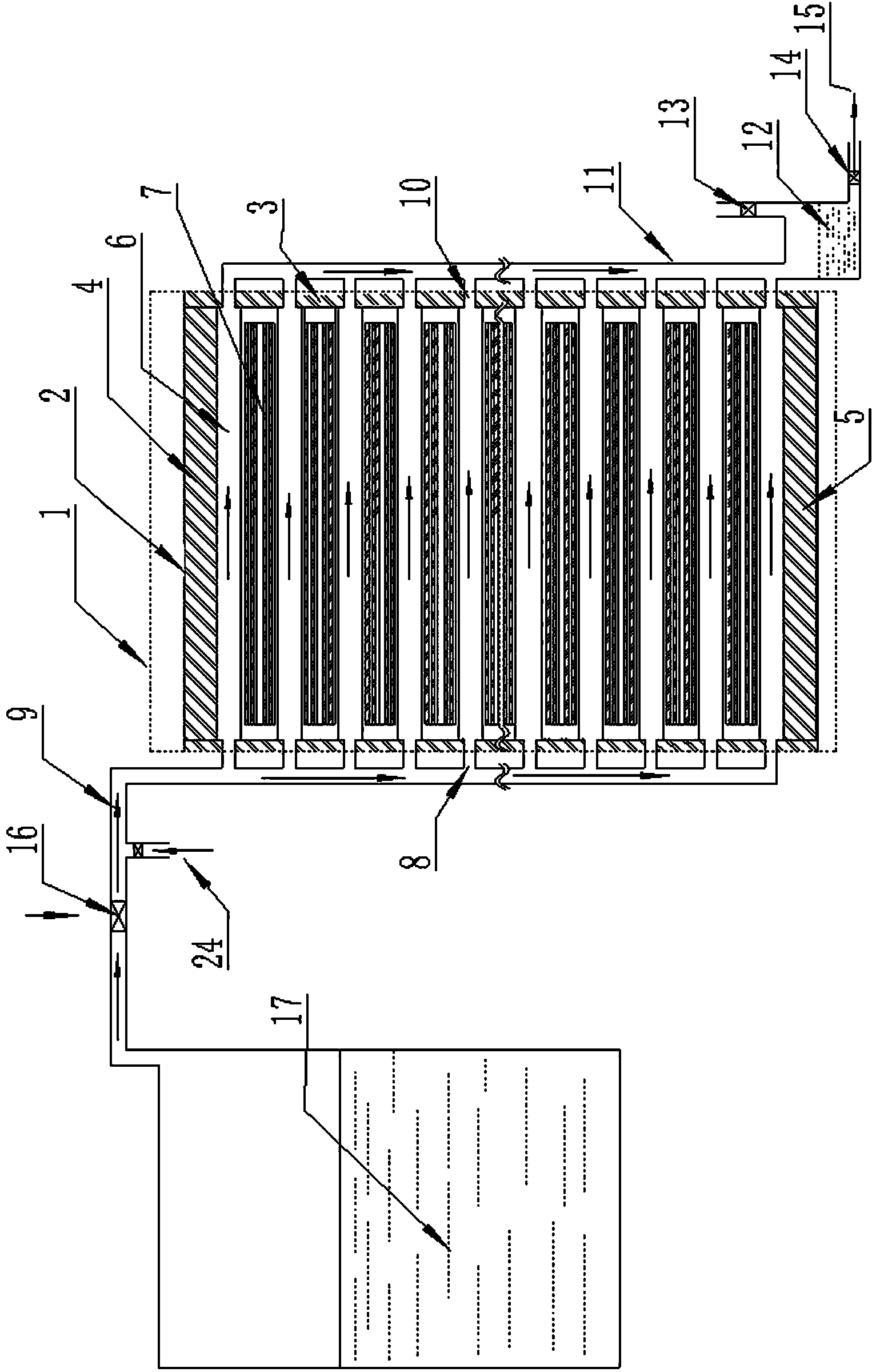

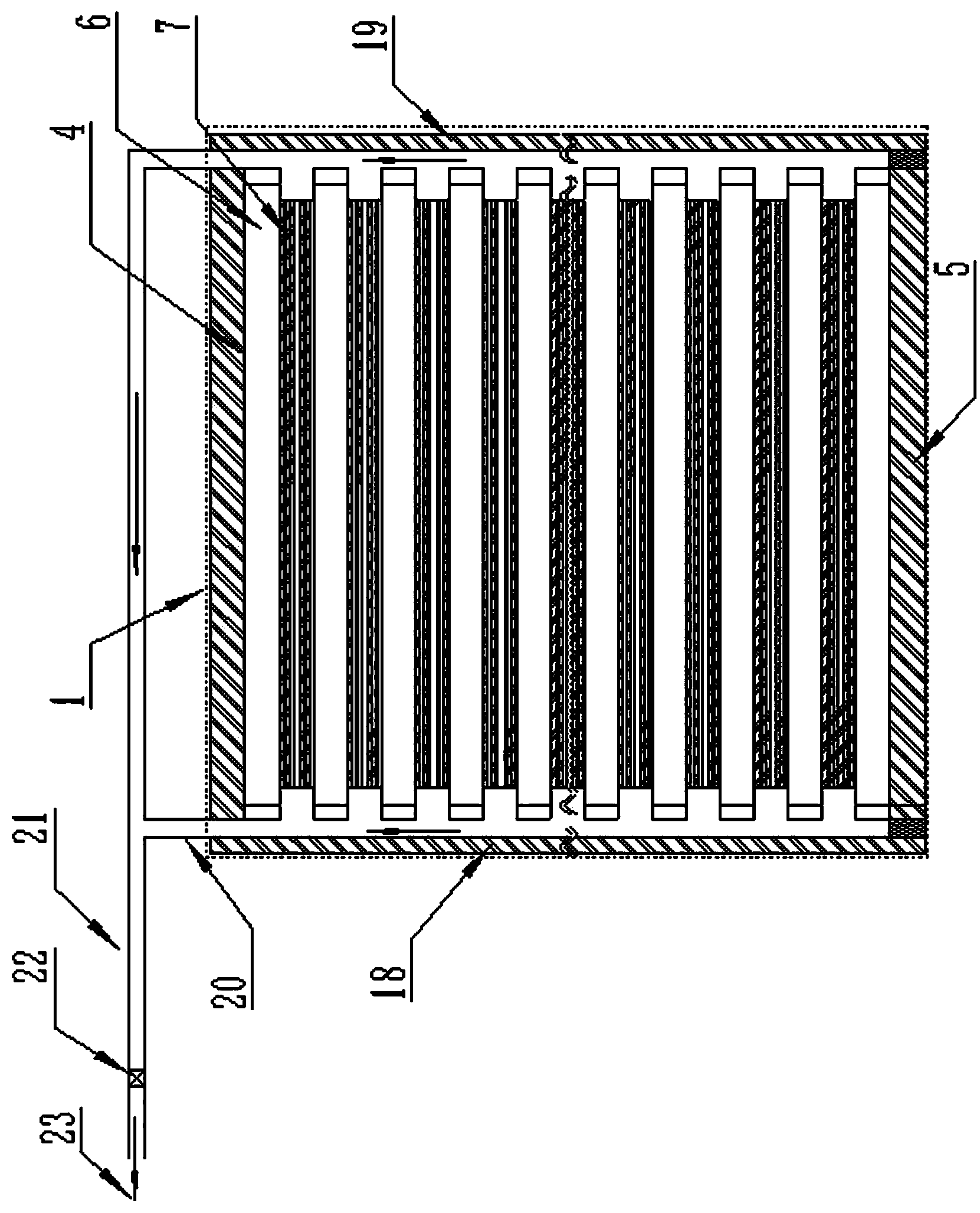

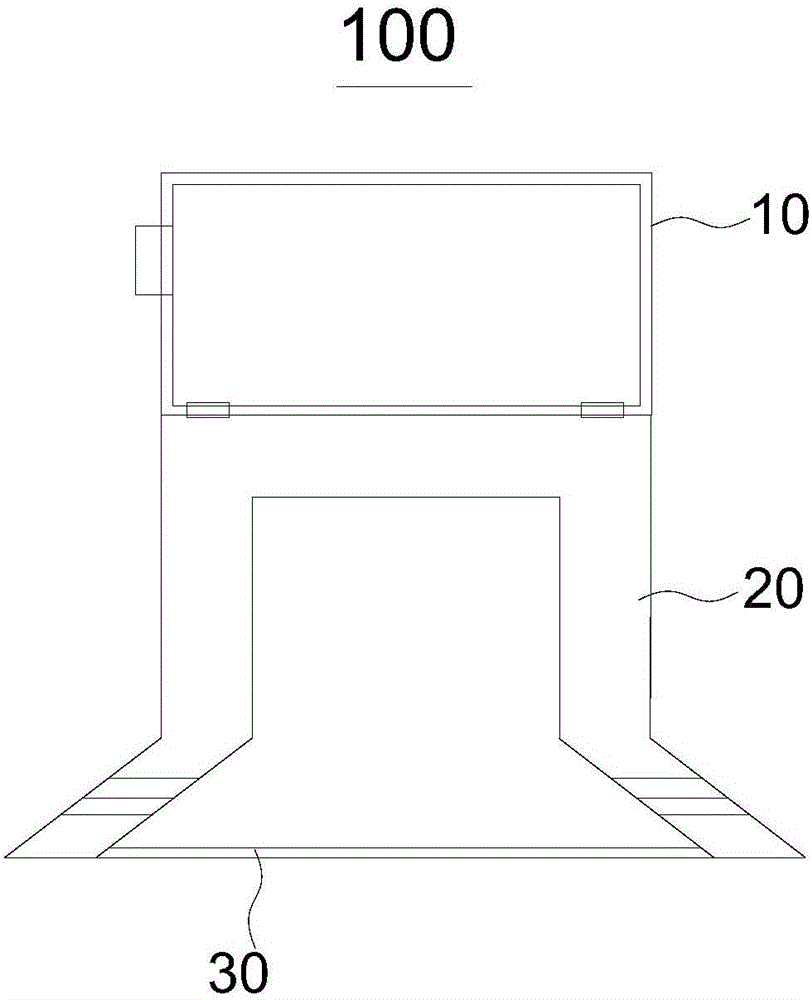

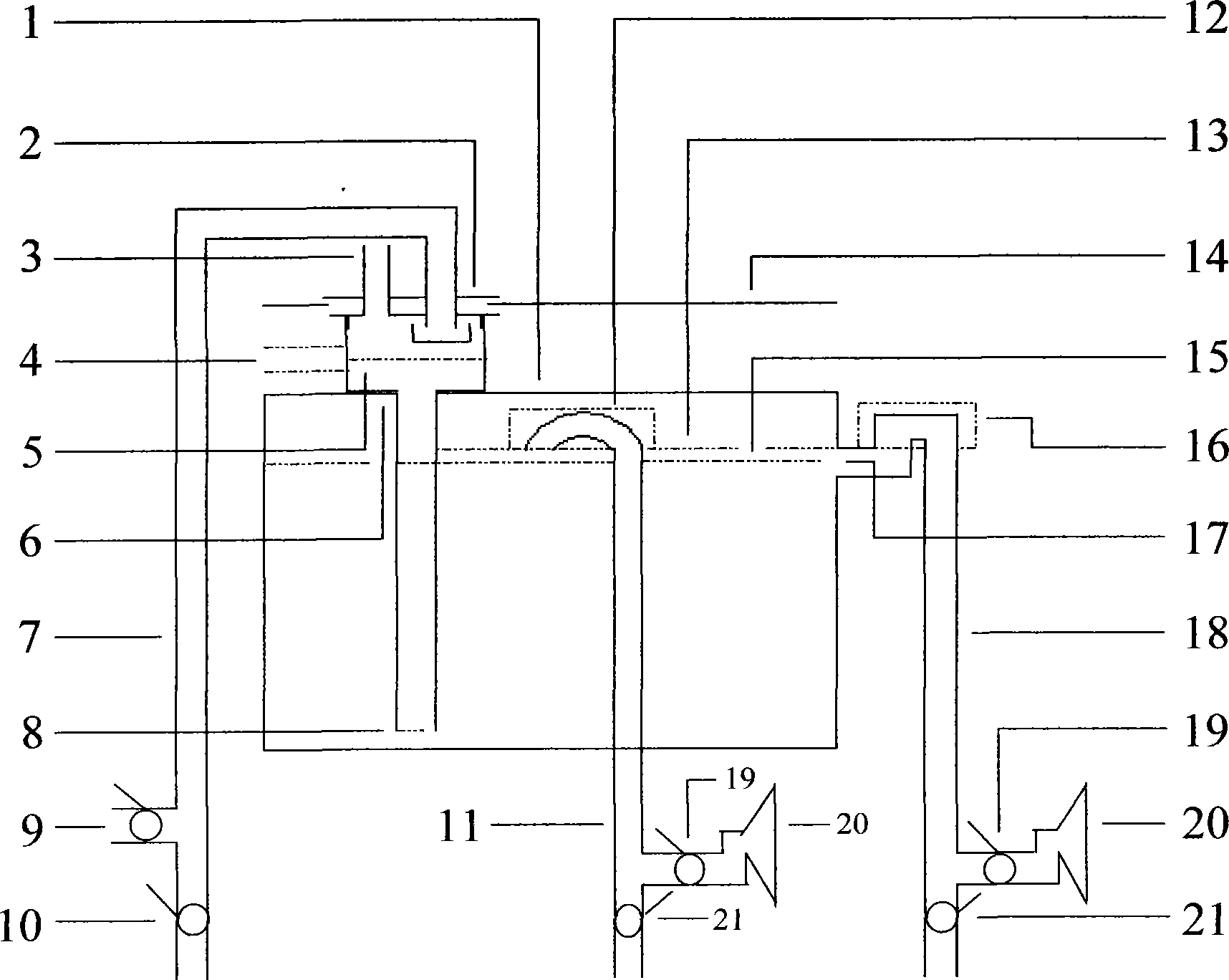

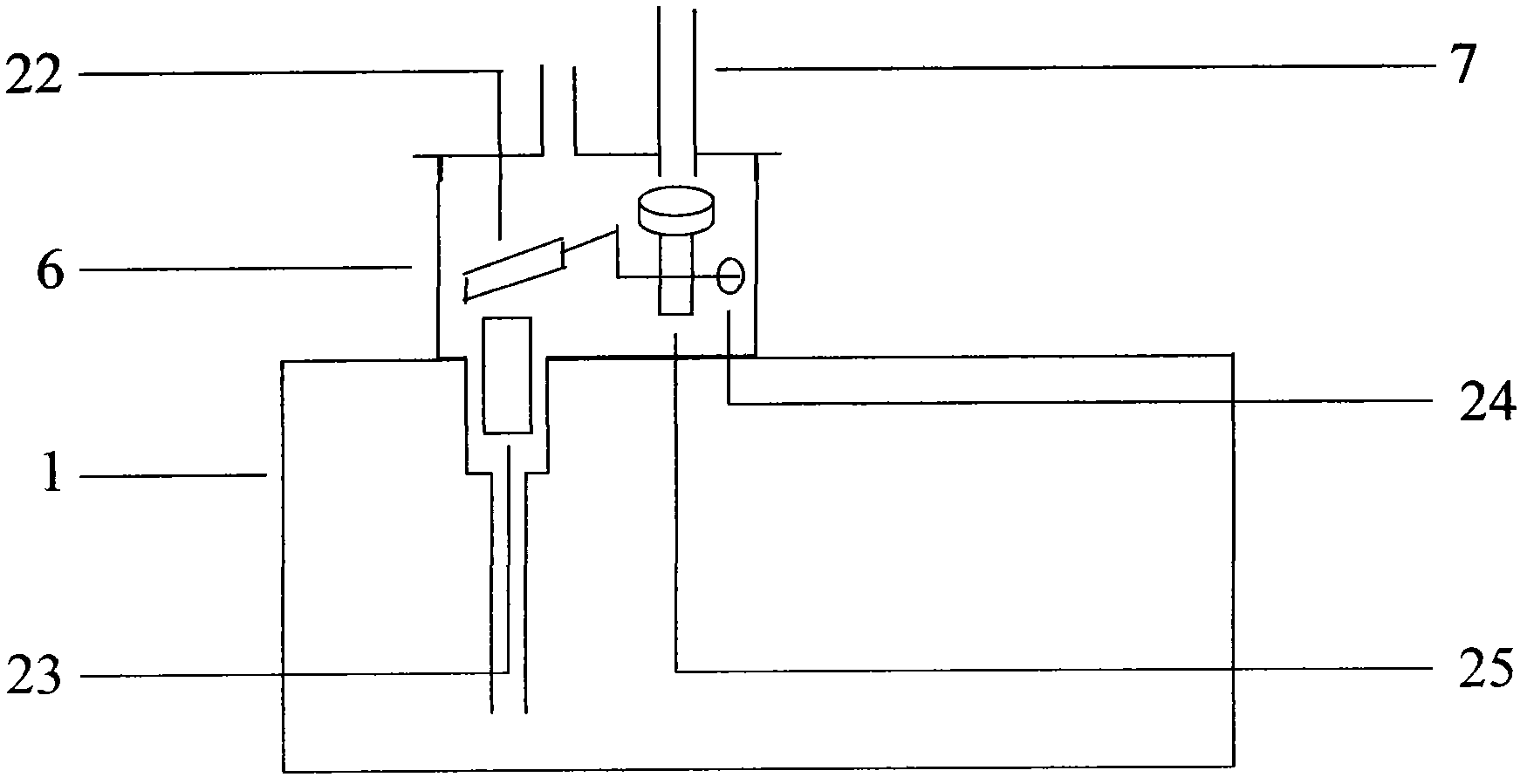

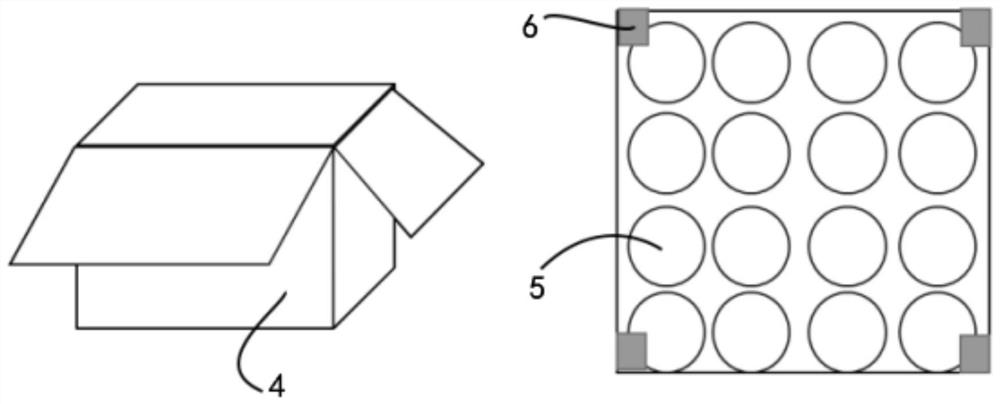

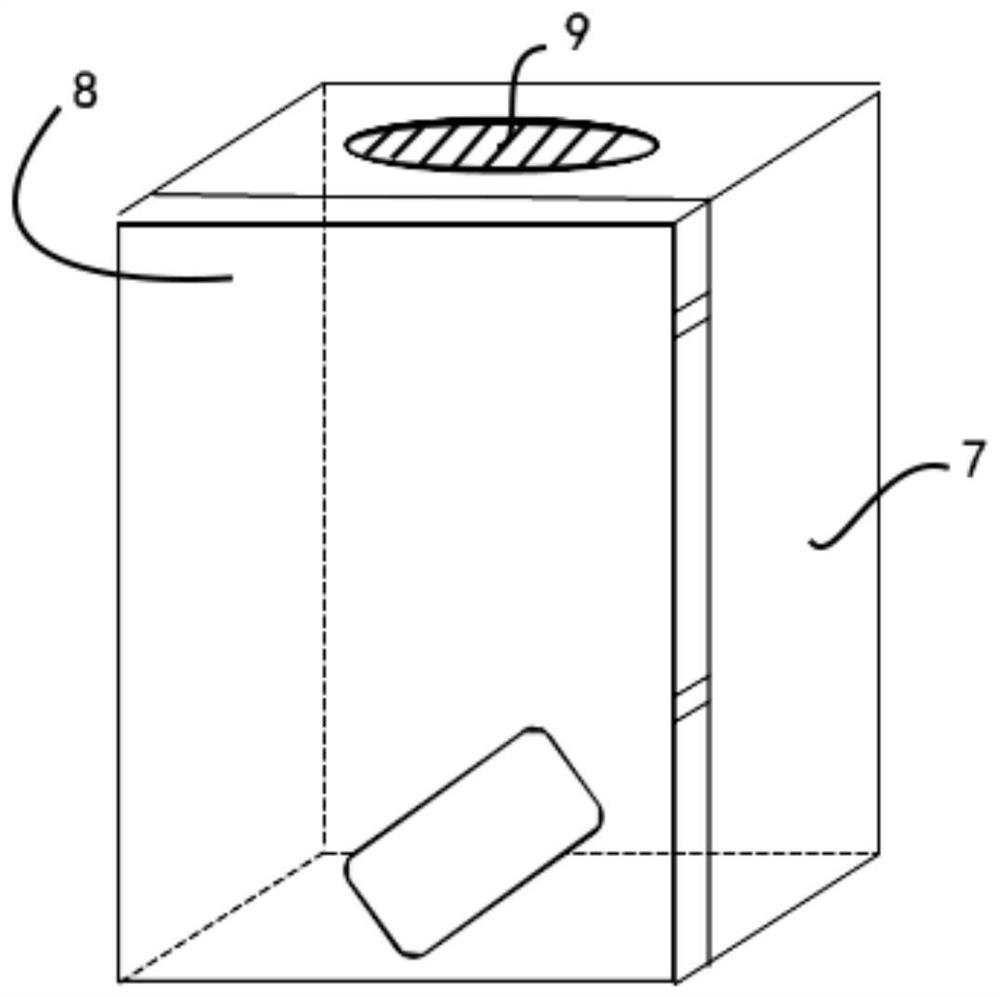

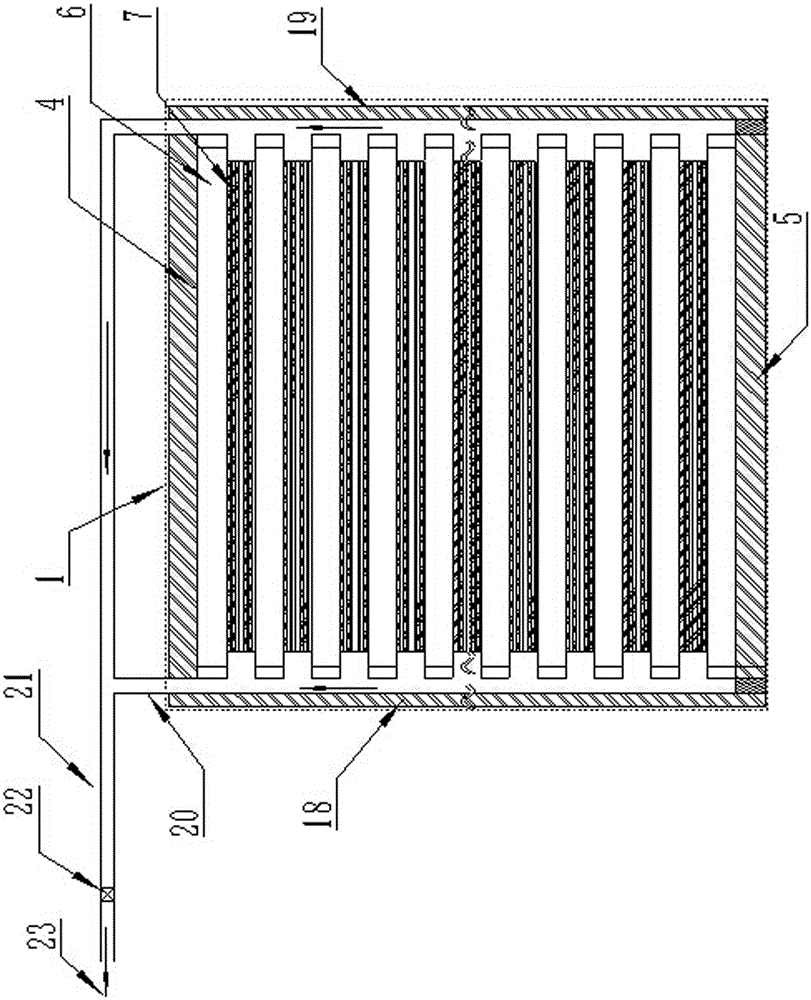

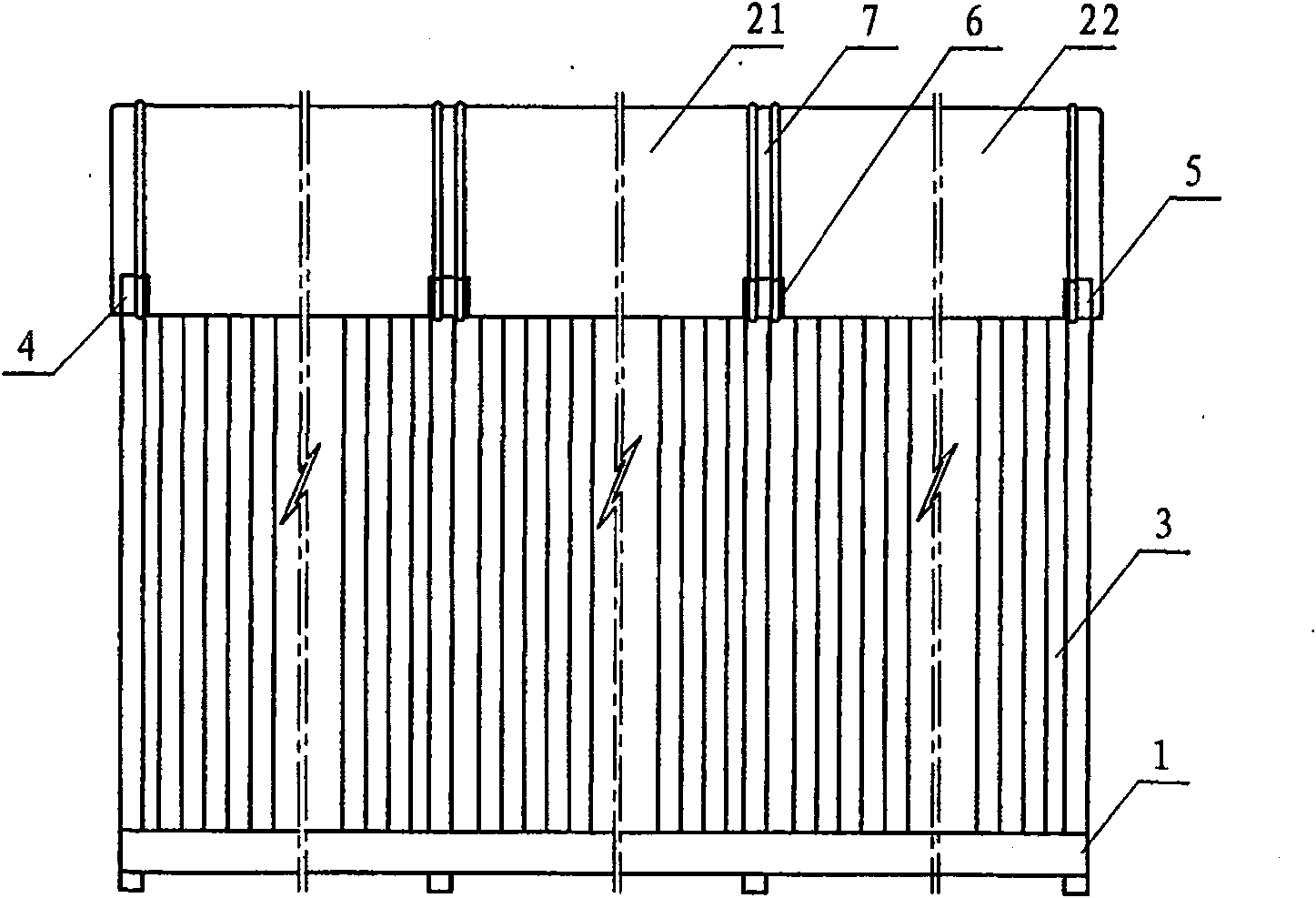

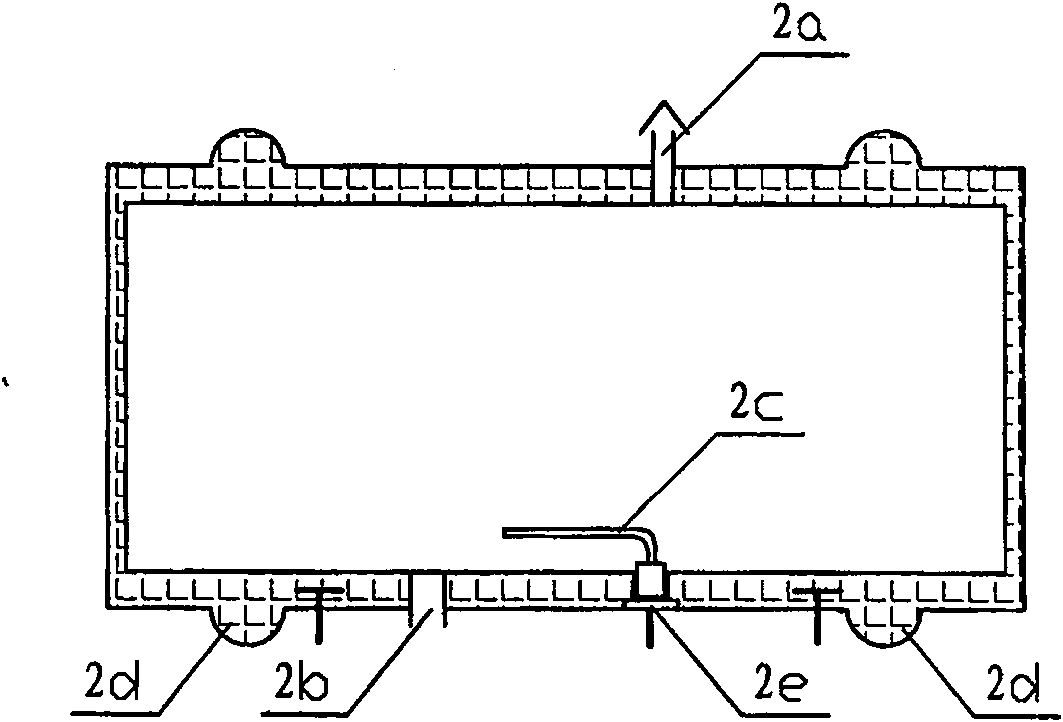

Solid electric heat storage equipment

InactiveCN107246732ASimple structureSave insulation materialHeat storage plantsStorage heatersElectricityInsulation layer

The invention provides solid electric heat storage equipment and relates to the field of solid electric heat storage. The solid electric heat storage equipment is characterized in that a first air return duct communicates with an air return chamber, all air ventilation ducts in a heat storage body, and the inlet of a heat exchanger; a second air return duct is formed among a second fire-barrier insulation plate, a heat storage body insulation layer and a shell insulation layer; and through circulation air ducts on two sides, the circulation air of the solid electric heat storage equipment enters the heat storage body from the two sides after being blown from draught fans on the two sides. The solid electric heat storage equipment is simple in structure, lower in insulation material consumption, high in efficiency and the like, and can be popularized and utilized as a novel air circulation system for the solid electric heat storage equipment.

