Vacuum insulated panel added with infrared reflecting layer and preparation method thereof

A technology of vacuum insulation panels and infrared reflection layers, which is applied to heat exchange equipment, mechanical equipment, and pipelines through heat insulation protection, can solve the problems of increasing the thickness of the insulation layer, consuming materials, and increasing production costs, so as to reduce the thickness and save energy. Thermal insulation material, effect of improving thermal insulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

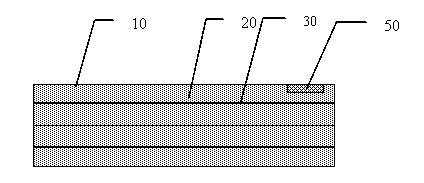

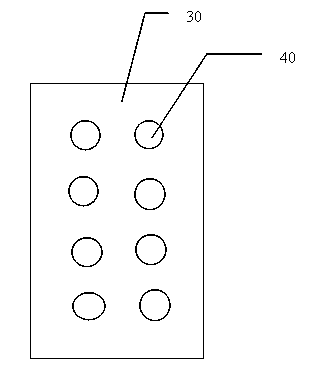

[0019] refer to figure 1 , is a cross-sectional view of a vacuum insulation panel with an infrared reflective film, where [10] is a high barrier film, [20] is an insulation material, [30] is an infrared reflective film, and [50] is a getter. Multiple pieces of thermal insulation materials are stacked, and a layer of infrared reflective film is placed between the laminated core materials, the area of which is equal to the area of the core material, and the thickness of the film is 400 um. The insulation material is glass fiber core material. The infrared reflective film is coated with titanium oxide on the surface of the PU film. There are circular holes on the film, the hole area is 50mm 2 , the hole area accounts for 10% of the thin plate, and the center-to-center distance between two holes is 25 mm.

[0020] A method for manufacturing a vacuum insulation panel with an infrared reflective layer, characterized in that it includes the steps in the following order:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com