Multilayer-arranged heat insulating material and preparation method thereof

A heat insulation material and infrared blocking technology, applied in the field of functional composite materials, to achieve the effect of improving heat insulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

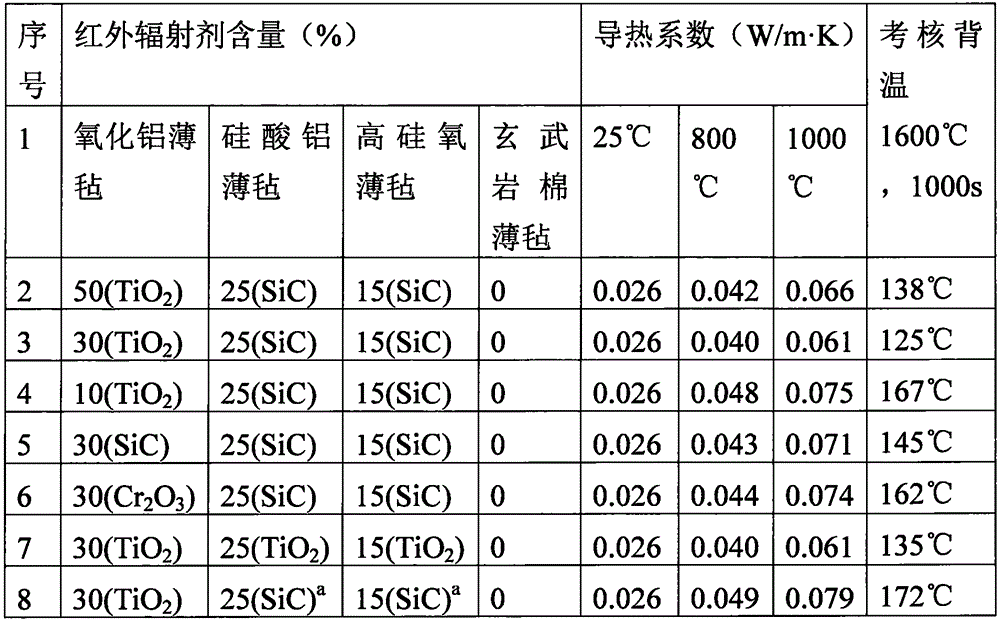

[0076] Example 1: Preparation of multi-layer thin felt composite heat insulation material at 1600°C

[0077] (1) Prepare 3 alumina fiber mats, aluminum silicate fiber mats, high silica fiber mats and basalt wool fiber mats each with a thickness of 3 mm, with a format size of 200 mm × 200 mm;

[0078] (2) Get three alumina fiber thin felts, two aluminum silicate fiber thin felts, high silica fiber thin felts and basalt cotton fiber thin felts, and lay layers in the airgel forming mold according to the above-mentioned sampling sequence;

[0079] (3) prepare alumina sol according to the ratio of aluminum sec-butoxide: ethanol: nitric acid: water=6.6: 20: 0.039: 1 (molar ratio), stir evenly and set aside;

[0080] (4) Inject the aluminum oxide sol prepared in step (3) into the mold with thin felt in step (2), close the mold to 25mm, gel, and age;

[0081] (5) Take out the wet gel in step (4), replace it with ethanol for solvent replacement, and finally supercritically dry to obta...