Owner:辽宁赛科新能源技术开发有限公司

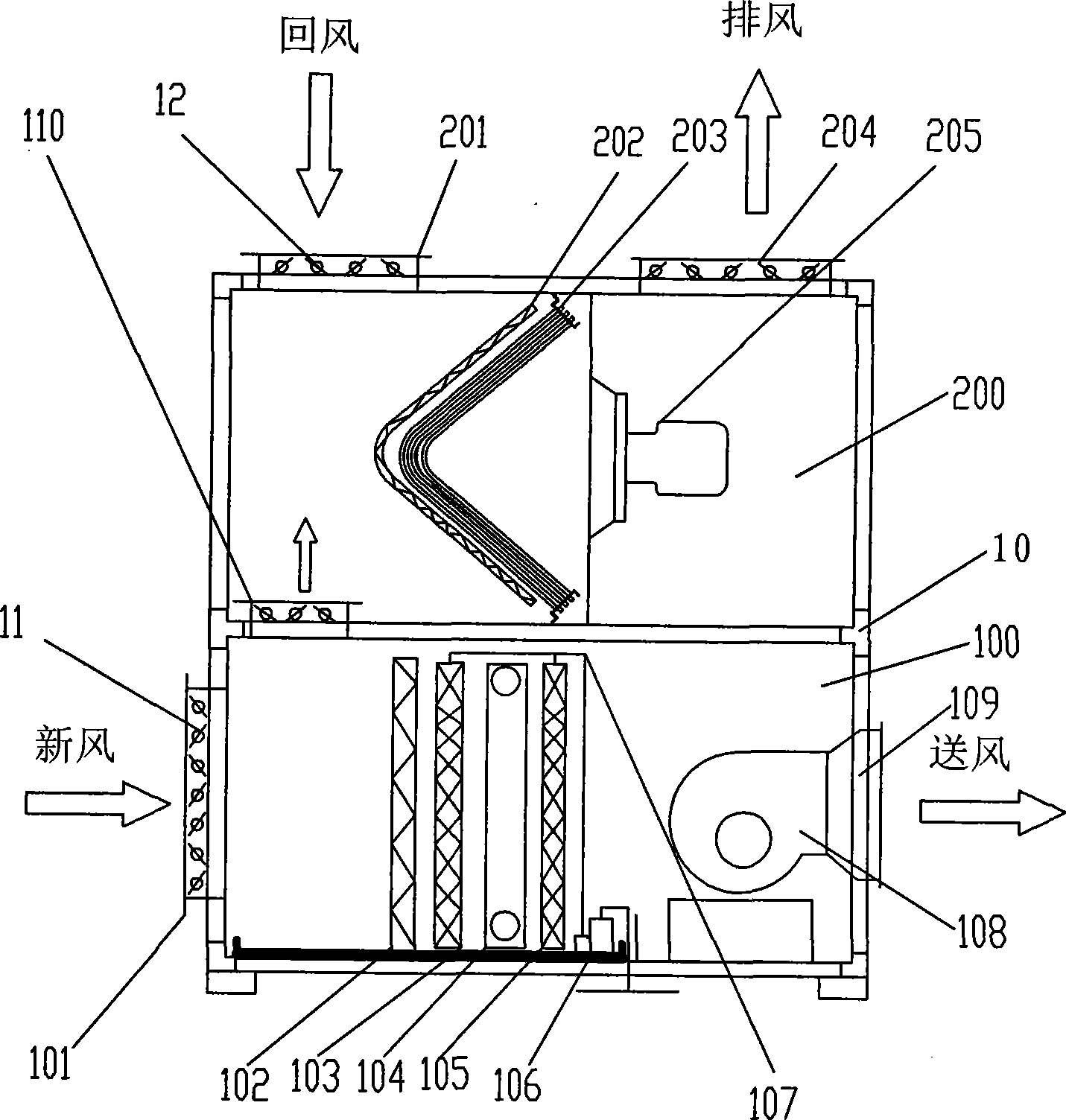

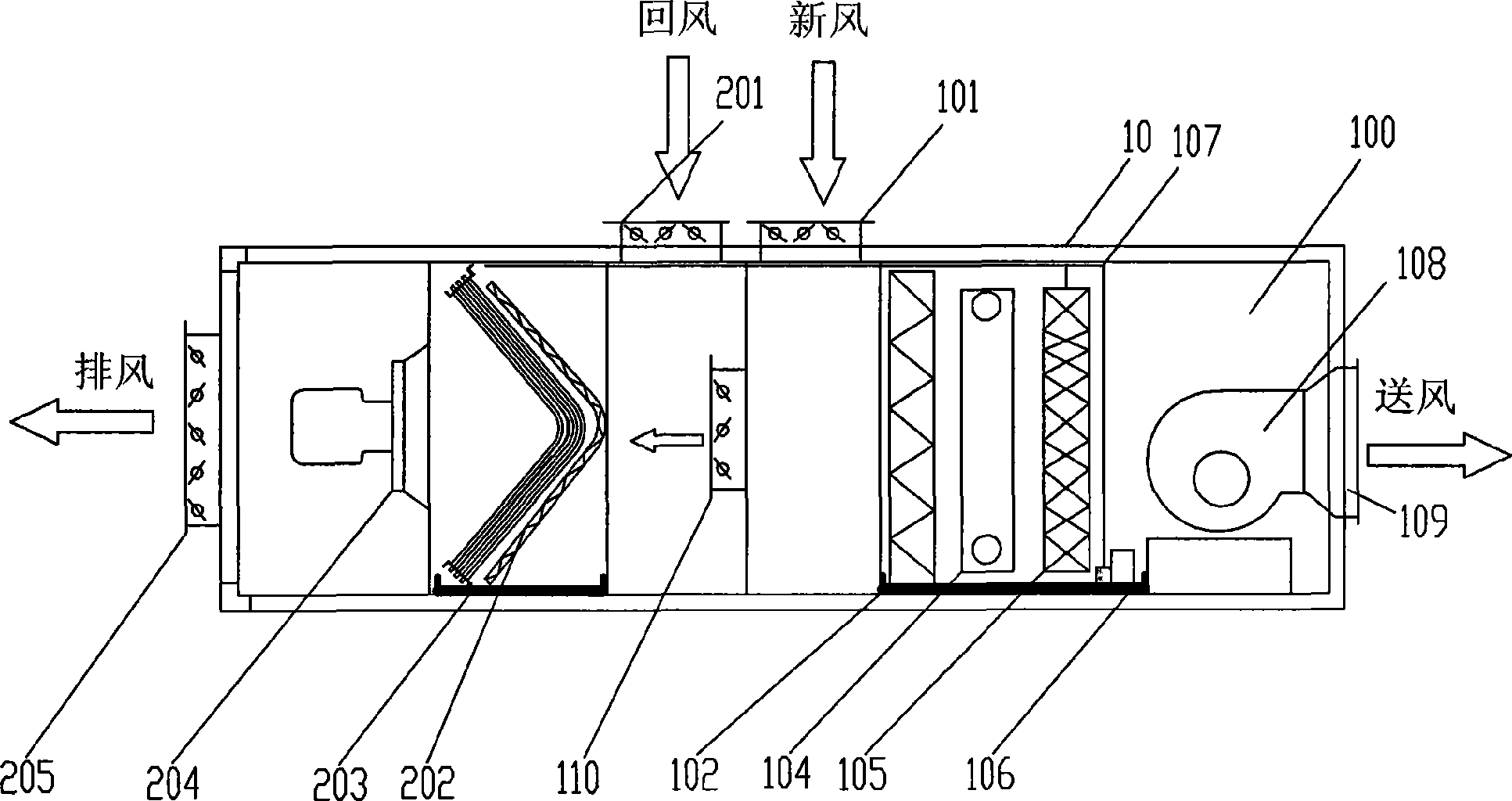

Integration full fresh air conditioner

ActiveCN101363647AGood heat exchange effectReduce air conditioning energy consumptionLighting and heating apparatusAir conditioning systemsIndoor airEvaporator

The invention provides an integrated all-fresh air conditioner which comprises a housing, a fresh air inlet for introducing fresh air, electrical elements such as a compressor, etc., a condenser, an evaporator, a water tank, a pipeline system of all parts, a blower arranged at the rear part of the evaporator, an air outlet communicated with the blower, a return air inlet for absorbing indoor air, a condensate fan arranged at the rear part of the condenser, and an air outlet communicated with the condensing fan; wherein, a chemical filter and a fresh-air pre-cooled film are arranged at the front part of the evaporator, and a humidification film is arranged at the rear part of the evaporator, and a filter is arranged at the front part of the condenser. The integrated all-fresh air conditioner is designed into a whole body, and is condensed by the return air in an air conditioned room and the precooled fresh air, which can realize all-fresh-air effect while saving energy.

