Heat energy storage and release system based on tubular heating furnace

A tubular heating furnace and thermal energy storage technology, which is applied to lighting and heating equipment, furnaces, waste heat treatment, etc., can solve the problems of high utilization cost, limited use scale and scope, endangering the stable operation of equipment and systems, and achieve land saving Cost of use, flexible and convenient system design, and significant economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the drawings and embodiments.

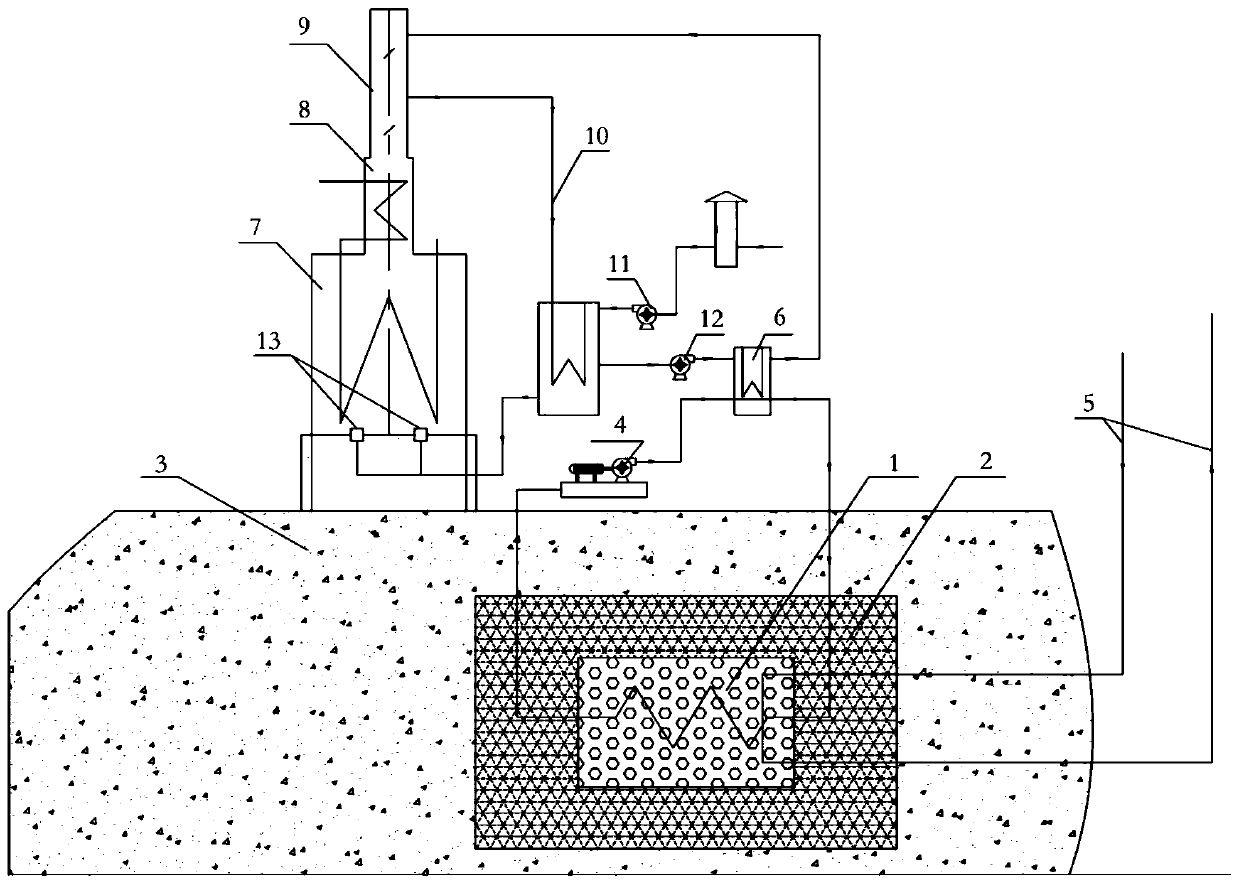

[0020] As attached figure 1 As shown, the present invention provides a thermal energy storage and release system based on a tube heating furnace. The thermal energy storage and release system is connected to the flue gas pipe 10 in the tube heating furnace, and the flue gas of the tube heating furnace is realized through heat exchange. The storage of thermal energy.

[0021] In the tubular heating furnace, the combustion unit 13 heats the equipment in the radiation chamber 7, and the high-temperature flue gas generated by the fuel flows into the chimney 9 from the convection chamber 8 above the radiation chamber, and the flue gas pipe 10 leads the high-temperature flue gas from the chimney In the air preheater, the outside air drawn by the air blower exchanges heat with the high-temperature flue gas in the air preheater and enters the radiation chamber 7 to participate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com