Composite material for ultrathin low-conductivity stainless steel kitchen cabinet and preparation method of composite material

A technology of stainless steel and kitchen cabinets, applied in the field of polyurethane, can solve the problems that cannot meet the pursuit of small volume and large volume, high density of polyurethane foam system, etc., achieve excellent heat preservation effect, excellent bonding performance, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

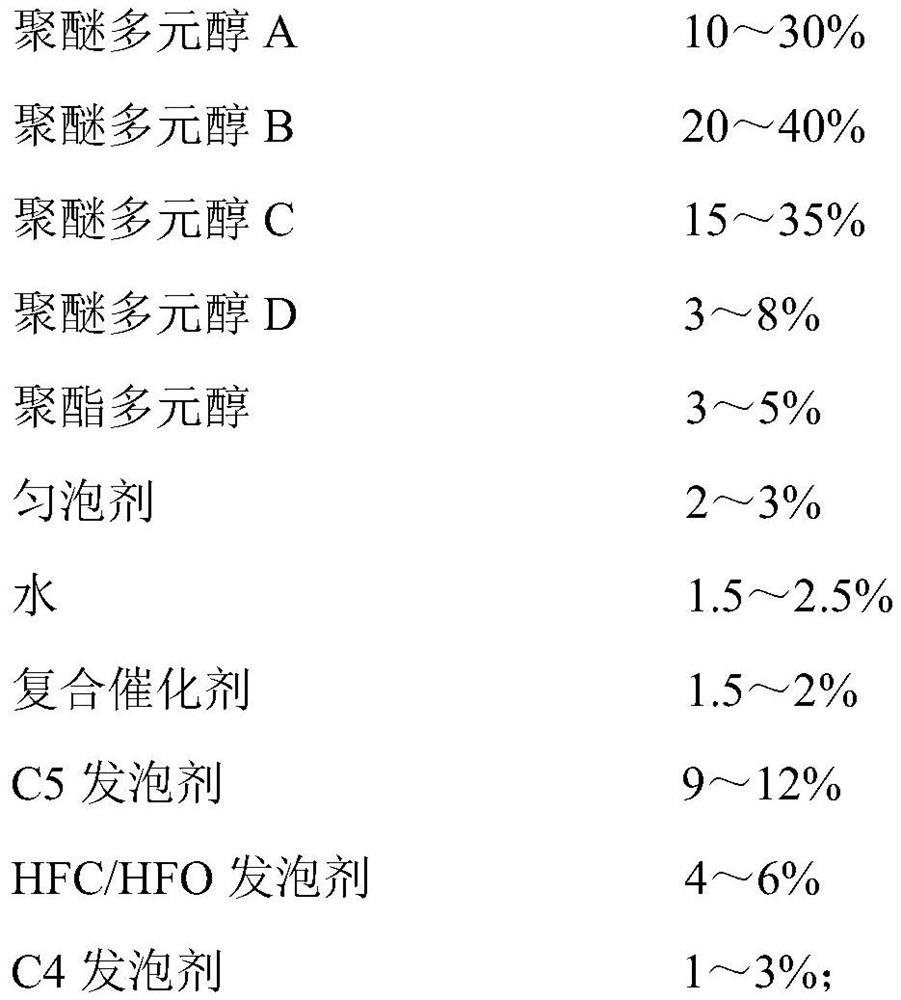

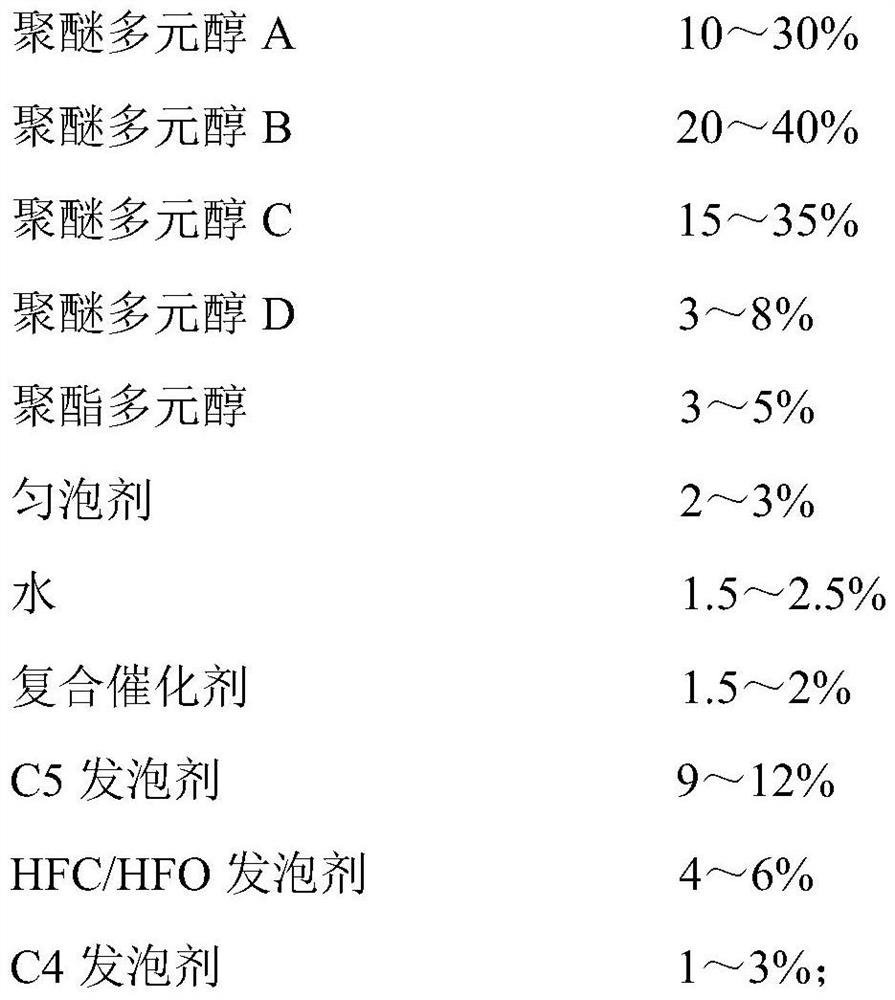

Method used

Image

Examples

Embodiment 1

[0045] Component A: 15 parts of sucrose starter polyether polyol INOVOL R6001C, 30 parts of sorbitol starter polyether polyol INOVOL R6207, 2 parts of glycerin starter polyether polyol INOVOL C310, toluene diamine starter 25 parts of polyether polyol INOVOL R4400T, 3 parts of polyester polyol PS-4051, 2.5 parts of foam stabilizer B84813, 3 parts of composite catalyst (0.5 parts of pentamethyldiethylenetriamine in composite catalyst, N, N' - 1.7 parts of dimethylcyclohexylamine, 0.6 parts of 1,3,5-tris(dimethylaminopropyl) hexahydrotriazine, 0.2 parts of TMR-2 catalyst), H 2 O 1.5 parts, blowing agent cyclopentane 11.5 parts, blowing agent HFC-245fa 5 parts, blowing agent R600a 1.5 parts.

[0046] According to the above formula, add each component into a stainless steel kettle according to the proportion and mix them, stir at 120 rpm for 1 hour at 3±2°C, and discharge as component A.

[0047] Component B is the isocyanate PM200 of Wanhua Chemical Co., Ltd.

[0048] Mix compon...

Embodiment 2