Owner:江苏国莱特空调设备有限公司

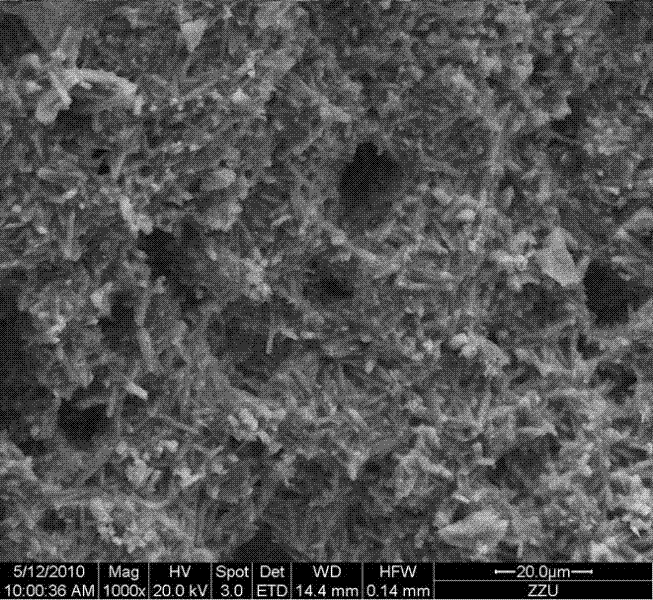

Mixed microwave sintering method of mullite composite material

InactiveCN102432303AHigh temperature and fast sinteringFast sinteringMaterials preparationResonant cavity

The invention belongs to the technical field of a composite material preparation technology and discloses a mixed microwave sintering method of a mullite composite material. The mixed microwave sintering method of the mullite composite material comprises putting a mullite composite material green-pressing into an auxiliary heating-insulation combined device, putting the auxiliary heating-insulation combined device with the mullite composite material green-pressing into a microwave resonant cavity, and carrying out a sintering process, wherein the sintering process comprises the following steps of 1, starting a microwave source, 2, adjusting microwave input power, 3, slowly heating at an average heating rate of 6 to 15 DEG C per minute in a low temperature stage, 4, after humidity elimination and smoke evacuation are finished, continuously adjusting the adjusting input power, 5, fast heating at a heating rate of 2 to 100 DEG C per minute, and simultaneously, monitoring reflection power, 6, when the reflection power is stable, heating to a sintering temperature of 1000 to 1500 DEG C at a heating rate of 20 to 30 DEG C per minute, 7, keeping the sintering temperature for 2 to 10 minutes, and 8, cooling to room temperature in a furnace to obtain the mullite composite material. The mixed microwave sintering method of the mullite composite material combines a traditional sintering technology and a microwave sintering technology according to microwave adsorption properties of an oxide, and realizes fast sintering of the mullite composite material.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

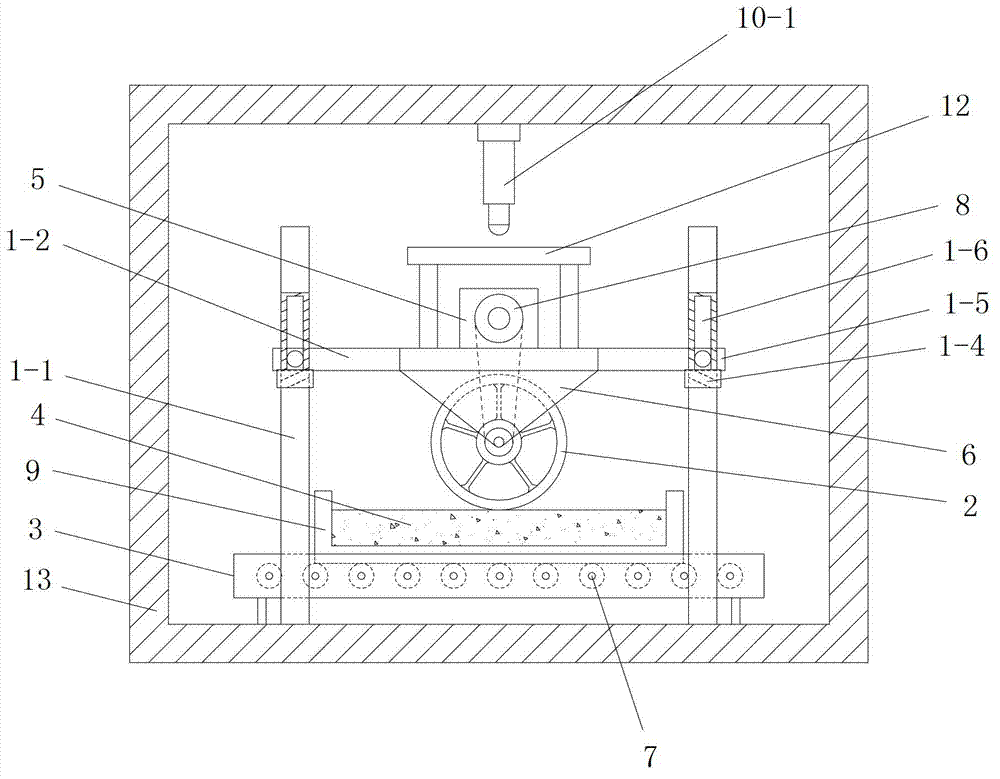

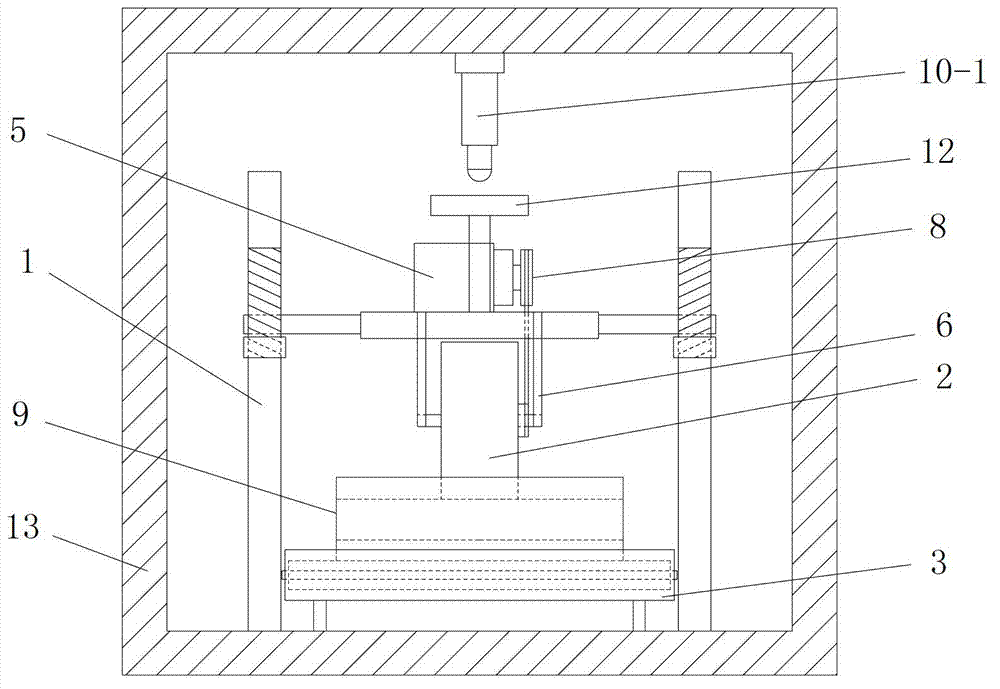

Indoor wheel rutting instrument

The invention discloses an indoor wheel rutting instrument. The indoor wheel rutting instrument comprises a horizontal test bench, a rolling support device arranged on the horizontal test bench, a horizontal sliding component which is used for mounting a test piece and can drive the test piece to move back and forth on the rolling support device, a test wheel holder with adjustable supporting height, a test wheel of which the bottom is supported on the test piece, and a drive motor for driving the test wheel to rotate. The horizontal sliding component is placed on the rolling support device; the test wheel holder is provided with a wheel frame for mounting the wheel shaft of the test wheel; the power output shaft of the drive motor and the wheel shaft are in transmission connection through a transmission mechanism; and the test wheel holder is provided with a loading device for applying vertical load on the test wheel from top to bottom. The indoor wheel rutting instrument is rational in structure design, compact in installation, simple and easy to control, excellent in using effects, capable of simulating the real running state of the vehicle driving wheels, and capable of effectively solving the practical problem that the existing wheel rutting instrument can only simulate the running state of the vehicle driven wheels when the test wheel is driven to run by a crank connecting link.

Owner:CHANGAN UNIV

General insulation composite material for exterior wall and application method

InactiveCN101691800AImprove insulation performanceGood heat insulationCovering/liningsInsulation layerMicrosphere

The invention relates to an insulation composite material for an exterior wall and an application method. The composite material is characterized in that the interior and exterior surface layers of a rigid polyurethane layer are combined with inorganic hollow microsphere polymer composite insulation layers, an anti-crack mortar layer is arranged on the exterior inorganic hollow microsphere polymer composite insulation layer and a wall decoration layer is combined with the exterior surface layer of the anti-crack mortar layer. The application method is as follows: the exterior wall to be treated is sequentially coated with the interior hollow microsphere polymer composite insulation layer, rigid polyurethane and the exterior hollow microsphere polymer composite insulation layer, the anti-crack mortar layer is coated on the exterior hollow microsphere polymer composite insulation layer and the wall decoration surface layer is coated on the exterior surface layer of the anti-crack mortar layer. The composite material has good heat insulation property and quick construction method, is strongly adaptive to main structures, reaches higher flame retardant level, is energy-saving and environment-friendly, is suitable for insulation of various walls, especially exterior walls, and is applicable to floors.

