Improved dircet expansion evaporator based chiller system

a chiller system and expansion evaporator technology, applied in refrigeration machines, superheaters, lighting and heating apparatus, etc., can solve the problems of reducing the performance of air conditioning and refrigeration systems that employ modern flooded type evaporators, affecting the efficiency of air conditioning and refrigeration systems, and difficult to achieve the viscosity requirements of oil-refrigerant mixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

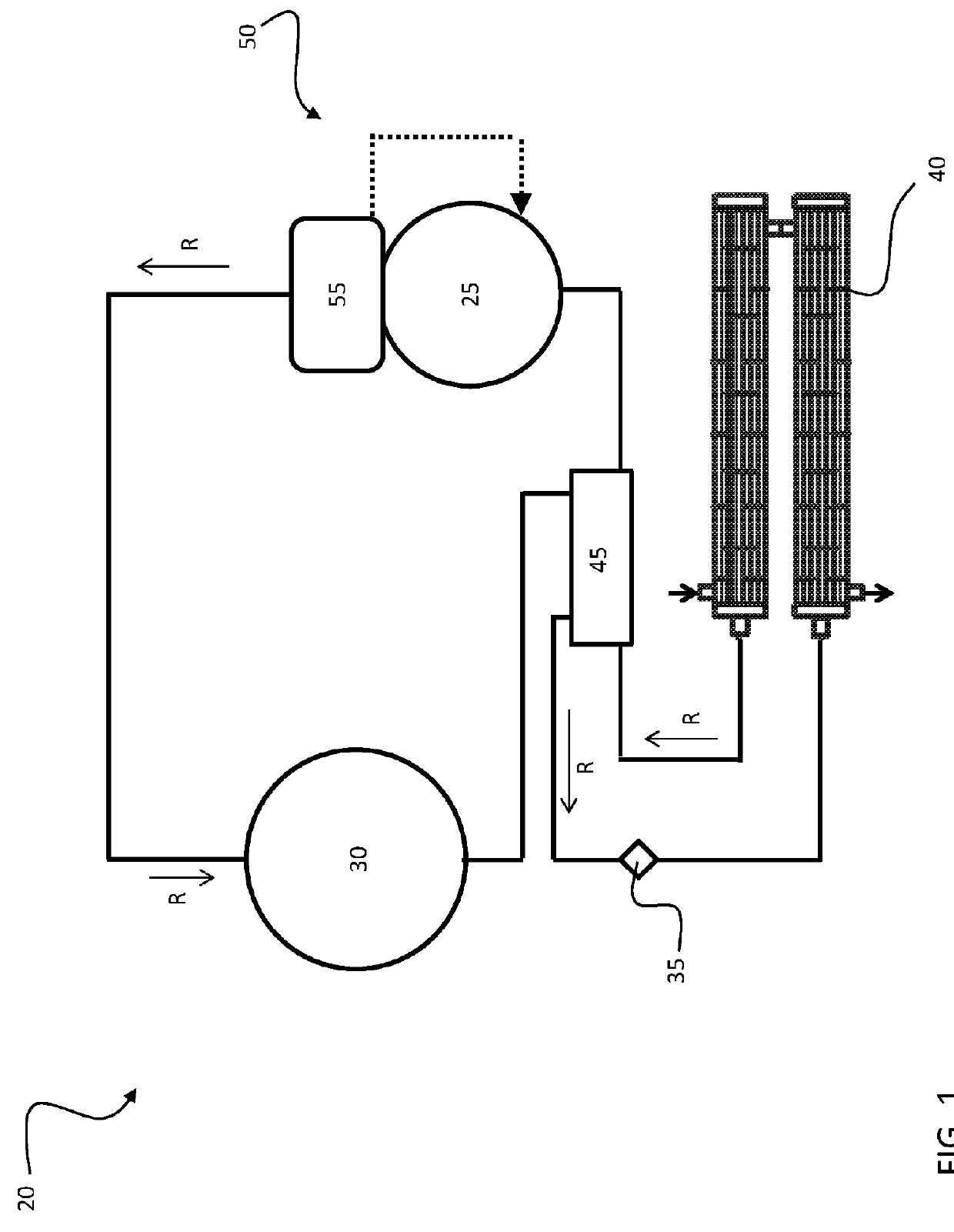