[0050] Component A: 15 parts of sucrose starter polyether polyol INOVOL R6001C, 30 parts of sorbitol starter polyether polyol INOVOL R6207, 2 parts of glycerin starter polyether polyol INOVOL C310, toluene diamine starter 25 parts of polyether polyol INOVOL R4400T, 3 parts of polyester polyol PS-4051, 2.5 parts of foam stabilizer B84813, 3 parts of composite catalyst (0.5 parts of pentamethyldiethylenetriamine in composite catalyst, N, N' - 1.7 parts of dimethylcyclohexylamine, 0.6 parts of 1,3,5-tris(dimethylaminopropyl) hexahydrotriazine, 0.2 parts of TMR-2 catalyst), H 2 O 1.5 parts, blowing agent cyclopentane 11.5 parts, blowing agent LBA 5 parts, blowing agent R600a 1.5 parts.

[0051] According to the above formula, add each component into a stainless steel kettle according to the proportion and mix them, stir at 120 rpm for 1 hour at 3±2°C, and discharge as component A.

[0052] Component B is the isocyanate PM200 of Wanhua Chemical Co., Ltd.

[0053] Mix components A...

Embodiment 3

[0055] Component A: 15 parts of sucrose starter polyether polyol INOVOL R6001C, 30 parts of sorbitol starter polyether polyol INOVOL R6207, 2 parts of glycerin starter polyether polyol INOVOL C310, toluene diamine starter 25 parts of polyether polyol INOVOL R4400T, 3 parts of polyester polyol PS-4051, 2.5 parts of foam stabilizer B84813, 3 parts of composite catalyst (0.5 parts of pentamethyldiethylenetriamine in composite catalyst, N, N' - 1.7 parts of dimethylcyclohexylamine, 0.6 parts of 1,3,5-tris(dimethylaminopropyl) hexahydrotriazine, 0.2 parts of TMR-2 catalyst), H 2 O 1.5 parts, foaming agent cyclopentane 11 parts, foaming agent LBA 5 parts, foaming agent R600a 2 parts.

[0056] According to the above formula, add each component into a stainless steel kettle according to the proportion and mix them, stir at 120 rpm for 1 hour at 3±2°C, and discharge as component A.

[0057] Component B is the isocyanate PM200 of Wanhua Chemical Co., Ltd.

[0058] Mix components A and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com