Owner:东营丰力输送带有限公司

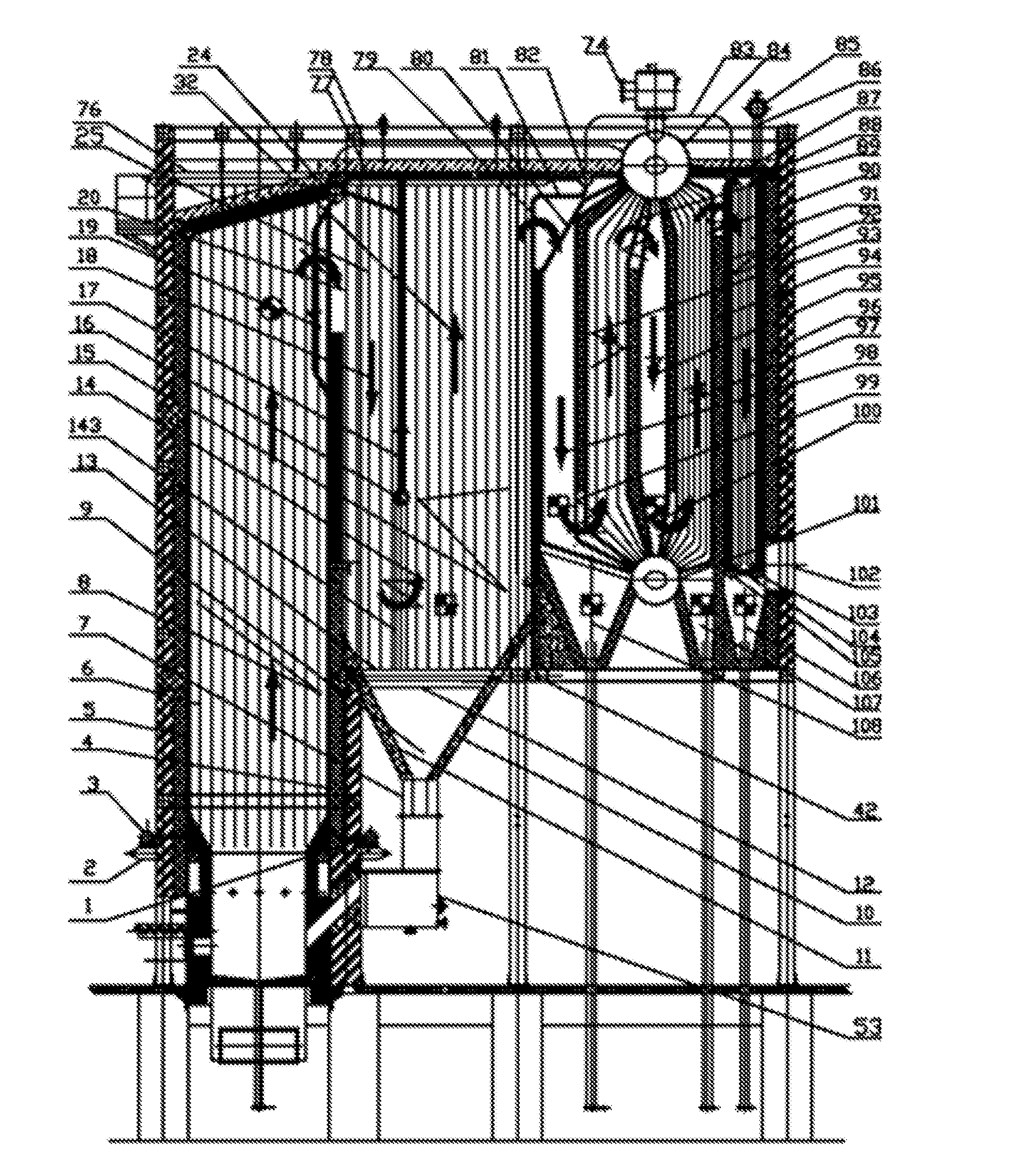

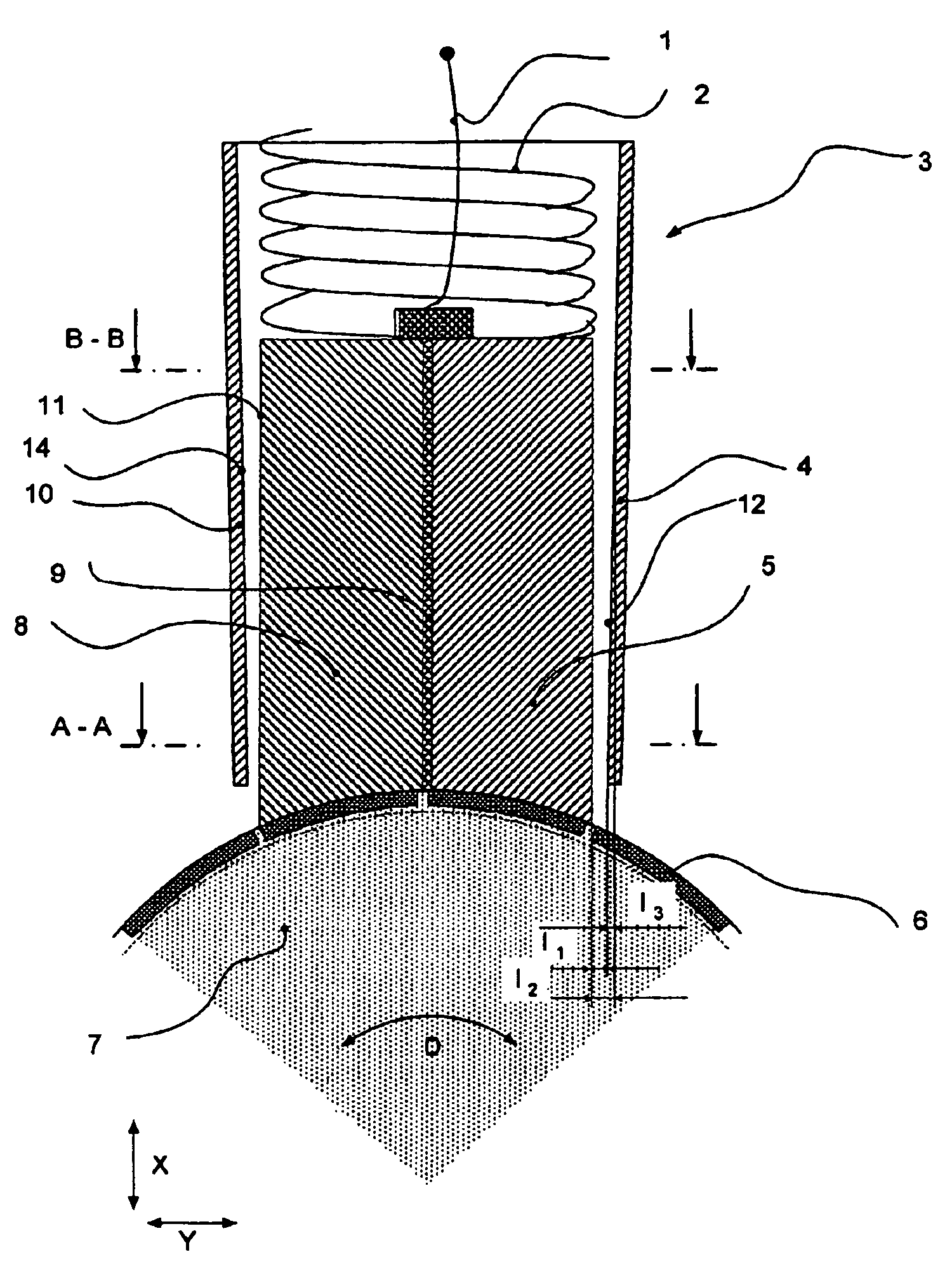

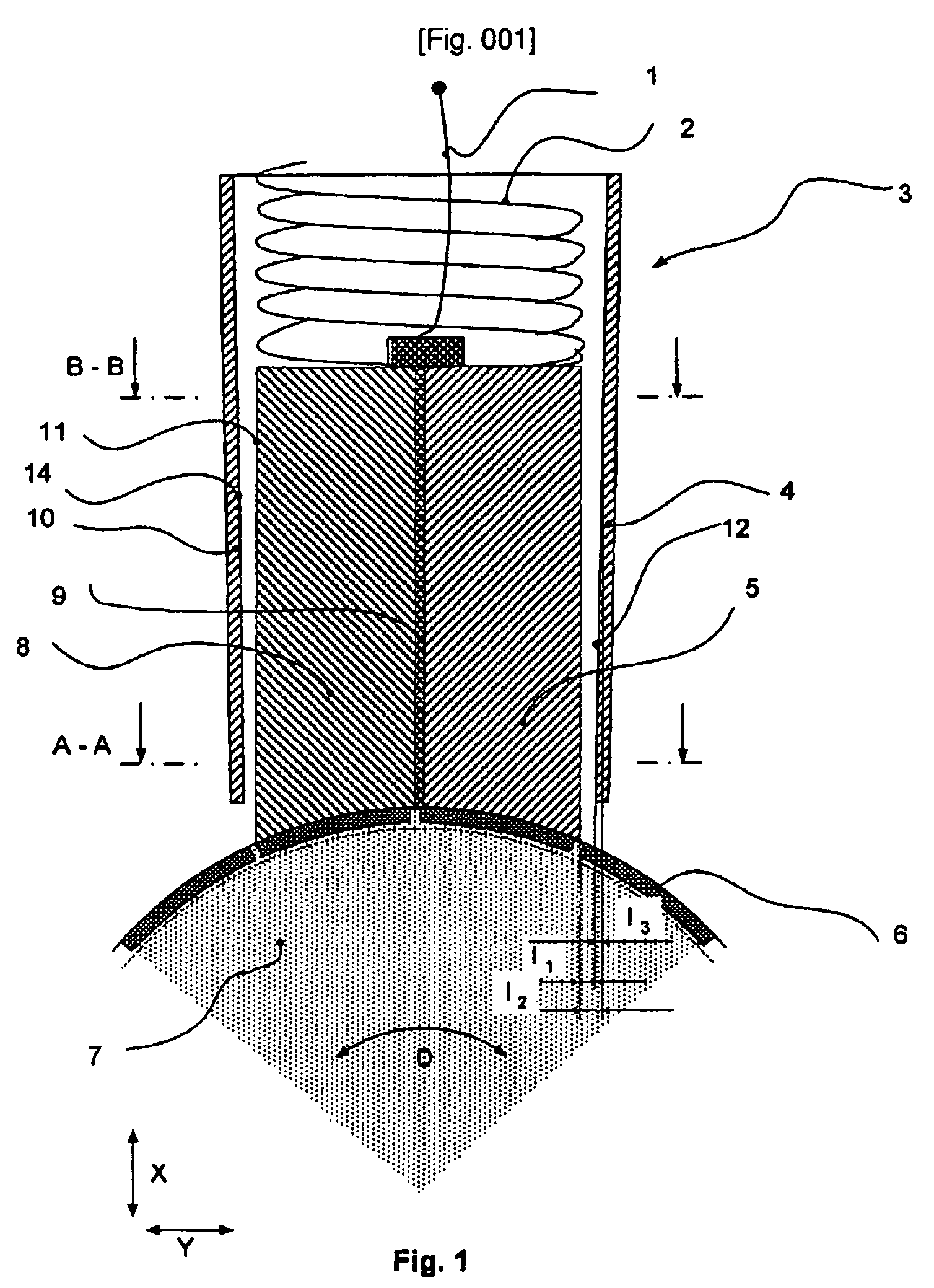

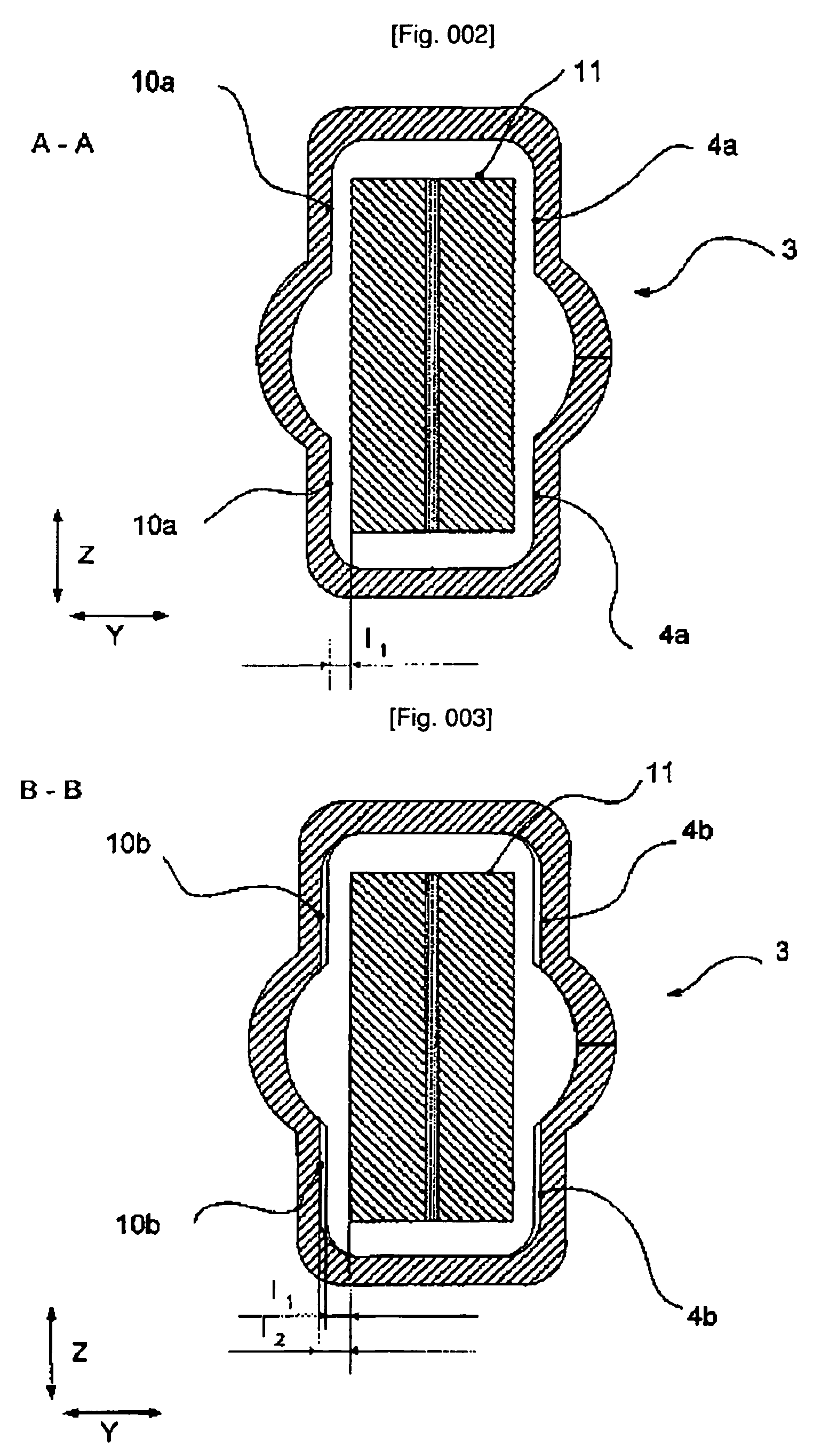

Fluidized-bed boiler integrating multifunctional inertia-gravity separator with multiple furnace profiles

InactiveUS20160146452A1Improve efficiencyEmission reductionFluidized bed combustionSteam generation heating methodsSuperheaterEngineering

A fluidized-bed boiler integrating a multifunctional inertia-gravity separator and a plurality of models of boilers, the fluidized-bed boiler being a steam boiler, a hot-water boiler or a phase-transformation boiler, the fluidized-bed boiler comprising a hearth, a single / double horizontal drum, a vertical single-drum / double-drum, vertical and horizontal headers, vertical and horizontal membrane wells, a primary high-temperature inertia-gravity water-cooling separator, a secondary low-temperature inertia-gravity water-cooling separator(a double-stage inertia-gravity water-cooling separator), a single-stage high-temperature water-cooling inertia-gravity separator, an equalizing, separating and heat storing device, a membrane water-cooling wall shaft, a shell shaft and a dry-wall shaft, the primary, secondary and single-stage inertia-gravity separators comprising a guiding gas-solid directly-raising storage bin water-cooling wall, a guiding fume directly-raising storage bin spacer, a downward flue, an upward flue, a turning passage, a large capacity-capacity-expanding space, a storage bin and a back-feeding device, characterized in that the primary high-temperature water-cooling inertia-gravity separator is disposed in a space between the rear wall of the hearth and the front wall of the shaft; the secondary low-temperature water-cooling inertia-gravity separator is disposed at the height-equal border of the lower end of a multi-stage over-heater or coal economizer within the shaft and a bending point of the lower end of a vertical segment of the rear wall of the primary high-temperature separator, and extends downward; a fume inlet is separately provided in the front upper part of each of the two-stage separators, and a fume outlet is separately provided in the rear upper part thereof; and the front sidewall and a rear sidewall are a heated water-cooling wail and an insulating wall, which are integrated to the main body of the boiler.

Owner:WANG LING +1

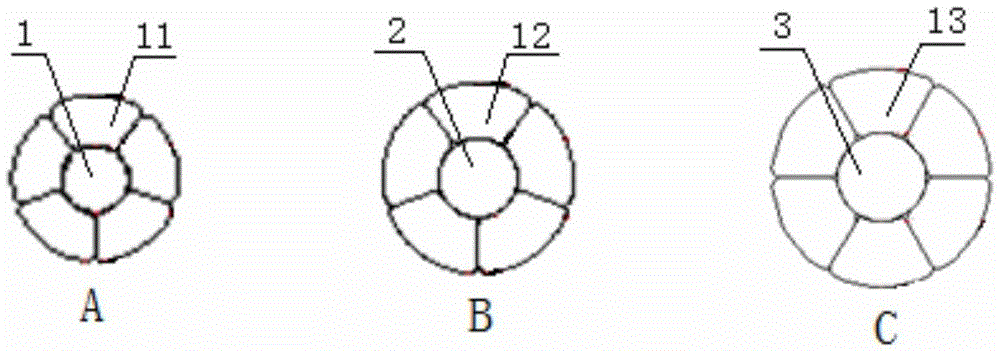

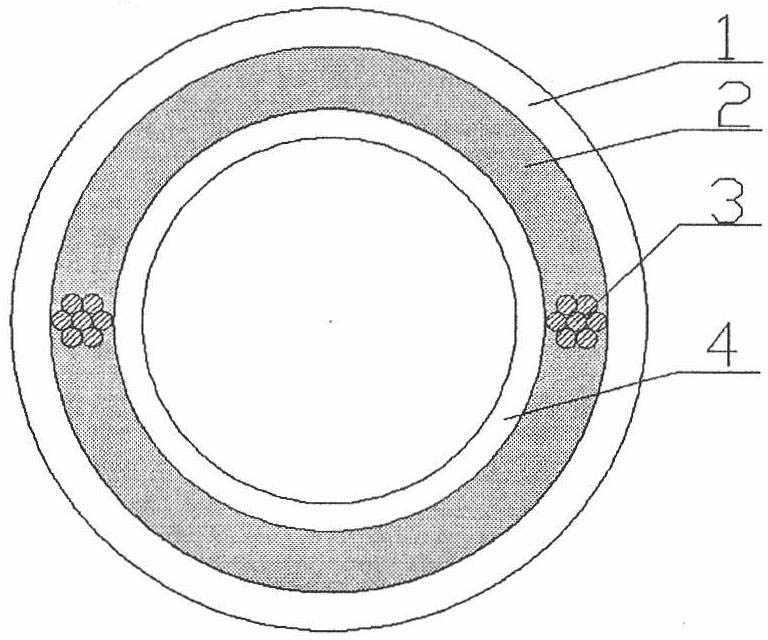

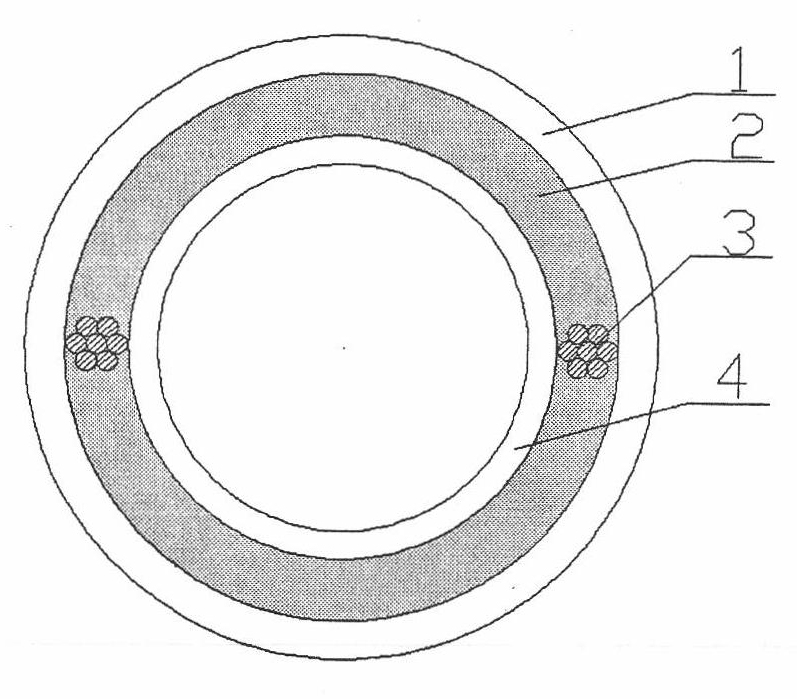

Shaped wire stranded cable conductor and production method thereof

ActiveCN104064256BStable structureStable structure and no loose stocksNon-insulated conductorsCable/conductor manufactureElectrical conductorEngineering

The invention relates to a special-shaped wire strand cable conductor and a production method of the special-shaped wire strand cable conductor and relates to a wire and cable special-shaped wire strand round conductor with the nominal cross section ranging from 25 mm<2> to 630 mm<2>. The cable conductor comprises a single round wire and special-shaped wires with all the strand layers designed in the tile-shaped structure according to the specifications of cables. The production method includes the steps that first, according to the designed special-shaped wire structure, the single round wire in the center is manufactured in a drawing mode through a drawbench, and then the special-shaped wires of various specifications of strand layer structures are manufactured on a water tank type or sliding type or fractional motor type drawbench in a drawing mode through a special-shaped high-speed wire drawing die; the round line in the center is placed on a payoff rack of a wire stranding machine, and all the stranding layer special-shaped wires are placed on a frame winch or fork winch and manufactured into the special-shaped wire strand cable conductor through stranding. The outer surface of the cable conductor is smooth and free of burrs, the gap between single wires is small, the filling coefficient is larger than 0.98, and the strand cable conductor is stable in structure. The production method is high in technology universality, and updating and upgrading of the products can be achieved in small and medium-sized enterprises through the technology.