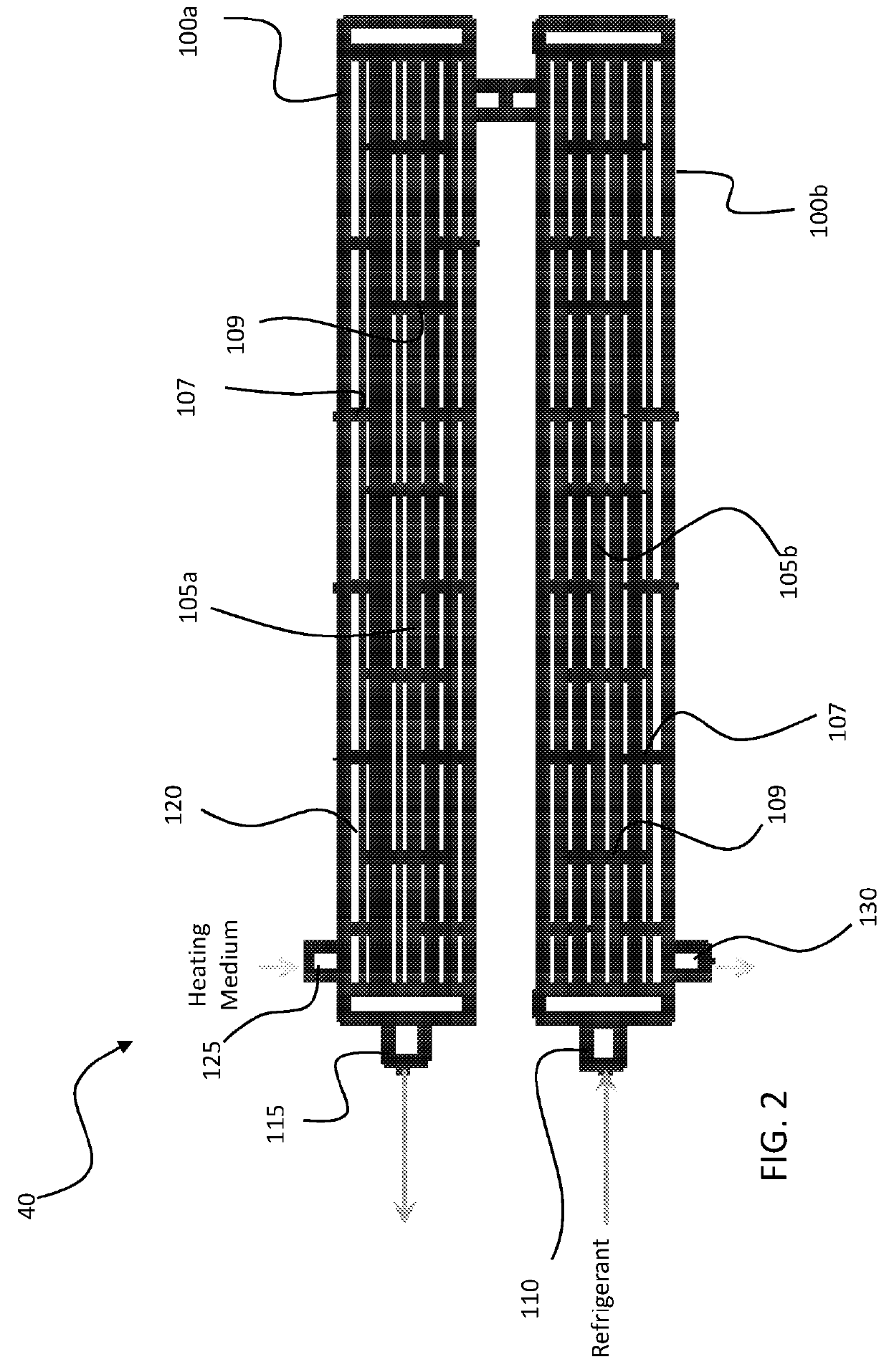

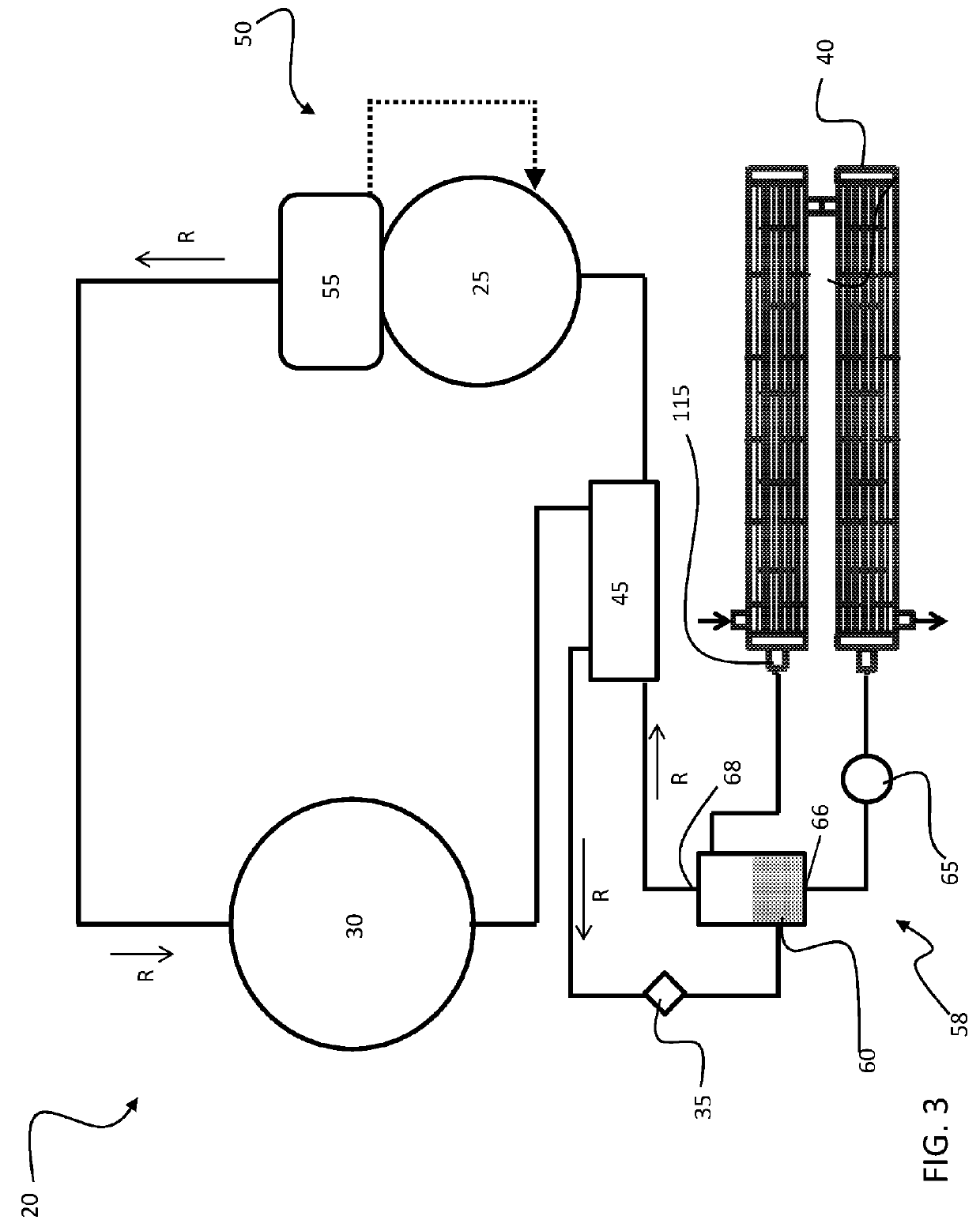

[0032]Referring now to the FIGS., an improved chiller refrigeration system 20 configured for use with either a miscible or immiscible oil is illustrated. A refrigerant R is configured to circulate through the chiller system 20 such that the refrigerant R absorbs heat when evaporated at a low temperature and pressure and releases heat when condensed at a higher temperature and pressure. In one embodiment, the refrigerant has a low global warming potential, such as a Hydrofluoroolefin (HFO) or an HFO blend refrigerant for example. Within this chiller system 20, the refrigerant R flows in a counterclockwise direction as indicated by the arrows. The compressor 25 receives refrigerant vapor from the evaporator 40 and compresses it to a higher temperature and pressure, with the relatively hot vapor then passing to the condenser 30 where it is cooled and condensed to a liquid state by a heat exchange relationship with a cooling medium, such as air or water for example. The liquid refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com