Embodiment 2

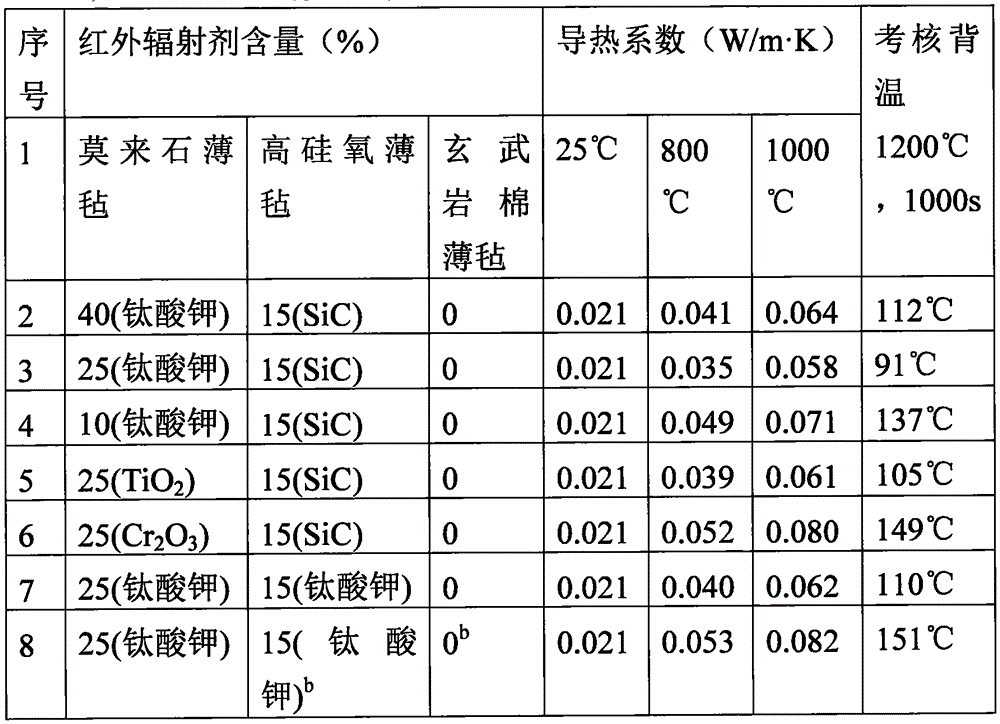

[0087] Example 2: Preparation of multi-layer thin felt composite heat insulation material at 1200°C

[0088] (1) Prepare 4 mullite fiber mats, high silica fiber mats and basalt cotton fiber mats each with a thickness of 3mm, with a format size of 200mm × 200mm;

[0089] (2) Get three pieces of mullite fiber thin felt, high silica fiber thin felt and basalt cotton fiber thin felt, and lay layers in the airgel forming mold according to the above-mentioned sampling sequence;

[0090] (3) Prepare silica sol according to the ratio of ethyl orthosilicate: ethanol: water: ammonia water: ammonium fluoride=1000: 1508: 340: 0.3: 0.1 (weight ratio), stir evenly and set aside;

[0091] (4) Inject the silicon oxide sol prepared in step (3) into the mold with thin felt in step (2), close the mold to 25mm, gel, and age;

[0092] (5) Take out the wet gel in step (4), replace it with ethanol for solvent replacement, and finally supercritically dry to obtain a multi-layer thin felt composite h...

Embodiment 3

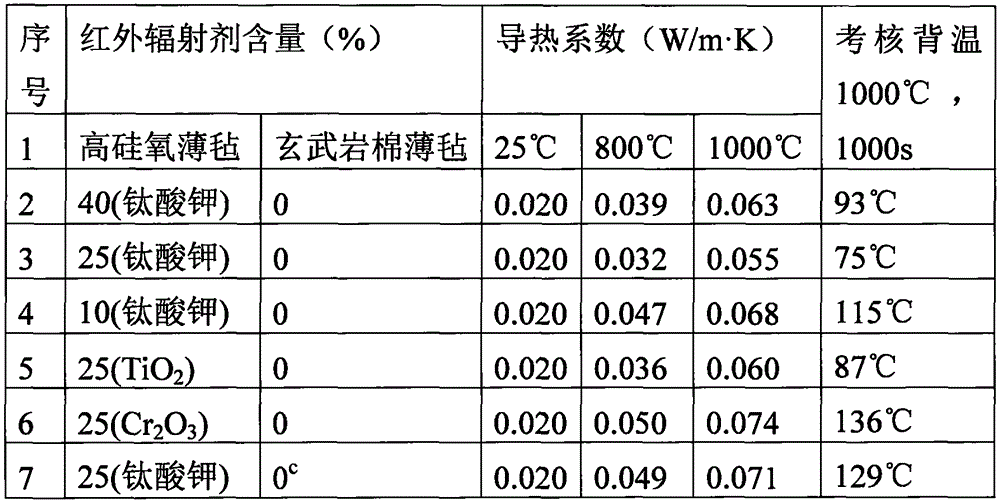

[0098] Example 3: Preparation of multi-layer thin felt composite heat insulation material at 1000°C

[0099] (1) The preparation thickness is 5 pieces of high silica fiber thin felt and basalt cotton fiber thin felt each with a thickness of 3mm, and the format size is 200mm×200mm;

[0100] (2) Get five high-silica fiber thin felts and four basalt wool fiber thin felts, and lay layers in the airgel forming mold according to the above-mentioned sampling sequence;

[0101] (3) Prepare silica sol according to the ratio of ethyl orthosilicate: ethanol: water: ammonia water: ammonium fluoride=1000: 1508: 340: 0.3: 0.1 (weight ratio), stir evenly and set aside;

[0102] (4) Inject the silicon oxide sol prepared in step (3) into the mold with thin felt in step (2), close the mold to 25mm, gel, and age;

[0103] (5) Take out the wet gel in step (4), replace it with ethanol, and finally supercritically dry it to obtain a multi-layer thin felt composite heat insulation material for 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com