Owner:湖北易缆通模具有限公司

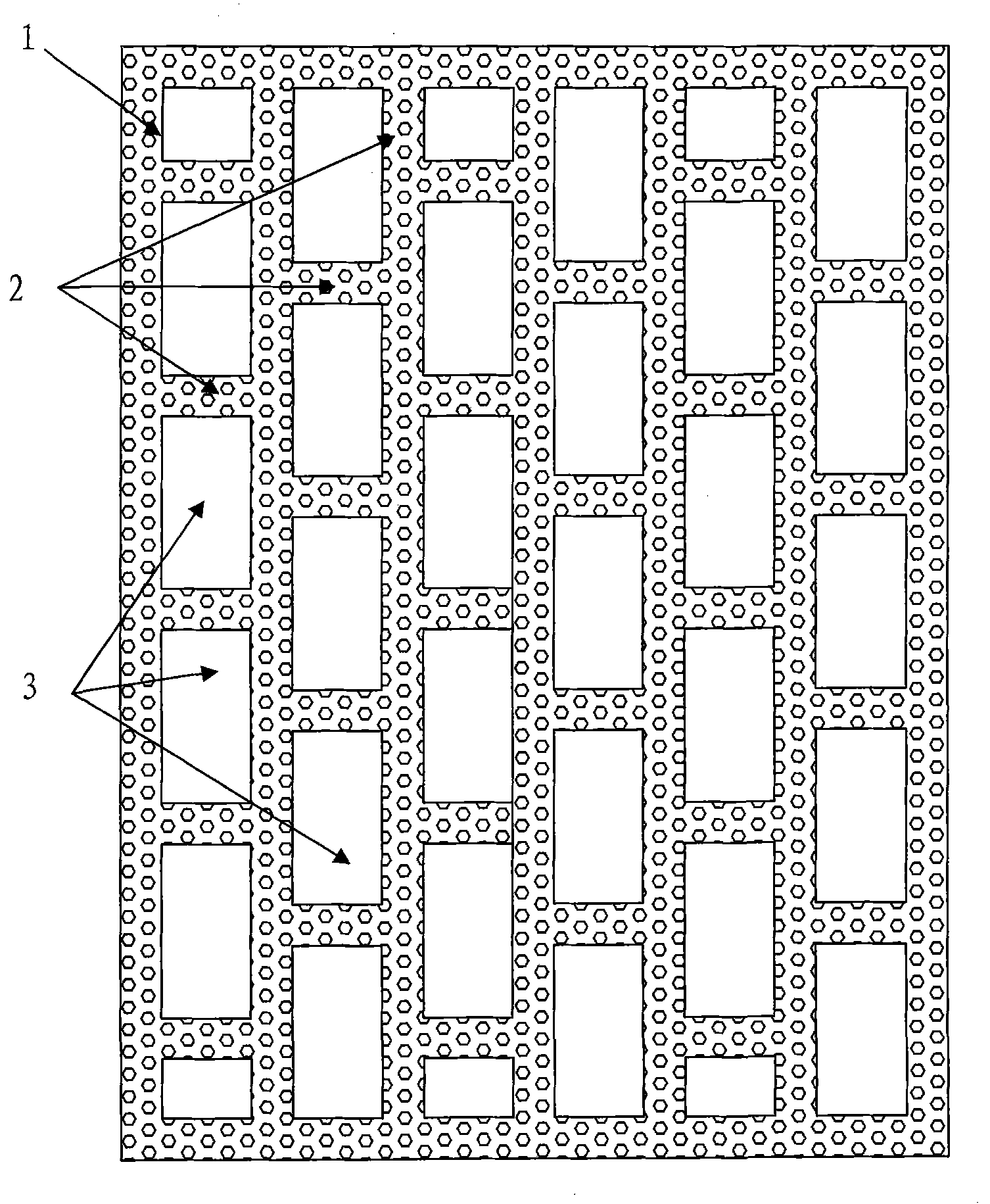

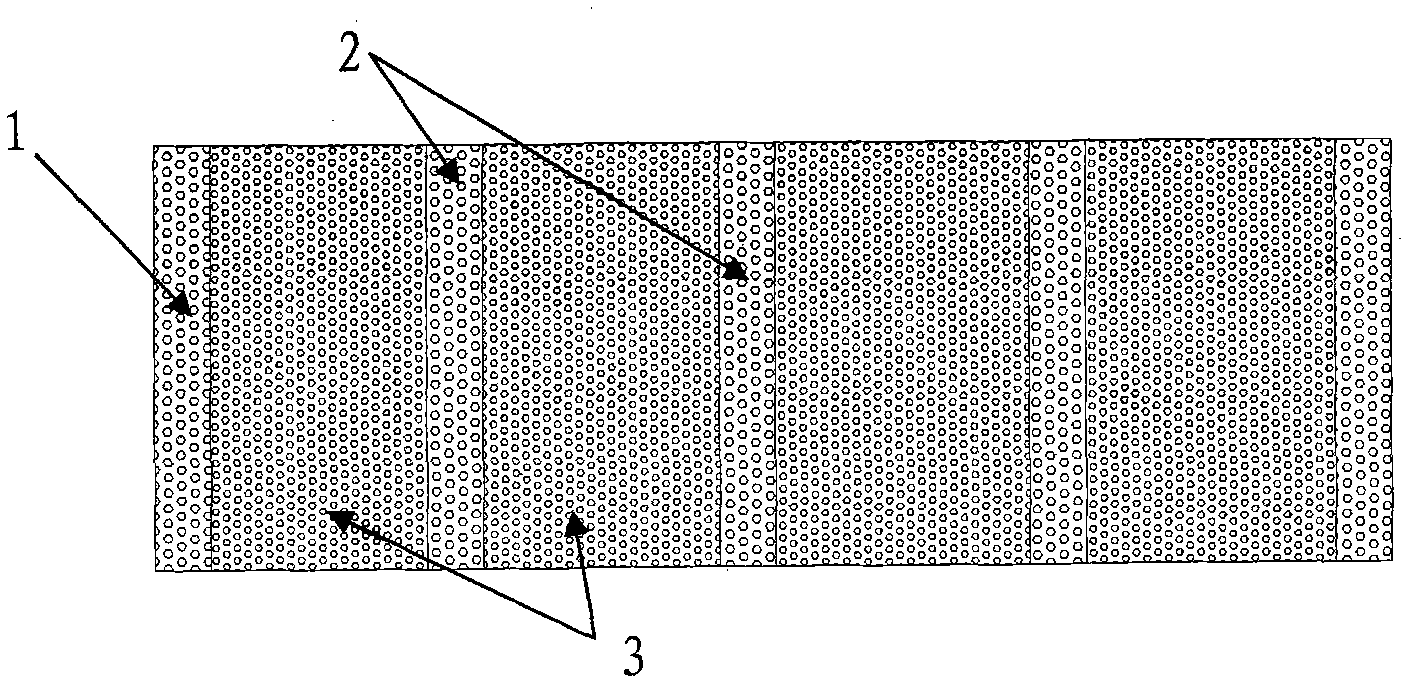

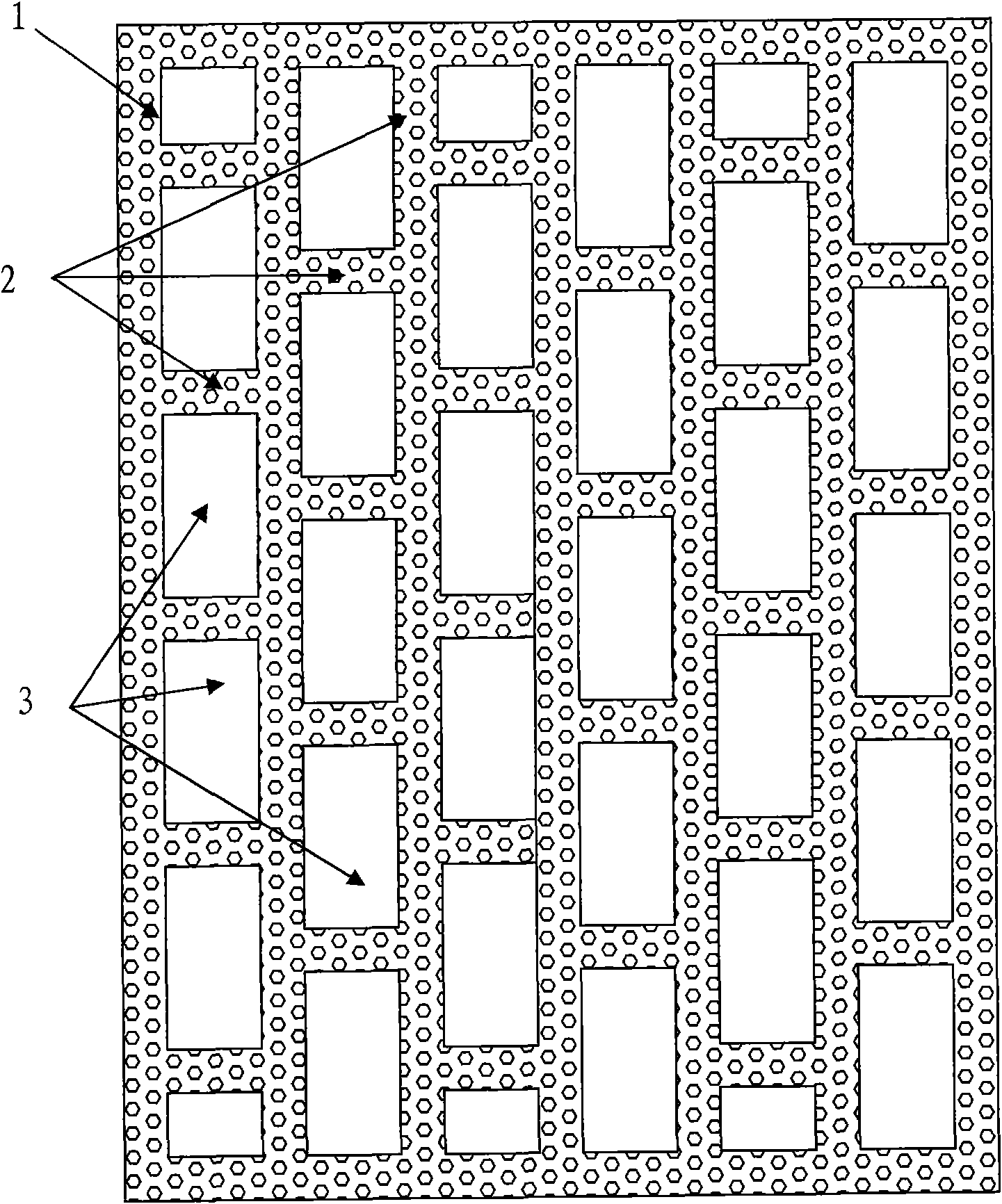

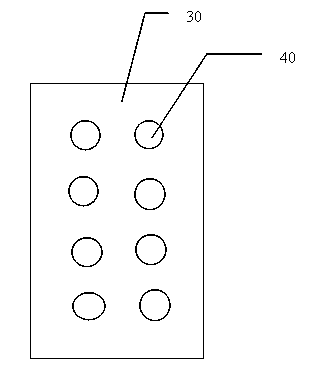

Micropore insulation baked brick and manufacturing method thereof

The invention discloses a micropore baked brick which is invented for solving the problems of poor insulation effect and the like of a shale baked brick in the prior art. The micropore baked brick comprises a brick body formed by baking shale, and micropores with diameters of above 0.5mm are formed on the brick body. After the structure is adopted, the micropores with the diameters of above 0.5mm are formed on the brick body, thus the brick body has light weight; and the formed micropores have a certain insulation effect, and can play a role in saving materials. The micropore baked brick has a simple structure, and has large strength so as not easy to damage due to the support function of a brick rib. When insulation materials are filled in the brick holes at the middle, thus the insulation performance of the brick body can be further enhanced; and the insulation materials are filled in the brick body without generating displacement and deformation, thus better mechanical strength and performance can be maintained.

Owner:中节能绿色建筑产业有限公司

Furnace body of atmosphere protection three-pushed-slab kiln

The invention discloses a furnace body of an atmosphere protection three-pushed-slab kiln. The furnace body comprises a furnace shell, a refractory material brick body and a heating device. The refractory material brick body comprises guide rails and guide blocks, wherein the guide rails and the guide blocks are used for carrying and pushing push plates and saggers. The guide rails and the guide blocks penetrate a kiln cavity and extend out of the kiln cavity. The three rows of pushed slabs located on the same transverse position are spaced through the guide blocks. The furnace body has the beneficial effects of being high in production efficiency, large in yield, even in sintering, stable in pushing, high in energy utilization rate, capable of saving energy, environment-friendly and the like.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

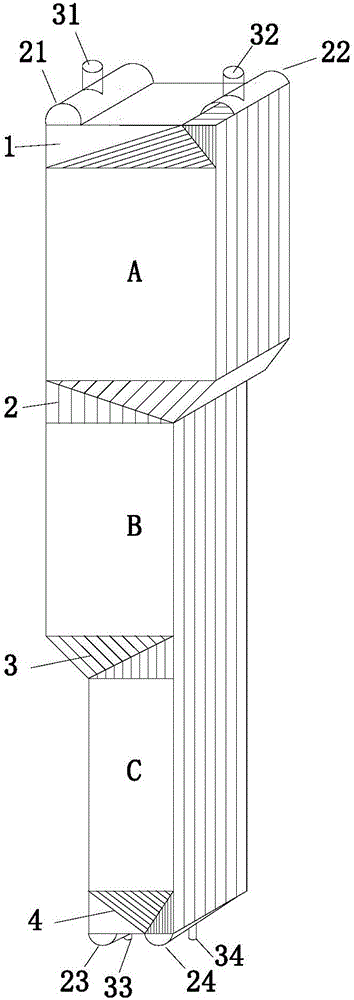

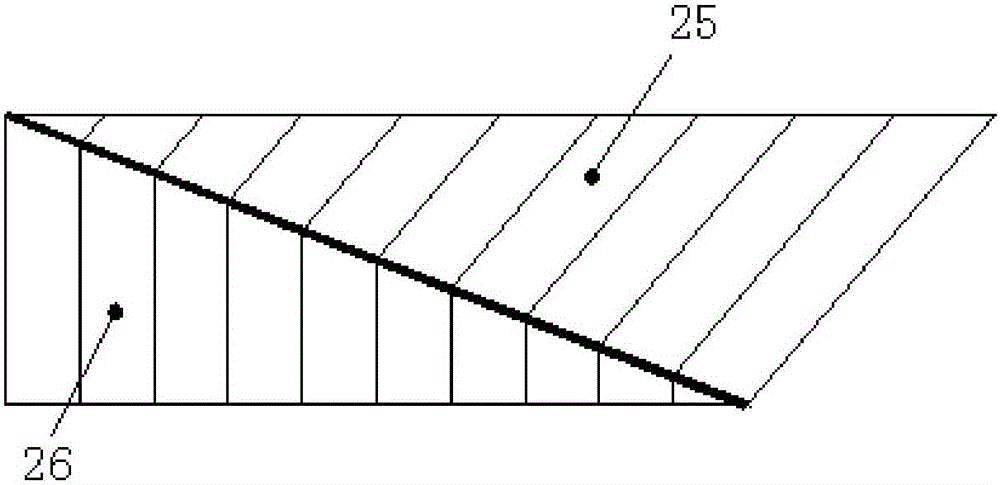

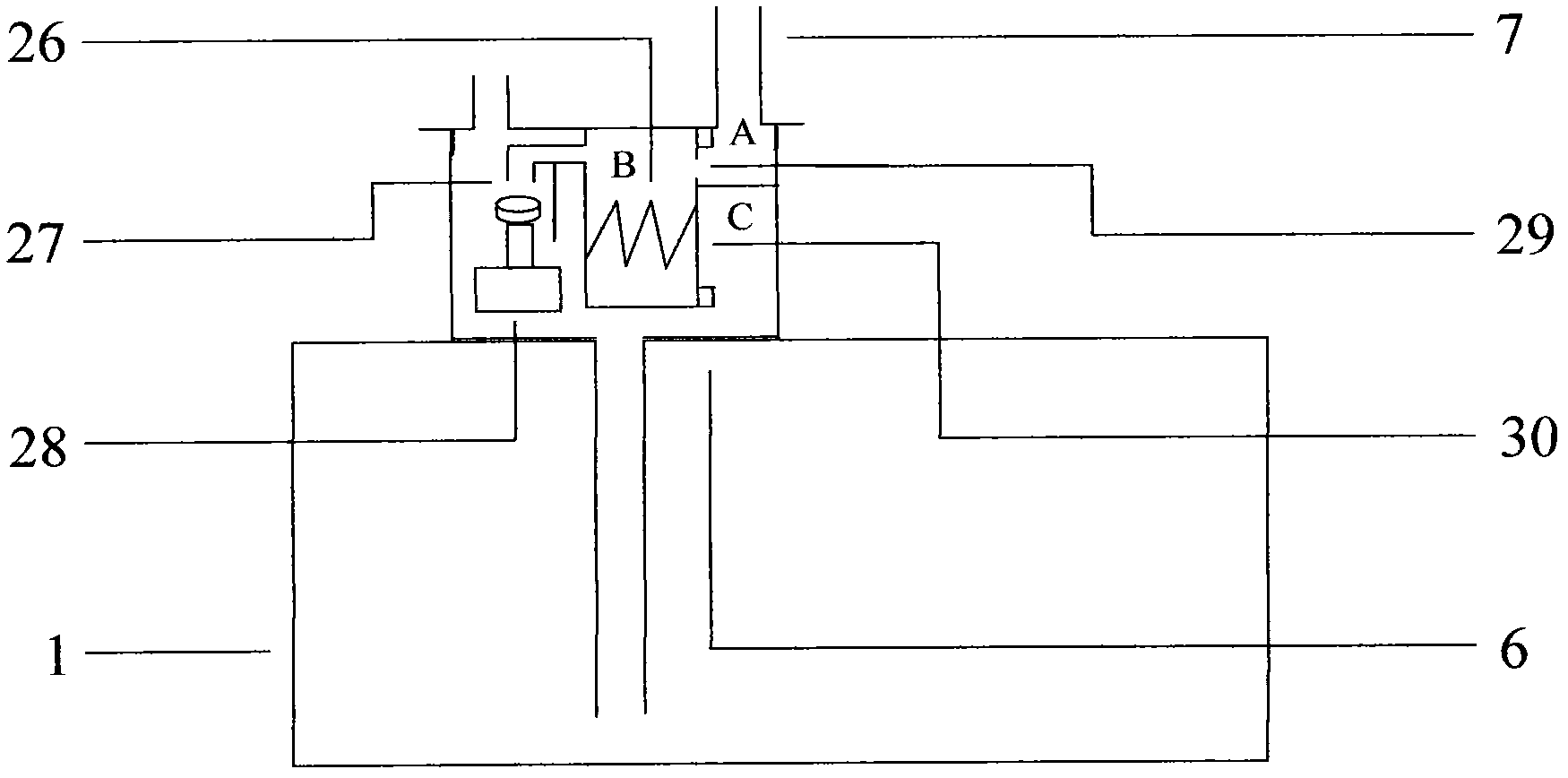

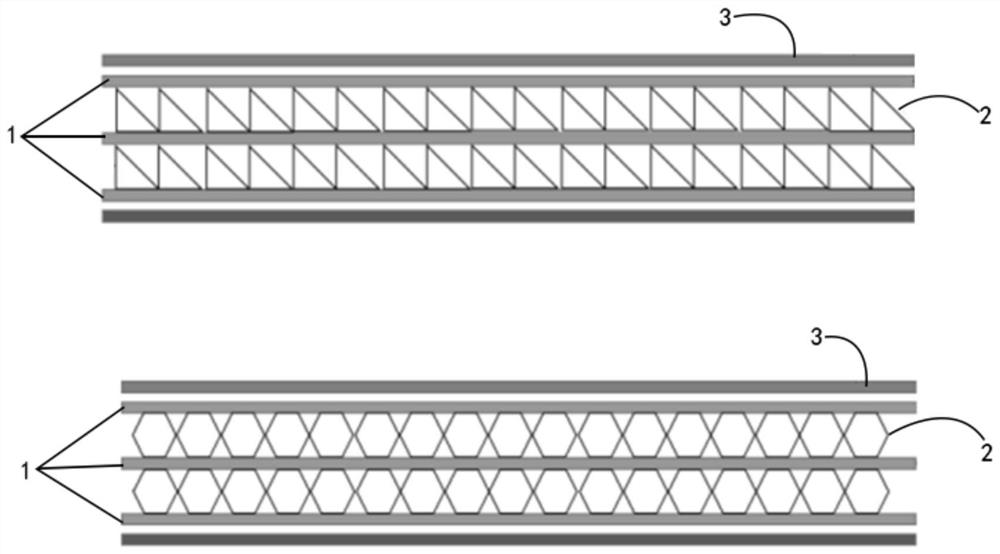

Flow-area-variable backflow plate-fin heat exchanger and control method thereof

InactiveCN105157455AReasonable pressure dropFirmly connectedStationary plate conduit assembliesRight triangleDevice form

The invention discloses a flow-area-variable backflow plate-fin heat exchanger and a control method thereof. The flow-area-variable backflow plate-fin heat exchanger comprises a high-temperature region heat exchange core body A, a medium-temperature region heat exchange core body B and a low-temperature region heat exchange core body C. The three regions are connected through a first core body middle flow guide device and a second core body middle flow guide device. The two core body flow guide devices are right trapezoid flow guide devices formed by welding obtuse-angled triangular flow guide devices and right-angled triangular flow guide devices in a brazing manner. The channel widths of the high-temperature region heat exchange core body, the medium-temperature region heat exchange core body and the low-temperature region heat exchange core body are successively decreased from top to bottom. Compared with a manner that plate-fin heat exchangers of different sizes are connected in series in the field of phase-change heat exchange, the flow-area-variable backflow plate-fin heat exchanger has the beneficial effects that machining is easy, materials are saved, and pipe connection is simple, the heat exchanger is especially applied to a deeply-low-temperature mixing working medium cooling system; heat preservation of the high-low temperature regions is more reasonable, and heat preservation materials are saved; and downward falling film boiling and upward concentration can be achieved by arranging the flow-area-variable backflow plate-fin heat exchanger in an inverted manner.

Owner:SOUTH CHINA UNIV OF TECH

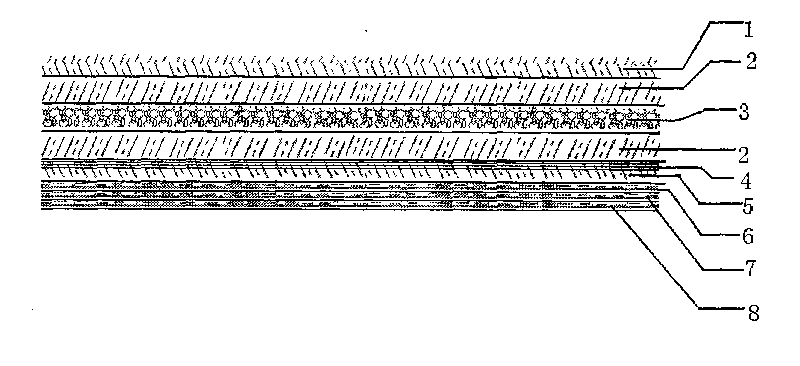

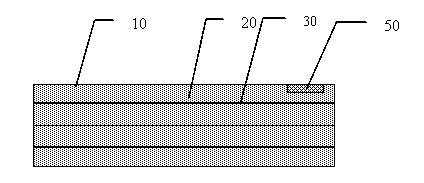

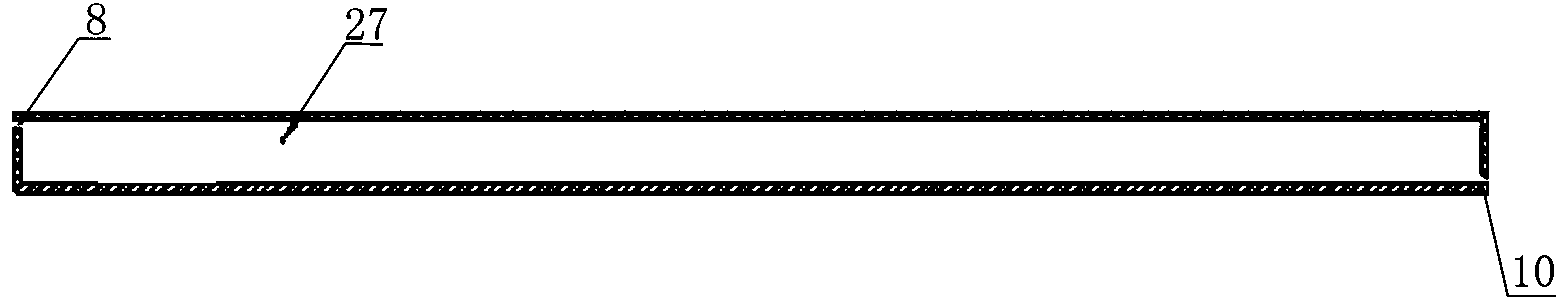

Vacuum insulated panel added with infrared reflecting layer and preparation method thereof

InactiveCN103574227AImprove insulation efficiencySave insulation materialThermal insulationPipe protection by thermal insulationHigh resistanceReflective layer

The invention discloses a vacuum insulated panel added with an infrared reflecting layer and a preparation method thereof. The vacuum insulated panel is characterized by comprising a high resistance membrane, an insulation material, an infrared reflecting film and a degasser, wherein a pretreated core material and the infrared reflecting membrane are stacked in sequence, and the area of the membrane is equal to the area of the core material. The vacuum insulated panel added with the infrared reflecting layer and the preparation method thereof have the advantages that the thermal insulation efficiency of the vacuum insulated panel is remarkably improved by the vacuum insulated panel, the thermal insulation material is saved, and the thickness of the vacuum insulated panel is reduced. The vacuum insulated panel is widely applied to the fields of cold storage of refrigerators and refrigeration houses, containers, medical incubators, aerospace, communication and transportation, food industry and novel building materials, in particular to the field with the especially high requirements on the heat-insulating property.

Owner:SUZHOU V I P NEW MATERIAL

Steam direct pressure type drying device of veneer materials

InactiveCN104006634AFast dryingReduce heat lossDrying gas arrangementsDrying machines with local agitationLiquid waterWater storage tank

The invention discloses a steam direct pressure type drying device of veneer materials. The steam direct pressure type drying device of the veneer materials comprises a drying oven, a steam boiler and a steam air supply pipe connecting the drying oven and the steam boiler. A horizontally arranged drying frame is arranged in the drying oven, the top layer and the bottom layer of the drying frame are an upper pressure bearing limiting plate and a lower pressure bearing limiting plate which are made of steel plates respectively, a connecting rod is arranged between the limiting plates and fixedly connected with the limiting plates, enclosed hollow heating plates made of stainless steel sheets are arranged between the limiting plates at intervals in parallel, the side edges of all layers of heating plates are fixedly connected with the connecting rod, a steam inlet connecting pipeline is arranged on the same side face of the heating plates and is communicated with the boiler steam air supply pipe, a gas-liquid inlet connecting pipeline is arranged on the other side face of the heating plates and is communicated with a gas-liquid water outlet pipe, and the gas-liquid water outlet pipe is communicated with a water storage tank. According to the steam direct pressure type drying device of the veneer materials, the heat energy for drying the materials is transmitted to the materials through the steam and is separated from the materials only through a thin layer of stainless steel sheet, and pressure is directly provided by the steam, so that a mechanism for providing pressure and energy consumption are omitted, the device is compact in structure, and the defects that an existing device is high in manufacturing cost and large in energy consumption are overcome.

Owner:黄达宏

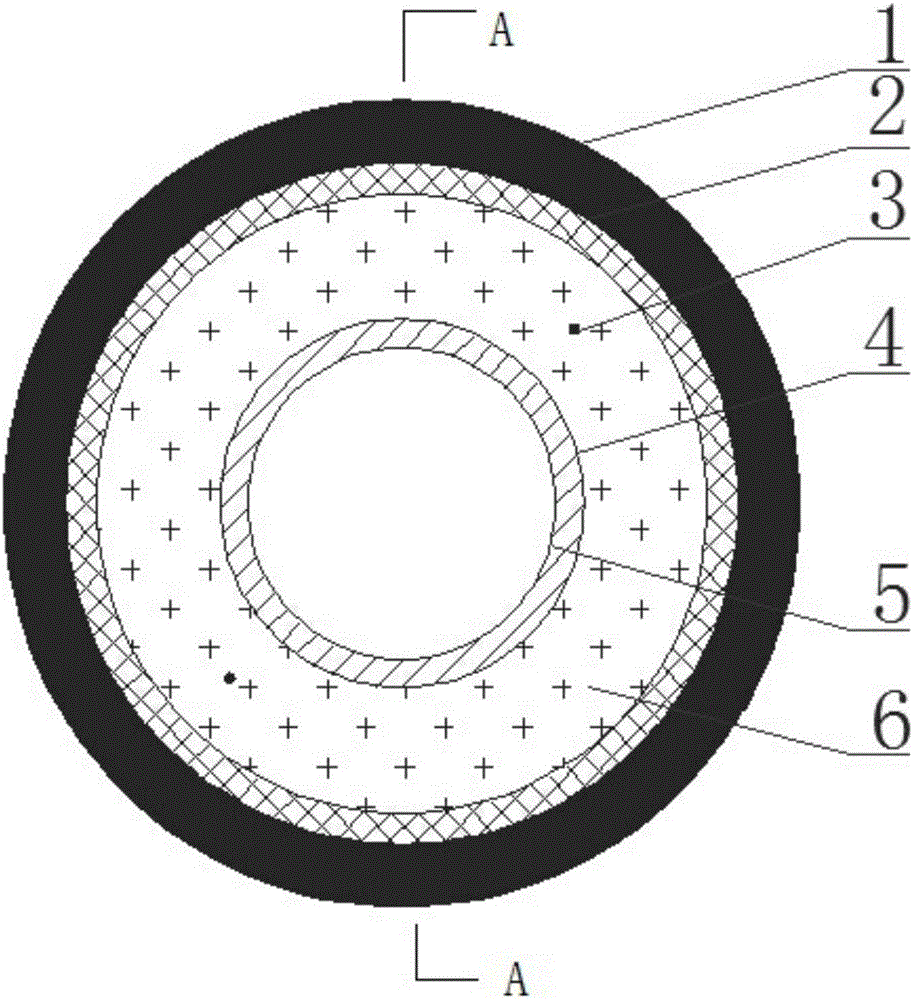

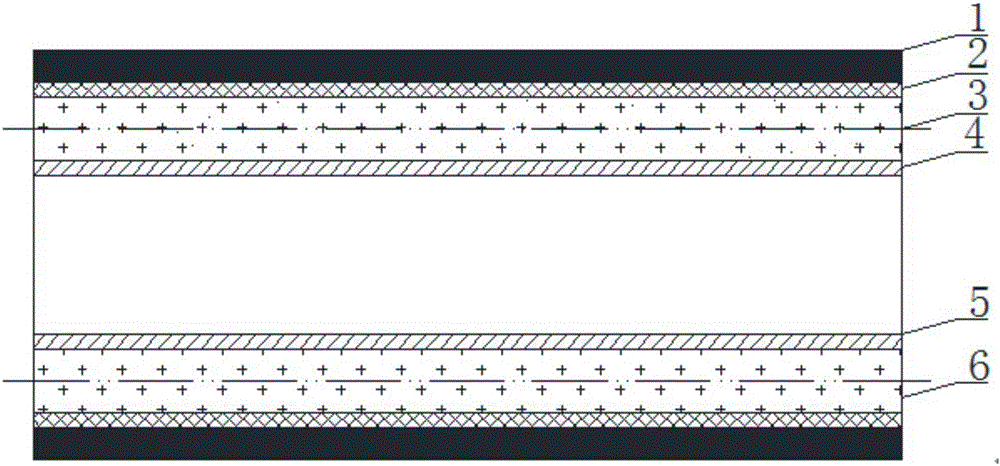

Prefabricated cryogenic heat-preservation pipeline

InactiveCN106015765ASimple structureEasy to makeThermal insulationCorrosion preventionLiquid oxygenLiquefied natural gas

Provided is a prefabricated cryogenic heat-preservation pipeline. The pipeline is composed of a working steel pipe, an anticorrosive layer, a heat-preservation layer, a waterproof and moisture-proof layer, an outer protective layer and an alarm detecting line, wherein the waterproof and moisture-proof layer is provided with a bonding surface. The pipeline anticorrosive layer, the heat-preservation layer and the waterproof and moisture-proof layer provided with the bonding surface are sequentially sprayed onto the steel pipe progressing spirally through a spraying device. The alarm detecting line is pre-buried in the heat-preservation layer. Molten polyethylene bands are adopted for the outer protective layer to be spirally wound on the bonding surface of the waterproof and moisture-proof layer to form a firm integrated structure. The thicknesses of all the layers can be randomly adjusted according to design requirements; the production process is simple; and the density of materials for each layer is even in distribution. The prefabricated spray-coating-wound cryogenic heat-preservation pipeline can resist the temperature of minus 196 DEG C or above and can transport cryogenic matter such as liquid nitrogen, liquefied natural gas, liquid oxygen and liquefied petroleum gas over a long distance. The prefabricated cryogenic heat-preservation pipeline is simple in structure, convenient to manufacture and capable of shortening the site construction period, reducing material wastage and lowering medium transportation cost.

Owner:TIANJIN PIPELINE ENG GROUP

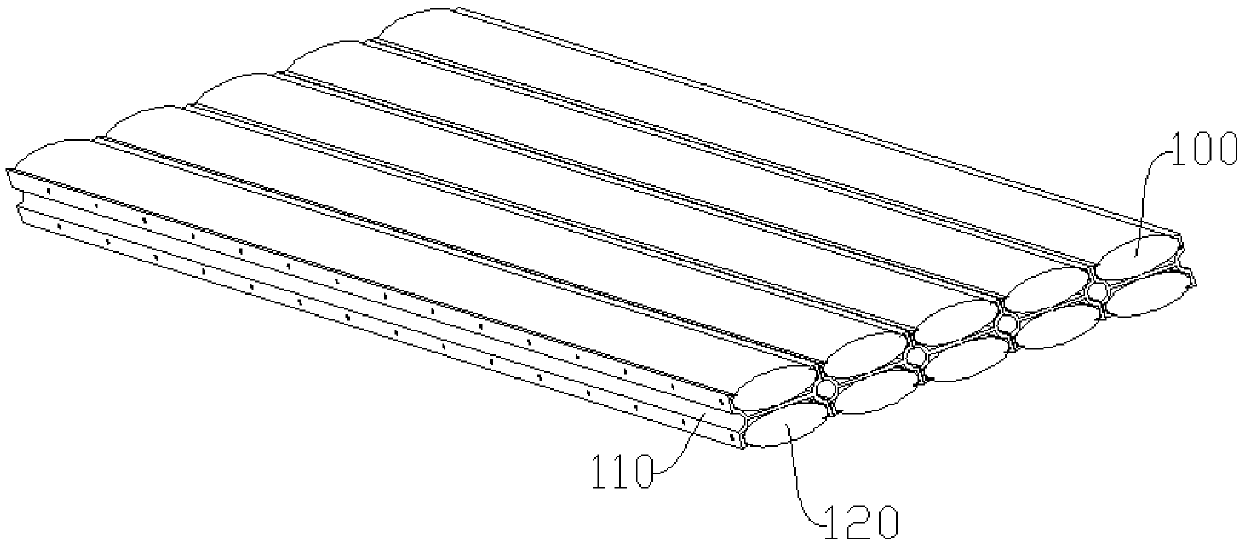

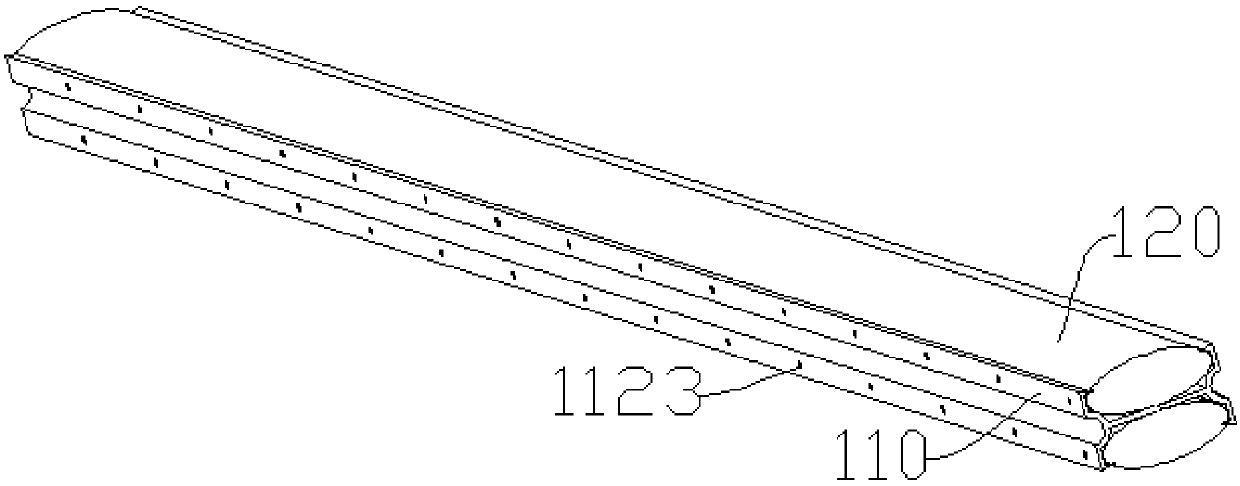

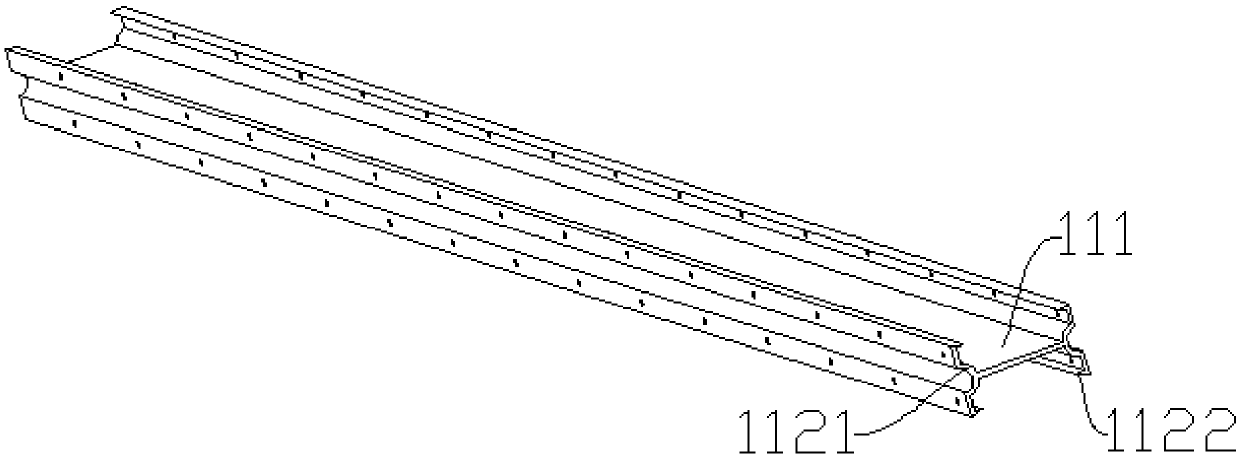

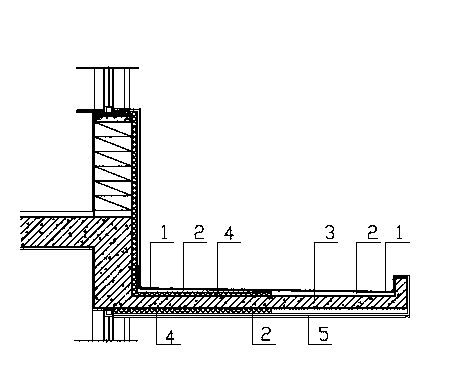

Prefabricated air feeding cooling beam and production method thereof

ActiveCN106760188ASimple designReduce noiseDucting arrangementsLighting and heating apparatusReinforced concreteEngineering

The invention provides a prefabricated air feeding cooling beam and a production method thereof and relates to the field of air-conditioning systems. The prefabricated air feeding cooling beam comprises a cooling beam main body, an air feeding piece and an air returning piece; and the cooling beam main body is a hollow box type beam, and an air pipe is installed in the cooling beam main body, of a hollow frame structure and embedded into the cooling beam main body. The cooling beam main body is integrated with the air pipe through reinforced concrete. An air inlet communicating with the air pipe is formed in the side wall of the cooling beam main body, and at least four ventilation openings communicating with the air pipe are formed in the bottom of the cooling beam main body in the length direction of the cooling beam main body; and the air feeding piece communicates with the ventilation openings, and the air returning piece communicates with the air inlet. By combining a normal air feeding pipeline, a tail end heat exchanging coil pipe and a building prefabricated beam, a system can achieve the air-conditioning aim through convection and radiation between indoor air and the coil pipe, noise generated by the air pipe during running can be effectively reduced while beam loading is not influenced, maintenance cost is low, more energy is saved, and people feel comfortable.

Owner:SICHUAN UNIV

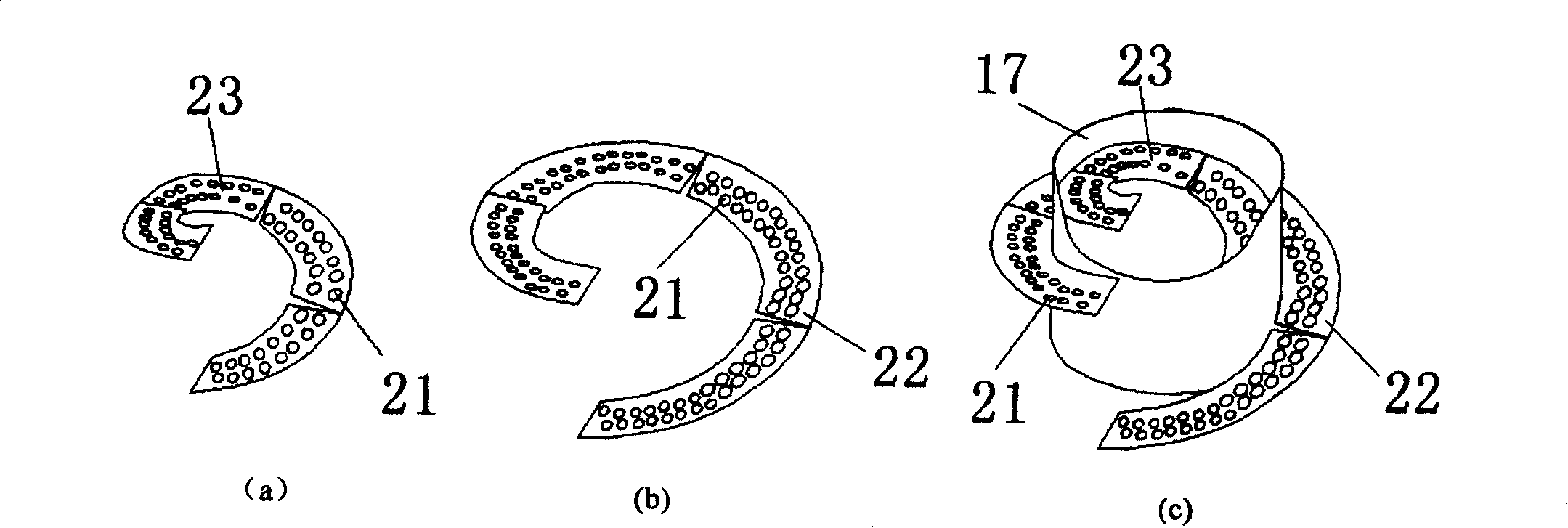

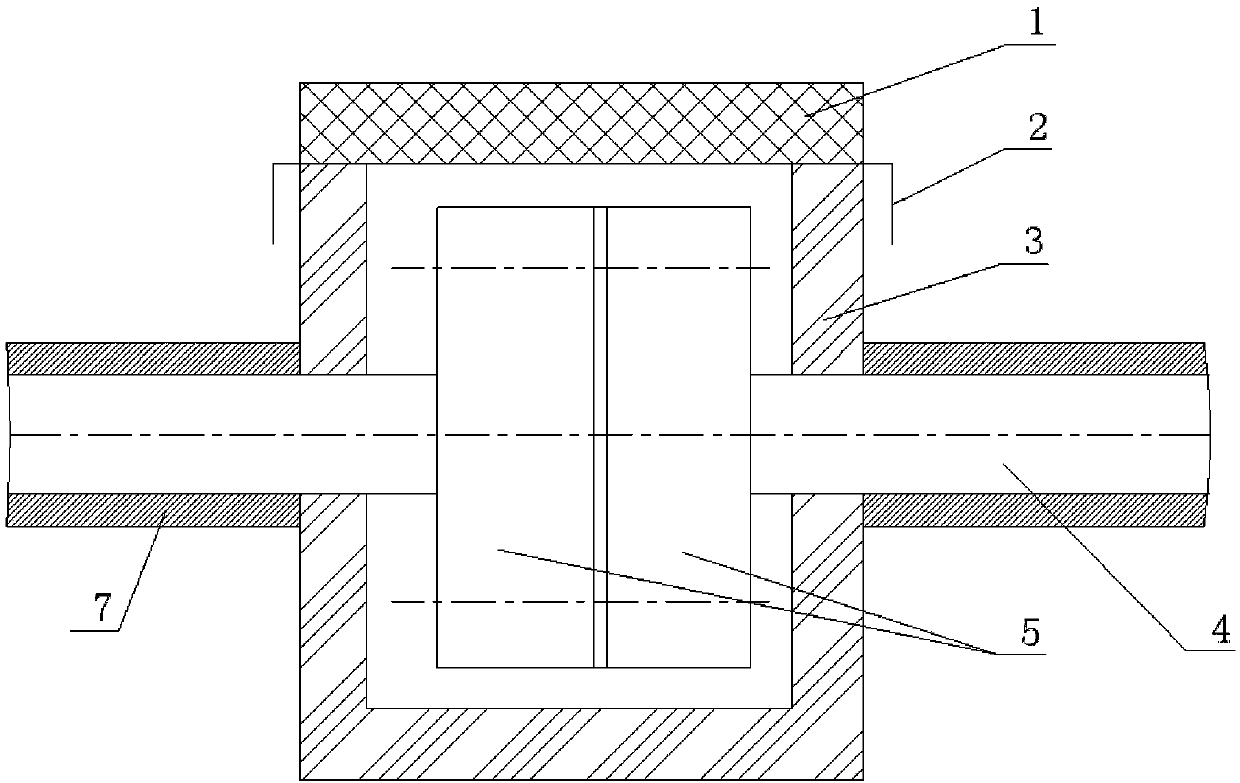

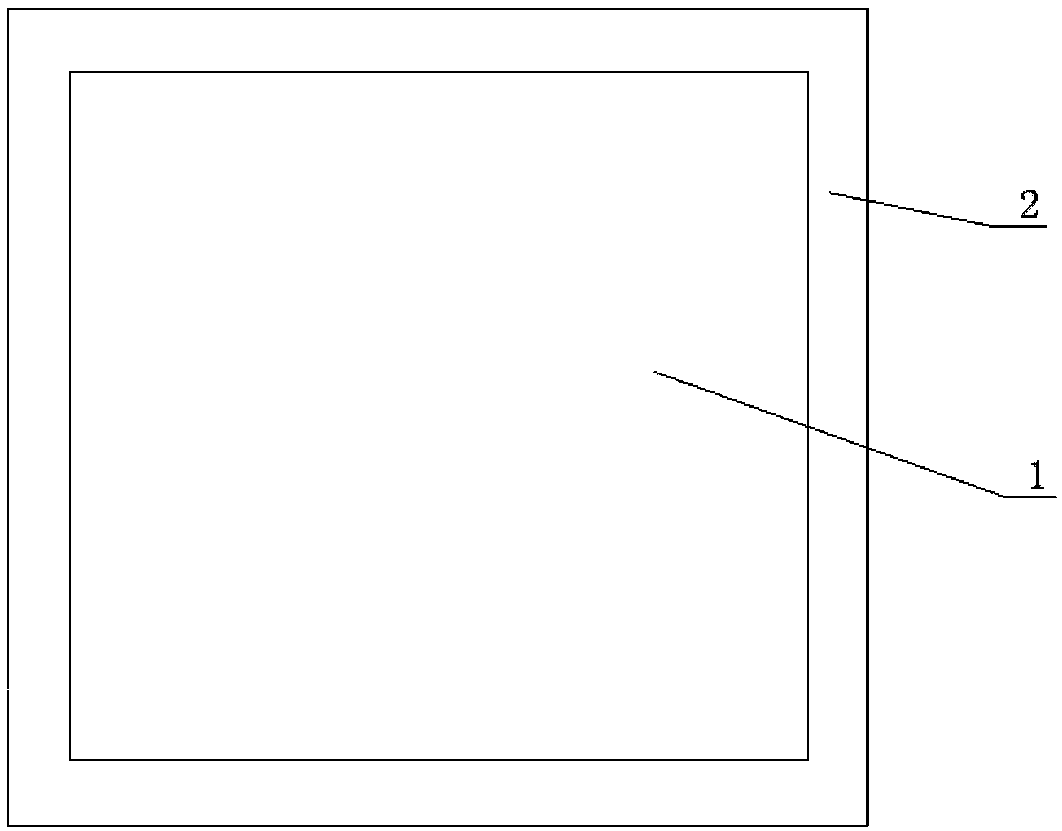

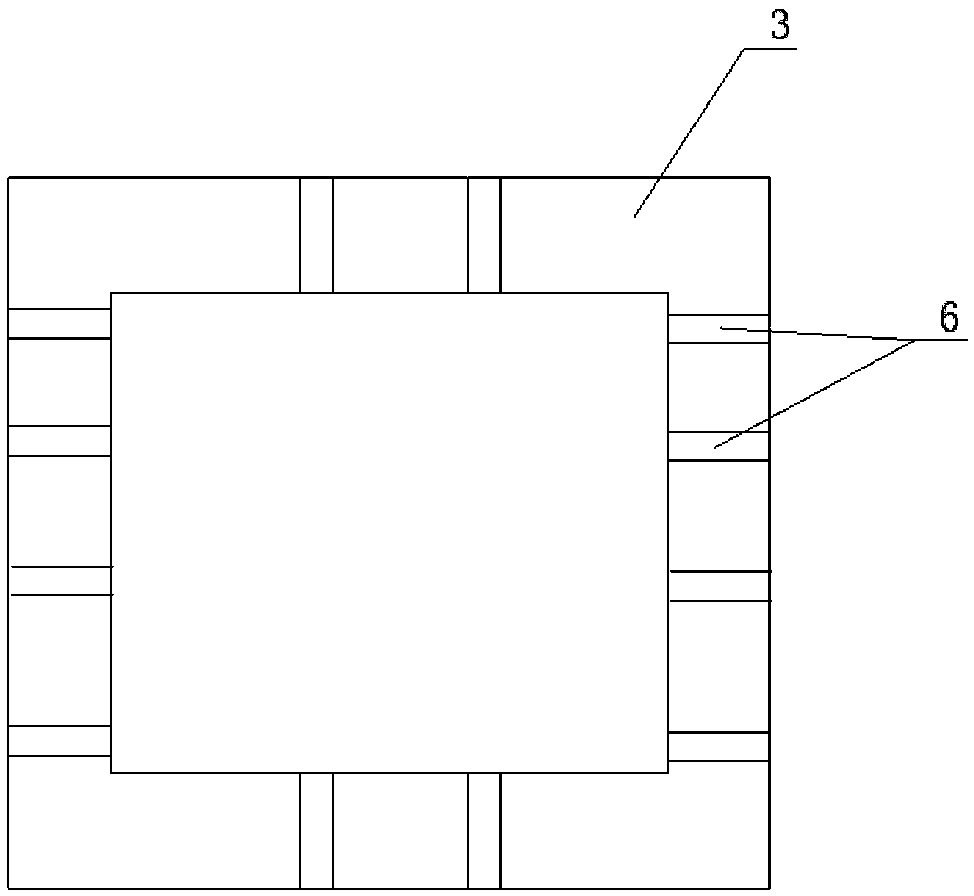

Multiple shell pass screw baffle pipe shell type heat exchanger

ActiveCN100386586CCompact structureExtended service lifeHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The multiple shell spiral baffle shell-and-tube heat exchanger includes one shell, one central tube in the center oft shell, two tube plates on ends of the shell and with separate end covers, one inlet pipe and one outlet pipe beside the tube, one heat exchange tube bundle, one inlet pipe and one outlet pipe beside the shell, one external spiral baffle plate and one internal spiral baffle plate, and one internal casing between the external spiral baffle plate and the internal spiral baffle plate. The shell, the external spiral baffle plate and the internal casing enclose one external spiral shell pass; and the internal casing, the internal spiral baffle plate and the central tube enclose one internal spiral shell pass, so that one two-shell pass spiral baffle plate shell-and-tube heat exchanger is formed. Adopting two or more internal casings can form multiple spiral shell pass. The present invention has raised heat exchange efficiency, compact heat exchanger structure, less vibration, high safety, less scaling and long service life.

Owner:上海益焓能源科技有限公司

Brush bag for a dynamo-electric machine

InactiveUS7671507B2Large playBig distanceRotary current collectorDynamo-electric machinesElectric machineDynamo

A brush bag, a brush and a current transfer unit for a dynamo-electric machine comprising a commutator, in particular for an electromotor. The current transfer unit comprises at least the brush, which is embodied, in particular, as a multi-layer carbon brush, and a brush bag. The brush bag is configured in such a manner that the distance between the brush and the brush bag in a front guiding area is smaller than the distance in a rear guiding area. Beating of the brush on the brush bag is visibly reduced due to the configuration thereof and noise caused by the beat is avoided.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Automatic temperature control anti-freezing pipe for solar water heater

InactiveCN102620454APrevent freezingAvoid breakingSolar heat devicesSolar thermal energy generationTemperature controlAnti freezing

The invention discloses an automatic temperature control anti-freezing pipe for a solar water heater. By adoption of the automatic temperature control anti-freezing pipe for the solar water heater, heat-preserving materials can be saved, and the freezing blocking and breakage of a pipeline are effectively prevented. The automatic temperature control anti-freezing pipe for the solar water heater comprises an inner layer (4) and a coverage layer (1), wherein an electric heat tracing layer (2) is arranged between the inner layer (4) and the coverage layer (1); and a conductor (3) is arranged in the electric heat tracing layer (2).

Owner:许锋

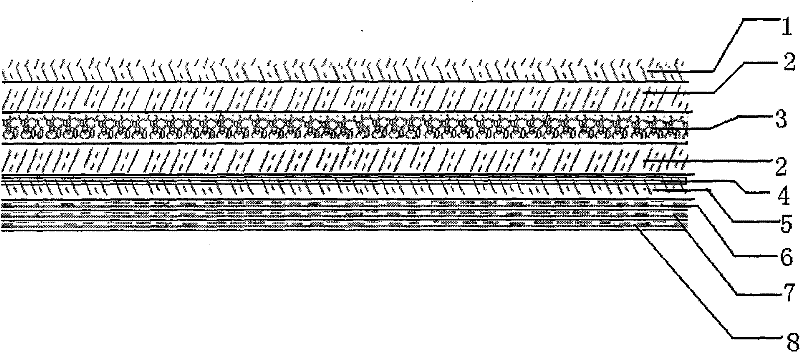

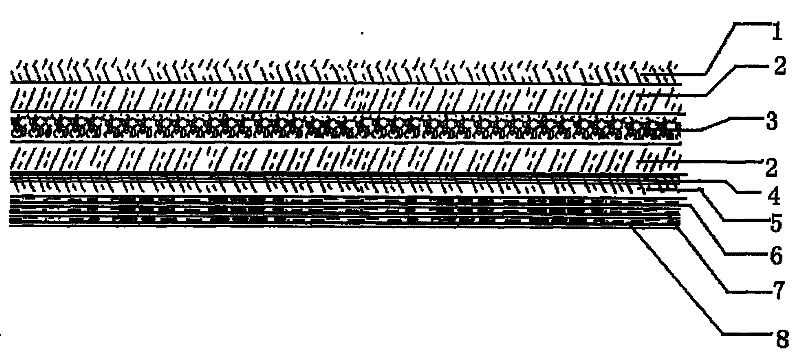

General insulation composite material for exterior wall and application method

InactiveCN101691800BImprove insulation performanceImprove insulation effectCovering/liningsSurface layerInsulation layer

The invention relates to an insulation composite material for an exterior wall and an application method. The composite material is characterized in that the interior and exterior surface layers of a rigid polyurethane layer are combined with inorganic hollow microsphere polymer composite insulation layers, an anti-crack mortar layer is arranged on the exterior inorganic hollow microsphere polymer composite insulation layer and a wall decoration layer is combined with the exterior surface layer of the anti-crack mortar layer. The application method is as follows: the exterior wall to be treated is sequentially coated with the interior hollow microsphere polymer composite insulation layer, rigid polyurethane and the exterior hollow microsphere polymer composite insulation layer, the anti-crack mortar layer is coated on the exterior hollow microsphere polymer composite insulation layer and the wall decoration surface layer is coated on the exterior surface layer of the anti-crack mortarlayer. The composite material has good heat insulation property and quick construction method, is strongly adaptive to main structures, reaches higher flame retardant level, is energy-saving and environment-friendly, is suitable for insulation of various walls, especially exterior walls, and is applicable to floors.

Owner:东营丰力输送带有限公司

Insulation structure

InactiveCN109798418AEasy to replaceImprove insulation effectThermal insulationPipe protection by thermal insulationInsulation layerPulp and paper industry

The invention provides an insulation structure. The insulation structure comprises a plurality of insulation units detachably connected in parallel, wherein each insulation unit comprises an insulation bracket and insulation cotton; and the insulation cotton is symmetrically fixed on both sides of the insulation bracket. According to the insulation structure, an insulation layer with high heat preservation effect is formed by arranging and assembling.

Owner:新昌县瑞宏自动化设备有限公司

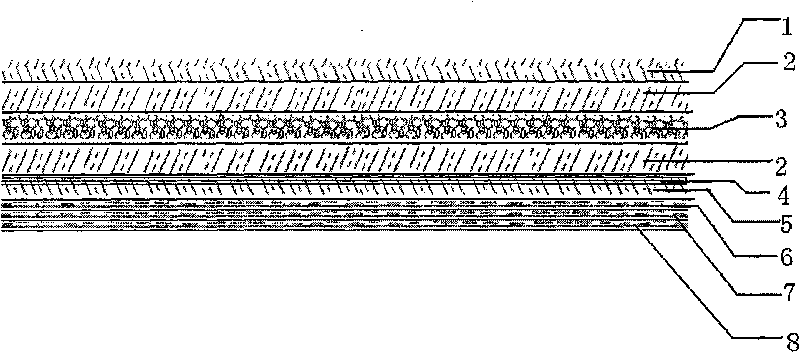

Horizontal plate thermal bridge structure

InactiveCN103669606ATo achieve the purpose of energy savingSave insulation materialHeat proofingThermal bridgeHeat resistance

The invention discloses a thermal bridge structure, and particularly relates to a horizontal plate thermal bridge structure. The horizontal plate thermal bridge structure is composed of a first waterproof mortar layer, a first polymer mortar gridding cloth, a first insulation board, a reinforced concrete plate, a second insulation board, a second polymer mortar gridding cloth, a second waterproof mortar layer and a finish coat. When a horizontal plate is too long and is larger than a length which meets the condition of non-condensate heat resistance, the part, beyond the length range corresponding to the requirement of the non-condensate heat resistance, of the horizontal plate is not insulated.

Owner:陈祥凤

A kind of insulation structure of isobutane dehydrogenation device

InactiveCN107166138BDoes not affect heat retentionInhibition of agglomerationThermal insulationPipe protection by thermal insulationInsulation layerHydrogen

The invention discloses a heat insulation structure of an isobutane dehydrogenation device. The heat insulation structure comprises pipelines connected through flanges, and heat insulation layers are arranged outside the pipelines. The heat insulation structure is characterized in that heat insulation chambers wrapping the flanges are arranged outside the flanges on the pipelines, each heat insulation chamber comprises a lower heat insulation chamber which can wrapping the corresponding flange and an upper heat insulation cover, the upper portion of each lower heat insulation chamber is provided with an opening, each upper heat insulation cover covers the opening of the corresponding lower heat insulation chamber, an upper port of each lower heat insulation chamber is provided with multiple grooves penetrating through the interior and exterior of the corresponding heat insulation chamber, the outer side of a lower port of each upper heat insulation cover is provided with a shield cover, each shield cover can cover the openings in the outer sides of the grooves in the upper port of the corresponding lower heat insulation chamber after closing of the corresponding upper heat insulation cover, and a gap is reserved between the outer side wall of each shield cover and the outer side wall of the corresponding lower heat insulation chamber. According to the heat insulation structure of the isobutane dehydrogenation device, the heat insulation effect is good, maintenance is convenient, leaked hydrogen can be effectively prevented from being gathered in the heat insulation chambers, and operation safety of the device is ensured.

Owner:山东海丰能源科技有限公司

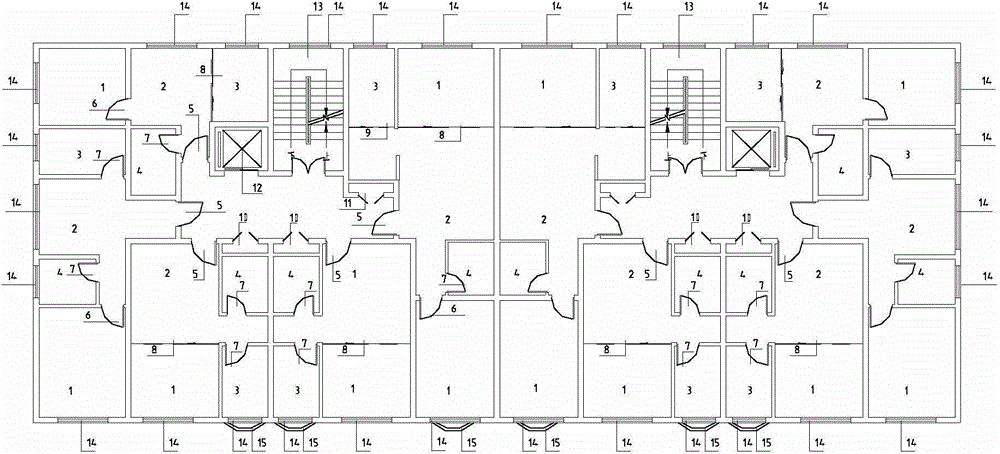

Large-depth land-saving residence

The invention discloses a large-depth land-saving residence which is composed of living rooms (1), bedrooms (2), kitchens (3), bathrooms (4), doors (5), bedroom doors (6), bathroom doors (7 ), kitchen doors (8), sliding doors (9), plumbing well doors (10), electric well doors (11), elevators (12), stairs (13), external windows (14) and flower beds (15). With adoption of the structure above, the residential depth is increased, and the width is reduced, so as to significantly save the land. Take one hectare of residential land for example, a 13.5 meters deep residence can save 690 square meters of land than a 10.5 meters deep residence. If concave-convex changes of external walls are reduced, areas of the external walls and roofs are reduced, the shape is regular, the shape coefficient is small, the used heat-preservation materials is reduced, the residential heat consumption is reduced, the residential energy conservation is favorable.

Owner:张影

Anti-freezing and water-saving solar water heater capable of discharging hot water firstly in automated mode

InactiveCN102840698BImprove stabilityShorten the timeSolar heat devicesSolar thermal energy generationWater dischargeThermal insulation

The invention provides an anti-freezing and water-saving method capable of discharging hot water firstly in an automated mode, which is changed from a non-pressure solar water heater. The method is characterized in that the upper part of the side face of a water tank is provided with a water outlet and a water discharge pipe, and the top of the water tank is provided with a controller water tank; the top of the controller water tank is provided with a breather pipe and a water inlet pipe, and a main floating ball, an assistant floating ball and a lever are arranged in the controller water tank; a main body of the controller water tank is arranged in a thermal insulation layer, and a thermal insulation cover is arranged on a thermal insulation skin; the lower end of the water inlet pipe is provided with a water control valve, and one side of the lower end of the water inlet pipe is provided with an anti-freezing valve; and the upper end of the water discharge pipe is provided with an n-shaped pipe, the lower end of the water discharge pipe is provided with an air release valve, one side of the lower end of the water discharge pipe is connected with a water mixing valve, and air in the water discharge pipe flows downwards. A pressure-differential type water surface control valve for controlling the water surface also can be arranged in the controller water tank. In the process of bathing, the water surface position in the controller water tank needs to be higher than the top of the n-shaped pipe. The automation of the controller water tank is guaranteed; a situation that hot water is discharged from the water outlet firstly is guaranteed; and due to the anti-freezing valve and the water control valve, anti-freezing and water-saving functions are guaranteed.

Owner:李兴奇

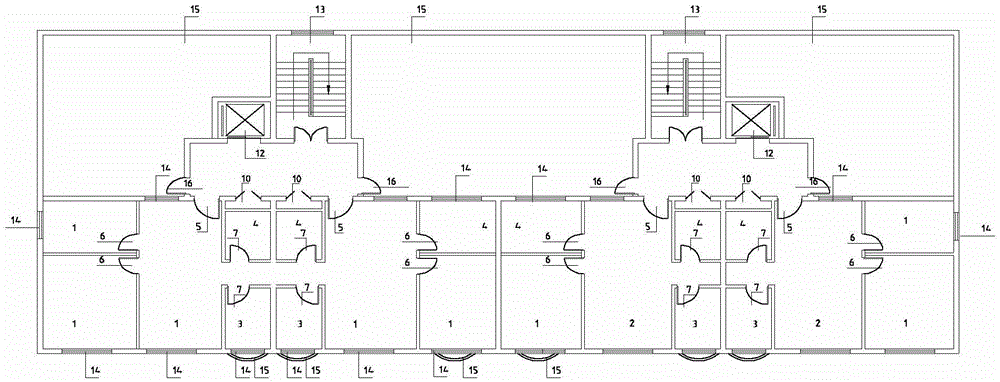

Land economizing residence reducing sunshine spacing

The invention discloses a land economizing residence reducing sunshine spacing. The land economizing residence consists of living rooms (1), bedrooms (2), kitchens (3), bathrooms (4), house doors (5), bedroom doors (6), bathroom doors (7), kitchen doors (8), sliding doors (9), water-well doors (10), electric-well doors (11), elevators (12), stairs (13), external windows (14), flower stands (15), roof doors (16) and roofs (17). The land economizing residence disclosed by the invention has the benefits that when the structure of the land economizing residence is adopted, the floor height is lowered, so that the total height of the residence can be lowered, and the sunshine spacing of the residence is correspondingly reduced; the top floor of the residence adopts set-back models, so that the top floor can obtain the effects of reducing the sunshine spacing and economizing land; the land economizing residence has a quite significant effect of economizing land; the concave and convex changes of outer walls are reduced, the areas of the outer walls and roofs are small, the structure is regular, the shape coefficient is small, a few thermal insulation materials are used, and the land economizing residence is very favorable for energy conversation.

Owner:张影

Heat preservation interlayer and heat preservation tool

PendingCN114132639AImprove structural performanceFlexibleDomestic cooling apparatusLighting and heating apparatusThermodynamicsInsulation layer

The invention discloses a heat preservation interlayer and a heat preservation tool, the heat preservation interlayer comprises a plurality of first heat insulation layers arranged at intervals, and the first heat insulation layers are made of aerogel materials; the first heat insulation layer is of a plane structure; each second heat insulation layer is arranged between every two adjacent first heat insulation layers; the second heat insulation layer is made of the aerogel material; and the second heat insulation layer is pressed into a three-dimensional pattern shape. According to the arrangement, the second heat insulation layers are pressed into the three-dimensional pattern shape to be arranged during manufacturing, so that the hollow part of the heat preservation interlayer can be increased, the heat preservation performance is improved, it is guaranteed that an enough cold insulation effect can be provided for fresh food during long-distance transportation and long-time selling, and it is guaranteed that the product quality is not changed; and heat insulation materials can be saved, and the requirement for strength is met.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Steam direct pressure type veneer material drying device

InactiveCN104006634BFast dryingReduce heat lossDrying gas arrangementsDrying machines with local agitationLiquid waterWater storage tank

The invention discloses a steam direct pressure type drying device of veneer materials. The steam direct pressure type drying device of the veneer materials comprises a drying oven, a steam boiler and a steam air supply pipe connecting the drying oven and the steam boiler. A horizontally arranged drying frame is arranged in the drying oven, the top layer and the bottom layer of the drying frame are an upper pressure bearing limiting plate and a lower pressure bearing limiting plate which are made of steel plates respectively, a connecting rod is arranged between the limiting plates and fixedly connected with the limiting plates, enclosed hollow heating plates made of stainless steel sheets are arranged between the limiting plates at intervals in parallel, the side edges of all layers of heating plates are fixedly connected with the connecting rod, a steam inlet connecting pipeline is arranged on the same side face of the heating plates and is communicated with the boiler steam air supply pipe, a gas-liquid inlet connecting pipeline is arranged on the other side face of the heating plates and is communicated with a gas-liquid water outlet pipe, and the gas-liquid water outlet pipe is communicated with a water storage tank. According to the steam direct pressure type drying device of the veneer materials, the heat energy for drying the materials is transmitted to the materials through the steam and is separated from the materials only through a thin layer of stainless steel sheet, and pressure is directly provided by the steam, so that a mechanism for providing pressure and energy consumption are omitted, the device is compact in structure, and the defects that an existing device is high in manufacturing cost and large in energy consumption are overcome.

Owner:黄达宏

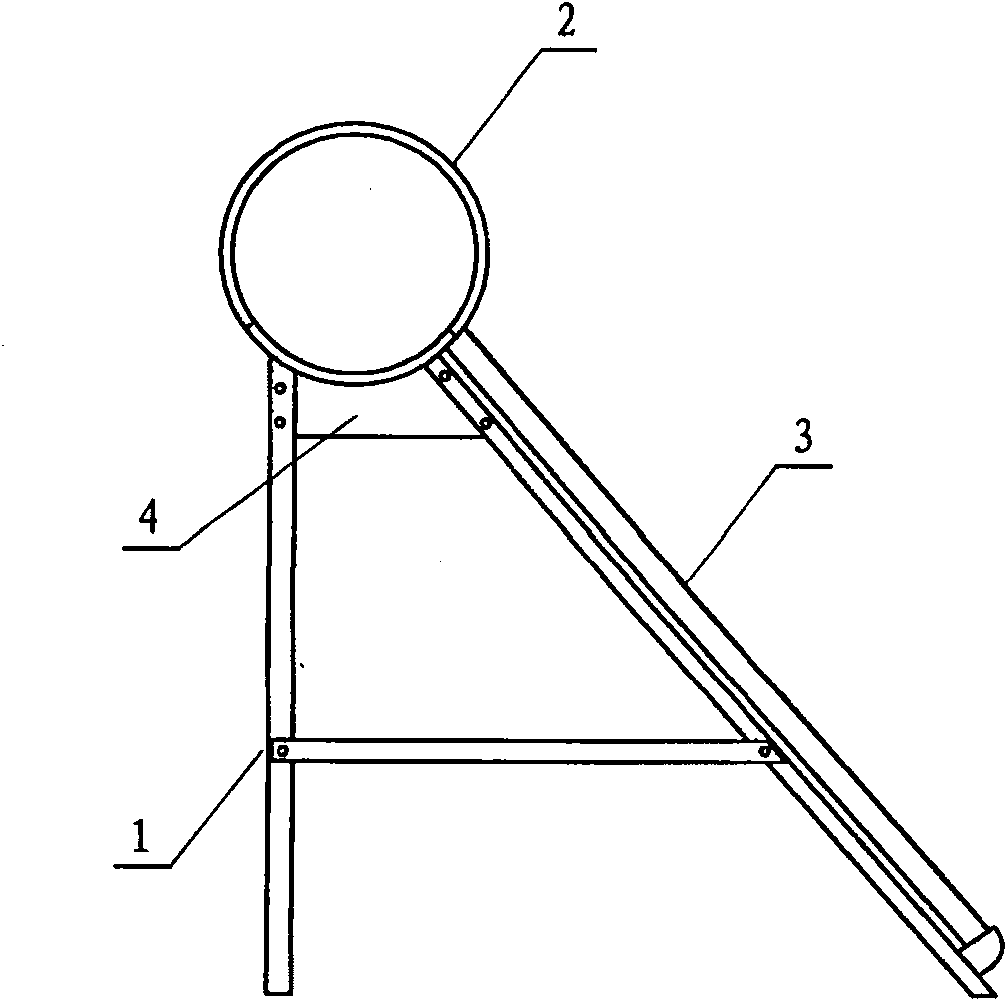

Engineering modularization solar water heater

InactiveCN100567849CImprove insulation effectSave materialSolar heat devicesSolar thermal energy generationArchitectural engineeringSolar water

The present invention relates to a solar water heater, in particular to an engineering modular solar water heater for uniform installation in a residence, which includes a bracket, a thermal insulation water tank, and a heat collection tube, and is characterized in that several thermal insulation water tanks are arranged in a line on the bracket, each The insulation water tank is a whole, and the thickness of the insulation layer at both ends is half of the thickness of the middle insulation layer. Each insulation water tank is equipped with a water inlet and outlet connection pipe, a ventilation pipe, and an electric auxiliary heater. The two ends of each insulation water tank are respectively equipped with Circumferential waterproof ribs; the upper part of the bracket is equipped with a bucket holder, the lower part of the bucket holder is fixed on the bracket by bolts, the upper part of the bucket holder is an arc-shaped tray matching the shape of the heat preservation water tank, and the inner side of the arc-shaped tray is equipped with at least A circumferentially extending groove matched with the waterproof rib. The invention not only has good overall structure and is convenient for installation, but also saves construction cost and is beneficial to the protection of the outer layer of buildings and the construction and installation of lightning protection facilities.

Owner:ZHEJIANG ZHONGXIN ENERGY SOURCE DEV

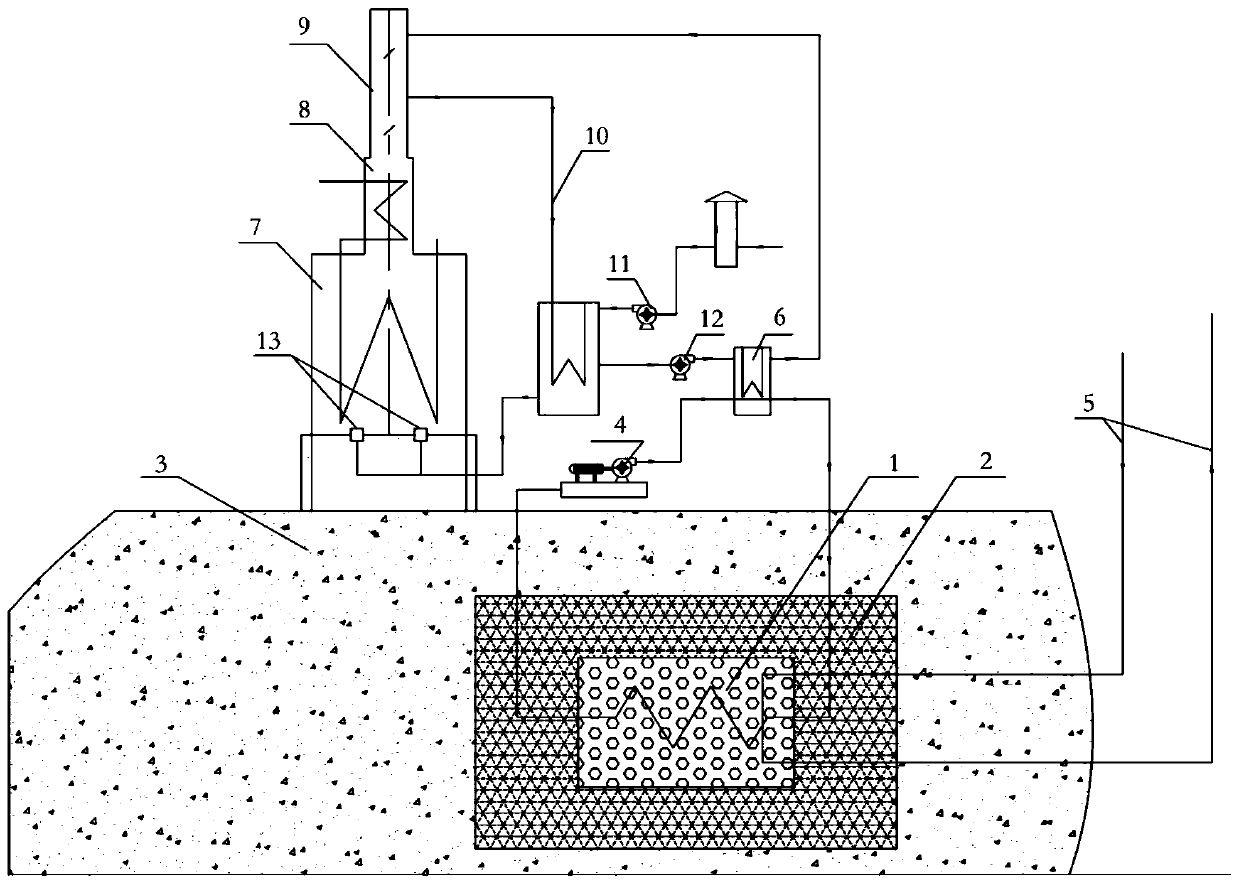

Heat energy storage and release system based on tubular heating furnace

PendingCN109780877AImprove heat transfer efficiencyGood economic valueHeat storage plantsCombustion processThermal energyFlue gas

The invention discloses a heat energy storage and release system based on a tubular heating furnace. The heat energy storage and release system comprises a phase change heat storage material, a heat preservation layer, an energy storage medium circulating unit, an energy storage outer conveying pipeline and an energy storage outer heat collector. The heat preservation layer is arranged in an energy storage tank excavated in soil. The phase change heat storage material is completely wrapped with the heat preservation layer. Positions above the heat preservation layer are backfilled with soil. The energy storage medium circulating unit is connected with the phase change heat storage material and the energy storage outer heat collector connected in a flue gas pipeline of the tubular heating furnace at the same time. Heat energy in the flue gas pipeline is stored in the phase change heat storage material after being subjected to heat exchange with the phase change heat storage material. The energy storage outer conveying pipeline is connected with the phase change heat storage material at the same time. The heat energy stored in the phase change heat storage material is released outwards through the energy storage outer conveying pipeline when needed. By means of the heat energy storage and release system, waste heat of the tubular heating furnace can be stably stored in a centralized manner, device energy consumption and the production cost are reduced, and climate change caused by greenhouse gas emission is reduced to the maximum extent.

Owner:BEIJING PIONEER IND FURNACE

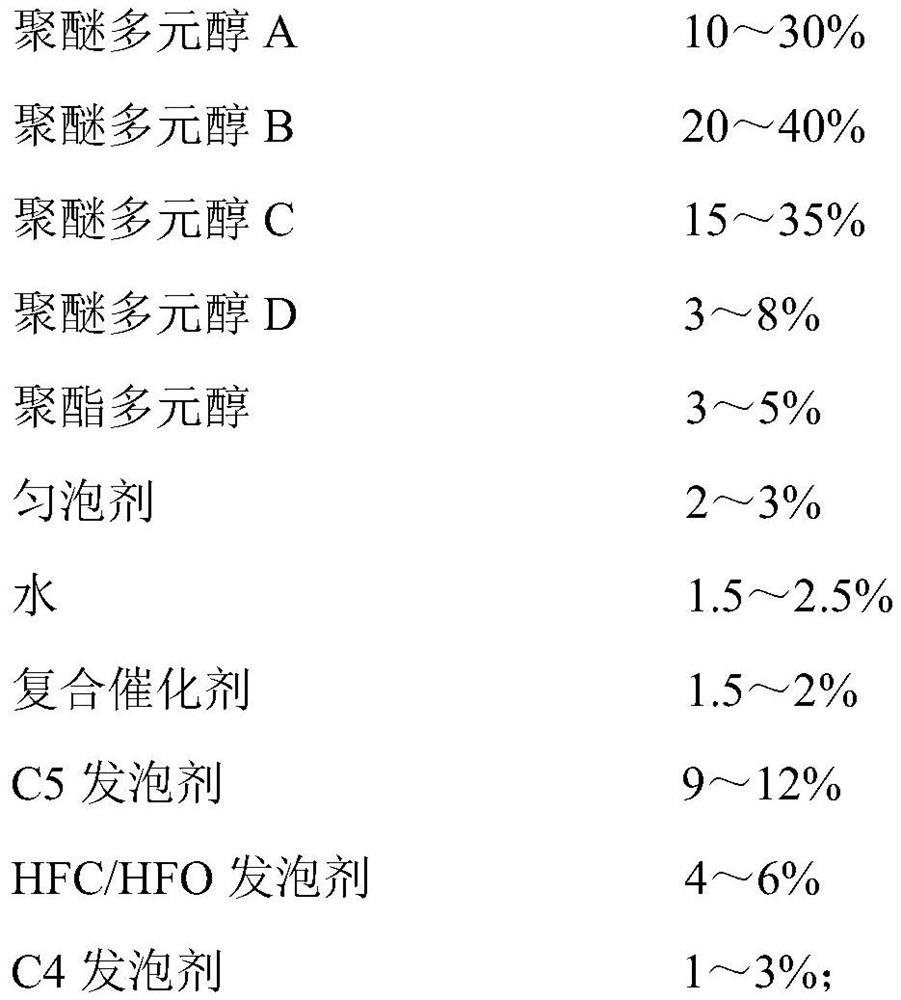

Composite material for ultrathin low-conductivity stainless steel kitchen cabinet and preparation method of composite material

The invention relates to a composite material for an ultrathin low-conductivity stainless steel kitchen cabinet and a preparation method of the composite material, and belongs to the technical field of polyurethane. The composite material comprises a component A and a component B, the mass ratio of the component A to the component B is 1: (1.15-1.3), and the component A comprises 10-30% of polyether polyol A, 20-40% of polyether polyol B, 15-35% of polyether polyol C, 3-8% of polyether polyol D, 3-5% of polyester polyol, 2-3% of a foam stabilizer, 1.5-2.5% of water, 1.5-2% of a composite catalyst, 9-12% of a C5 foaming agent, 4-6% of an HFC / HFO foaming agent and 1-3% of a C4 foaming agent. The composite material provided by the invention has excellent fluidity and low-temperature dimensional stability, and the rigid polyurethane foam prepared from the composite material has good dimensional stability, higher compression strength and lower heat conductivity coefficient, and is energy-saving, consumption-reducing and environment-friendly; the invention also provides a simple and feasible preparation method.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com